Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Reduce void volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

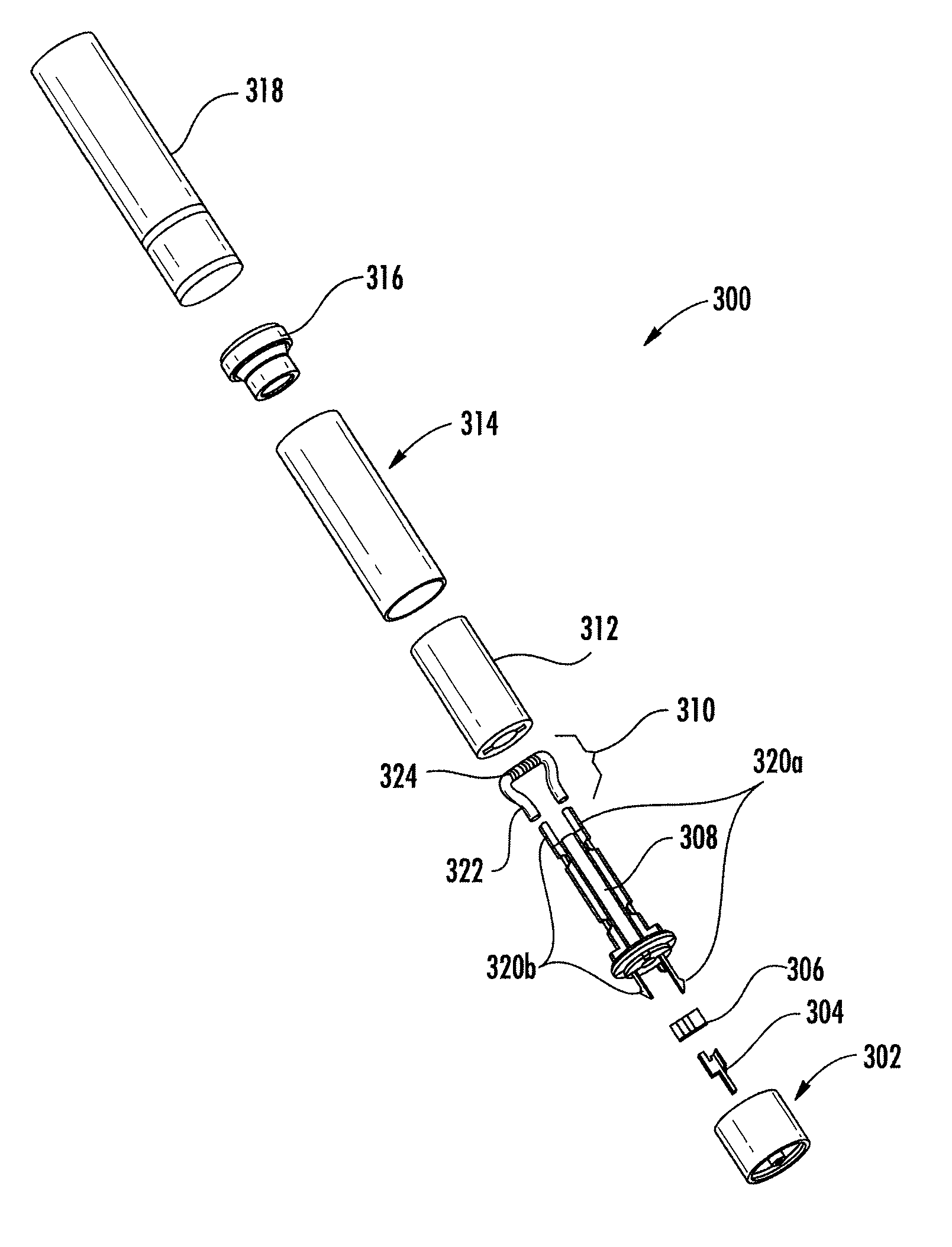

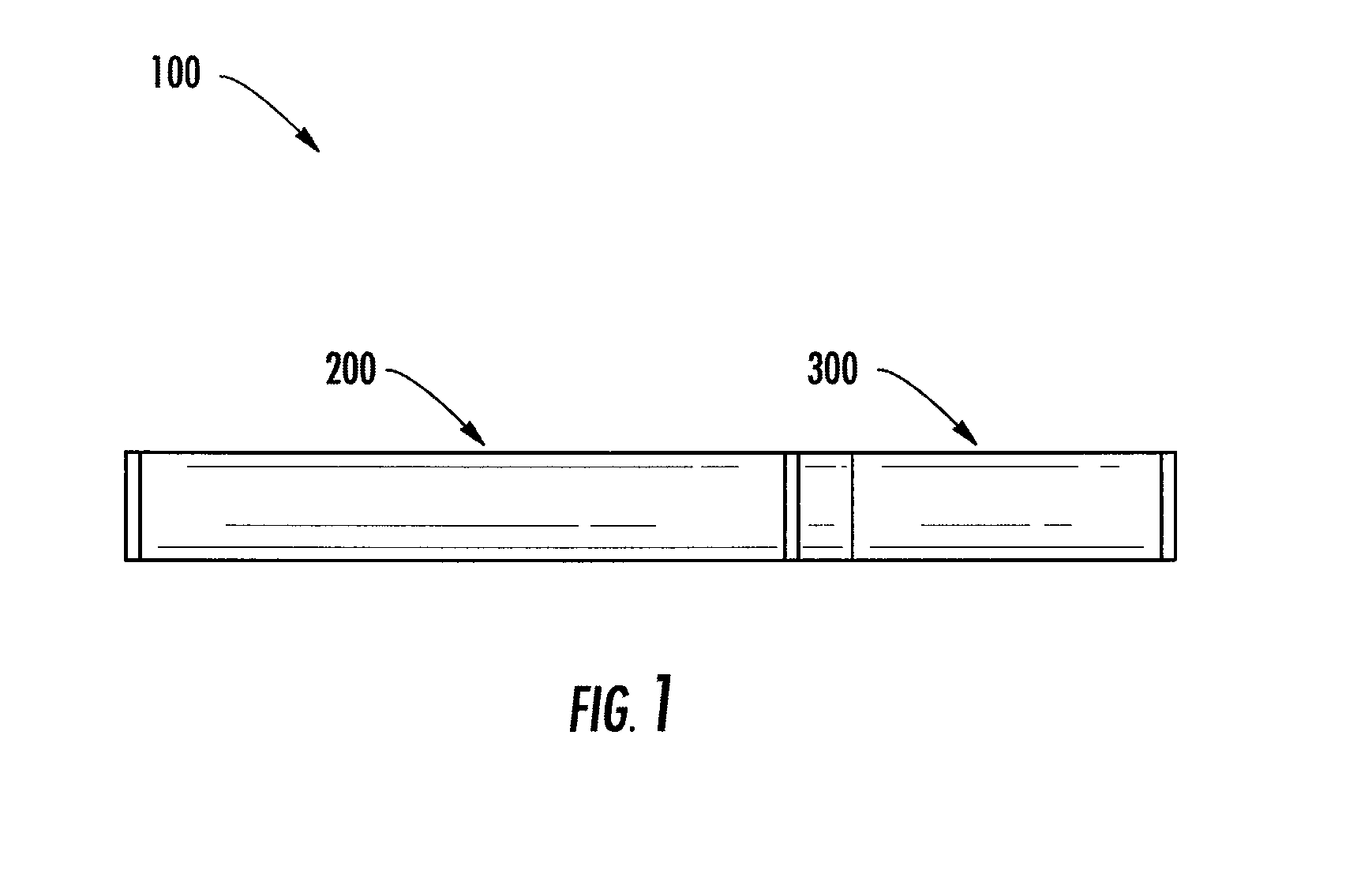

