Five-axis linkage horizontal type helical tooth non-circular gear hobbing machine tool

A non-circular gear, five-axis linkage technology, used in gear tooth manufacturing devices, metal processing machinery parts, gear cutting machines, etc. higher question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] See attached figure 1 , is a structural schematic diagram of a five-axis linkage horizontal helical non-circular gear hobbing machine tool. The five-axis linkage horizontal helical non-circular gear hobbing machine tool includes a base 1, a column 2 (the first support structure), Hob device 3, working device 4, turntable 5 and lifting platform 6 (second support structure), the column 2 is provided with a hob device 3 for processing the non-circular blank 44 into helical non-circular gear , one end of the hob device 3 is fixedly installed on the top of the column 2, and the other end of the hob device 3 protrudes toward the working device 4. The lifting table 6 is provided with a turntable 5 , and the turntable 5 is provided with a working device 4 , and the non-scalloped blank 44 is arranged on the working device 4 .

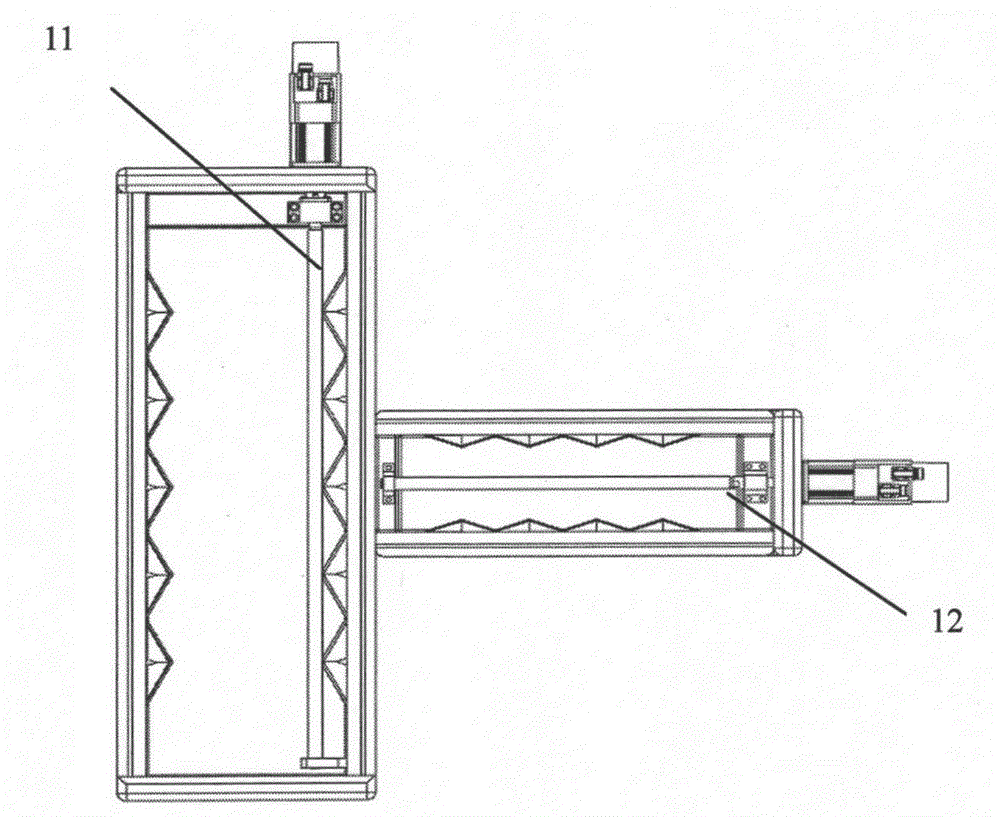

[0034] See attached figure 2 , the base 1 includes a horizontal X-direction track 11 and a horizontal Z-direction track 12, the horizontal Z-direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com