Elastic membrane-type low-frequency sound insulation metamaterial structure

An elastic film and metamaterial technology, applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of difficult to control cost, can not meet the requirements of low frequency, and space conditions are not allowed, and achieve the effect of simple design, easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

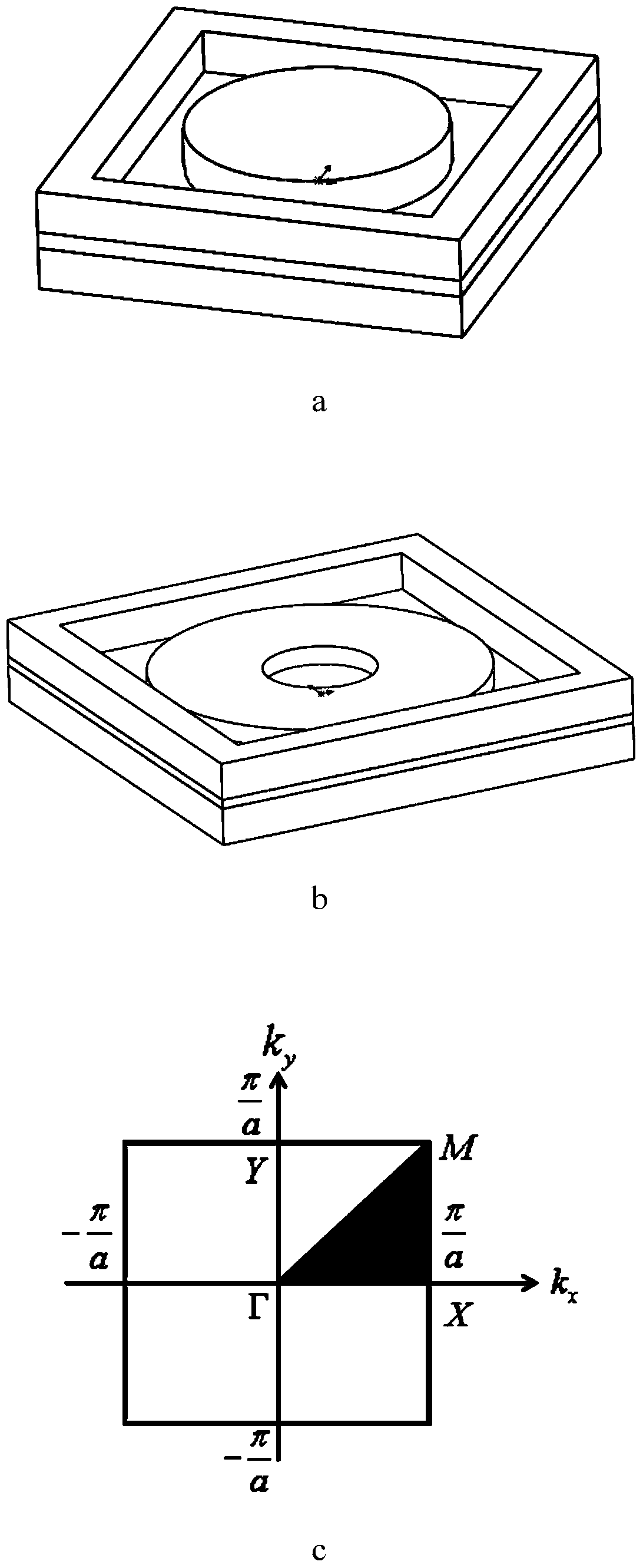

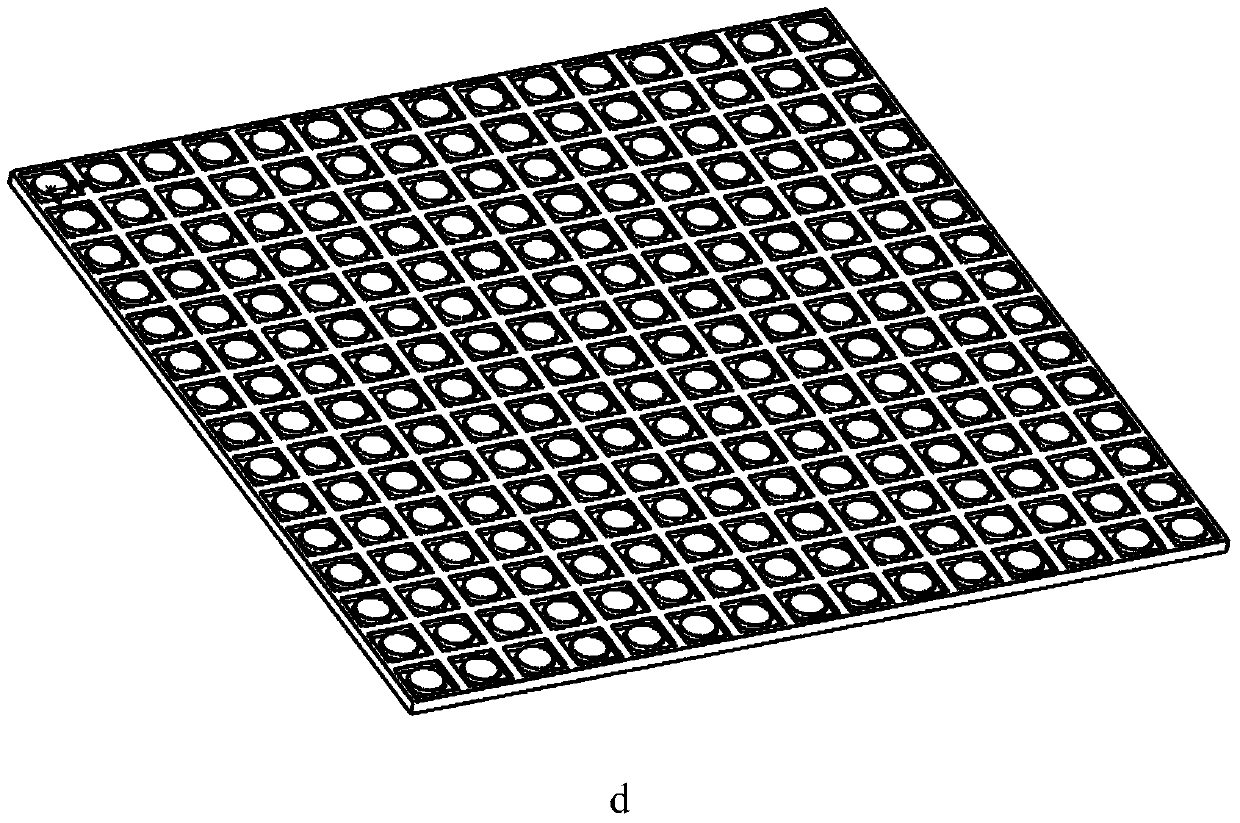

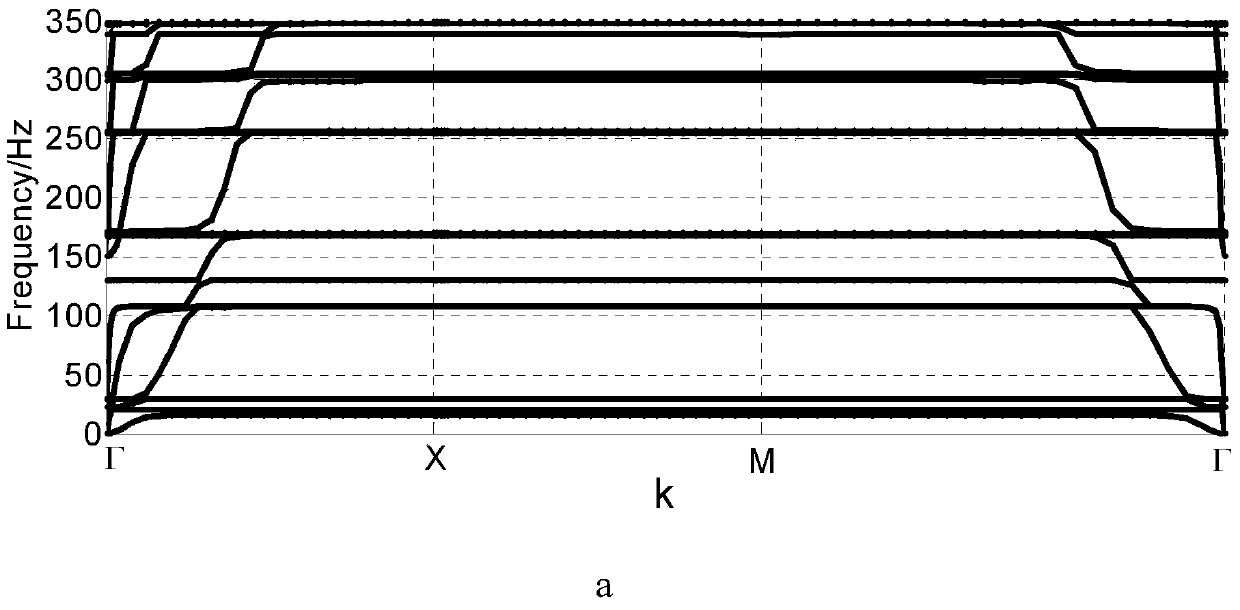

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0037] (1) Thin layer lightweight solution

[0038] In order to give scientific analysis data, some test pieces were designed and manufactured for research. The test piece is mainly composed of a 0.1-1mm silicone rubber film and a plastic or EVA (ethylene-vinyl acetate copolymer, ethylene-vinyl acetate copolymer) frame with a thickness of 1-2mm and a rib width of no more than 2mm. The density of the silicone rubber is about 1300kg / m 3 , the density of plastic is about 1180kg / m 3 , The density of EVA is equivalent to that of silicone rubber, and the density is generally low, which is a lightweight material. In addition, from the perspective of thickness, the thickness of the film is at the sub-mm level, and the thickness parameter of the plastic does not exceed 2mm, which belongs to the thin layer structure.

[0039] In addition, in order to achieve the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com