Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

461 results about "Non-circular gear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A non-circular gear (NCG) is a special gear design with special characteristics and purpose. While a regular gear is optimized to transmit torque to another engaged member with minimum noise and wear and with maximum efficiency, a non-circular gear's main objective might be ratio variations, axle displacement oscillations and more. Common applications include textile machines, potentiometers, CVTs (continuously variable transmissions), window shade panel drives, mechanical presses and high torque hydraulic engines.

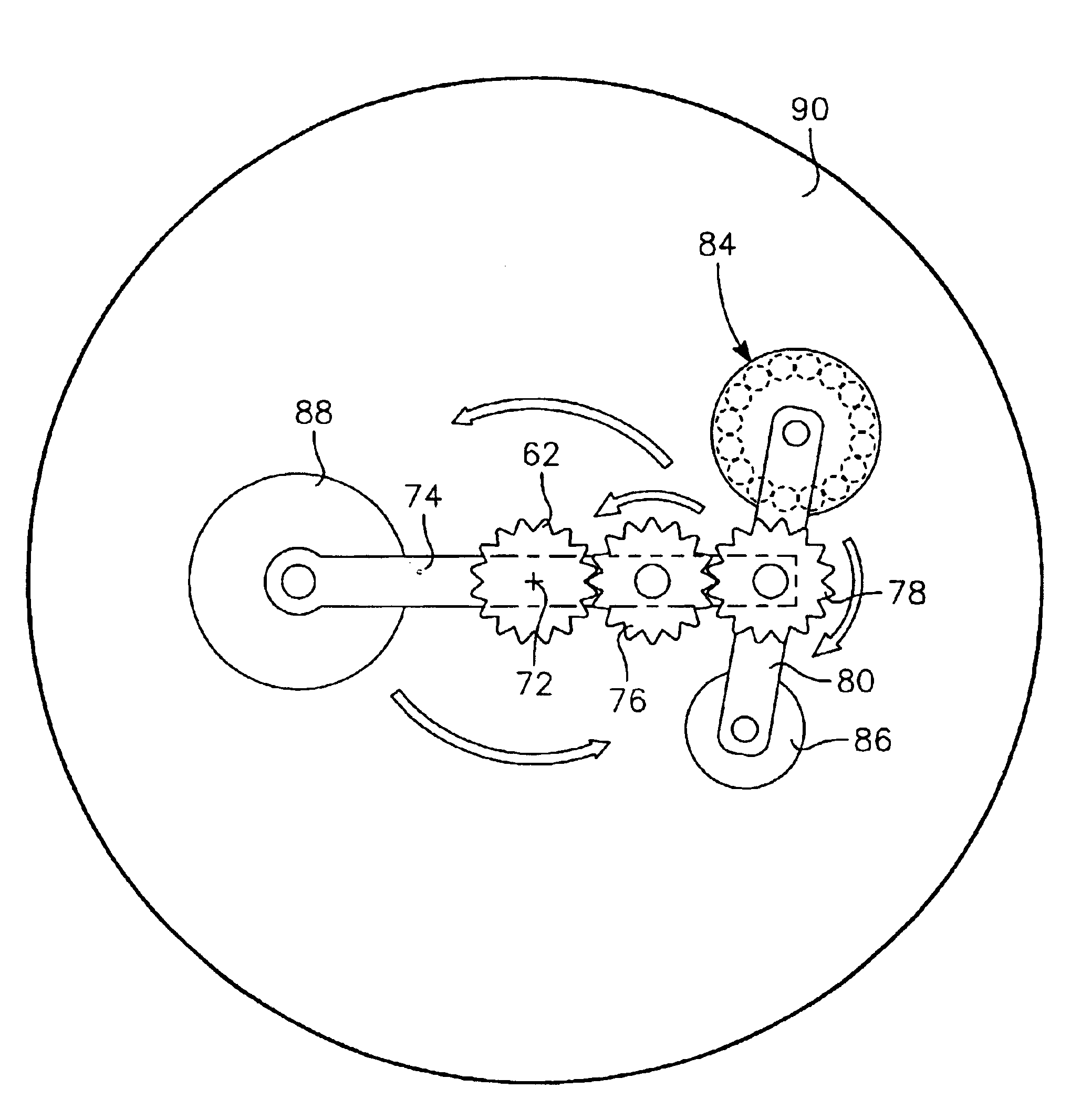

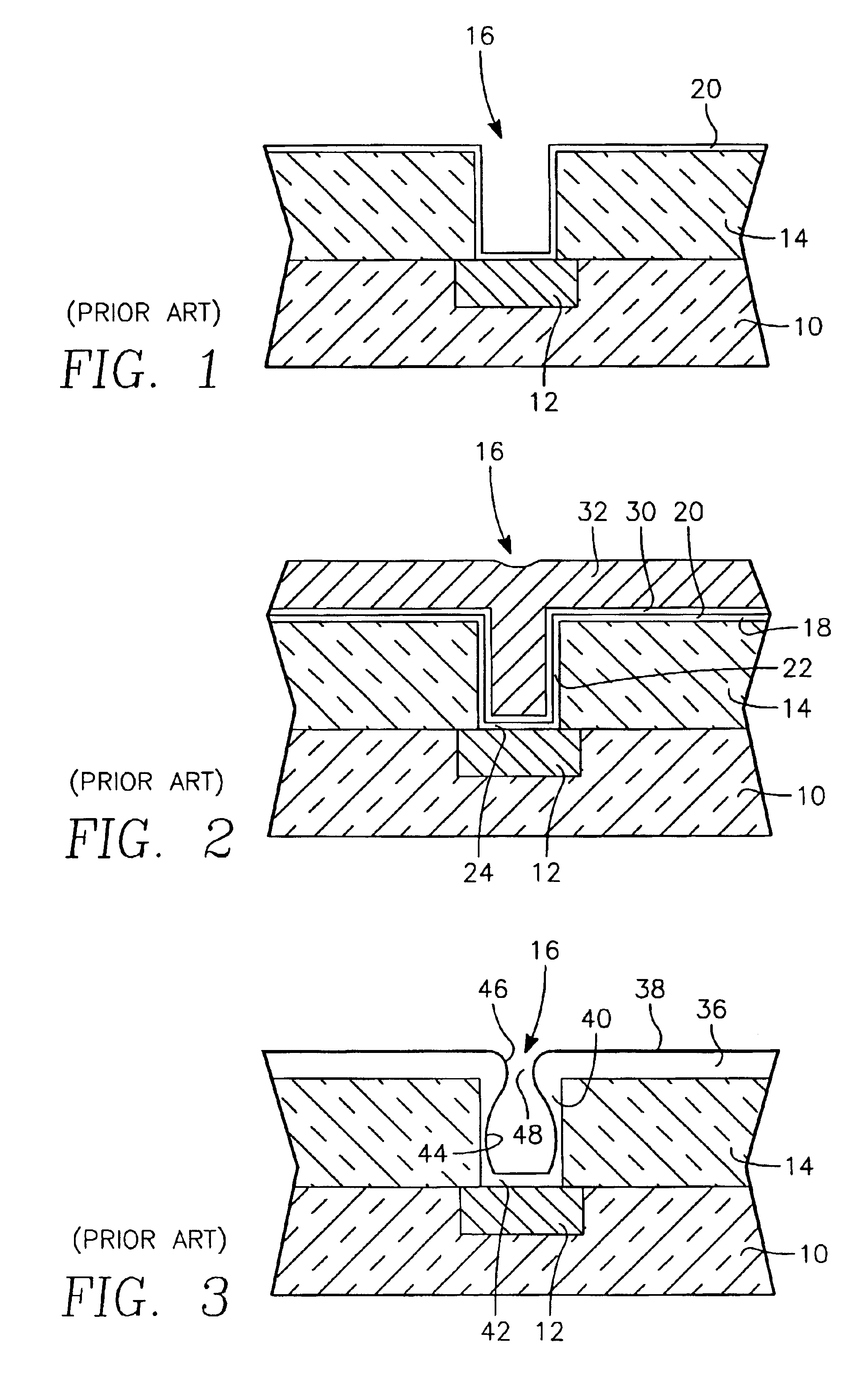

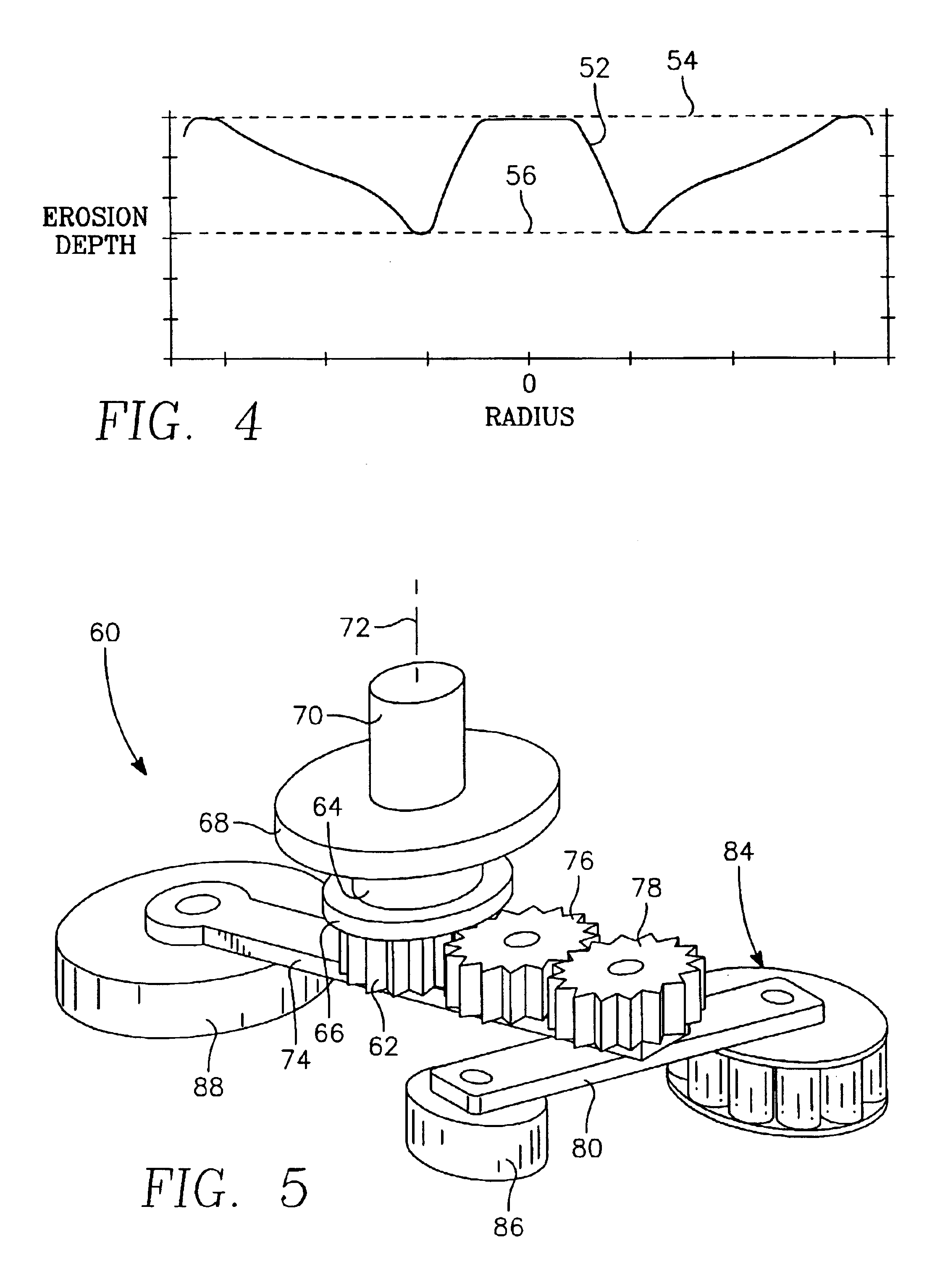

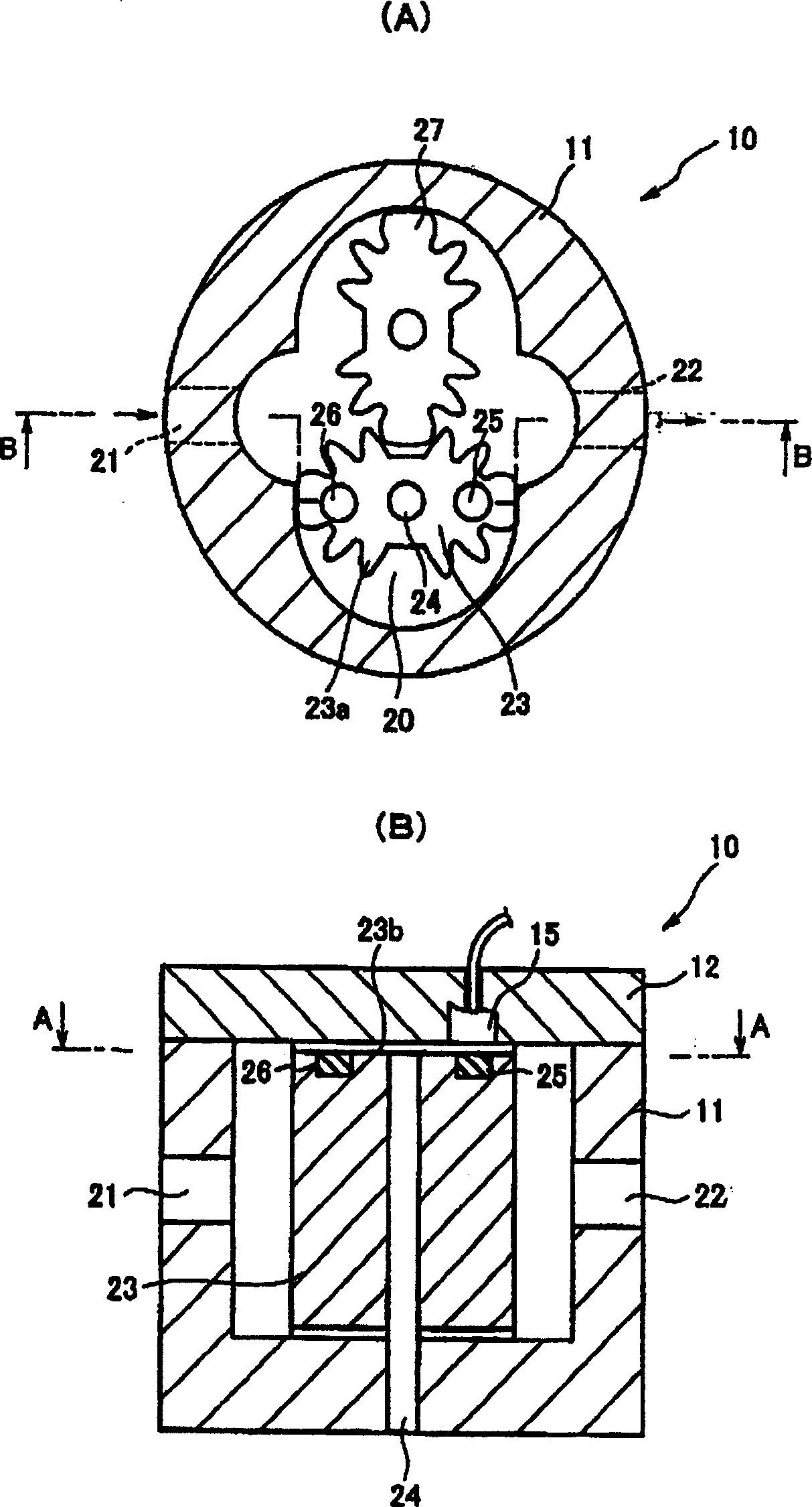

Small epicyclic magnetron with controlled radial sputtering profile

InactiveUS6852202B2Improve uniformityMore target utilizationCellsElectric discharge tubesSputteringSection plane

A small unbalanced magnet assembly is scanned in a retrograde planetary or epicyclic path about the back of a target being plasma sputtered including an orbital rotation about the center axis of the target and a planetary rotation about another axis rotating about the target center axis. The magnet assembly may pass through the target center, thus allowing full target coverage. A geared planetary mechanism may include a rotating drive plate, a fixed center gear, and an idler and a follower gear rotatably supported in the drive plate supporting a cantilevered magnet assembly on the side of the drive plate facing the target. The erosion profile may be controlled by varying the rotation rate through the rotation cycle or by modulating the target power. A second planetary stage may be added or non-circular gears be used. Auxiliary electromagnetic coils may create a focusing magnetic field.

Owner:APPLIED MATERIALS INC

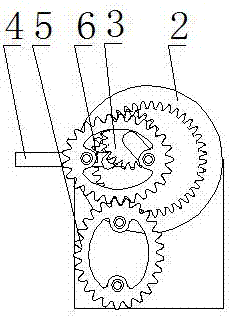

Eccentric gear-incomplete non-circular gear planetary gear plug seedling picking mechanism

The invention discloses an eccentric gear-incomplete non-circular gear planetary gear plug seedling picking mechanism. Power inside a sprocket box is transmitted to a center shaft, one end of which is fixed with a gear box. Longitudinally symmetrical planetary gear mechanisms are installed inside the gear box. An upper and lower planetary shaft that extend out of the gear box are respectively equipped with a seedling pickling arm of the same structure. An incomplete non-circular gear inside the gear box is fixed at one side of the sprocket box and is engaged with an upper and a lower eccentric gear respectively, and the upper and a lower eccentric gear are engaged with an upper and a lower planetary non-circular gear respectively. The incomplete non-circular gear is in coaxial and fixed connection with a convex locking arc, and the upper and the lower eccentric gear are coaxially in fixed connection with an upper and a lower concave locking arc respectively. In the invention, two sets of planetary gear transmission mechanisms are arranged relative to the center shaft, and set drives the motion of a seedling picking arm. Each circle of turning by the gear box can realize twice seedling picking. The plug seedling picking mechanism of the invention has the advantages of high operation efficiency, simple structure, small volume, light weight, and small vibration.

Owner:ZHEJIANG SCI-TECH UNIV

Eccentric gear-noncircular gear planetary gear train vegetable pot seedling automatic transplanting mechanism

The invention discloses an eccentric gear-noncircular gear planetary gear train vegetable pot seedling automatic transplanting mechanism. Gear boxes with the same structure are fixed at the two side shaft ends of a central shaft in a sprocket box extending out of the sprocket box. The two ends of a central shaft in the gear boxes are provided with central incompletely circular gears which are fixed on the sprocket box through a flange and fixedly connected with a convex locking arc; the central shaft and the gear boxes are fixedly connected and rotate together; intermediate shafts on the two sides of the central incompletely circular gears in the gear boxes are respectively