Locking device for torque tool handle collet

A locking device and tool shank technology, applied in tool holder accessories, turning equipment, metal processing equipment, etc., can solve the problems of easy locking of worm gears, time-consuming and labor-intensive, etc., achieve tight assembly structure, solve easy locking, Good dynamic balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solution of the present invention is further illustrated below through specific examples.

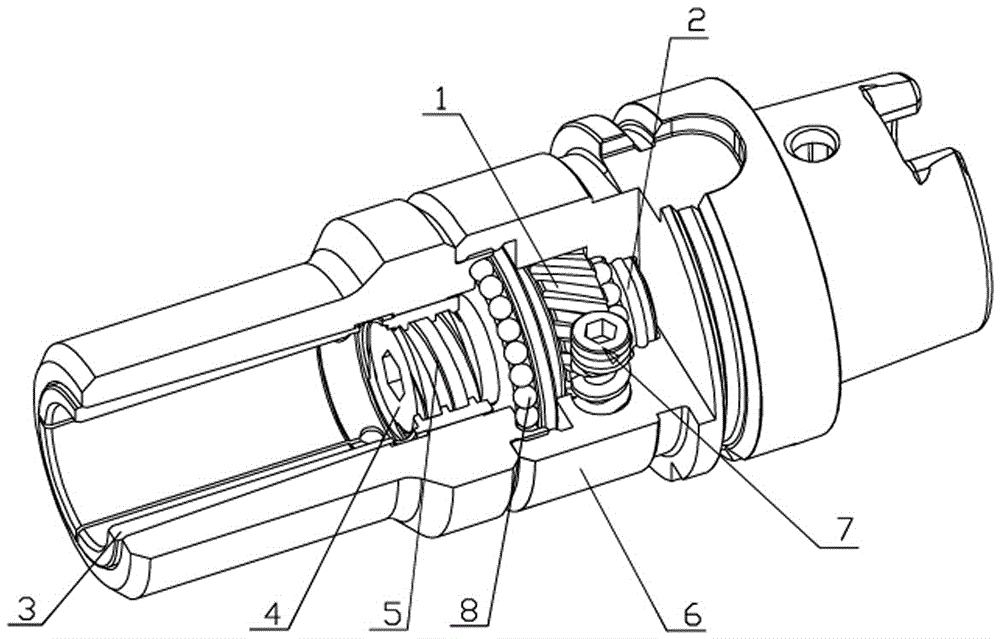

[0011] Such as figure 1 Shown: a torque tool handle collet locking device, including a tool handle body 6, a collet 3 and a worm gear mechanism, the tool handle body 6 is provided with a central shaft hole, and the collet 3 is co-located in the central shaft hole In the conical cavity at the front end, the worm gear 1 in the worm gear mechanism is arranged in the middle of the central axis hole, and is coaxially installed with the handle body 6, and an extension assembly 4 is threaded between the worm gear 1 and the collet 3; The extension assembly 4 is a pipe body, the outer wall of the pipe body is provided with thread 5, the cross section of the outer wall thread 5 of the front end of the pipe body is a rectangular thread or trapezoidal thread, and is threadedly connected with the guide inner circular wall of the collet 3, the rear end of the pipe body The cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com