Milling method of curved surface of titanium alloy parts

A processing method and technology of titanium alloy, which is applied in the field of surface processing of titanium alloy parts, can solve the problems of easy sticking to the knife, slow down the processing speed of the tool, and poor thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

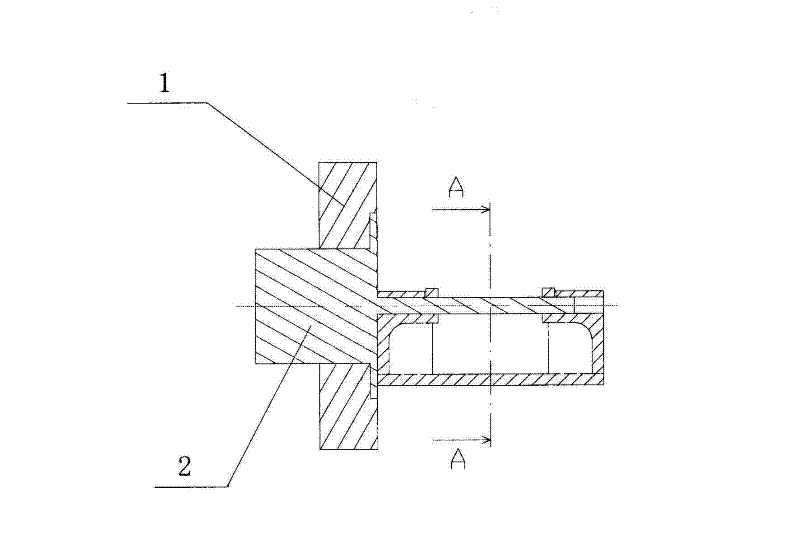

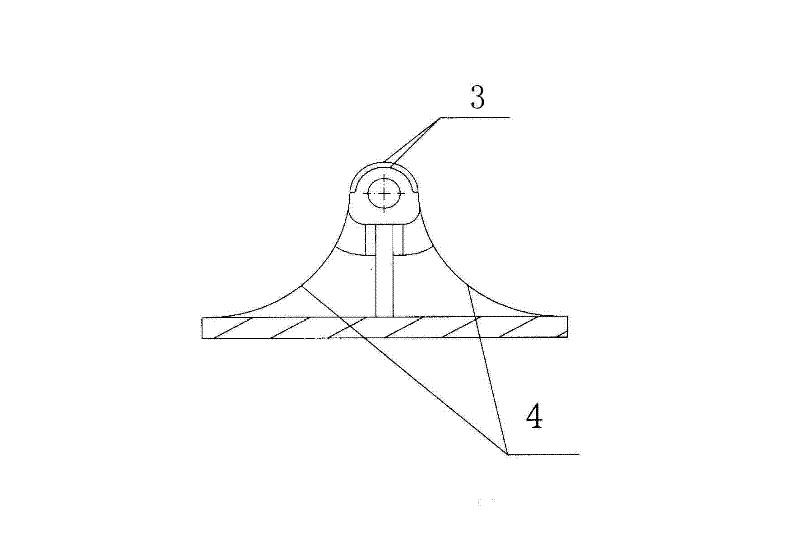

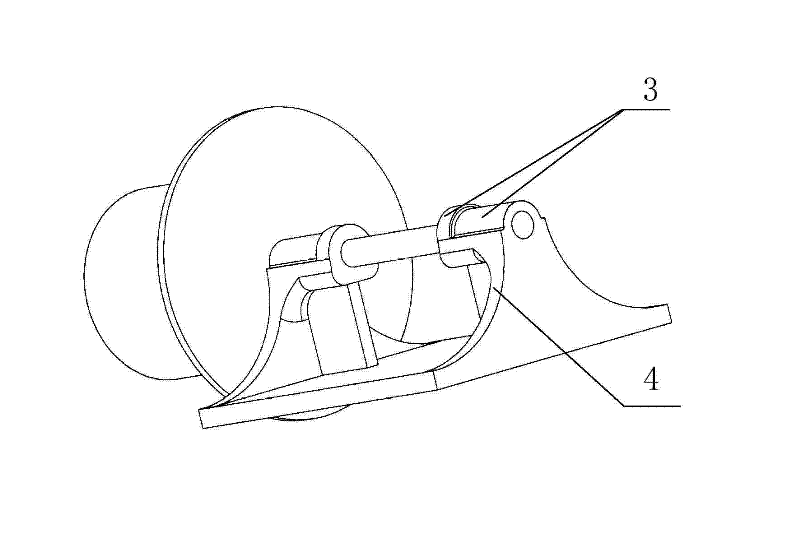

[0015] Such as figure 1 and 2 Shown, a kind of surface milling processing method of titanium alloy part is characterized in that comprising the following steps:

[0016] 1) Insert the drilled and reamed hole of the part into the positioning pin of the auxiliary positioning fixture 2, and fix it with the auxiliary positioning fixture;

[0017] 2) Install the rotary table 1 on the table of the milling machine;

[0018] 3) Install the auxiliary positioning fixture 2 embedded on the rotary table 1, so that the curved surface of the part is vertical and tangent to the vertical milling cutter;

[0019] 4) Rotate the rotary table so that the rotary table rotates 180°, and the side edge of the milling cutter can be used to mill the small curved surface 3 of the part to be processed.

Embodiment 2

[0021] Same as steps 1 to 3 in Embodiment 1, then control the direction of the milling cutter to be consistent with the direction of the large curved surface 4 to be processed, and use the side edge of the milling cutter to process the large curved surface 4 to be processed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com