symmetrically provided with an intermediate circular gear engaged with the central incompletely circular gears; the intermediate circular gears are respectively fixedly connected with a concave locking arc matched with the convex locking arc; the intermediate circular gears are respectively fixedly connected with an intermediate elliptic gear through the intermediate shaft; the intermediate elliptic gear is engaged with a planet elliptic gear fixedly fixed on a planet wheel shaft; and a transplanting arm is fixed at one end of the planet wheel shaft extending out of the gear boxes. Transplantation is carried out twice when the gear box rotates a circle, so that the working efficiency is improved; and the mechanism has the advantages of simple structure, small volume, light weight and small vibration.

Owner:ZHEJIANG SCI-TECH UNIV

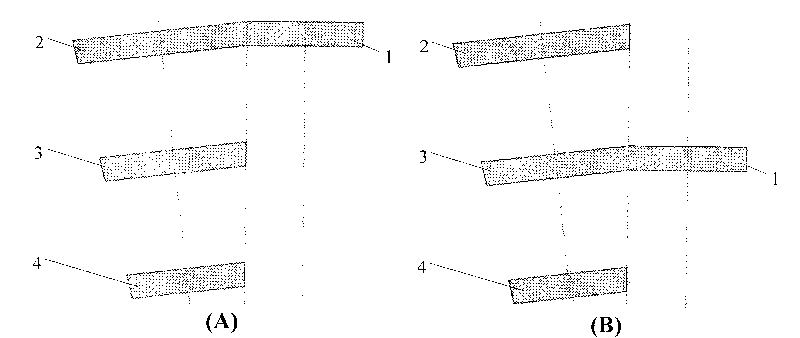

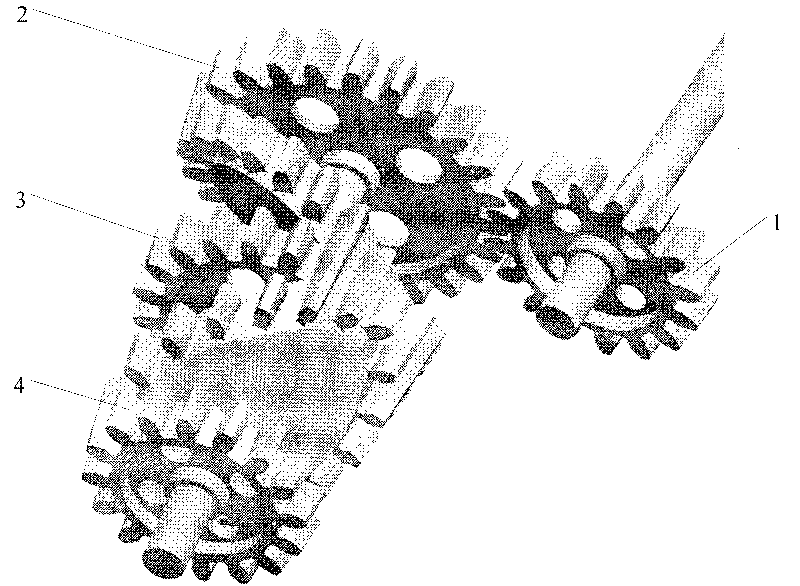

High-speed pot seedling transplanting mechanism with free second-order non-circular gear and planet system

InactiveCN102792814AFlexible control of the secondary swing lawSimple structureTransplantingPaddy fieldH shaped

The invention discloses a high-speed pot seedling transplanting mechanism with a free second-order non-circular gear and planet system. The working principle of the mechanism is as follows: power is transmitted to a planet carrier via a central shaft; free second-order central non-circular gears are fixedly connected with a rack; two free second-order intermediate non-circular gears are connected with hinges of the planet carrier by two intermediate shafts; two free second-order planet non-circular gears are connected with the hinges of the planet carrier by two planet shafts; the two free second-order intermediate non-circular gears are connected with pairs of the two free second-order central non-circular gears; the two free second-order planet non-circular gears are connected with pairs of the two free second-order intermediate non-circular gears; the two free second-order planet non-circular gears are connected with splines of the two planet shafts; and two seedling picking claws are fixedly connected with the two planet shafts. The mechanism has the following beneficial effects: an h-shaped locus needed for pot seedling transplanting is formed through drive of the free second-order non-circular gears; and the mechanism has compact structure, is stable in drive, carries out transplanting twice while the planet carrier rotates a circle, has high efficiency, meets the requirements of pot seedling picking and transplanting and is suitable for transplanting operations in paddy fields and dry fields.

Owner:ZHEJIANG SCI-TECH UNIV

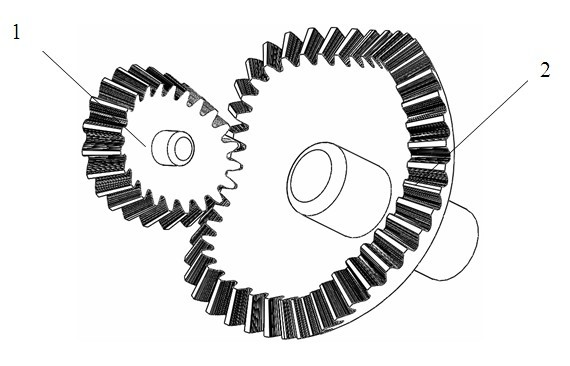

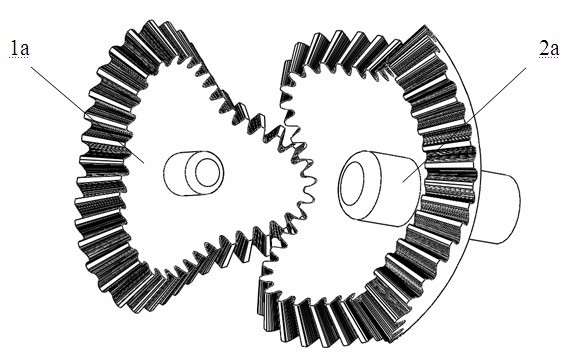

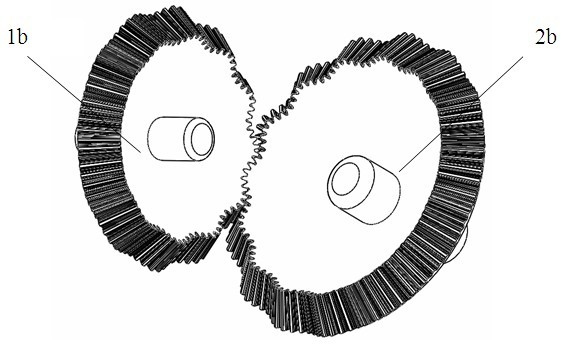

High-order denatured elliptic bevel gear pair with variable transmission ratio

InactiveCN101975247ARich diversityIncrease gear ratioPortable liftingToothed gearingsGear wheelEllipse

The invention discloses a novel high-order denatured elliptic bevel gear pair with a variable transmission ratio, comprising a driving elliptic bevel gear and a driven elliptic bevel gear in mutual engagement. The driving elliptic bevel gear is a high-order elliptic bevel gear, and the driven elliptic bevel gear is a high-order elliptic bevel gear which is engaged with the driving elliptic bevel gear and is at a different order. in the invention, two elliptic bevel gears with different orders are used for transmission in paired and engaged way; and the bevel gears with different orders are paired according to a required transmission speed, thereby not only realizing the non-uniform speed ratio of crossed shafts, but also improving the transmission ratio of the elliptic bevel gear pair to further realize the aim of increasing or reducing the speed in the transmission process with the variable transmission ratio by the matched transmission between a low-order bevel gear and a high-order bevel gear. The invention not only has the advantages of bevel gear pair transmission, non-round gear pair transmission, and the like, but also can realize the function of rapid or slow transmission to enrich the transmission variety of the elliptic bevel gears to a greater extend.

