Liquid level variable and gear variable combination high-precision measurement method and device

A technology for measuring and measuring and measuring devices, which is applied to measuring devices, liquid/fluid solids measurement, and optical devices, etc., and can solve the problems of large cumulative error, unmatched products, and inability to collect accurately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

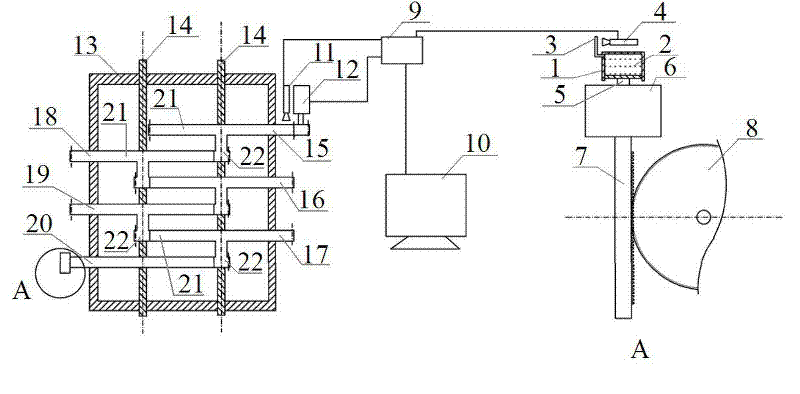

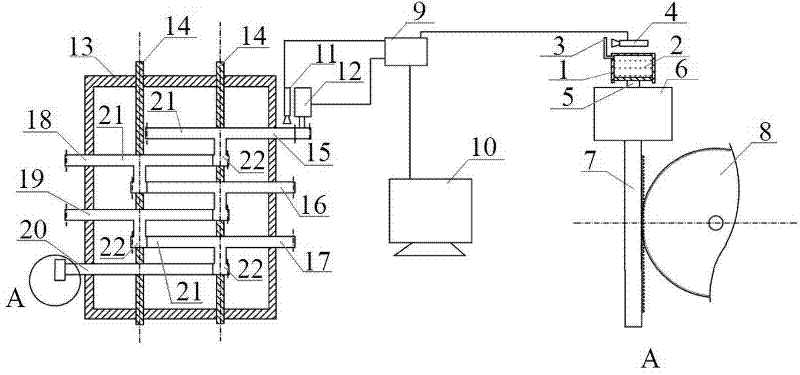

[0060] Referring to the accompanying drawings, the liquid level variable and gear variable combination high-precision measurement method of the present invention is:

[0061] 1) Place the measured object between the hydraulic container or oil cylinder liquid level variable precision measuring device and the gear variable combiner, make sure that the hydraulic container or oil cylinder liquid level variable precise measurement measuring device is closely matched with the measured object without gap, and When the gear variable combiner is pushed by external force, determine the true zero position or displacement under the conditions of eliminating the gap, overcoming the mass of the object, and frictional resistance; or accurately measure the liquid level variable of the hydraulic container or cylinder with the output of the servo motor output or the push device The ends are closely matched to determine the real zero point or displacement of the output end after overcoming the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com