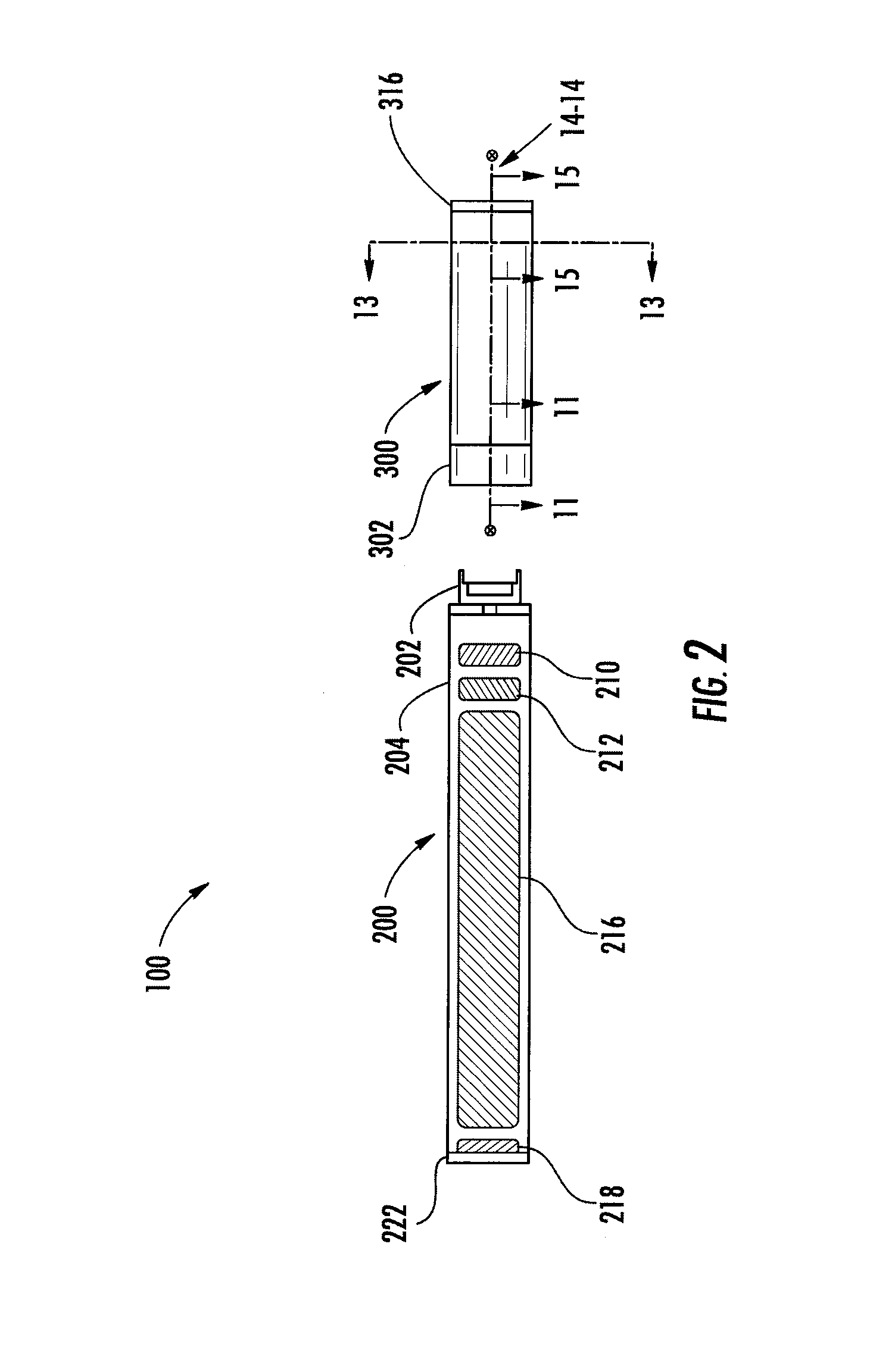

