High-precision six-jaw duplex floating type self-centering clamping mechanism and clamping method

A self-centering clamping and floating technology, used in clamping, positioning devices, metal processing machinery parts, etc., can solve the problem of prolonging the labor time and labor intensity of processing workers, thin-walled parts easily deformed, and parts processing rigidity. It can overcome the problems of poor turning and other problems, and achieve the effect of overcoming the thermal deformation of turning, stable clamping and reduced processing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

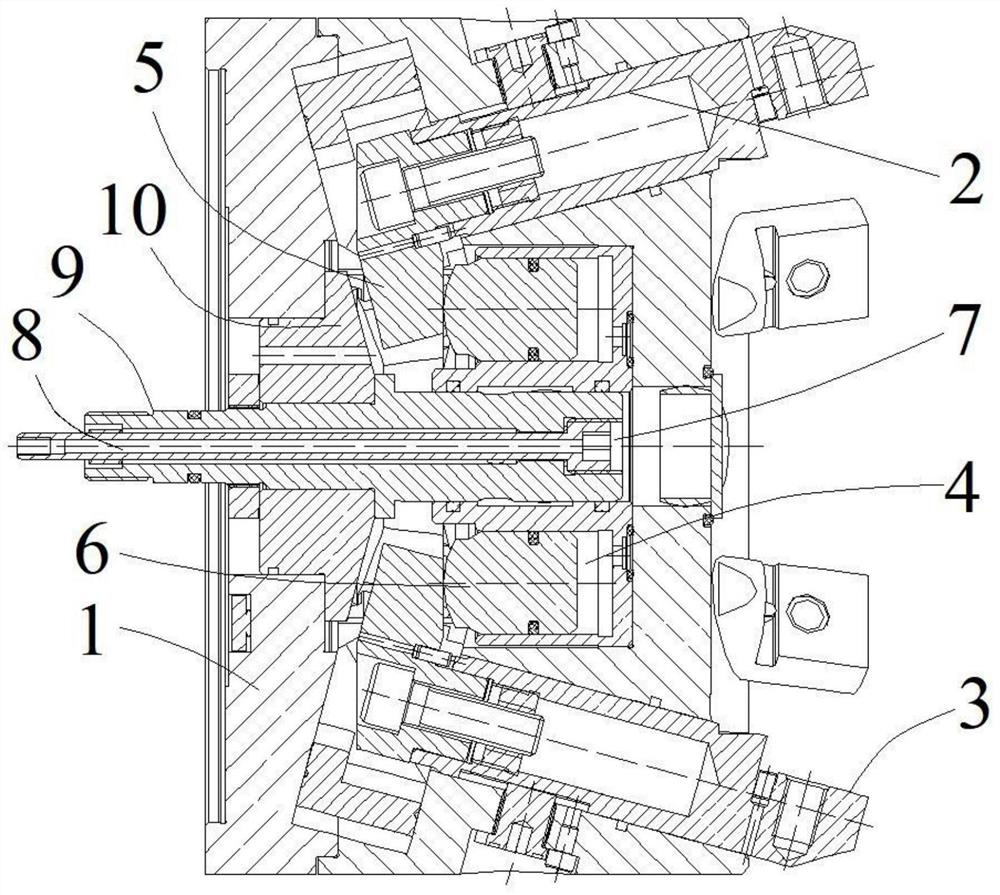

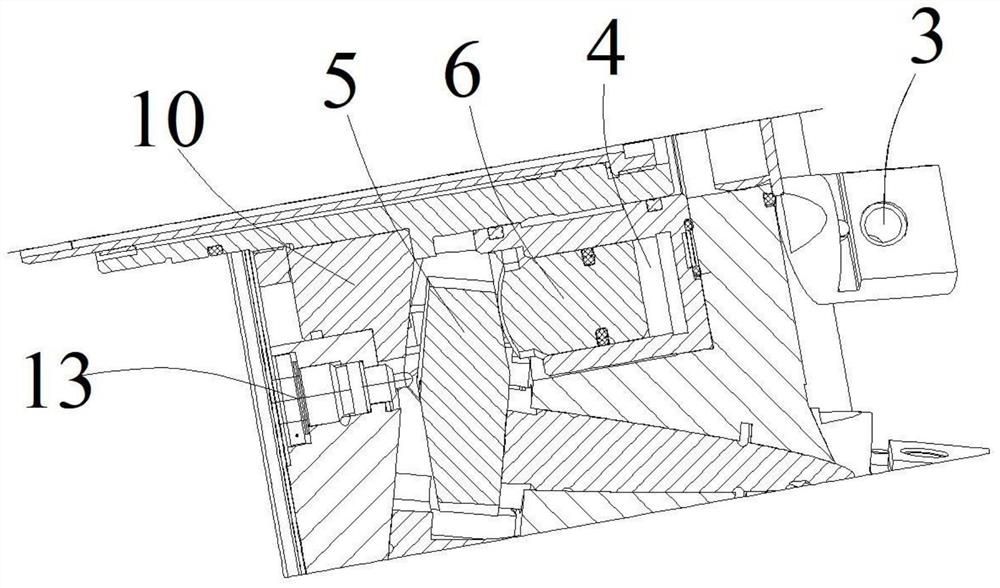

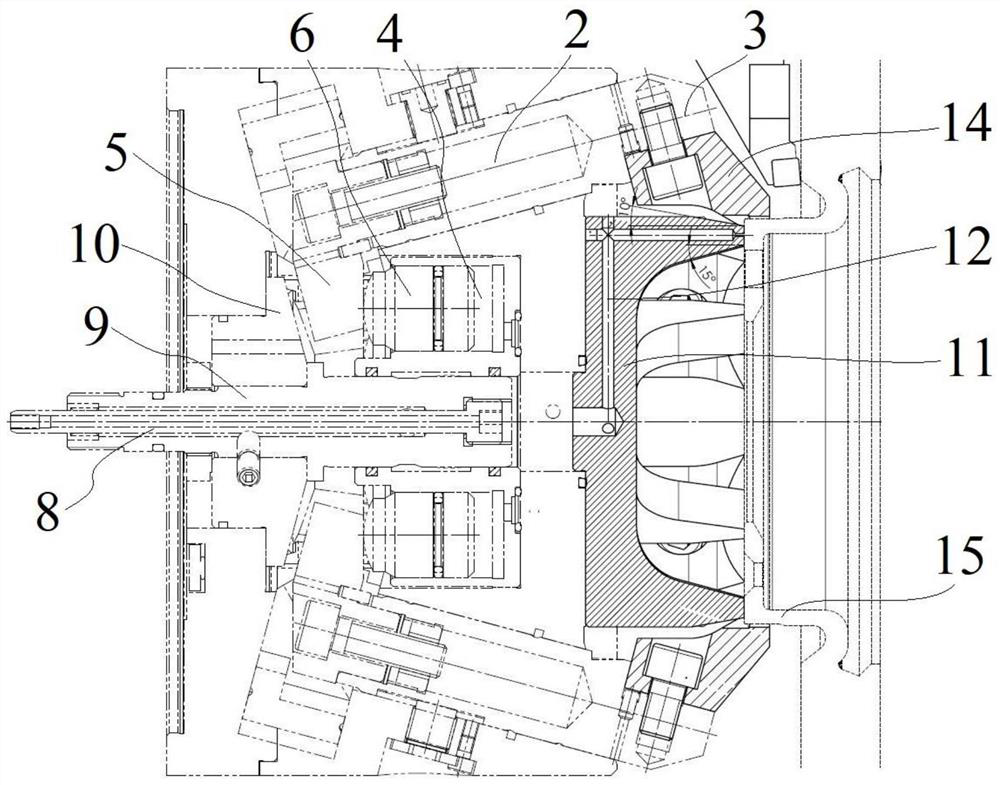

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] Such as Figure 1~4 As shown, the clamp of this embodiment includes a clamp body 1 on which two sets of jaws are arranged, each set of jaws includes three jaws, and each jaw includes a diagonal stay rod 2 pierced through the clamp body 1 . Such as Figure 1~3 As shown, the fixture body 1 of this embodiment is provided with installation grooves corresponding to the diagonal stay rods 2 one by one. The installation grooves are arranged obliquely. One end of the outer side of 1 is provided with a claw 3, and a clamping block 14 is installed on the claw 3, and the clamping block 14 is a block structure fixed on the claw 3 for enlarging the contact area with the workpiece.

[0034] One end of the oblique tie rod 2 of the present embodiment extending into the clamp body 1 is provided with a wedge 5, such as Figure 1~3 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com