Lifting appliance for perforated steel structure component

A technology for steel structures and components, applied in the field of spreaders, can solve the problems of loose hoisting fixtures, large volume, and unreasonable force on components, and achieve the effects of reasonable force, high safety performance, and good lifting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below through specific embodiments.

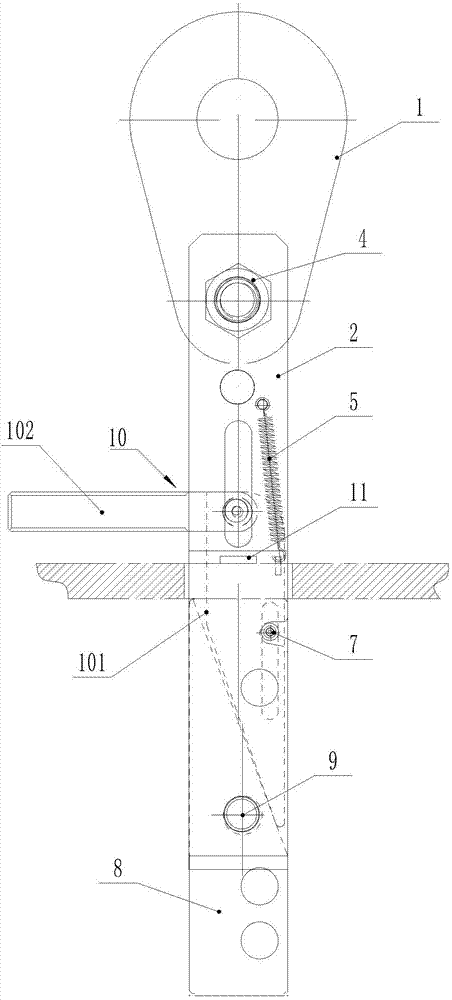

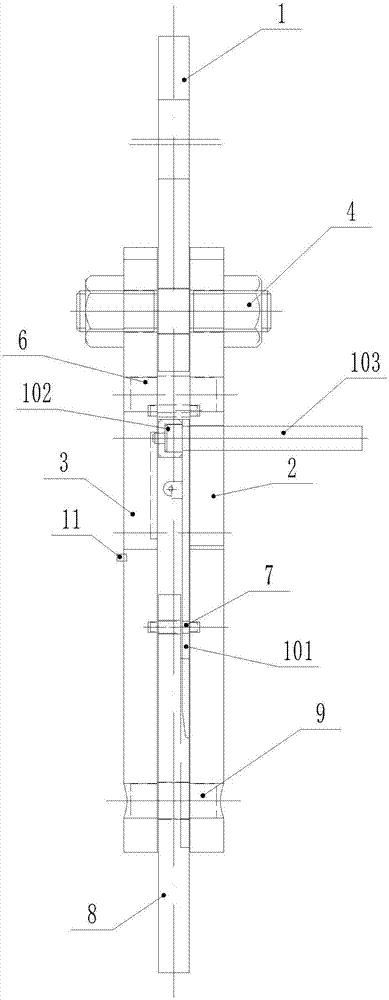

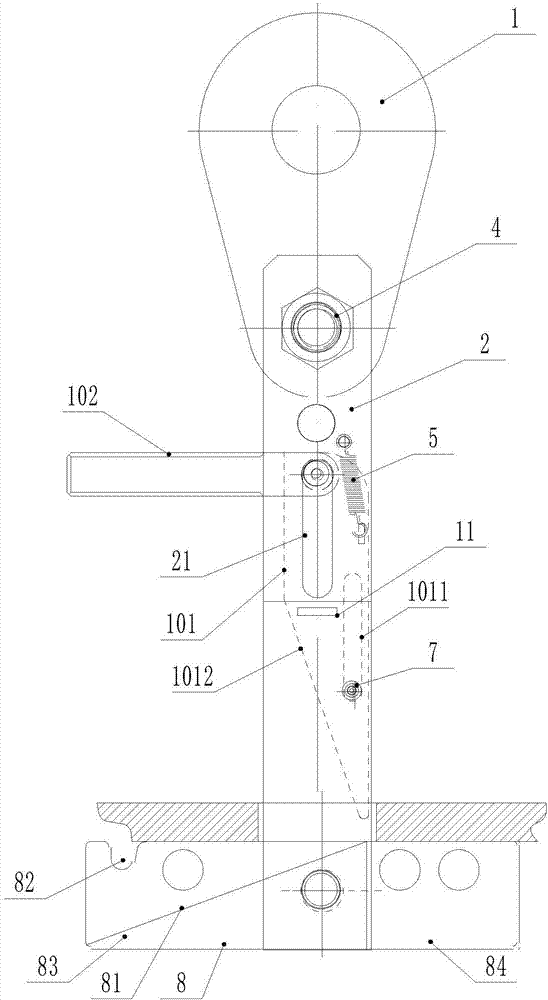

[0030] like Figure 1 to Figure 11 As shown, a hanger for steel structural members with holes includes a lifting lug 1, a first hanging plate 2, a second hanging plate, a movable tongue plate 8 and a pushing device 10, and the lifting lug 1 is fastened by bolts and nuts Part 4 is fixed on the upper ends of the first suspension plate 2 and the second suspension plate and is located between the first suspension plate 2 and the second suspension plate, and the first suspension plate 2 and the second suspension plate are fixed by connecting pins 6 .

[0031] The center of the bolt nut fastener 4 is located on the longitudinal symmetry line 22 of the first hanging plate 2 and the second hanging plate, and the middle part of the movable tongue plate 8 is installed on the first hanging plate 2 and the second hanging plate through the hinge shaft 9 to rotate. The lower section of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com