Owner:CHONGQING UNIV

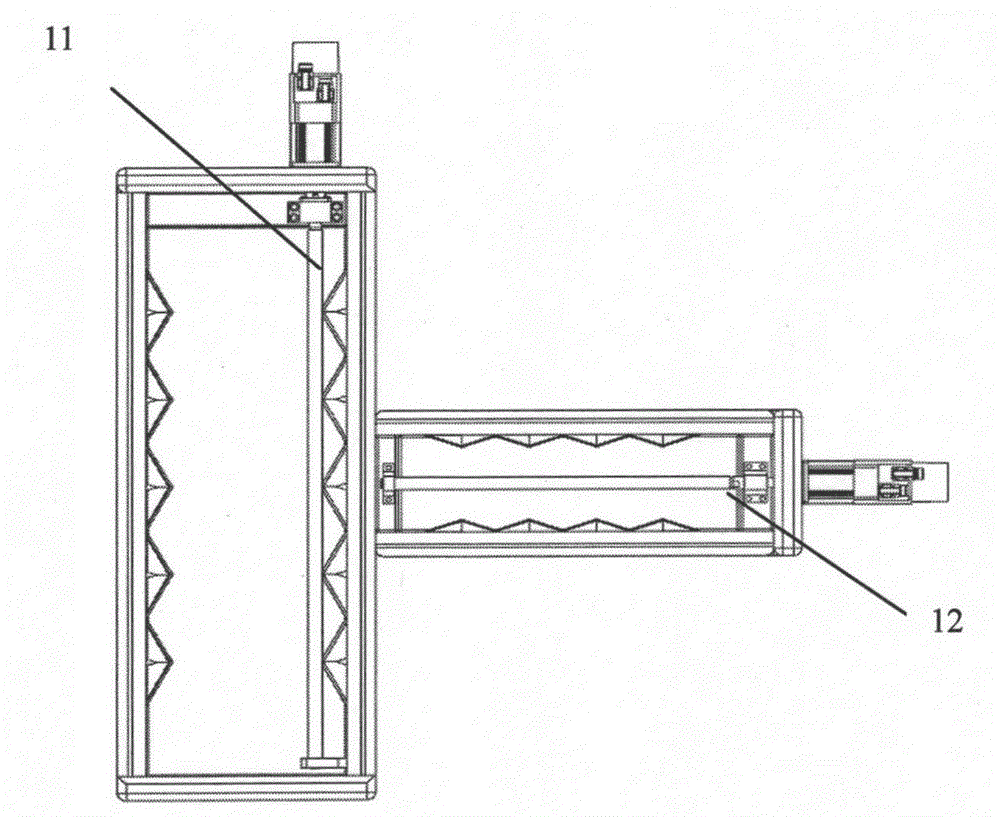

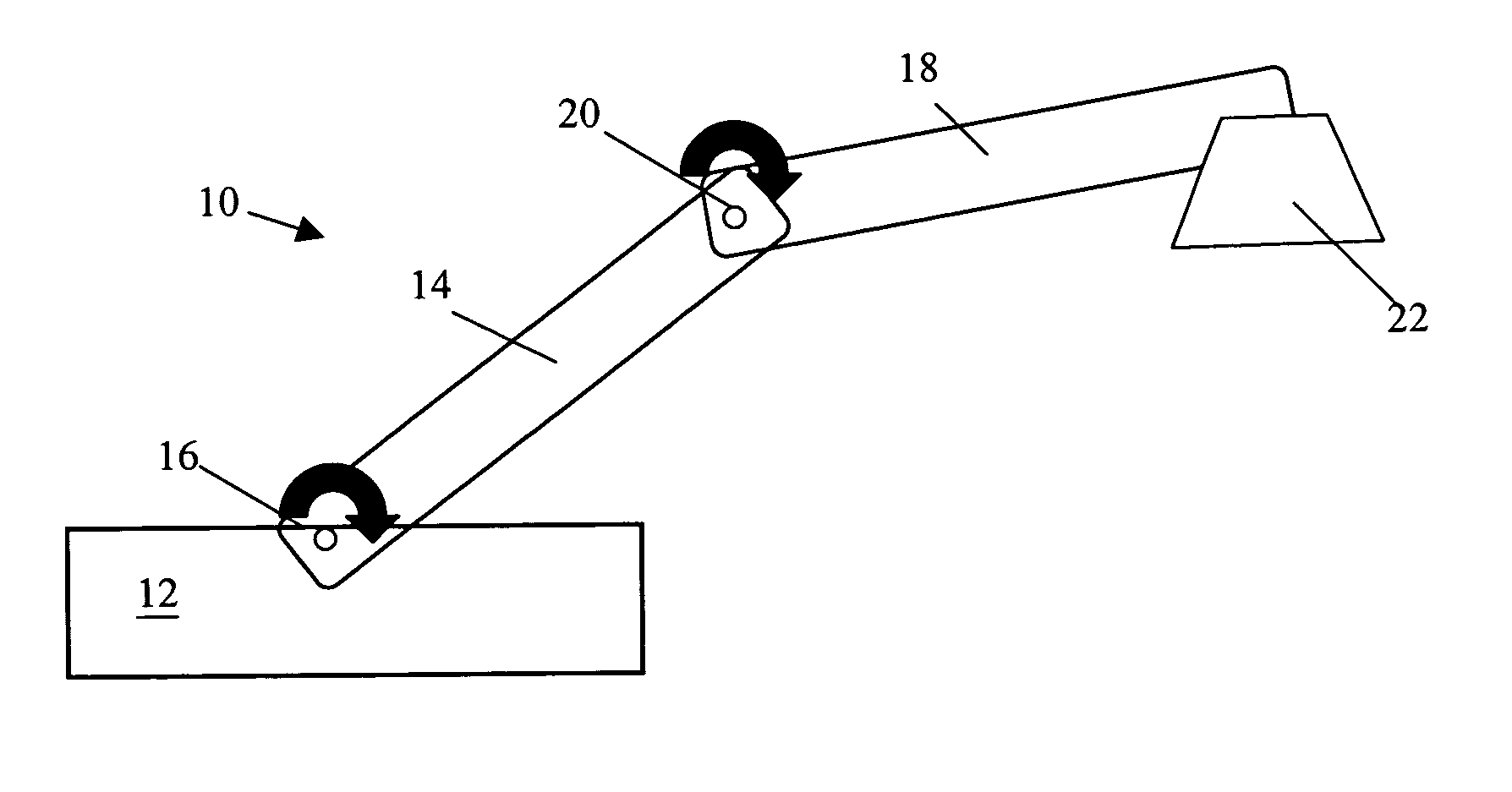

Five-axis linkage horizontal type helical tooth non-circular gear hobbing machine tool

InactiveCN104889504APrecise cuttingAvoid Cutting PoleFeeding apparatusLarge fixed membersHobbingMachine tool

The invention provides a five-axis linkage horizontal type helical tooth non-circular gear hobbing machine tool. The five-axis linkage horizontal type helical tooth non-circular gear hobbing machine tool is characterized in that the machine tool comprises a base, the base is provided with a first supporting structure and a second supporting structure, the height of at least one of the first supporting structure and the second supporting structure can be adjusted, the first supporting structure is provided with a hob device used for machining non-circular gear blank into a helical tooth non-circular gear, the second supporting structure is provided with a rotary table, the rotary table is provided with a working device, and the non-circular gear blank is arranged on the working device. According to the five-axis linkage horizontal type helical tooth non-circular gear hobbing machine tool, by setting the included angle between the hob device and the working device which operate synchronously and by setting the vertical distance between the two devices when the machine tool rotates, the non-circular gear blank mounted on the working device can be cut into a helical gear, and the machine tool is high in machining efficiency and high in precision.

Owner:DONGHUA UNIV

Non-circular gear transmission and its transmission mechanism

InactiveCN101463889AIncrease or decrease projection lengthToothed gearingsFluid removalReduction driveGear wheel

The invention relates to a non-circular gear transmission case and a transmission mechanism thereof. The transmission mechanism is a combined type transmission mechanism with a non-uniform velocity ratio, comprising a non-circular gear transmission case (24), a low speed motor (20), a chain wheel train (21, 22, 23) or a belt wheel train. The output torque and the output rotating speed of the transmission mechanism are consistent with a mainframe load change form; therefore, the transmission mechanism can save energy by a big margin when being used in a mechanism requiring transmission with a non-uniform velocity ratio. The pitch curve shape of non-circular gears (27, 28), and geometric and initial position parameters are determined by an optimized design according to the mainframe load change form, continuity of the pitch curve and fabrication procedure and the like. When the non-circular gears (27, 28) are connected with a circular gear train and a circular gear planetary gear train power, non-circular gear transmission cases of various forms can be formed. An energy-saving beam pumping unit can be formed by removing a speed reducer, a belt wheel and an electric motor and installing the non-circular gear transmission case and the transmission mechanism thereof on a conventional beam pumping unit.

Owner:BEIJING FENGYUAN TECH

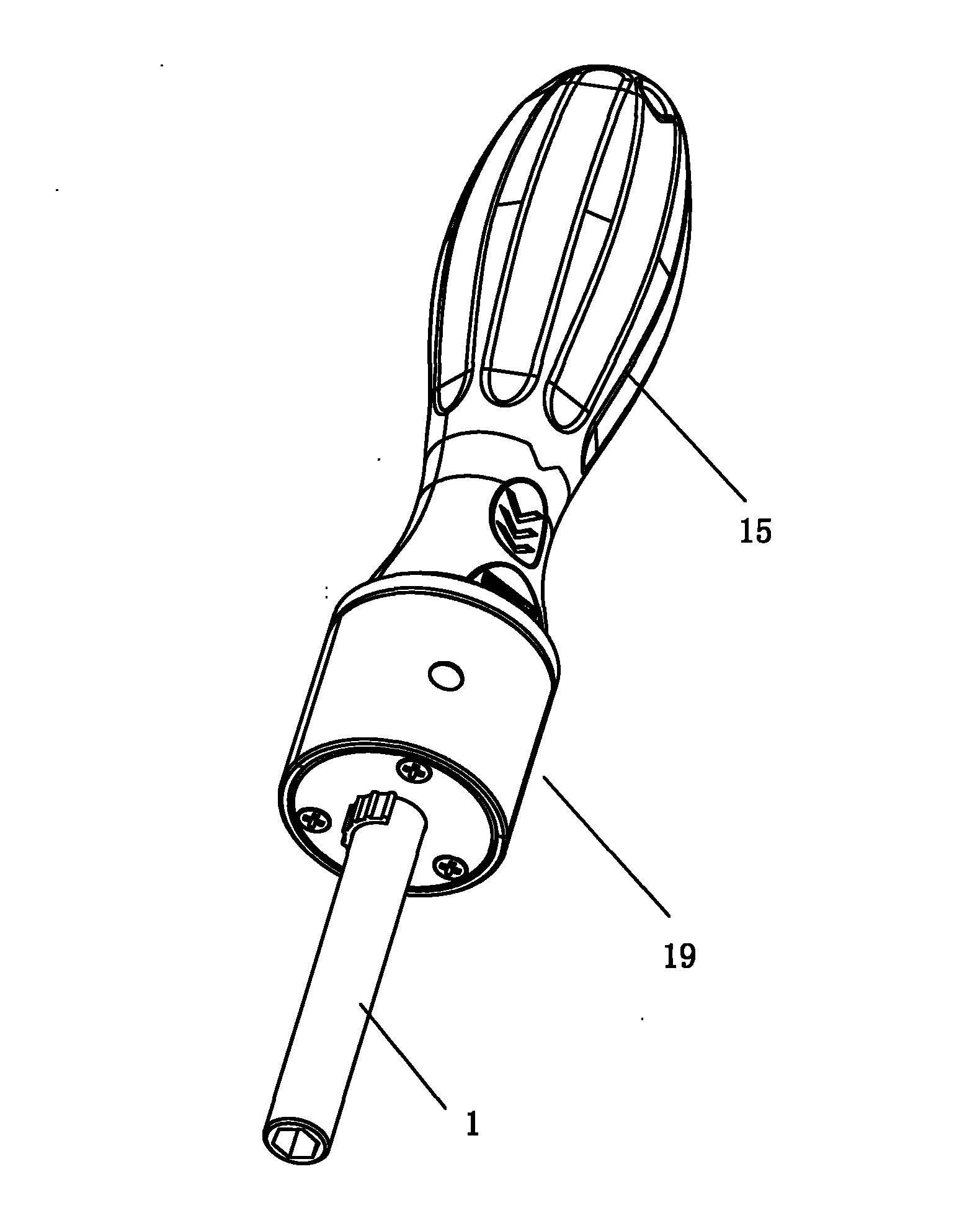

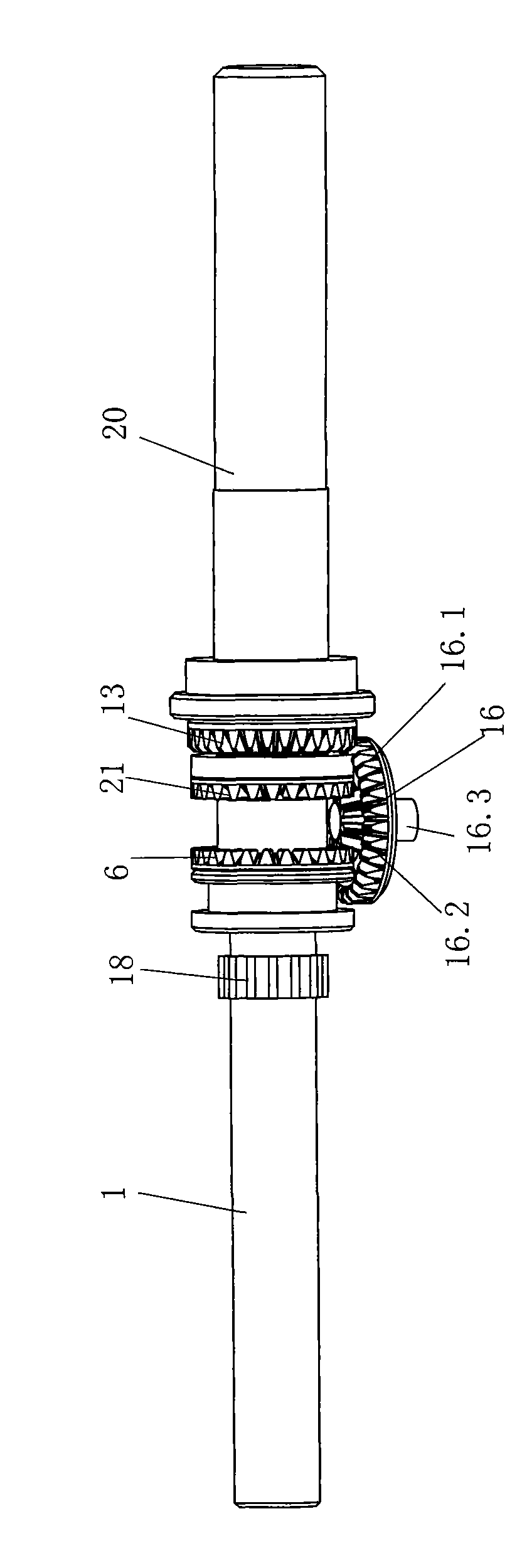

Screwdriver

The invention relates to a screwdriver comprising a handle, a gear device and a screwdriver head. The screwdriver is characterized in that the gear device at least comprises a device shell, a main driving gear, a front circular gear, a rear circular gear, a secondary driving gear group, a spring mounting pin, a front gear block, a rear gear block and a steering button, wherein the front circular gear and the rear circular gear are arranged corresponding to a homocentric shaft, lateral ring gears are distributed on the opposite circular surfaces, the inner rings of the front circular gear and the rear circular gear are inner gear rings; a gearwheel of the secondary driving gear group is engaged with the main driving gear, coaxial pinions in the secondary driving gear group are respectively engaged and connected with the front circular gear and the rear circular gear; the spring mounting pin penetrates into the rear end of the screwdriver head, the front and the back of the spring mounting pin are respectively provided with openings so that the spring and the steel beads can be sequentially filled in the openings; the front gear block and the rear gear block are respectively mounted in containing opening at the front and the back of the rear segment of the screwdriver head, the inner surfaces of the front gear block and the rear gear block abut on and match with respectively steel beads, the outer surfaces of the front gear block and the rear gear block keep contact with the inner gear rings of the front circular gear and the rear circular gear, and the steering button is mounted on the screwdriver head. The invention has more reasonable and practical structure and improves the efficiency.