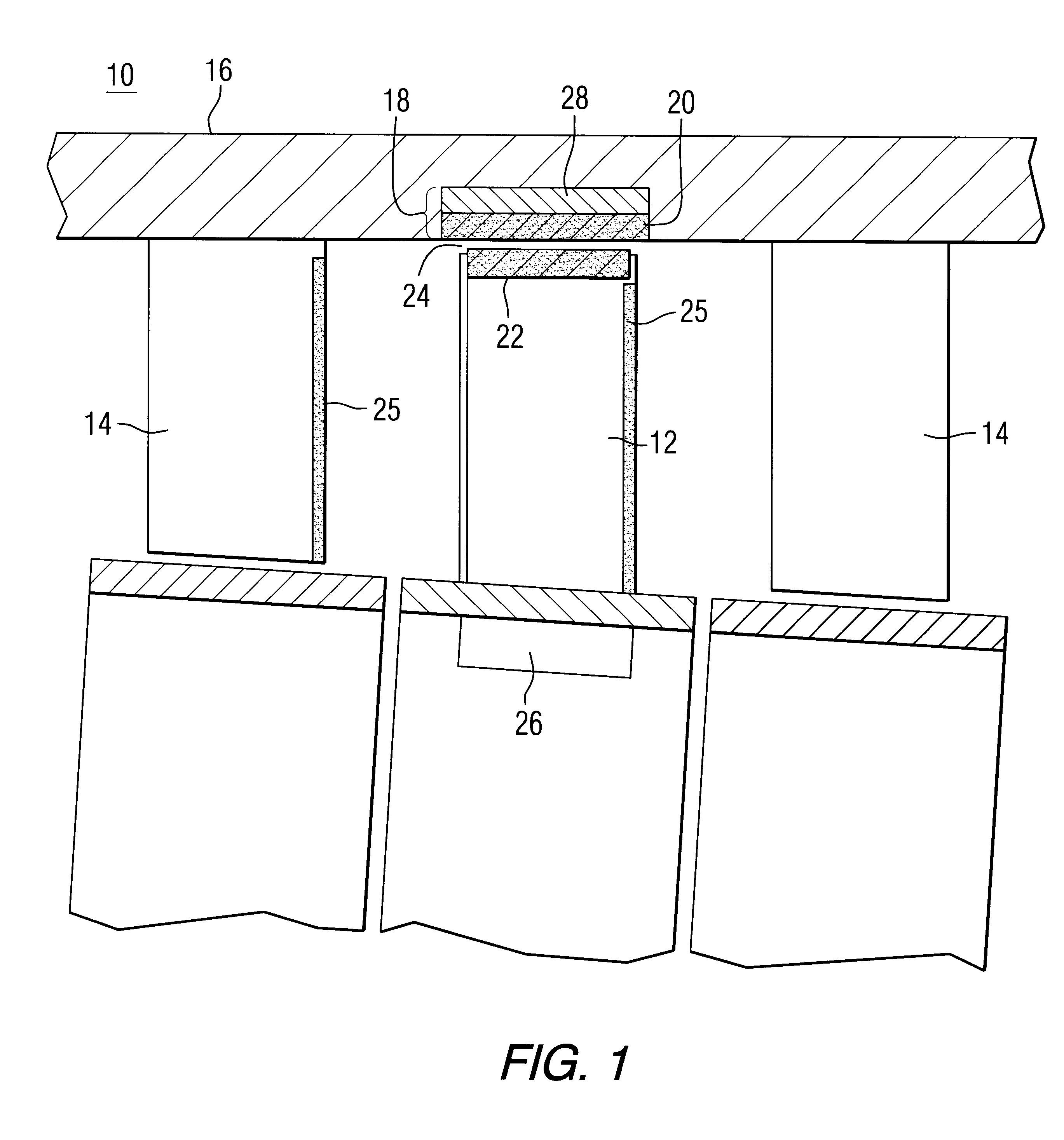

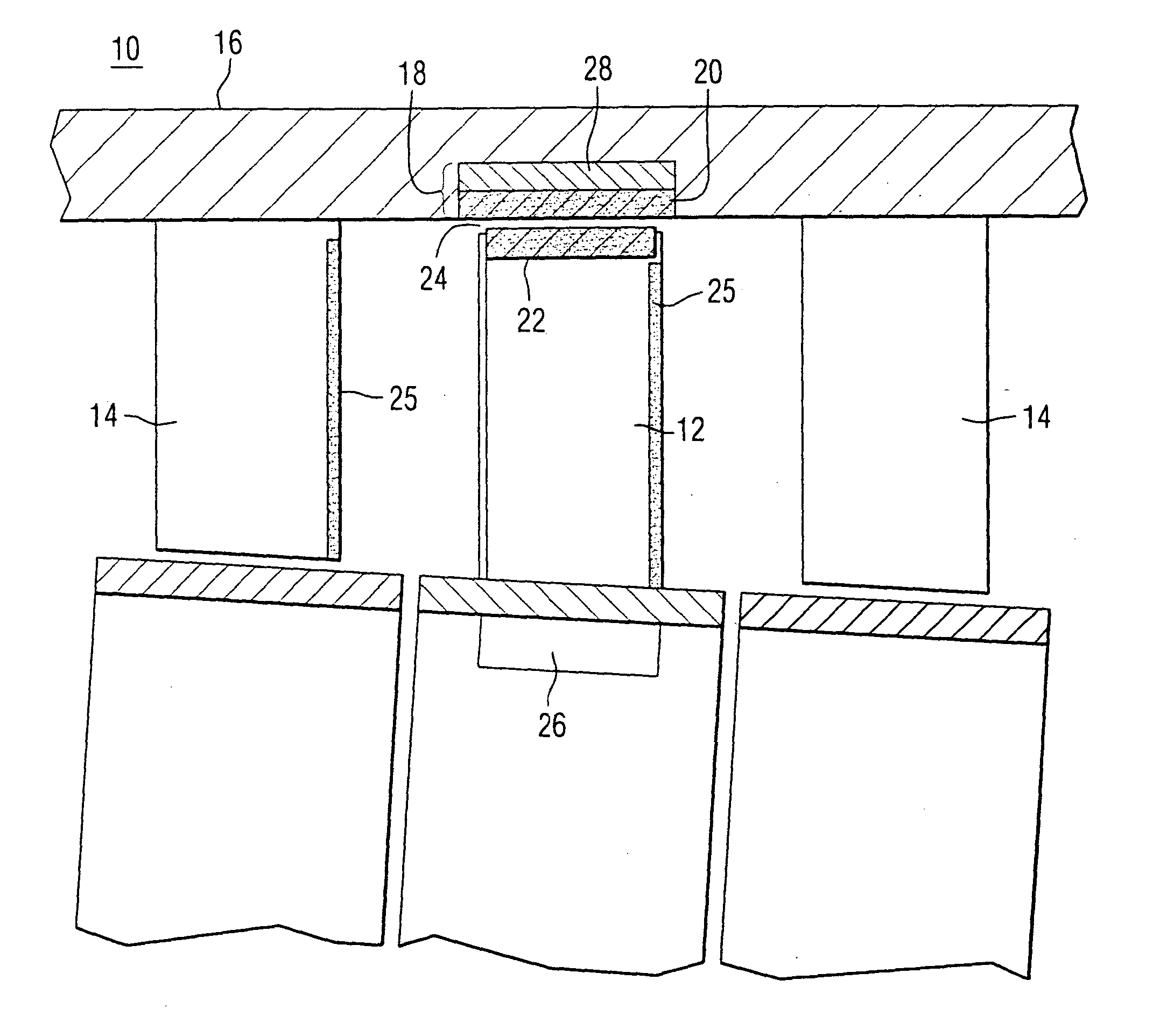

