Revolving internal-combustion engine

An internal combustion engine, rotary technology, applied to rotary piston engines, internal combustion piston engines, rotary or swinging piston engines, etc., can solve the problems of power consumption, increased dynamic load, bearing wear, and large fuel consumption, etc., and achieve simplification The effects of manufacturing procedures, saving manufacturing costs, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

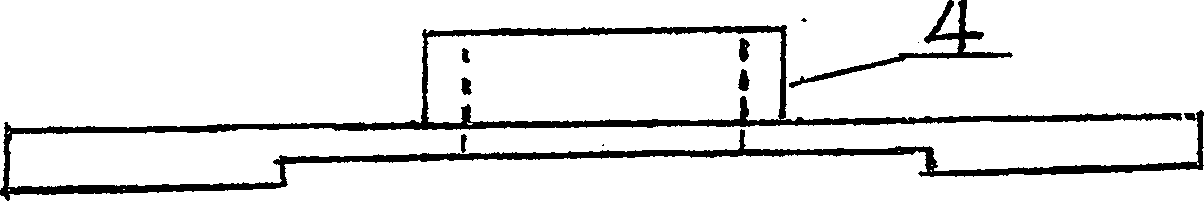

[0029] This structure is to be semicircular annular cylinder body 2,12 by two identical sections (as Figure 6 shown) to form a circular cylinder with a circular cross-section, which contains two identical rotors 4, 5, such as figure 2 As shown; the two sides of the rotors 4, 5 and the corresponding parts of the cylinder body are provided with sealing ring grooves 28, and sealing rings (not shown in the figure) are installed in the grooves; there are also four identical pistons 3 fixed on the two rotors respectively. On both ends of 4 and 5, the hole 24 on the piston is installed on the rotor end, the piston pin hole 23 on the piston is concentric with the piston pin hole 22 on the rotor end, and is fixed with the same piston pin or bolt as on the reciprocating internal combustion engine , the four pistons are installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com