High-order denatured elliptic bevel gear pair with variable transmission ratio

A technology of denatured elliptical and bevel gear pairs, which can be applied to transmission devices, gear transmission devices, belts/chains/gears, etc. It can solve the problems of difficult processing, complex design, small average transmission ratio of non-conical gear pairs, etc., to achieve rich and diverse Sex, improve the effect of transmission ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

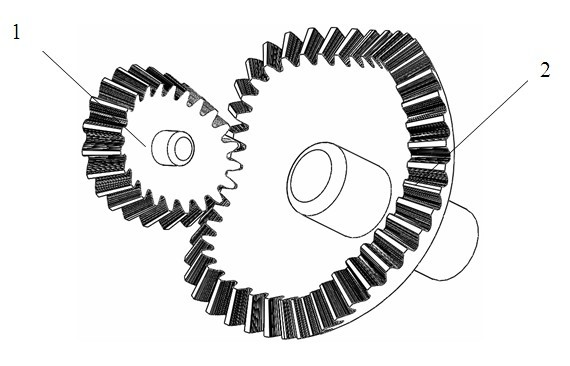

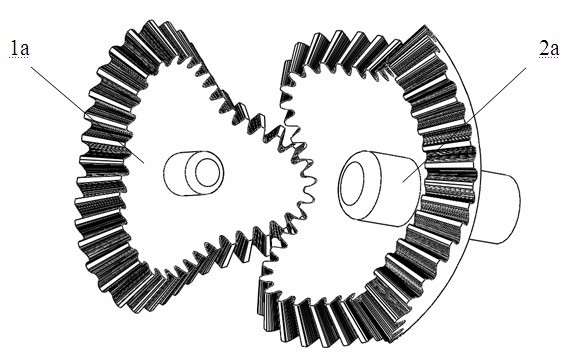

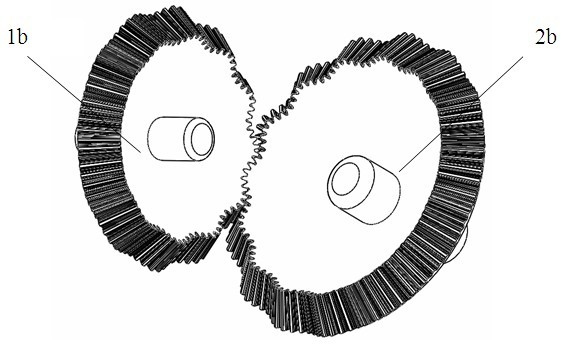

[0036] figure 1 Is a schematic diagram of a 2nd to 4th meshing pair of a high-order modified elliptical bevel gear with a variable transmission ratio, figure 2 Is a schematic diagram of a 3rd to 4th meshing pair of a high-order modified elliptical bevel gear with variable transmission ratio, image 3 The schematic diagram of the 12-step to 15-step meshing pair of the variable transmission ratio high-order modified elliptical bevel gear is shown in the figure: the variable transmission ratio high-order modified elliptic bevel gear pair of this embodiment includes an active elliptical bevel gear and a driven ellipse that mesh with each other Bevel gears, the driving elliptic bevel gear is a high-order elliptic bevel gear, and the driven elliptic bevel gear is a high-order elliptic bevel gear meshing with the driving elliptic bevel gear and having different orders; the sub-cone equation of the driving elliptic bevel gear is:

[0037]

[0038] The achieved transmission ratio is:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com