Owner:SHAOXING EVERPOWER TOOLS

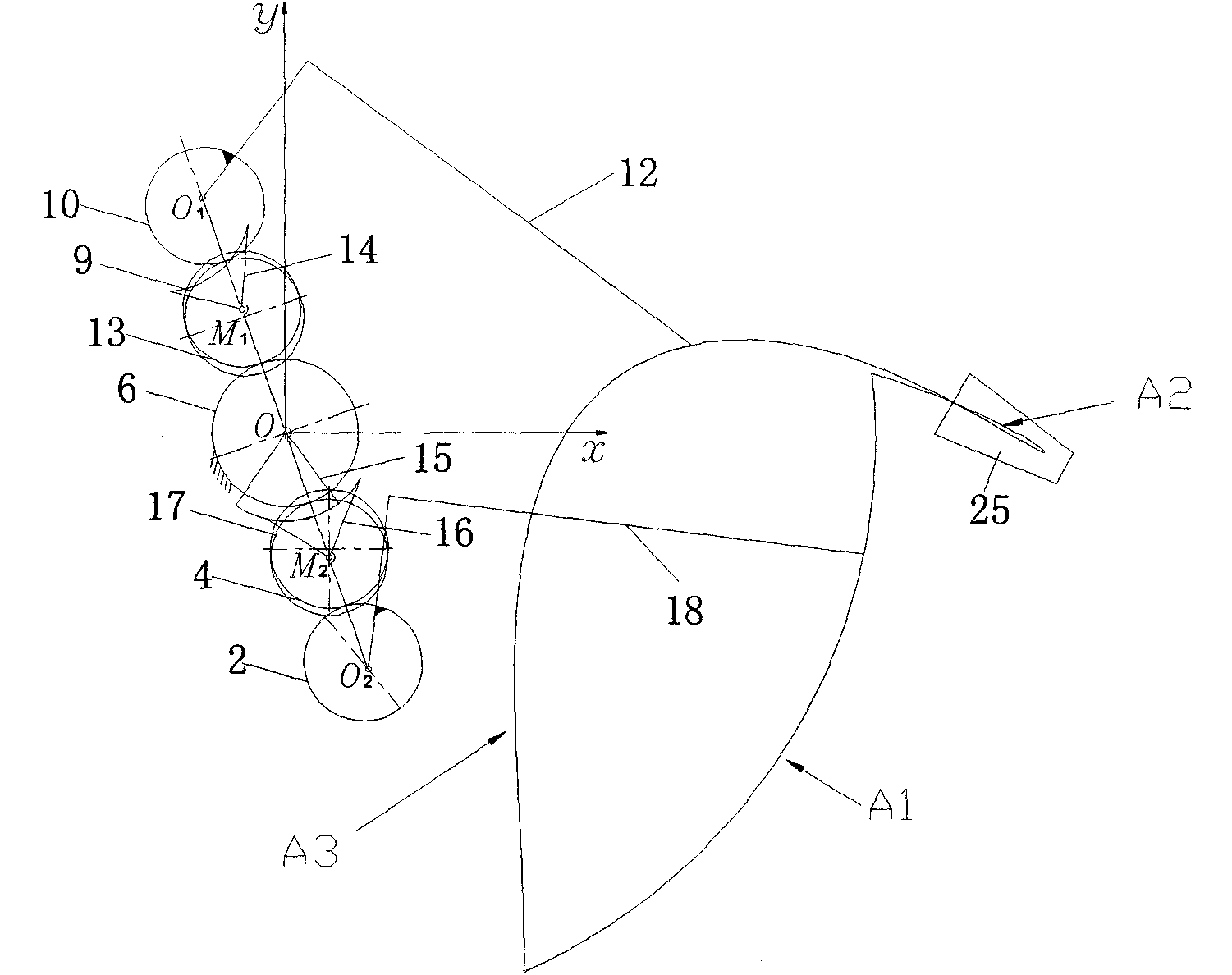

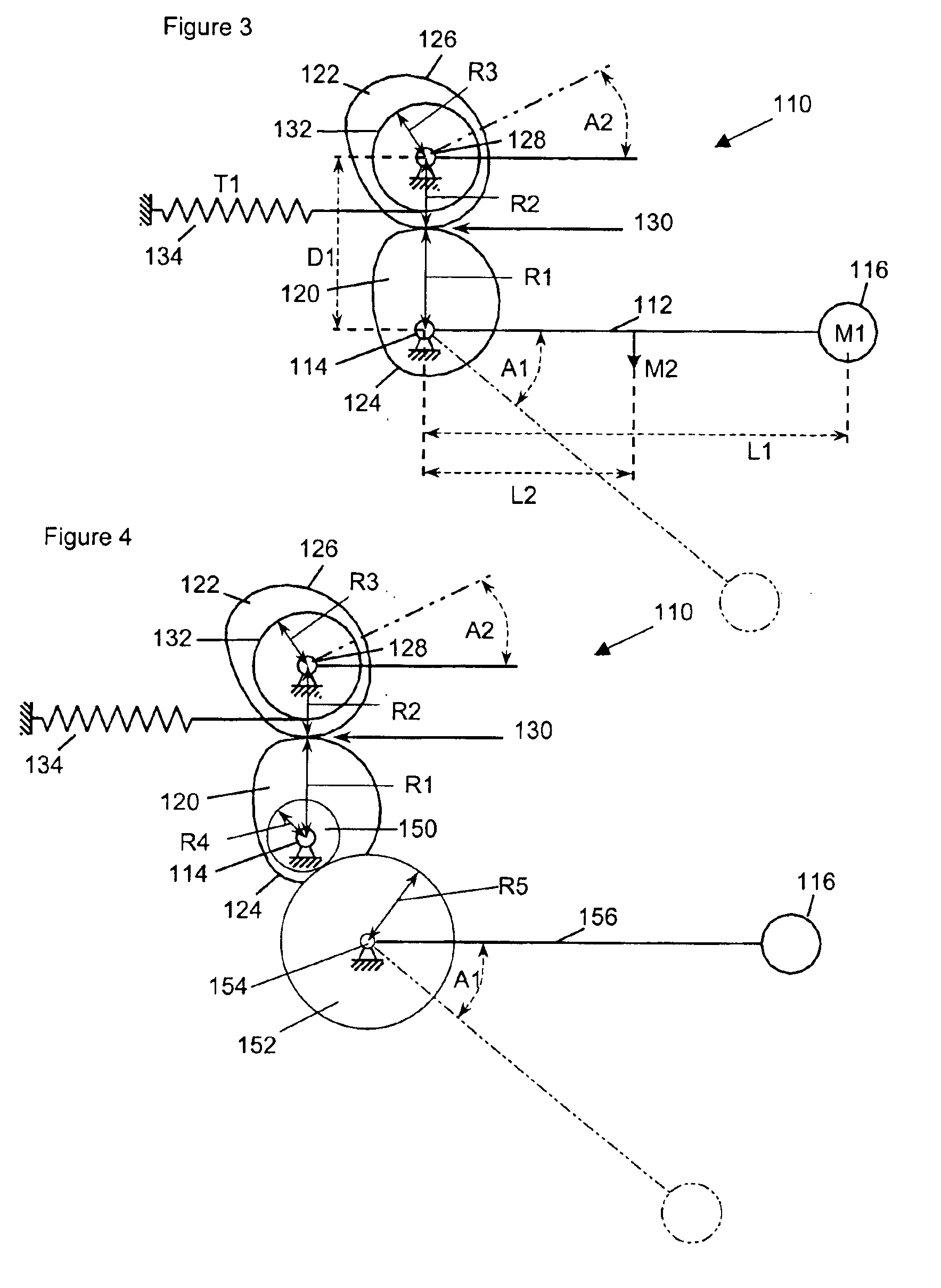

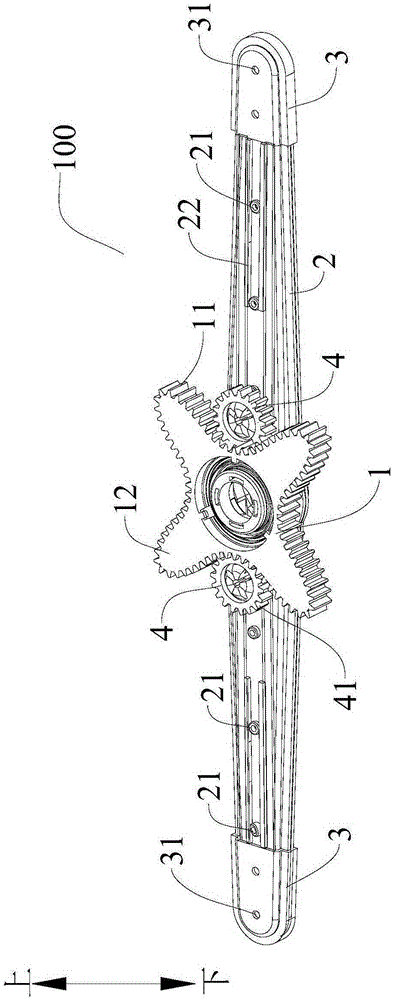

Passive gravity-compensating mechanisms

Mechanisms for passive gravity compensation for a system of linkage arms are provided. Gravity compensation is provided through a pair of non-circular gear profiles, with an end of each linkage arm connected to a separate gear set of two non-circular cam bodies, by way of separate cables. Springs in the gear sets provide tension in the cables. The tension in each cable varies according to the angle through which the cam bodies have turned as a result of the co-operating non-circular surfaces of the cam bodies. This, in turn is based on the amount the arms have turned and thereby allows the tension in the cables to compensate for the moments on the arms due to gravity, whatever angles they are at, independently of the angle of the other arm. To achieve this for the first arm of the linkage, the tension in the cable leading to the second arm of the linkage is also transmitted as a torque to the first arm through a pulley mounted on the rotation axis of the first arm.

Owner:AGENCY FOR SCI TECH & RES

Novel plunger pump

InactiveCN107327382AMovement speed is stableExtended service lifeGearingPump controlReciprocating motionEngineering

The present invention relates to a new type of plunger pump, which includes a driving device, a pump body, a power actuator assembly, and a power transmission assembly; the power actuator assembly includes a guide rod, a chute, and a swing plate that reciprocate in the pump body; The chute is fixedly mounted on one end of the guide rod protruding from the pump body, and the inner side of the chute has two parallel and opposite working planes, the working planes are perpendicular to the guide rod; The power transmission assembly includes an active non-circular gear and a passive non-circular gear meshing with each other, the passive non-circular gear is in transmission connection with the oscillating plate, the active non-circular gear is connected with the driving device, and is driven by the driving device its spinning. The plunger pump can realize the transmission of the sinusoidal mechanism, the pressure angle can be realized by the rotation of the chute and the oscillating disk, and the non-circular gear can realize the smooth movement speed of the guide rod. The equipment is driven by non-circular gears, which can greatly overcome many shortcomings of the cam mechanism, and has a long service life and is not easy to wear.

