Screwdriver

A screwdriver and gear technology, applied in the field of screwdrivers, can solve the problems of unsatisfactory structural reliability of the ratchet, inability to twist, spinning in situ, and decreased efficiency of screwing, etc., so as to achieve a reasonable and compact overall structure design, save time, and increase the number of new additions. The effect of the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

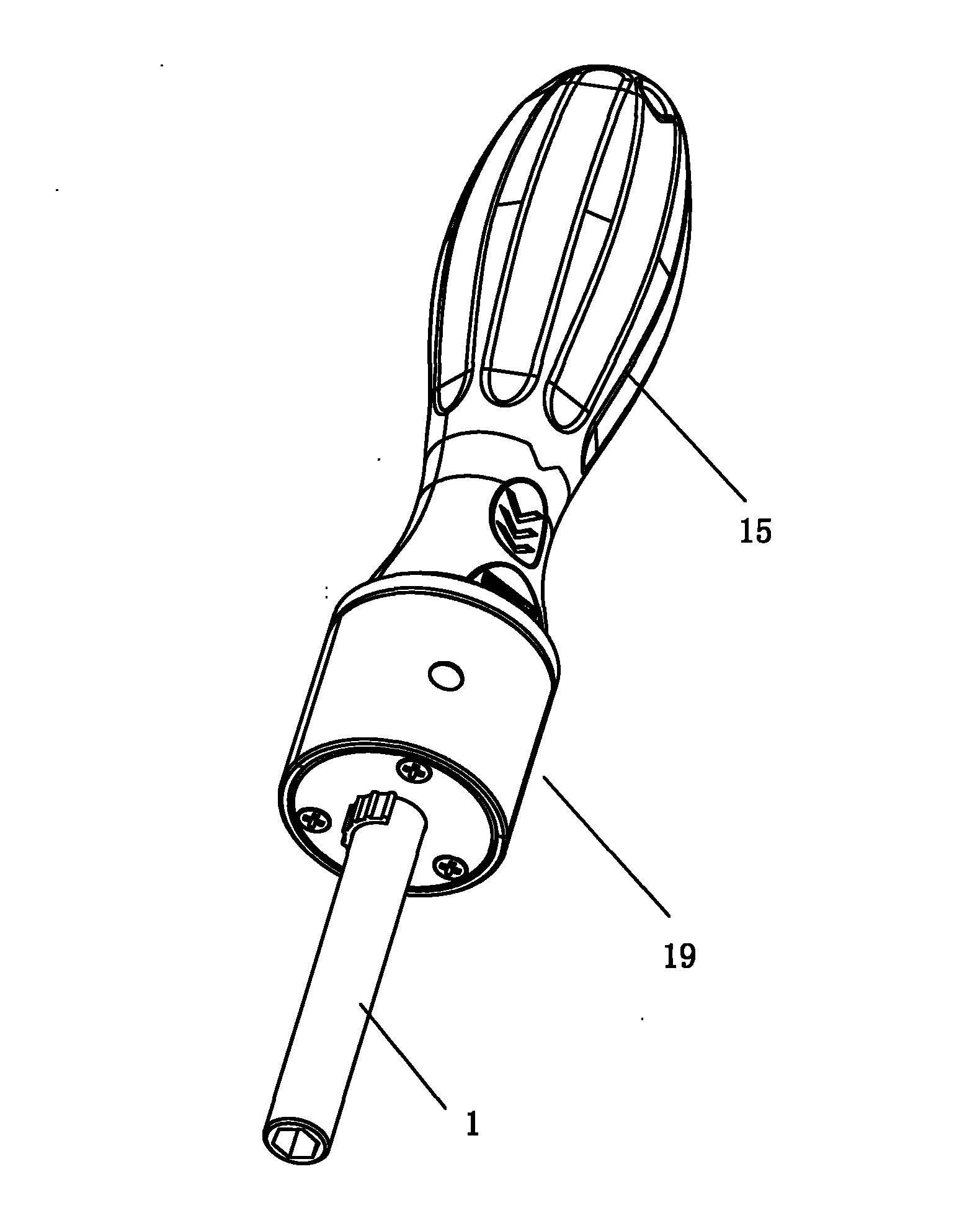

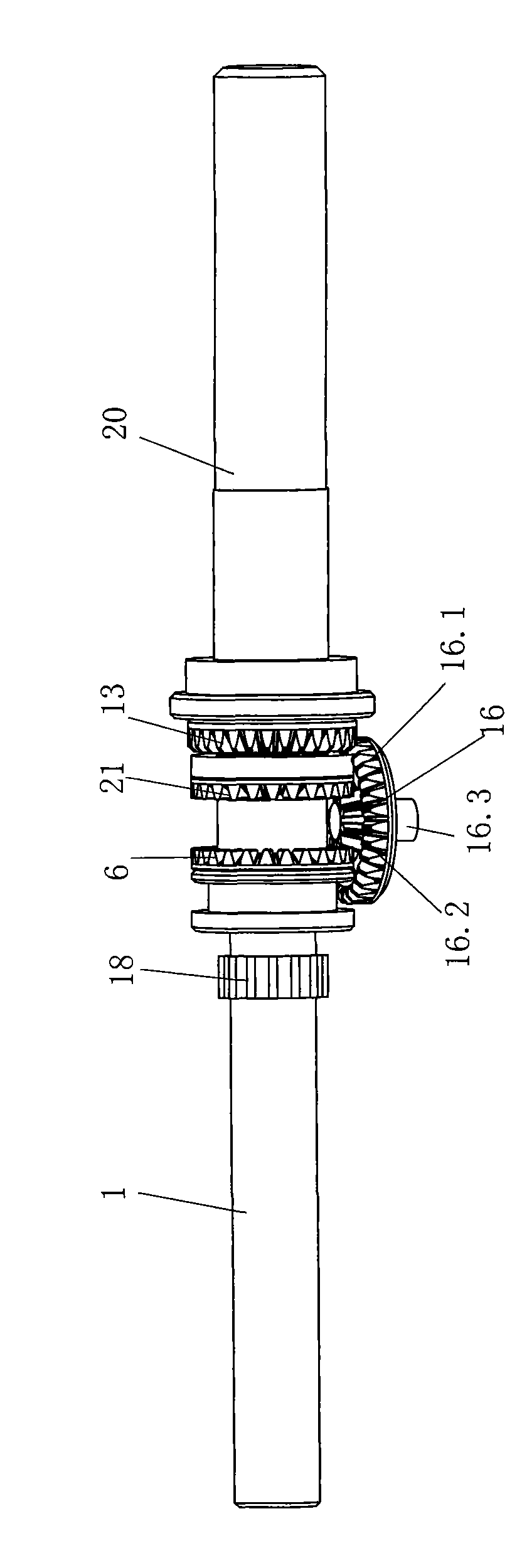

[0031] As shown in the figure, a screwdriver includes: a handle 15, which is usually made of plastic, and is a part for manual operation to provide a source of power; a gear device 19 is arranged at the front end of the handle 15 to realize rotation. The positive and negative rotation of the tool head 1 usually allows the screwdriver head 1 of the locking screw to rotate clockwise or counterclockwise, and the efficiency of locking the screw can be improved through the function of idling, without the need to turn the power driver (hand) back one by one Original position; screwdriver head 1, one end is connected with gear unit 19, and the other end is detachably inserted with screwdriver head, is convenient to insert the screwdriver head of various specifications; The key point of its invention is that gear unit 19 is A gear device with new func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com