Gear and rack transmission anti-backlash mechanism

A technology of rack and pinion, which is applied in the direction of transmission parts, belt/chain/gear, mechanical equipment, etc., can solve the problems of backlash and other problems, and achieve the effect of large transmission torque, reliable operation and clearance elimination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

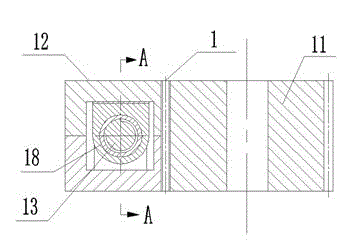

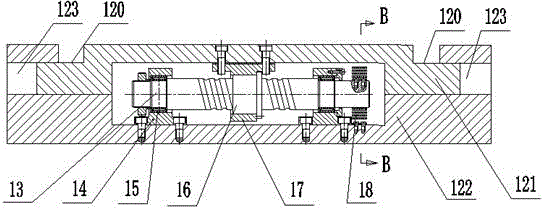

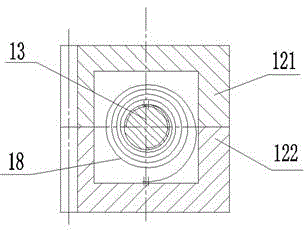

[0016] Such as Figure 1 to Figure 3 As shown, the rack and pinion transmission anti-backlash mechanism 1 of the present invention includes a gear 11, a rack 12, a screw shaft 13, a bearing support 14, a needle bearing 15, a nut 16, a nut support 17 and a plane scroll spring 18.

[0017] The rack 12 is composed of two racks superimposed on the first rack 121 and the second rack 122, and meshes with the gear 11; the thickness of the first rack 121 and the second rack 122 are equal, and the first rack 121 and the second rack The sum of the thicknesses of the two racks 122 is equal to the width of the gear 11;

[0018] The two ends of the first rack 121 are symmetrically provided with guide rods 120, and the guide rods 120 are symmetrical about the axial ends of the screw shaft 13; The two sides protrude to both sides respectively;

[0019] Both ends of the second rack 122 are provided with guide holes 123 along the direction of the guide rod 120 of the first rack 121, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com