Owner:殷图源

Gushing arm assembly for bowl washing machine and bowl washing machine with gushing arm assembly

ActiveCN105286752AIncreased wash areaEasy to cleanTableware washing/rinsing machine detailsEngineeringMechanical engineering

The invention discloses a gushing arm assembly for a bowl washing machine and a bowl washing machine with the gushing arm assembly. The gushing arm assembly comprises a fixed gear, a main gushing arm, at least one movable gushing arm and a transmission gear, wherein the fixed gear is a non-round gear; the main gushing arm is arranged on the fixed gear around the axial line of the fixed gear in a rotatable manner; a first spraying opening is formed in the main gushing arm; the movable gushing arms are movably arranged on the main gushing arm in the directions close to and far away from the axial line of the fixed gear; a second spraying opening is formed in each movable gushing arm; and the transmission gear is connected with the movable gushing arms in a rotatable manner, is meshed with the fixed gear, and is used for driving the movable gushing arms to move during rotation of the main gushing arm. According to the gushing arm assembly for the bowl washing machine, telescopic moving traces of the movable gushing arms can be formed under the meshing transmission of the transmission gear and the fixed gear, so that the flushing area of the gushing arm assembly is enlarged, and the cleaning effect is enhanced.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

Passive gravity-compensating mechanisms

Mechanisms for passive gravity compensation for a system of linkage arms are provided. Gravity compensation is provided through a pair of non-circular gear profiles, with an end of each linkage arm connected to a separate gear set of two non-circular cam bodies, by way of separate cables. Springs in the gear sets provide tension in the cables. The tension in each cable varies according to the angle through which the cam bodies have turned as a result of the co-operating non-circular surfaces of the cam bodies. This, in turn is based on the amount the arms have turned and thereby allows the tension in the cables to compensate for the moments on the arms due to gravity, whatever angles they are at, independently of the angle of the other arm. To achieve this for the first arm of the linkage, the tension in the cable leading to the second arm of the linkage is also transmitted as a torque to the first arm through a pulley mounted on the rotation axis of the first arm.

Owner:AGENCY FOR SCI TECH & RES

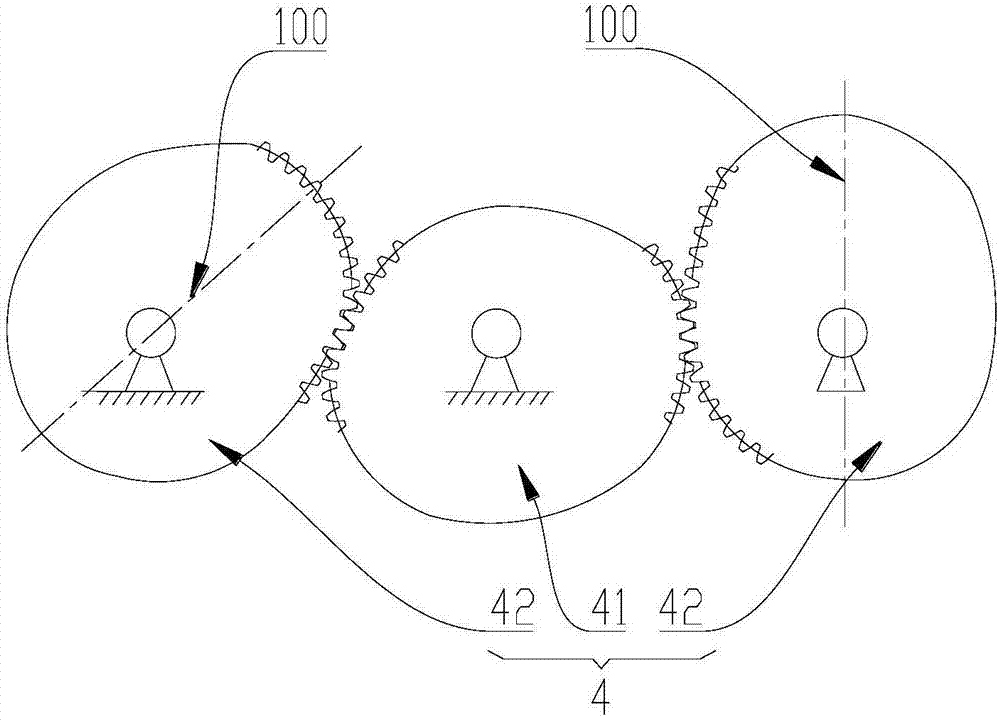

Transmission mechanism of combing machine detaching roller

InactiveCN101311393AImprove transmission control precisionWork fasterToothed gearingsCombing machinesEngineeringGear train

The invention relates to a transmission mechanism of a detaching roller on a combing machine which is provided with a non-circular planetary gear train. The mechanism comprises two sun gears, a tie bar and an even number of planetary gears. The transmission mechanism outputs variable motions including natural rotation, stop and reversion in every working circle (which means the 360 degree rotation of a cylinder), drives the detaching roller to change the speed and the direction of the rotation in accordance with the requirements of the process when the tie bar is rotating at the constant speed driven by a single power source by constructing a pitch curve of the non-circular gear.

Owner:胡平 +1

Non-circular gear-based variable transmission mechanism

InactiveCN101737461AOmit stallHigh transmission precisionToothed gearingsPortable liftingDrive wheelDynamic balance

The invention relates to a non-circular gear-based variable transmission mechanism. The mechanism is provided with a driving wheel, a plurality of driven wheels, transition gear teeth and transmission gear teeth, wherein the driving wheel and the plurality of driven wheels are fixedly arranged on a driving shaft and a driven shaft at a set included angle respectively, and have the same modulus of the gear teeth; the transition gear teeth and transmission gear teeth are positioned on a non-circular pitch curve between the adjacent driven wheels; the transition gear teeth and transmission gear teeth on the non-circular pitch curve are used for completing gear shifting of the driving wheel between the two adjacent levels of driven wheels, namely axial feed movement is applied to the driving wheel on the premise of keeping the rotating speed of the driving wheel invariable, so that the driving wheel can be meshed with the transition gear teeth, the transmission gear teeth and the transition gear teeth on the non-circular pitch curve between each level of driven wheels in sequence to complete gear shifting and variable speed without the process of stalling and clutching. The device abandons a clutch, realizes variable transmission between the two shafts by using a non-circular gear on the non-circular pitch curve, and has the characteristics of compact structure, precise transmission, reliability, stability and easy dynamic balance of non-circular gear transmission mechanisms.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Continuously variable transmission

A constant mesh gear driven continuously variable transmission including a minimum of two cones in mesh with either an axial sliding ring gear or an axial sliding circular gear. The cones and ring gear or circular gear are enclosed in a housing. An input shaft is journaled in the housing. The cones rotate about their own axes and revolve about the shaft in some embodiments. The ring gear or axial sliding circular gear is slidable axially relative to the cone gear, and the output gear ratio is varied by the axial position on the ring gear or sliding circular gear.

Owner:TROESTER THOMAS F

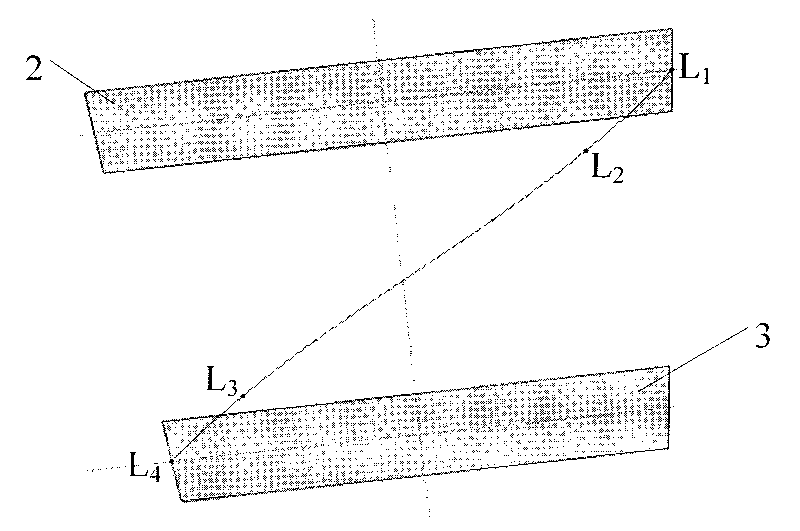

Separating and planting mechanism of eccentric knuckle gear-nonknuckle gear planetary train

InactiveCN101066012ASimple structureEasy to processSeed and root treatmentFertiliser equipmentsGear wheelEngineering

The present invention discloses separating and planting mechanism of eccentric knuckle gear-nonknuckle gear planetary train. There are one central chain wheel inside the chain wheel box to rotate the right and the left gear boxes, two fixed central eccentric knuckle gears in the gear boxes, two nonknuckle gears meshed separately with the central eccentric knuckle gears and rotating with the nonknuckle gears and one planetary eccentric knuckle gear meshed with these two nonknuckle gears, with the five gears having rotating centers in the same straight line. The planetary eccentric knuckle gear rotates with the gear boxes in even speed while rotating in uneven speed relatively to the gear boxes. One pair of planting arms fixed to the planetary eccentric knuckle gear via the planetary gear shaft performs uneven speed oscillation, and proper structural parameters ensure the operating track of the rice seedling pin suitable for forward planting operation.

Owner:ZHEJIANG SCI-TECH UNIV

Stroke-adjustable type intermittent movable mechanical device based on non-circular gear divider

InactiveCN106594220AHigh movement precisionImprove transmission efficiencyToothed gearingsGear wheelEngineering

A stroke-adjustable type intermittent movable mechanical device based on a non-circular gear divider comprises a power supplying and braking device, an indexing device and a stroke-adjustable crank block device. A variable-frequency and variable-speed motor of the power supplying and braking device is connected with the input end of a brake through an elastic sleeve pin coupler. The output end of the brake transfers force to the indexing device. The indexing device is the non-circular gear divider, the input end of the indexing device is connected with the output end of the brake, and the output end of the indexing device is connected with the stroke-adjustable crank block device. The stroke-adjustable crank block device is composed of a crank disc, an adjusting bolt, a connecting rod, a working actuating device and a hinging device, wherein the crank disc is connected with the output end of the non-circular gear divider and the connecting rod, and the connecting rod is connected with the working actuating device through the hinging device. According to the device, intermittent reciprocating movement of a working mechanism is achieved, the moving stroke is large, the stroke range is adjustable, the motion precision is high, impact and noise are quite low, the transmission efficiency is high, the service life is long, and the stroke-adjustable type intermittent movable mechanical device can be used for high-speed heavy loads.

Owner:WUHAN UNIV OF TECH

Rotary transplanting device of pot seedling transplanting machine

InactiveCN101878692ASmall inertia forceMeet the agronomic requirements for transplantingTransplantingGear wheelEngineering

The invention discloses a rotary transplanting device of a pot seedling transplanting machine. Power is output by a sprocket shaft and transferred to a left planetary carrier system transplanting device and a right planetary carrier system transplanting device. A planetary carrier is driven by the sprocket shaft, a non-circular sun gear is fixedly connected with a sprocket box and is stationary in work, and a middle non-circular gear and a planetary non-circular gear are symmetrically arranged at both sides of the non-circular sun gear. The extending end of a planetary axle is upwards articulated with an inner half transplanting nozzle and an outer half transplanting nozzle which are respectively provided with a groove and a pin for realizing the centering opening of the transplanting nozzles. The transplanting nozzles are opened by the relative rotation of a roller on the inner half transplanting nozzle and an end surface cam fixed on the planetary carrier and closed by springs mounted on the inner half transplanting nozzle and the outer half transplanting nozzle. By a non-circular gear planetary system, the uniform rotation of the sprocket shaft is turned into the swinging absolute motion of the planetary axle to form an orbit and a stance which are needed by the transplanting nozzles on the planetary axle and satisfy the agricultural requirement of pot seedling transplantation.

Owner:ZHEJIANG SCI-TECH UNIV

Belt drive

InactiveUS20060035738A1Simple and reliable processEasy to useValve arrangementsPortable liftingDrive shaftEngineering

A belt drive is provided, especially a timing-belt drive for an internal-combustion engine, with a driving gear of a driveshaft, at least one driven gear of a driven shaft, and a belt means, wherein the driving or the driven gear imparts additional irregularity to the belt drive due to its noncircular shape and its phase position, which leads to stable running of the belt means. A noncircular gear that can be mounted easily and in phase, as well as with a fixed position, is realized in that the driving or driven noncircular gear has in its in-phase rotational position a rotationally fixed connection to its driving or driven shaft.

