Special crankshaft multi-bend reversing machine

A special machine and crankshaft technology, which is applied in the field of crankshaft torsion equipment, can solve the problems that affect the twisting quality and twisting processing effect, the assembly parts are huge, and the distance between the conveying device and the operating table is increased, so as to meet the requirements of industrial process batch production and serialized crankshaft product processing requirements, the reduction of equipment footprint and floor space, and the effect of reducing the workpiece conveying distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

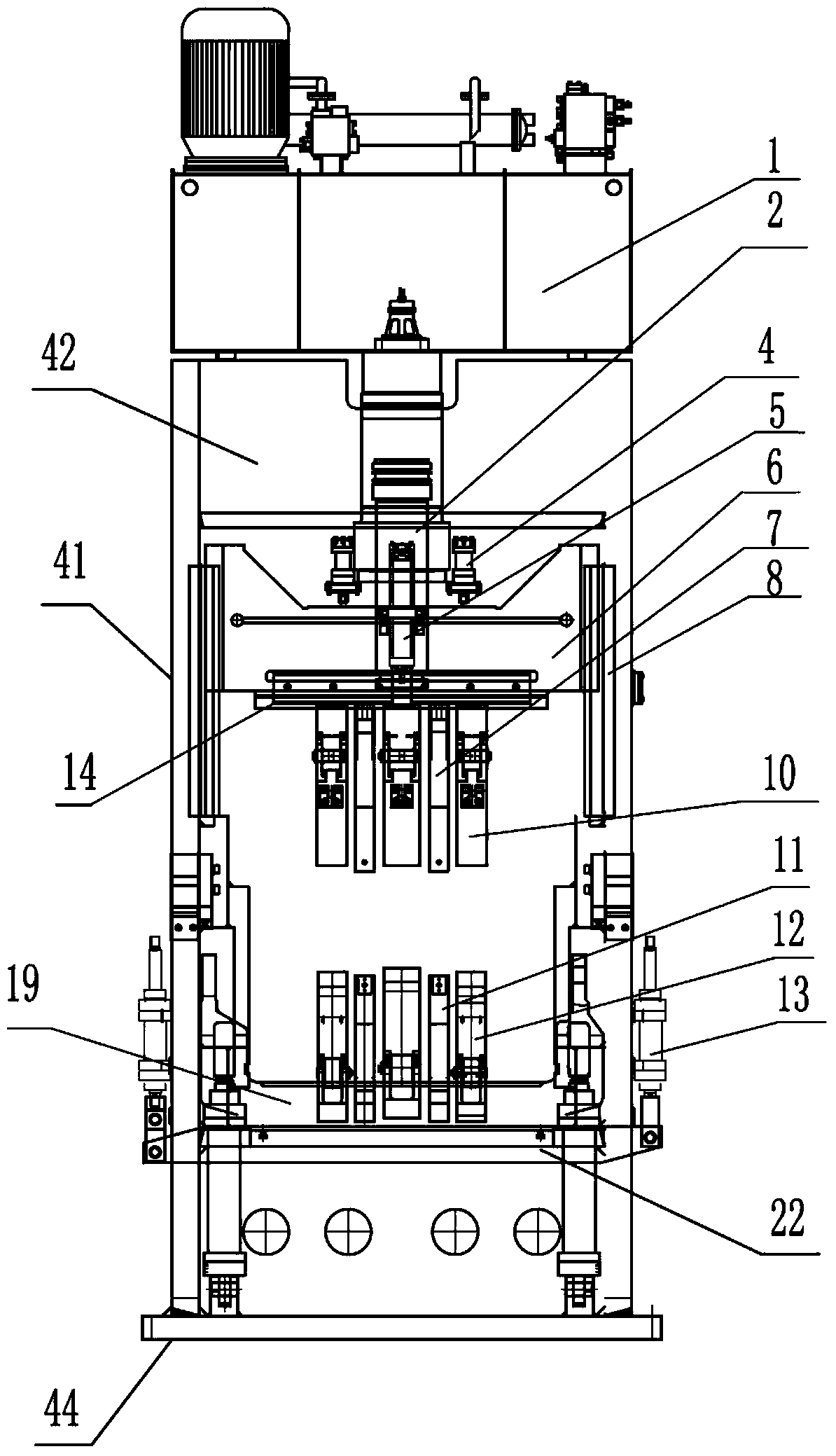

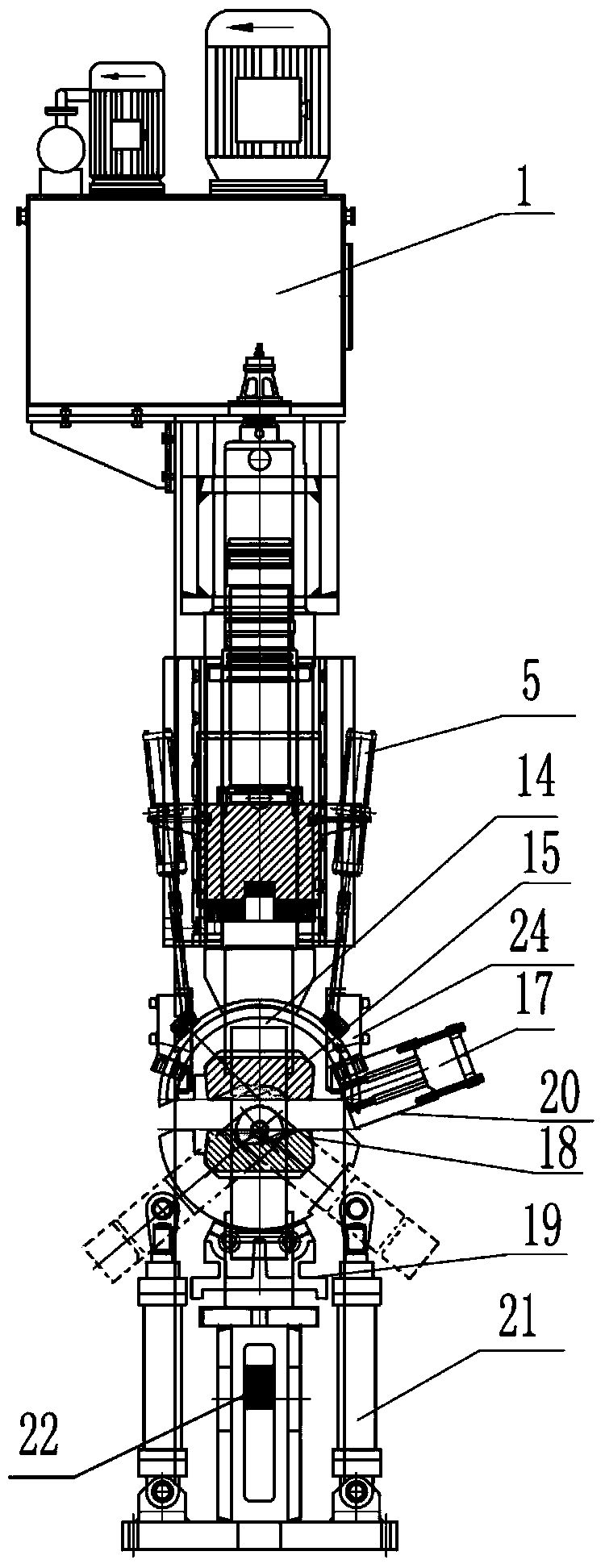

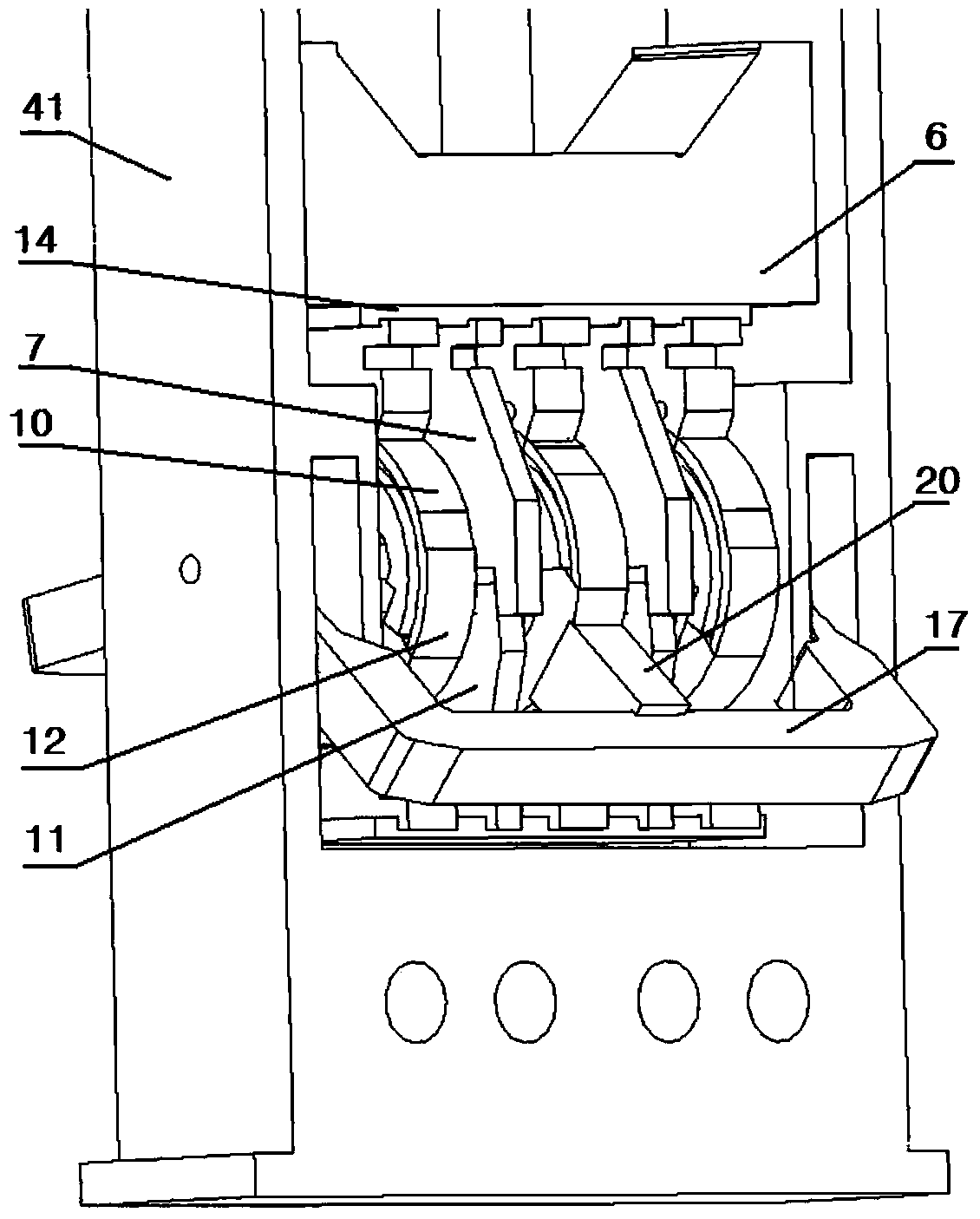

[0014] The crankshaft multi-turn twist special machine provided by the patent application of the present invention is a single rectangular body stand assembly structure, and its body stand is composed of two side columns 41, an upper assembly beam 42 and a bottom frame 44. In this implementation structure, the The vertical frame of the hydraulic machine is made of integral casting, which has more excellent structural stability and rigidity. The hydraulic machine 1 is fixedly installed on the upper assembly beam 42 of the machine body vertical frame. The main hydraulic cylinder 2 in the hydraulic machine 1 drives the slide block 6, and the slide block 6 is assembled with an upper mold part, and the two sides of the slider 6 are slidably matched with the longitudinal slide rail 8 of the column 41. The lower mold part is installed on the lower bracket 19, and the upper and lower mold parts are assembled with upper and lower corresponding upper fixed mold frames 7 And lower fixed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com