Planet gear ring oil pumping unit

A technology of planetary gears and pumping units, applied in mechanical equipment, belts/chains/gears, mining fluids, etc., can solve problems such as complex manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

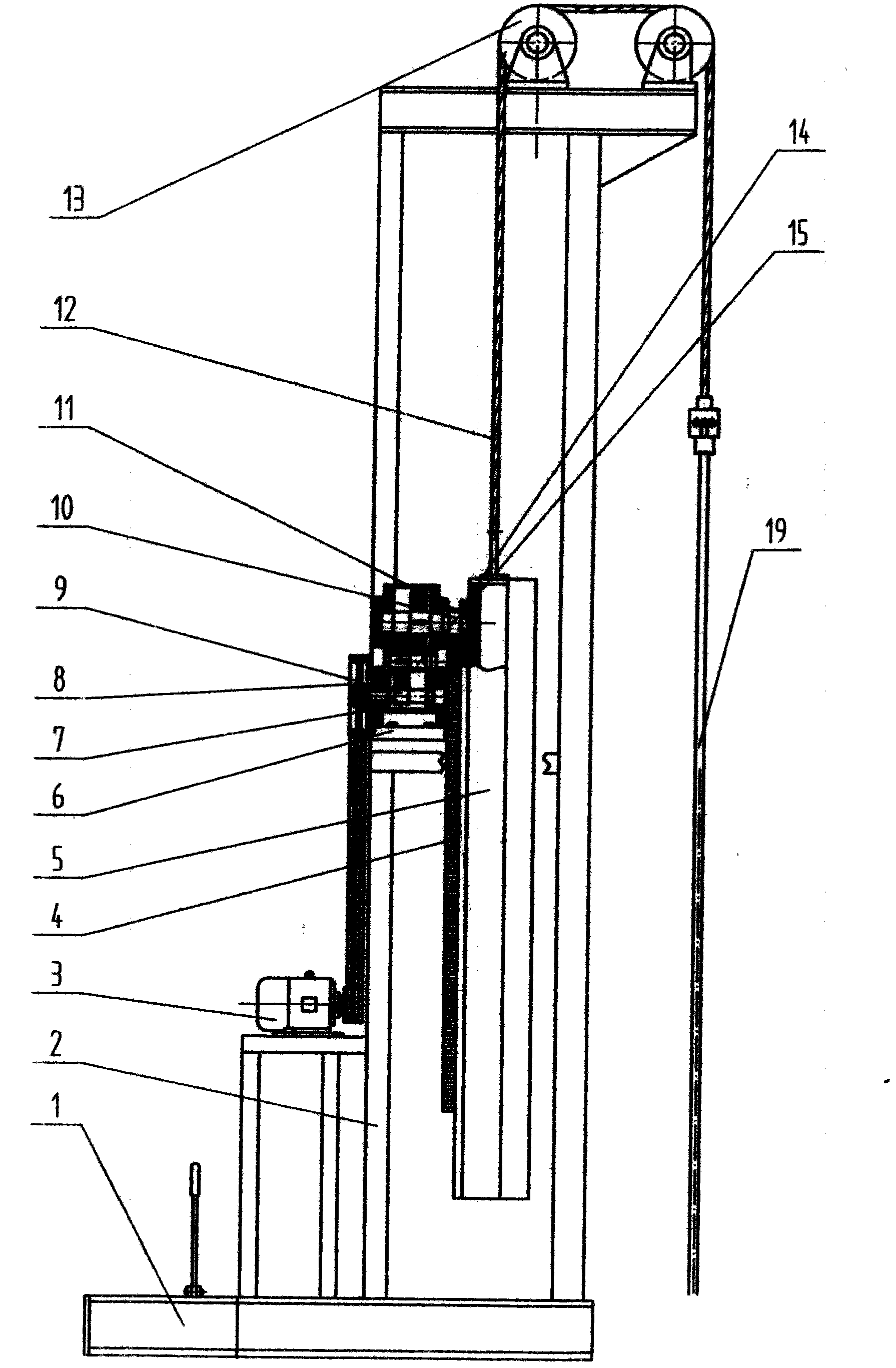

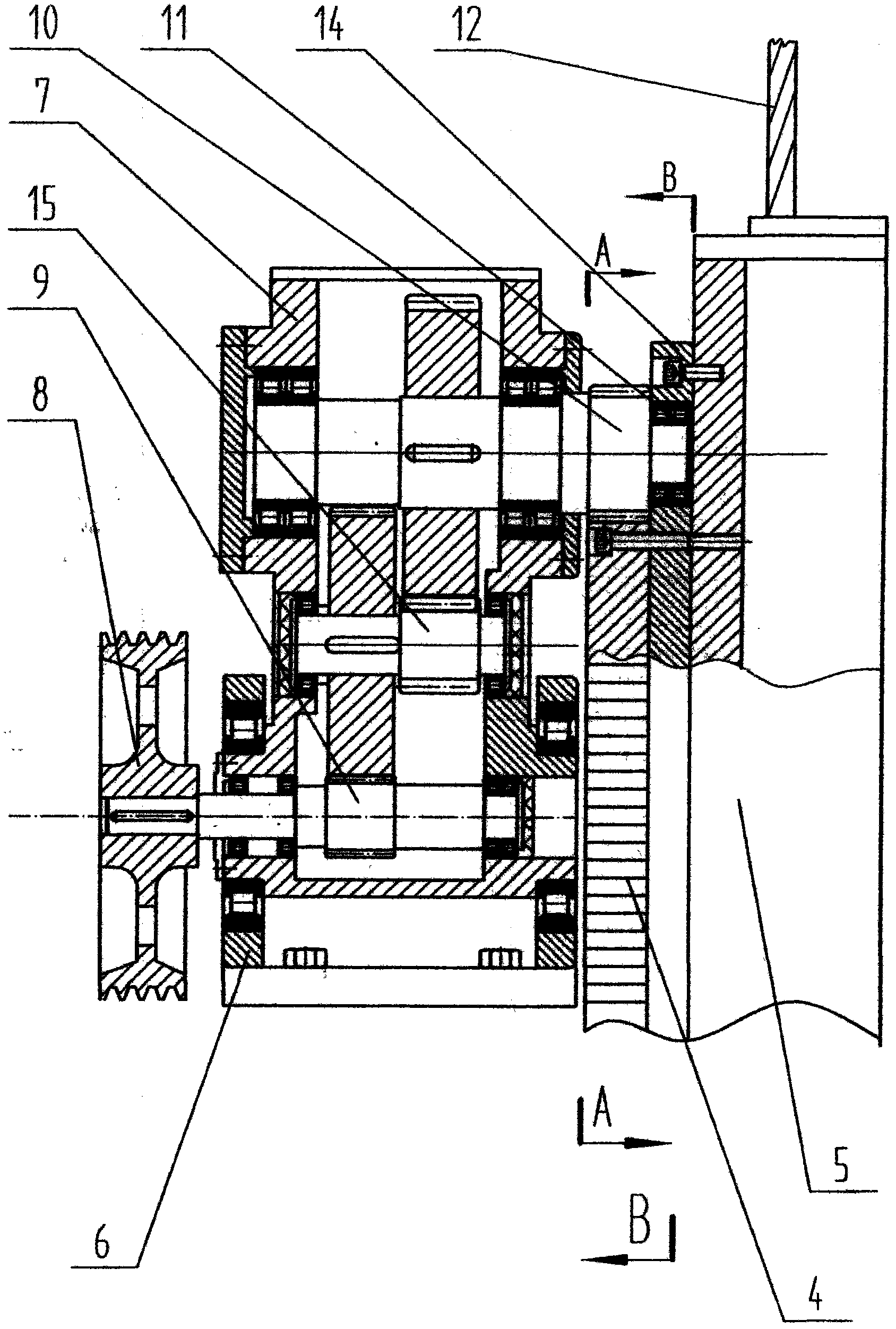

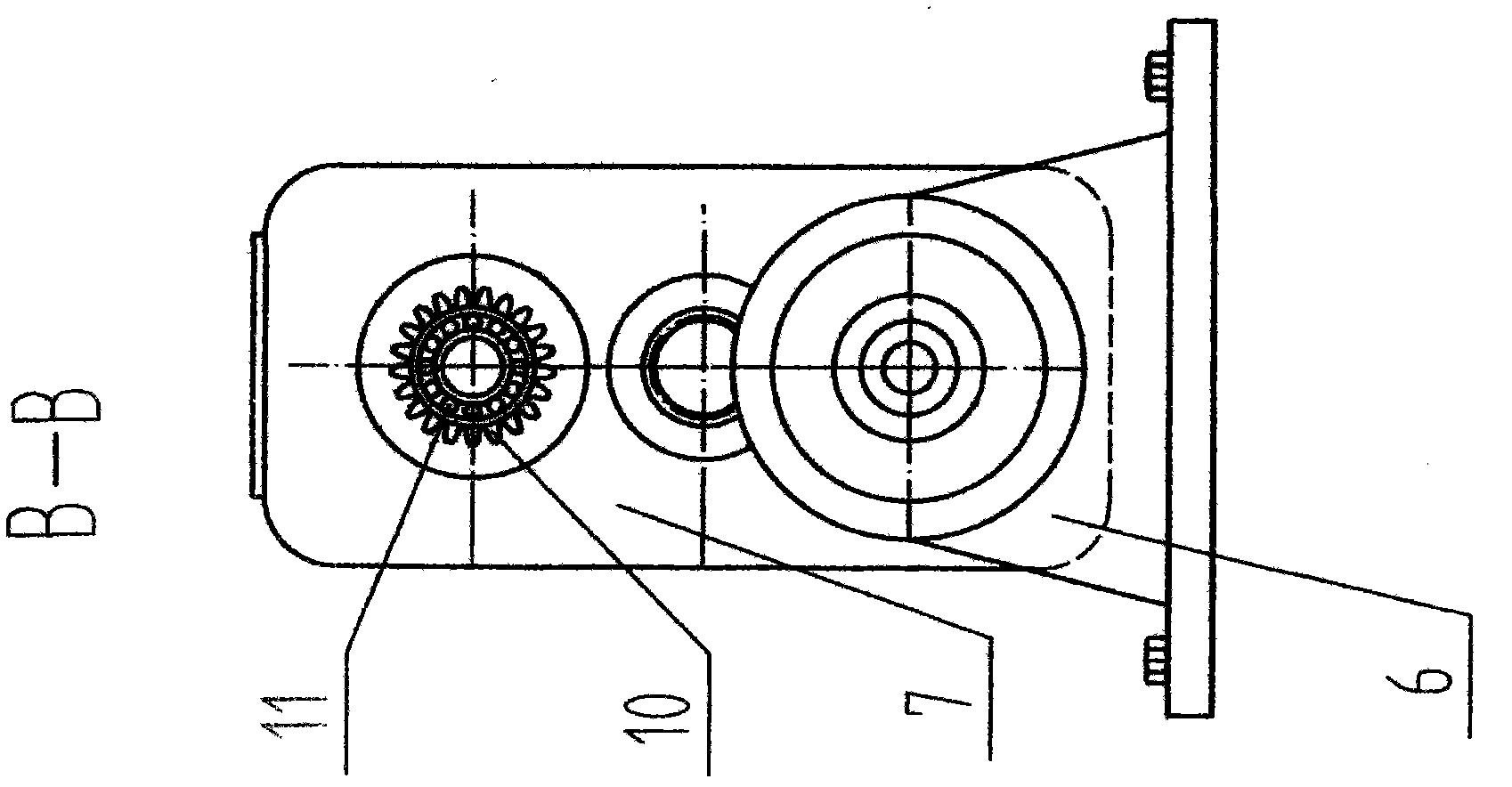

[0013] From the drawings, the planetary gear pumping unit is composed of a base, a frame, a motor, a support, a gear box, a sun gear shaft, a reduction gear, a planetary gear shaft, a speed gear, a ring rack, a suspension system and a system. composed of moving devices. It is characterized in that: a support 6 is installed in the middle of the frame 2, a gear box 7 is installed on the support 6, a sun gear shaft 9, a reduction gear shaft 15 and a planetary gear shaft 10 are installed on the gear box, the reduction gear shaft 15 and the planetary gear shaft 10 are equipped with a reduction gear 20, 21. Among them, the sun gear shaft 9 meshes with the reduction gear 20 on the reduction gear shaft 15, and the reduction gear shaft 15 meshes with the reduction gear 21 on the planetary gear shaft 10. The gear shaft 10 meshes with the ring gear 4. A reversing guide wheel 11 is installed at one end of the planetary gear 10. Since the two ends of the ring rack 4 are semicircular long r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com