Owner:SCHAEFFLER KG

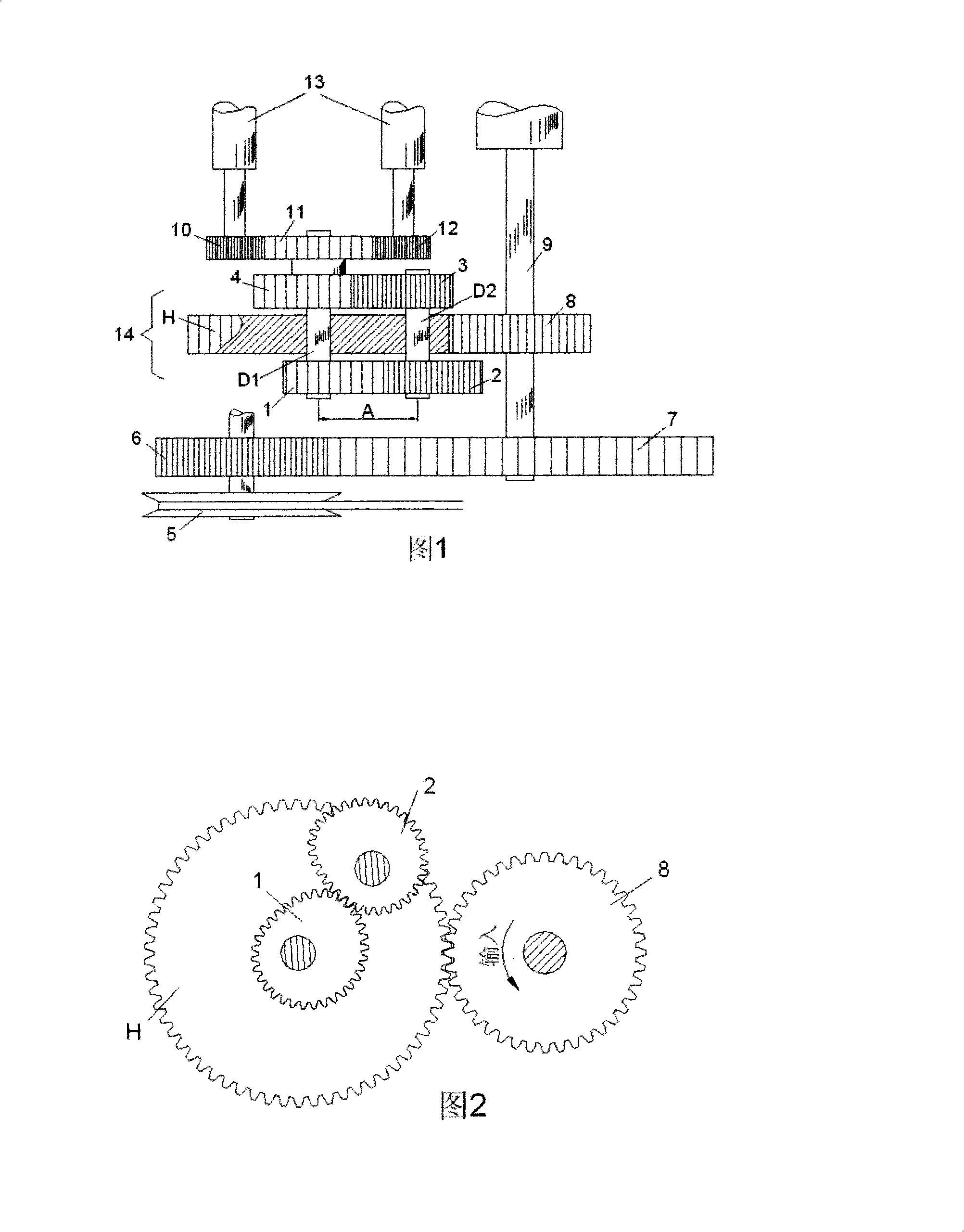

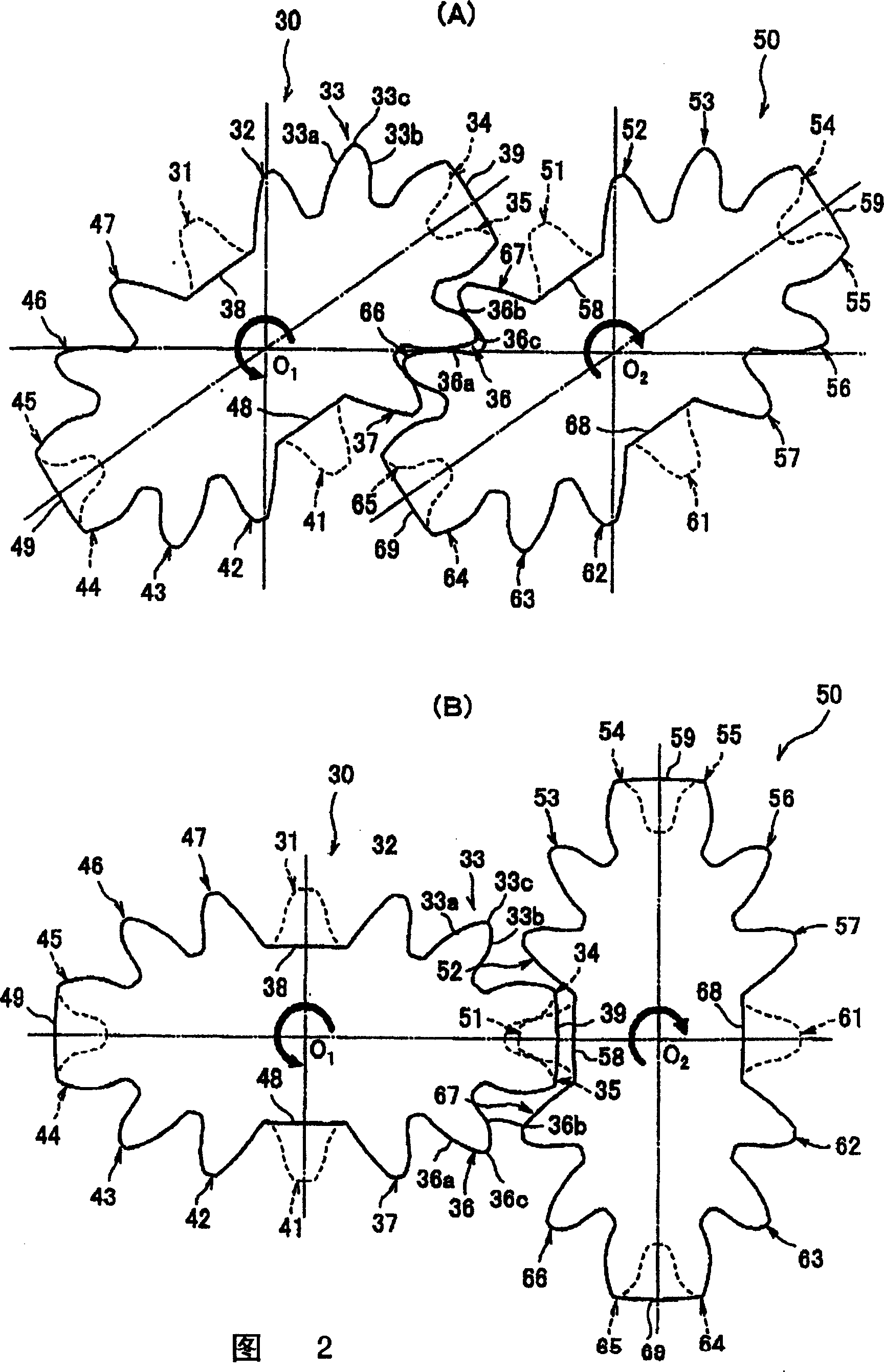

Non round gear and volumetric flowmeter using same

InactiveCN1573302ALittle changeEasy to set upVolume/mass flow measurementRotary piston pumpsEllipseEngineering

The number of teeth is set to 4n+2 (n is a natural number), both the ends on a long axis are set to be teeth grooves, both the ends on a short axis are set to be tips, a pitch curve is set to be, for example, an ellipse, and tooth marks 31-37, 41-47 are set to be basic tooth mark curves. With the tooth mark curve, the engagement teeth surface is set to be an involute curve, a non-engagement tooth surface is set to be a cycloid curve, and the tool pressure angle of each tooth mark is set by an undercut limit and a point limit. The non-circular gears 30, 50 bury the recess between two tooth marks, holding the tooth space located at both the ends on the long axis, based on the basic tooth mark curve, and have a shape, where the tooth section including the tip at both the ends on the short axis are scraped off, and the number of teeth completed is finally set to 4n-2. Accordingly, it is able to obtain a non-circular gear that reduces the change in an engagement pressure angle, is advantageous for setting the tool pressure angle of an engagement teeth surface, can reduce the number of teeth without forming an overhang section, and can fully secure the sealing performance with the inner wall of a casing to be installed.

Owner:OVAL CORP

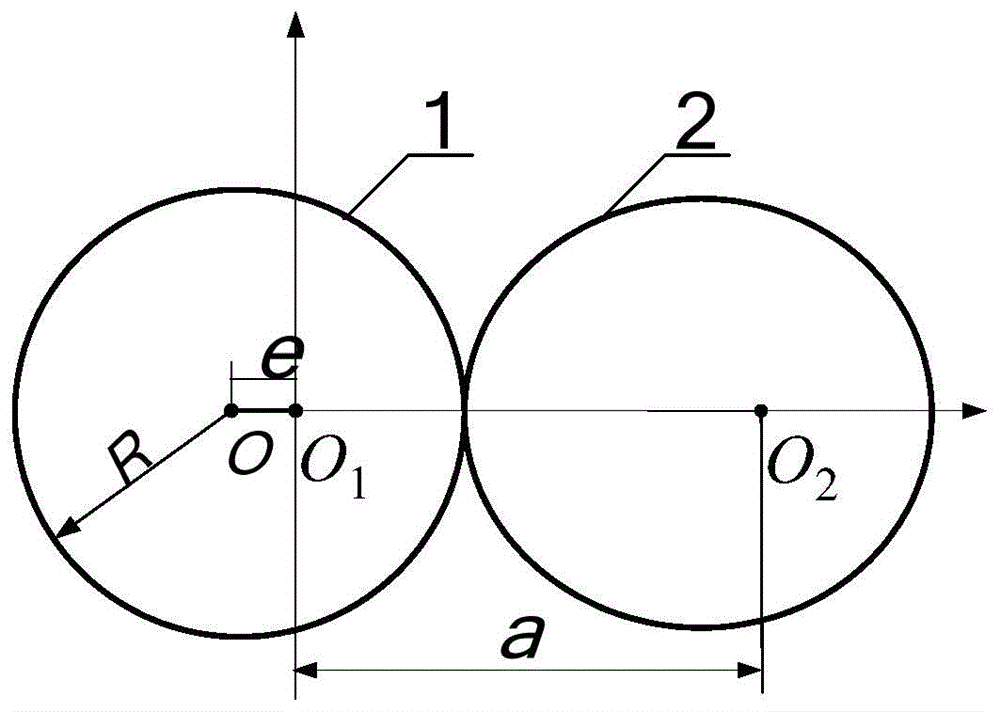

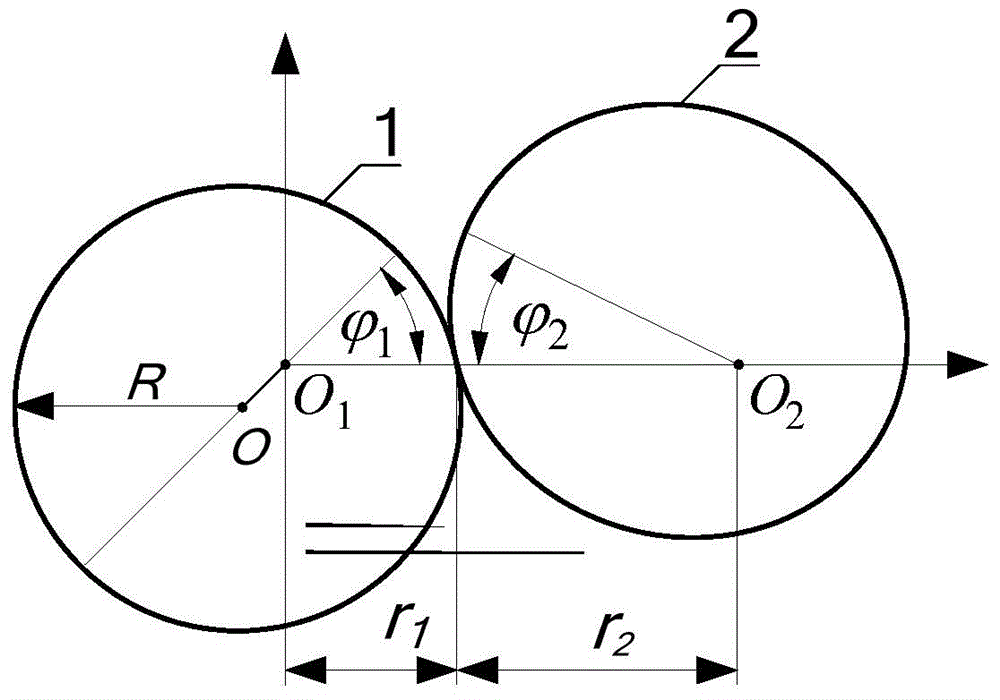

Design method of high-order modified eccentric circular gear and non-circular gear pair conjugated with high-order modified circular gear

InactiveCN104455313AEasy programmingHigh solution accuracyPortable liftingToothed gearingsEngineeringMaximum pressure

The invention discloses a design method of a high-order modified eccentric circular gear and a non-circular gear pair conjugated with the high-order modified circular gear. There is no literature report on design and application research on a high-order modified eccentric circle-non-circular gear pair so far. The design method specifically comprises the following steps that firstly, a pitch curve equation of a high-order modified eccentric circle gear and a non-circular gear pair conjugated with the high-order modified eccentric circle gear is established, and a center distance is calculated through the numerical method; secondly, the concavity and convexity of a pitch curve are verified, the maximum modulus under the situation that undercutting is not carried out when a gear is machined through the gear shaping method is obtained, the pressure angle change range is calculated, the maximum pressure angle value is verified, and the contact ratio when the high-order modified eccentric circle gear and the non-circular gear pair conjugated with the high-order modified eccentric circle gear are meshed is calculated. According to the design method, a whole set of thorough design theoretical basis is provided for the high-order modified eccentric circle gear and the non-circular gear pair conjugated with the high-order modified eccentric circle gear in actual application, and the using and popularizing of the high-order modified eccentric circle gear and the non-circular gear pair conjugated with the high-order modified eccentric circle gear are promoted.

