Double-piston type pneumatic conveyer

A pneumatic conveying and double-piston technology, which is applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of smaller spraying distance, short conveying distance, and large conveying dust, so as to shorten the contact distance and reduce dust production , the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

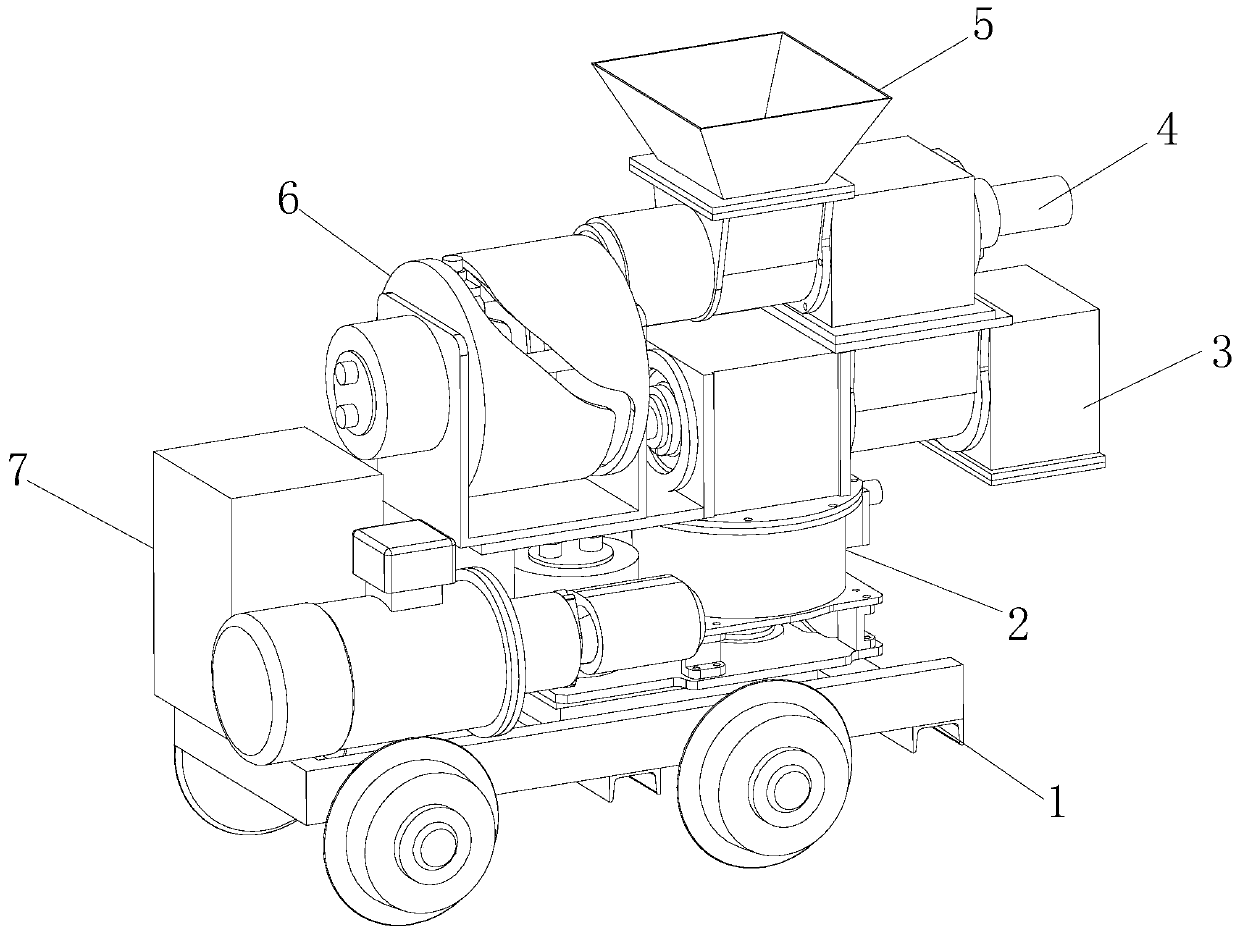

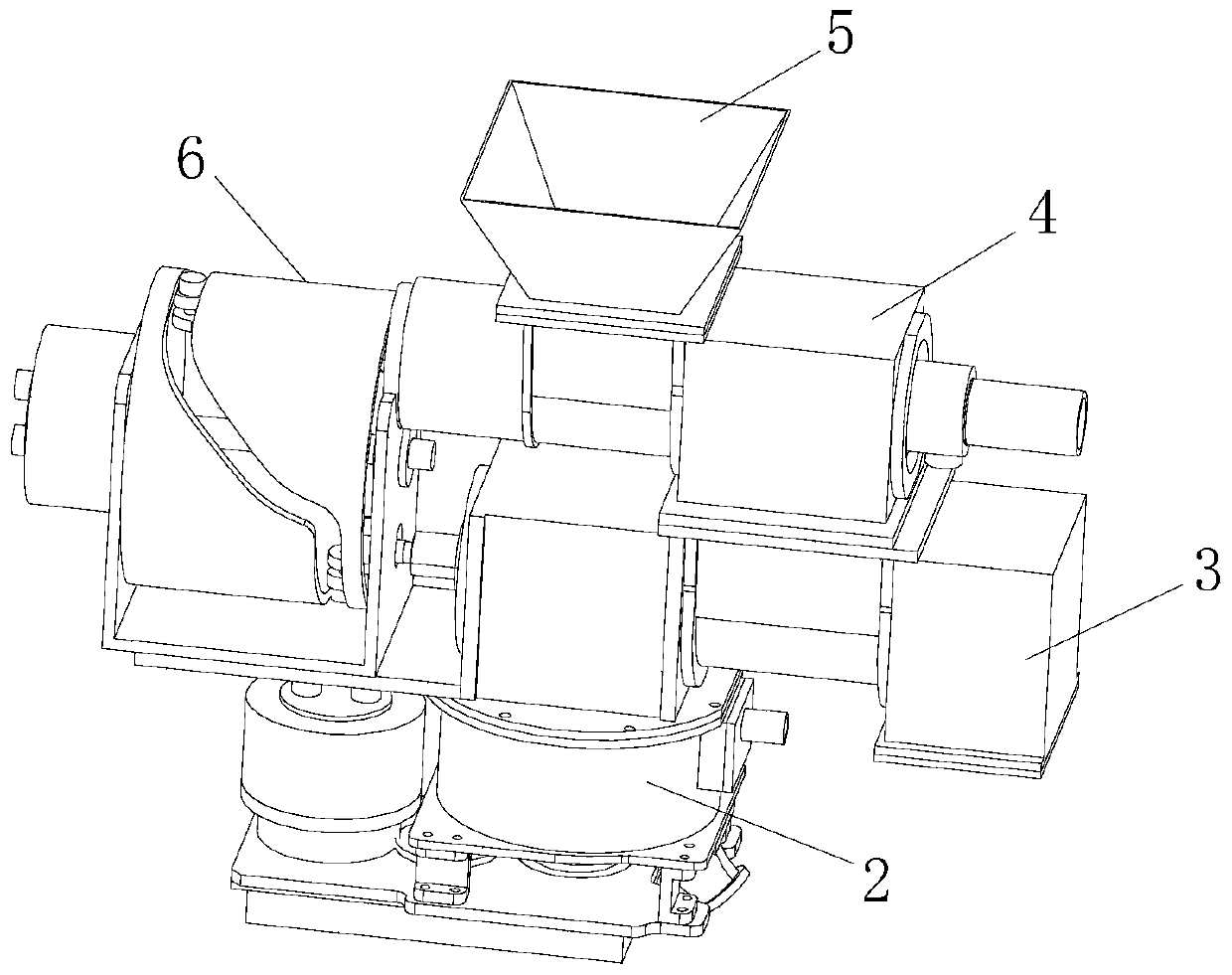

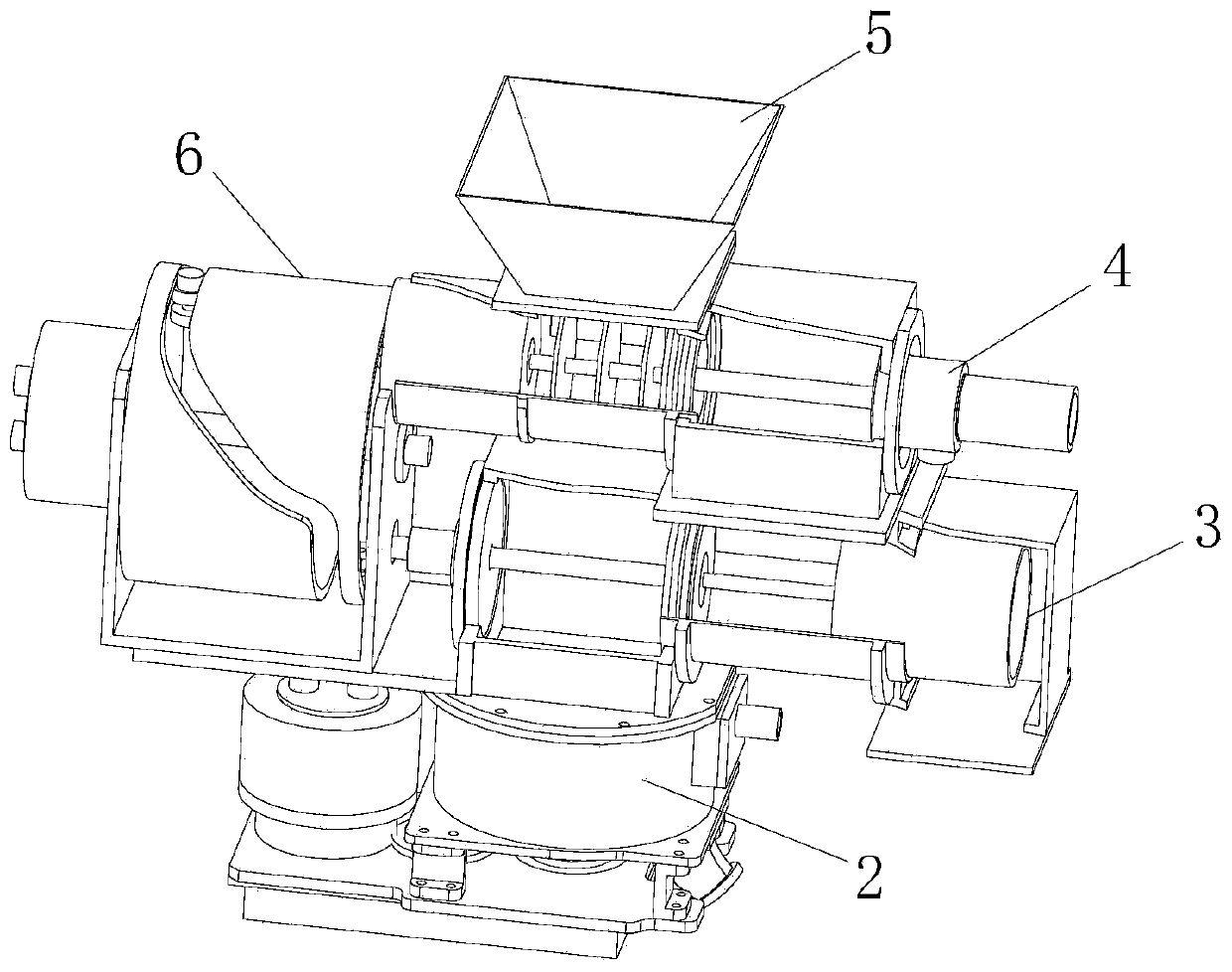

[0038] Such as Figure 1 to Figure 15 As shown, the specific implementation of a double-piston pneumatic conveyor provided by the present invention is as follows.

[0039] A double-piston pneumatic conveyor includes a frame 1, a rotor mechanism 2, an upper cylinder mechanism 4, a lower cylinder mechanism 3, a piston driving mechanism 6 and a hydraulic mechanism 7. The frame 1 is used to carry the structure of the pneumatic conveyor and assist the pneumatic conveyor in walking. The upper and lower cylinder mechanisms arranged in parallel are used to control the material supply to the rotor mechanism 2, especially the sealing design of the upper and lower cylinder mechanisms during the working process, to achieve It ensures good sealing and improves the service life of the equipment; the rotor mechanism 2 is used to evenly distribute materials and realize the continuous delivery of concrete, reducing pulses, and the hydraulic mechanism 7 provides power for each working part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com