Shot blasting treatment method for rust removal and rust prevention of steel plate

A treatment method and steel plate technology, applied in the used abrasive treatment device, pretreatment surface, surface coating liquid device, etc., can solve the steel plate deformation, steel plate shot blasting did not achieve the desired effect, etc., to achieve Cost-effective, meet the production rate, improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

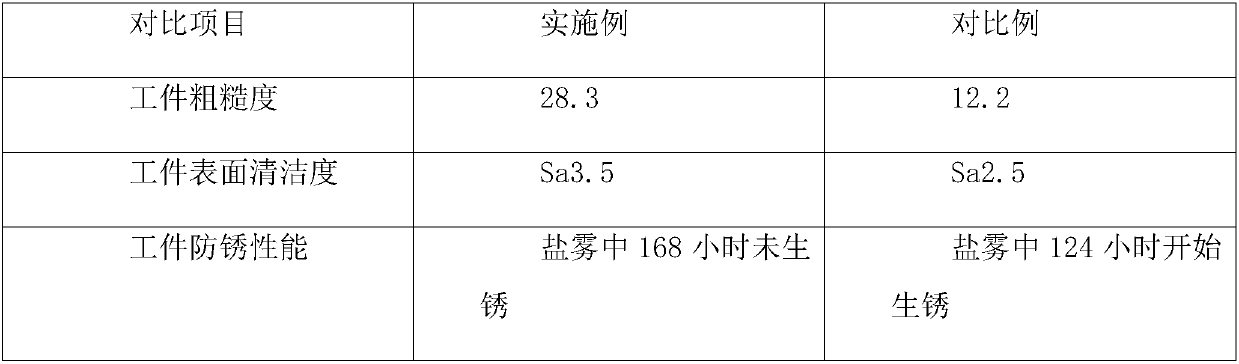

Examples

Embodiment Construction

[0027] A kind of shot blasting treatment method for rust removal and antirust of steel plate provided in this embodiment comprises the following steps:

[0028] S1: Measure the thickness of the steel plate;

[0029] S2: Place the steel plate on the operating table, make a 2wt% aqueous solution of alkaline degreasing agent 364FS, heat the alkaline degreasing agent aqueous solution to 40-50°C, and then spray it evenly on the surface of the steel plate for degreasing treatment ;

[0030] S3: placing the degreased steel plate in clean water, washing it with water, then taking out the steel plate, draining, and drying at a temperature of 80-100°C;

[0031] S4: Place the steel plate in the shot blasting chamber for shot blasting treatment. Adjust the current and time of the shot blasting machine in the shot blasting process according to the thickness of the steel plate measured in S1. If the thickness of the steel plate is less than 3mm, shot blasting treatment It will cause serio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com