Owner:HUZHOU ZHILI CHILDRENS CLOTHING DEV

Variable speed continuous box moving mechanism for transplanting pot seedlings

The invention provides a variable speed continuous box moving mechanism for transplanting pot seedlings and belongs to agricultural machinery. A driving noncircular gear and a driven noncircular gear are fixedly mounted on a main transmission shaft and a spiral shaft, which are rotatable and mounted in parallel, in a box moving assembly, respectively; and the driving noncircular gear and the driven noncircular gear are normally meshed with each other. The variable speed continuous box moving mechanism provided by the invention has the advantages of simple structure and low manufacturing cost; the spiral shaft obtains variable speed transmission power while continuous variable speed rotation of the main transmission shaft is guaranteed, so that regular variable speed continuous linear reciprocating motion of the transverse box movement is achieved; and a problem that various transplanting seedling fetching mechanisms are interfered by the continuous and transverse moving seedling box during fetching the seedlings can be solved.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Revolving internal-combustion engine

InactiveCN1873197ALow powerSimple structureInternal combustion piston enginesRotary piston enginesPiston ringInternal combustion engine

The invention discloses a rotary internal combustion engine that includes a cylinder with circular section, containing two identical cylinder blocks with semi-circular sections. Two identical rotors are installed within the cylinder block and are provided with four pistons with piston rings similar to the reciprocation engine. Two identical rotor shafts are vertically fixed on the two rotors respectively. Two non-circular gears are installed on the two rotor shafts separately, which engage with two eccentric gears respectively attached to one output shaft respectively. The rotors work four times every revolution, equivalent to the work done by a 4 cylinder 4 stroke internal combustion engine for every two revolutions of the crankshaft. The engine may include multi spark plugs or injectors, multi intake ports and multi exhaust ports. The engine may also combine multi cylinder blocks to provide larger output power.

Owner:庞乐钧

Dual-planet-carrier elliptical non-circular gear planetary gear train pot seedling transplanting mechanism

The invention provides a dual-planet-carrier elliptical non-circular gear planetary gear train pot seedling transplanting mechanism. An existing pot seedling transplanting mechanism integrating seedling taking and transplanting capability can take seedlings only by virtue of a direct seedling clamping mode, and therefore, damage is caused to roots of the seedlings; seedling taking and transplanting are realized by virtue of two mechanisms, and therefore, the overall mechanism is relatively complicated. A drive sprocket shaft and a central shaft are supported on two ends of a power drive box by virtue of bearings; a drive sprocket fixed to the drive sprocket shaft is connected with a central sprocket fixedly connected to the central shaft by virtue of a chain; two ends of the central shaft are symmetrically provided with two main planetary gear trains; an upper auxiliary planetary gear train and the lower auxiliary planetary gear train are respectively arranged at two ends of the main planetary gear train. The upper auxiliary planetary gear train is provided with an upper transplanting arm, and the lower planetary gear train is provided with a lower transplanting arm. By use of one mechanism, seedlings are taken in a manner of extending into a pot and taking soil; in the seedling taking process, a seedling claw translates, so that the pot soil integrality can be kept to the greatest extent; and the locus of a seedling push segment is far away from the rotation center of the mechanism, so that the working height of the overall mechanism is increased.

Owner:泰州博瑞企业管理咨询有限公司

Free second-order non-circular gear-deformation ellipse gear pot seedling transplantation and clamping type taking mechanism

InactiveCN103621227AFlexible secondary swing characteristicsRealize automatic transplantingTransplantingProbe typeGear wheel

The invention discloses a free second-order non-circular gear-deformation ellipse gear pot seedling transplantation and clamping type seedling taking mechanism. A soil clamping type seedling taking mode causes the irregularity of a non-circular gear or the increase of a 'probing type' seedling needle; melon, fruit and vegetable crops permit a clamping type seedling taking mode. A central shaft and a planet carrier are fixedly arranged; a free second-order central non-circular gear is hollowly arranged on the central shaft in a sleeved manner; a fist middle shaft, a second middle shaft, a first planet shaft and a second planet shaft are connected with the planet carrier through a bearing; the first planet shaft and the second planet shaft are fixedly arranged on a housing provided with a seedling taking paw; the free second-order central non-circular gear is meshed with a first free second-order middle non-circular gear and a second free second-order middle non-circular gear; a first middle deformation ellipse gear and a first planet deformation ellipse gear are meshed; a second middle deformation ellipse gear and a second planet deformation ellipse gear are meshed; a sharp point of the head of the seedling taking paw is in favor of forming a clamping type seedling taking track. The seedling taking track is in favor of achievement of mechanisms, and the fully automatic transplantation of melons, fruits and vegetables can be achieved.

Owner:ZHEJIANG SCI-TECH UNIV

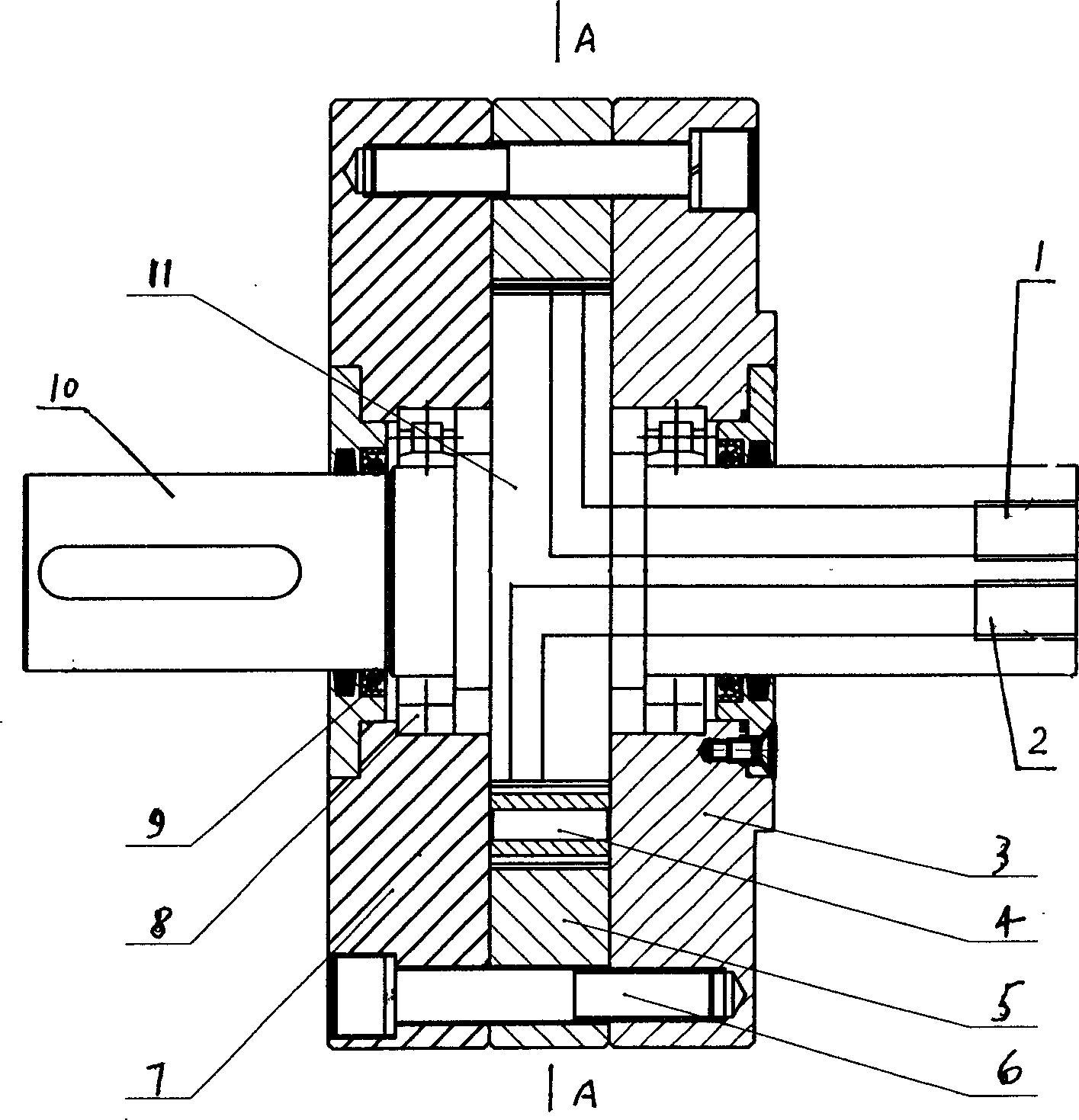

Numerical control servo press machine with non-circular gear transmission mechanism

The invention discloses a numerical control servo press machine with a non-circular gear transmission mechanism, which comprises a servo motor (2), a connection device (16), a gear transmission mechanism (17) and a crank slider mechanism (18); wherein the output end of the servo motor (2) is connected with the connection device (16), and the connection device (16) is connected with the crank slider mechanism (18) through the gear transmission mechanism (17); and the gear transmission mechanism (17) comprises a non-circular gear set, which is used for changing the transmission ratio of the servo press machine and comprises a first non-circular gear (5) and a second non-circular gear (7), and the first non-circular gear (5) and the second non-circular gear (7) are meshed with each other. By means of the coordination of the servo motor and the non-circular gear set, the movement of a crank in the crank slider mechanism is regulated in real time so that the crank continuously moves and swings in cycle, thus, different motion characteristics of a slider connected with the crank is realized, and the process adaptability and the production efficiency of the press machine are improved.

