A damper opening and closing angle changing mechanism of a hinge

A technology of angle change and damper, which is applied to hinges with pins, switches with braking devices, mechanical equipment, etc., can solve the problems of unsatisfactory use requirements, inability to achieve uniformity, high friction, etc., and improve the use of The effect of experience, wide range of use, and small collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

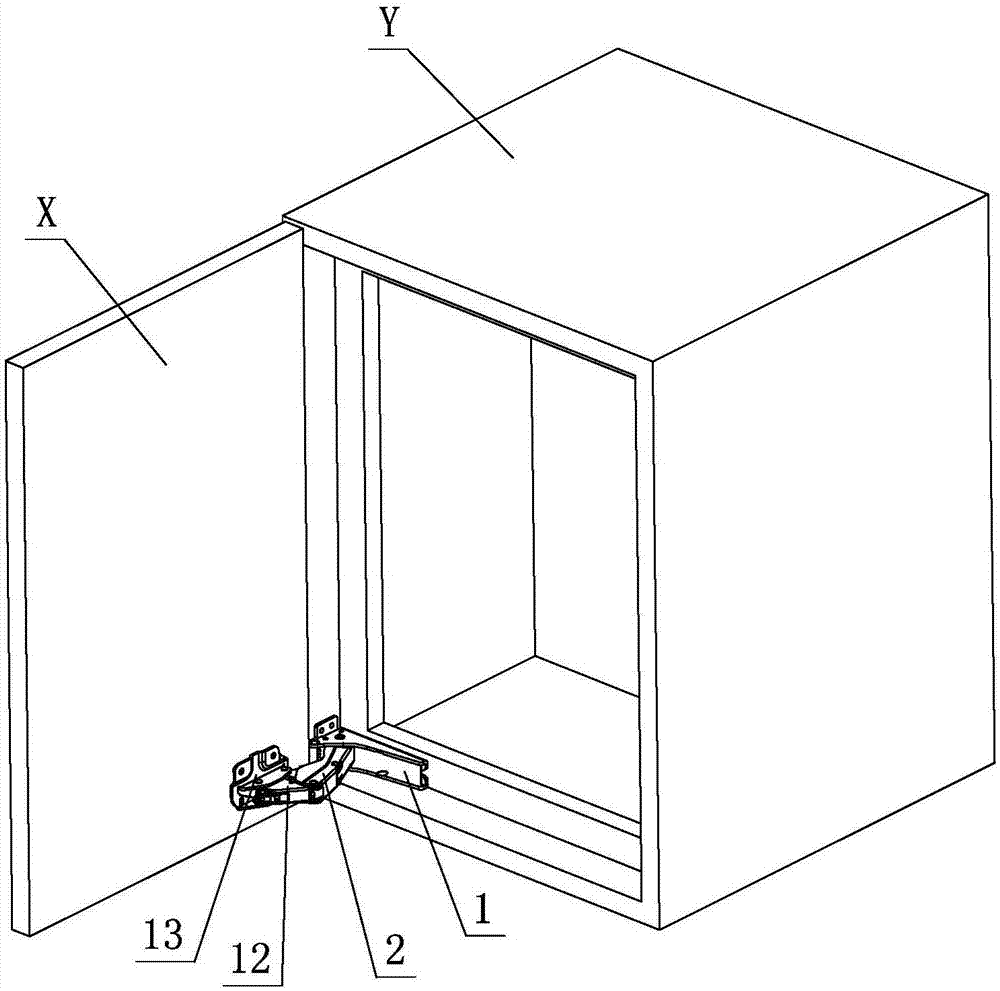

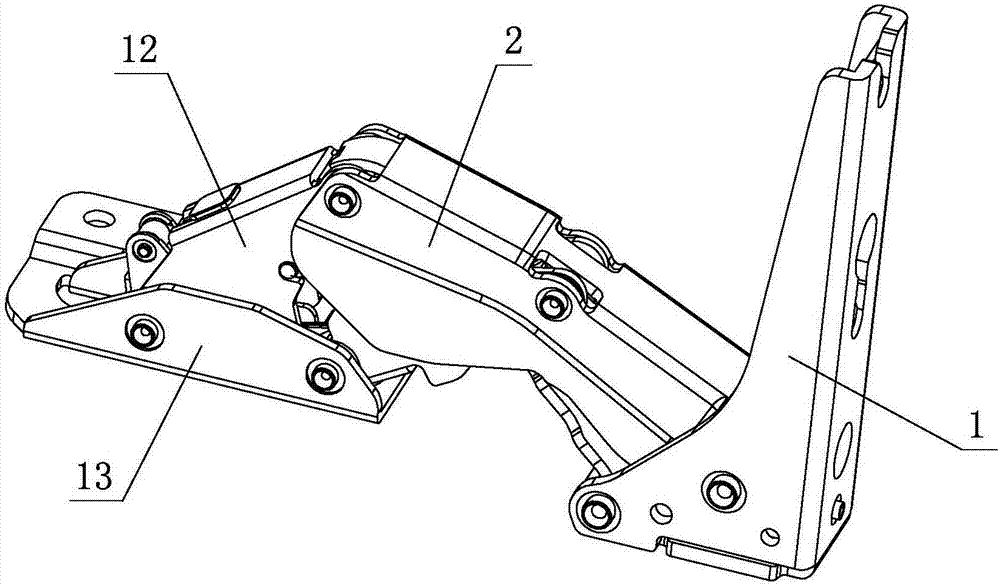

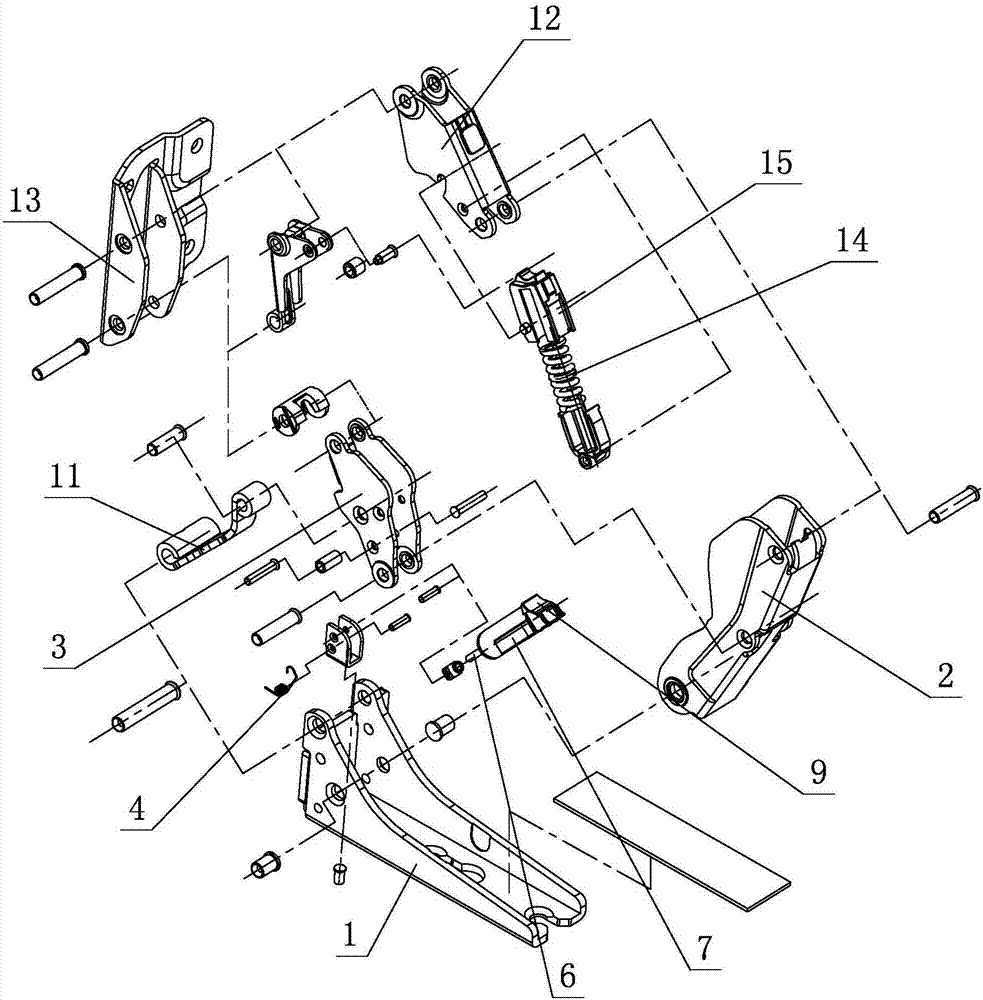

[0023] see Figure 1-Figure 7 The opening and closing angle change mechanism of the damper of this hinge includes a stop element 1, a connecting element 2 and a lever element 3 which are hingedly matched with each other, a damper is arranged between the stop element 1 and the connecting element 2, and one end of the damper is rotated to set On the blocking element 1, the other end rests on the connecting element 2, and the connecting element 2, the lever element 3 and the damper are interlocked with each other relative to the blocking element 1 when the hinge is opened and closed; at least when the hinge is closed at a certain angle, The lever element 3 acts on the damper and drives the damper to stop and slide on the connecting element 2, and the damper compresses and generates a damping force to realize damped closing of the hinge.

[0024] Furthermore, one end of the connecting element 2 is rotatably hinged on the blocking element 1, the other end is rotatably hinged on the...

no. 2 example

[0035] see Figure 8 , the damper opening and closing angle change mechanism of this hinge is different from the first embodiment in that: the connecting element 2 is provided with a sliding limiter 5, one end of the damper is rotated and set on the blocking element 1, and the other end is passed through The sliding limiting part 5 limits sliding and relies on the connecting element 2 .

[0036] Other unmentioned parts are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com