Tool for assembling driving motor and speed reducer

A technology for driving motors and reducers, which can be used in metal processing, manufacturing tools, workpiece clamping devices, etc., and can solve the problem of damage to the positioning accuracy of the drive motor and reducer, extrusion deformation, spline mating noise, etc. problems, to achieve the effect of convenient assembly operation, avoiding radial force, and ensuring meshing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

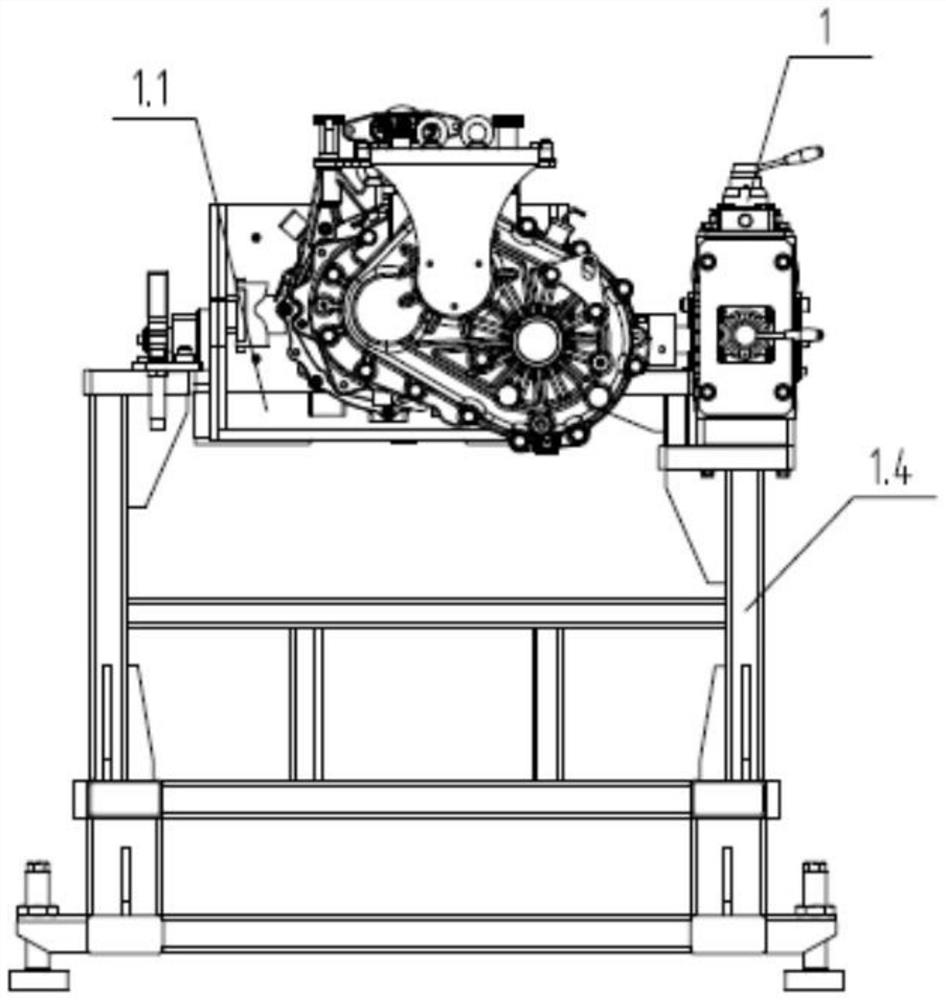

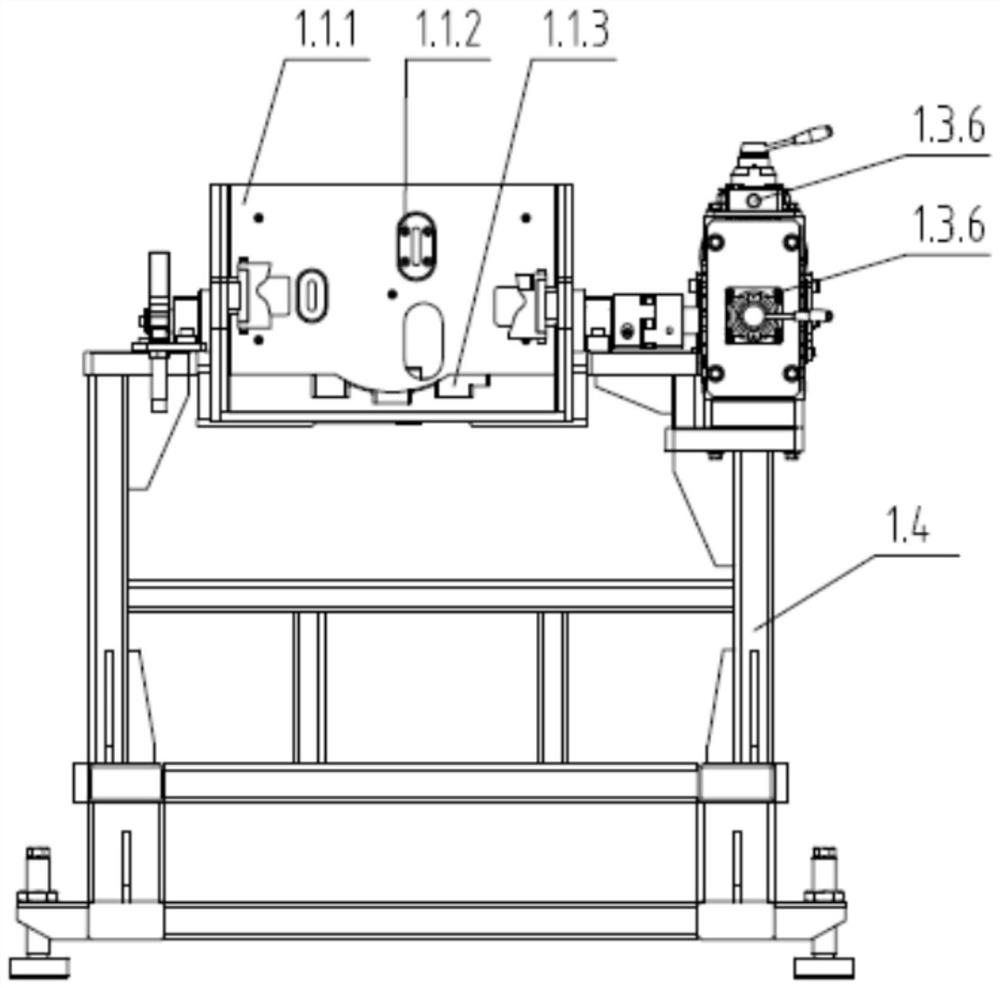

[0033] Embodiment: This application provides a drive motor and reducer combined tooling, combined with reference Figure 1 to Figure 9 , The drive motor and reducer assembly tooling includes: drive motor overturn trolley 1, drive motor assembly positioning plate 3, reducer spreader 4, spline shaft hook wrench 6.

[0034] The drive motor overturn trolley 1 realizes the overturn of the drive motor 2 in the horizontal or vertical direction of the spline shaft. The drive motor overturn trolley 1 is equipped with a drive motor positioning mechanism, a pneumatic clamping mechanism, a pneumatic overturn mechanism, and a supporting steel frame structure; the drive motor positioning The mechanism is used to locate and install the drive motor 2, the pneumatic clamping mechanism is used to clamp the drive motor 2, the pneumatic turning mechanism is used to realize the turning and positioning of the drive motor 2 during the assembly process, and the supporting steel frame structure is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com