Owner:HOHAI UNIV CHANGZHOU

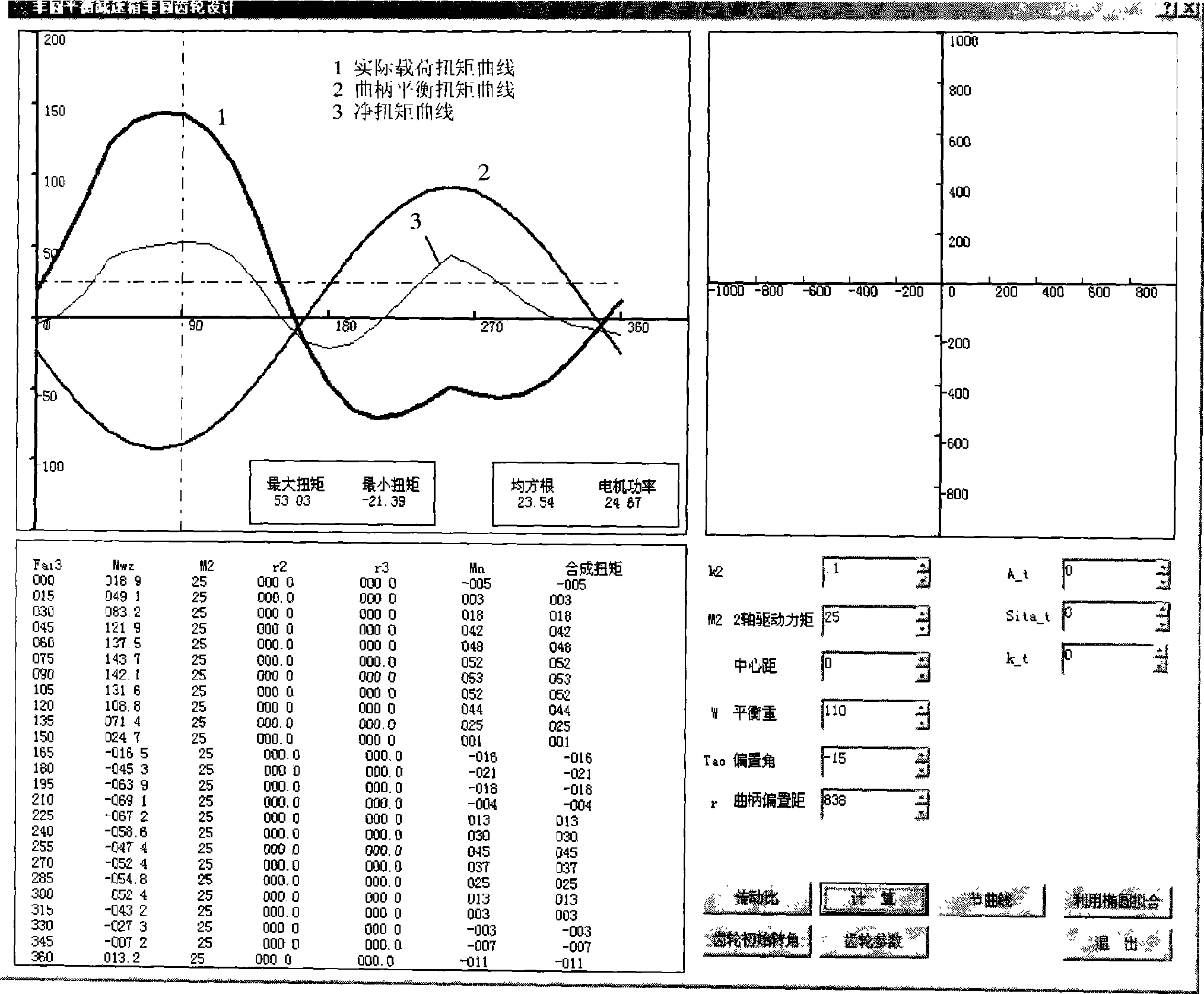

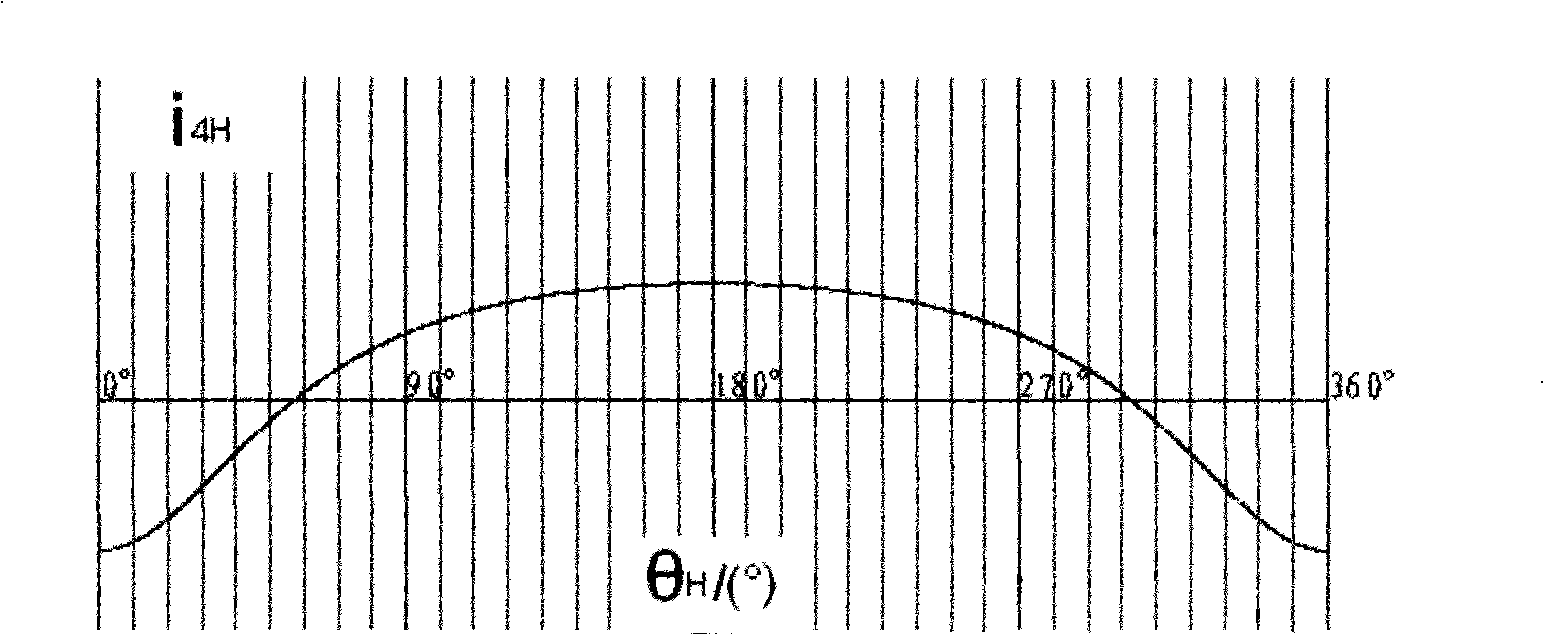

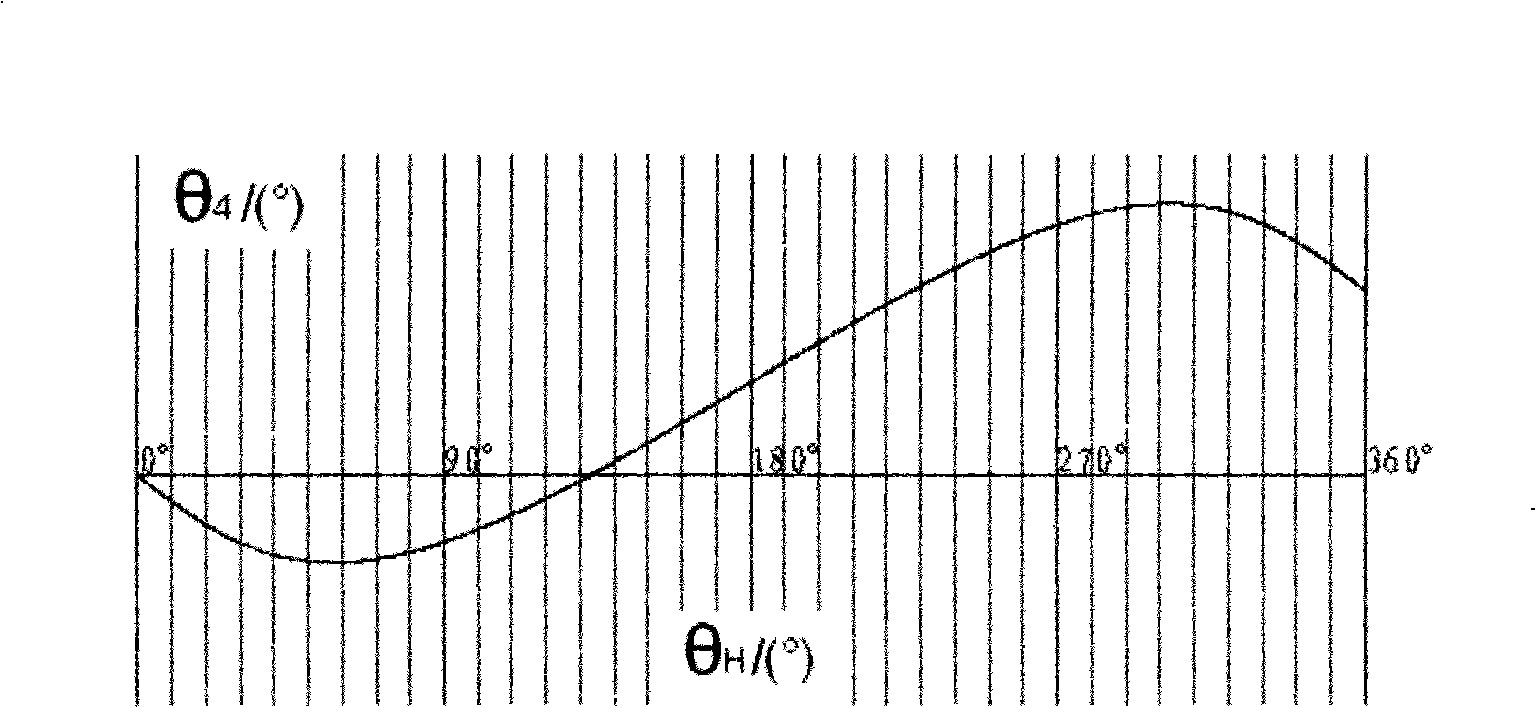

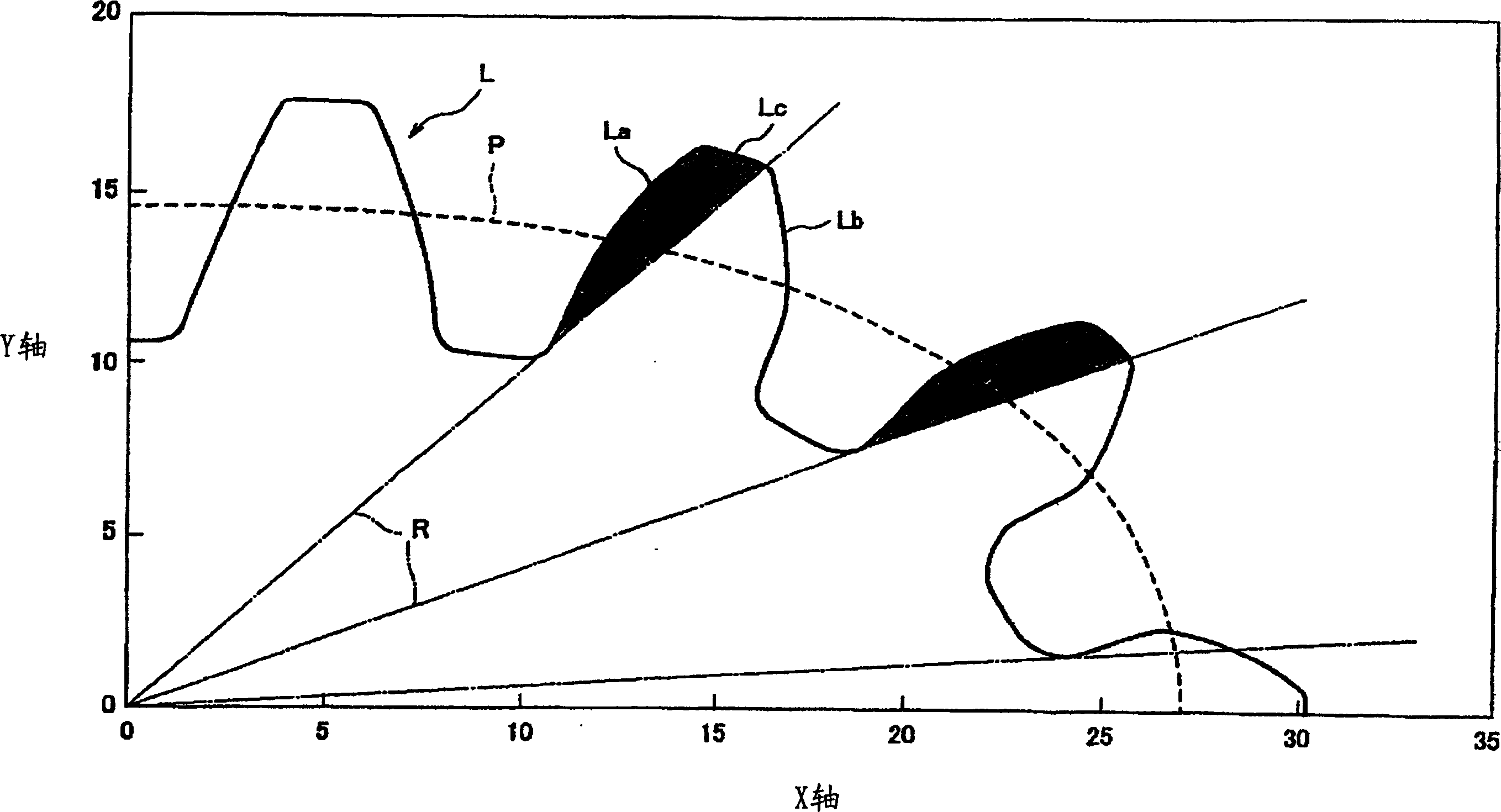

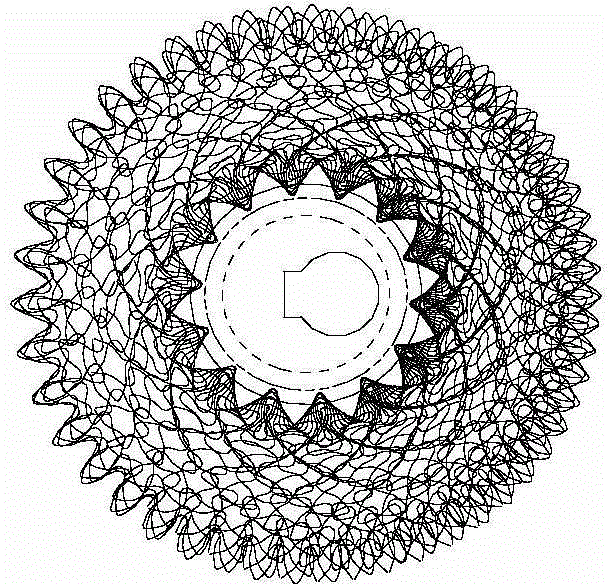

Method for designing non-circular gear planetary system through Fourier function segment transmission ratios

ActiveCN103939531AAvoid blindnessSave the program modulation processToothed gearingsTransplantingEffective equationEngineering

The invention discloses a method for designing a non-circular gear planetary system through Fourier function segment transmission ratios. The method includes the steps that according to the structural symmetry characteristic of a planetary gear system of a rotary type transplanting mechanism, a transmission ratio between non-circular gears is segmented at the 180-degree position, and the relation among the segment transmission ratios of the planetary gear system is constructed; under the condition of meeting the total transmission ratio of the gear system, in order to solve the problem that effective equations for solving the segment transmission ratios are not enough, the Fourier hypothesis of the non-circular gear segment transmission ratios is provided, and other transmission ratios are distributed successfully; through mirror image, weighting, iterating and fitting processing performed on the segment transmission ratios, an ideal transmission ratio is obtained finally, and therefore a non-circular gear pitch curve is obtained. The method is simple in process, small in calculation amount and high in efficiency, and the designed non-circular gear transplanting mechanism is highly targeted.

Owner:ZHEJIANG SCI-TECH UNIV

Transmission device capable of converting rotational motion into reciprocating variable rectilinear motion

The invention relates to a transmission device, in particular to a transmission device capable of converting rotational motion into reciprocating variable rectilinear motion. The transmission device comprises a rack, a sun gear, a planetary gear, a guide rod, a non-circular gear A and a non-circular gear B; the sun gear is fixedly installed on the rack through an installing base, and the planetary gear is arranged in the sun gear and is movably connected with the guide rod. In the working process of the transmission device, under the condition of being meshed with the sun gear, the planetary gear can revolve on own axis as well as revolve around the sun gear under the action of a planet carrier, and the problems that an existing guide rod needs to do reciprocal rectilinear motion, a rotor cannot rotate continuously in one direction, an existing crank cannot rotate at the fixed angle, and complex rectilinear motion with specific requirements is difficult to realize accurately are solved. The transmission device achieves variable continuous operation and accurate and complex rectilinear motion and has broad application prospects.

Owner:YANGTZE UNIVERSITY

Non-circular gear epicyclic train shell-rotating hydraulic motor

This invention discloses a non-round gear planetary wheel system shell rotary hydraulic motor, which contains oil intake, oil outlet, front unit, rear unit, core wheel, cycle wheel, planetary wheel and core shaft featuring the core shaft is fixed and the shell is rotated, flow distributed hole is holed in core shaft and its number is two times of the number of cycle of core wheel, the cycle wheel and core wheel forming unique section curve. Said invention has simple making process, large torsion, stable driving, low noise and fine sealability.

Owner:徐州非圆机械科技有限公司

Gear shaping processing method of noncircular gear

ActiveCN104816045AImprove processing efficiencyImprove machining accuracyGear teethNumerical controlEngineering

The invention discloses a gear shaping processing method of a noncircular gear. According to parameters (node curve, modulus and center distance) and processing parameters of the noncircular gear, the movement locus of each shaft of a noncircular gear numerical control gear shaping machine is calculated through comprehensive considering the cutting output, the tool retraction and the positioning reference to generate processing codes; the noncircular gear can be processed on a common numerical control gear shaping machine; and the processing method has such characteristics of high processing efficiency, good processing precision and low comprehensive cost.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com