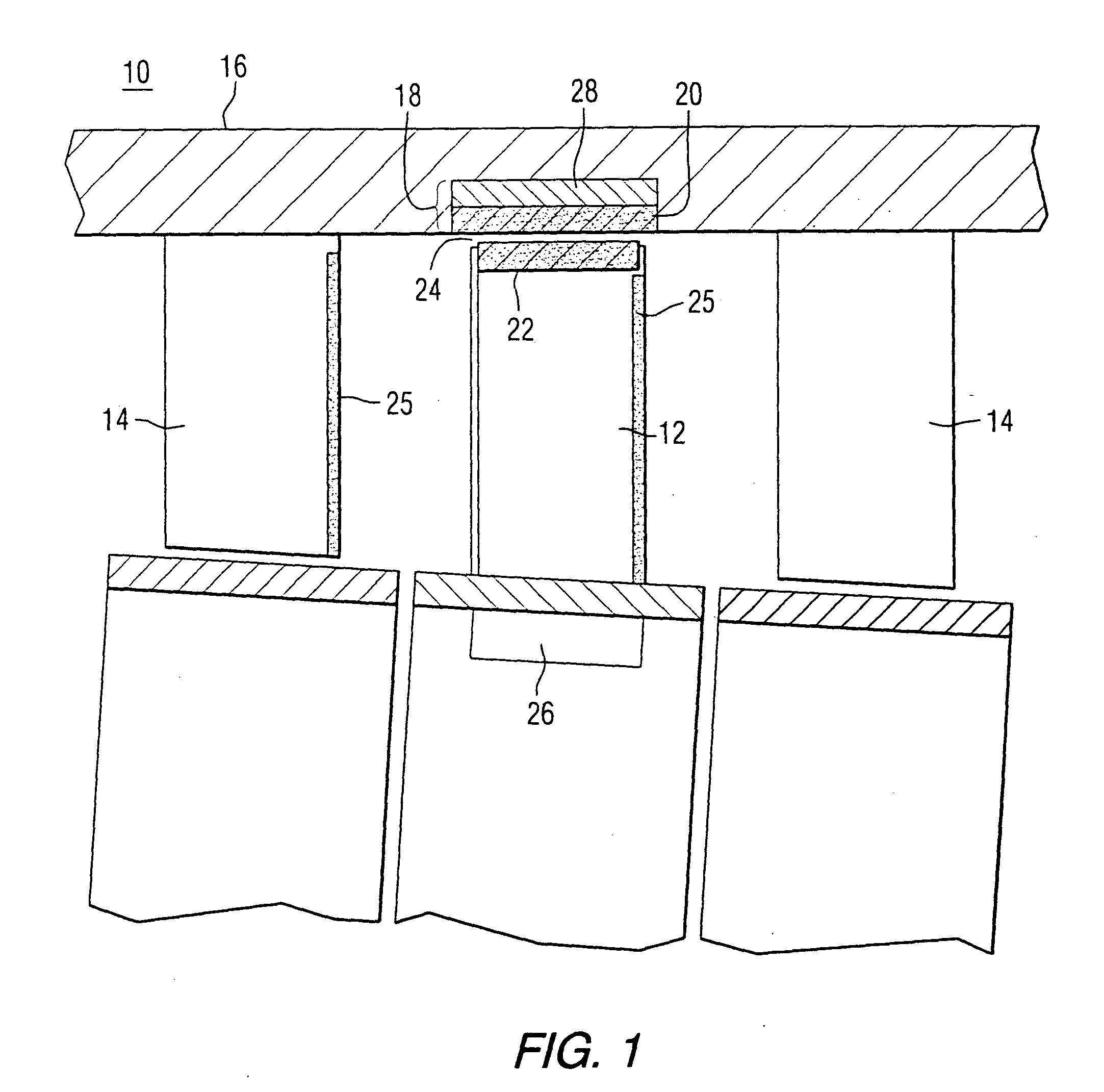

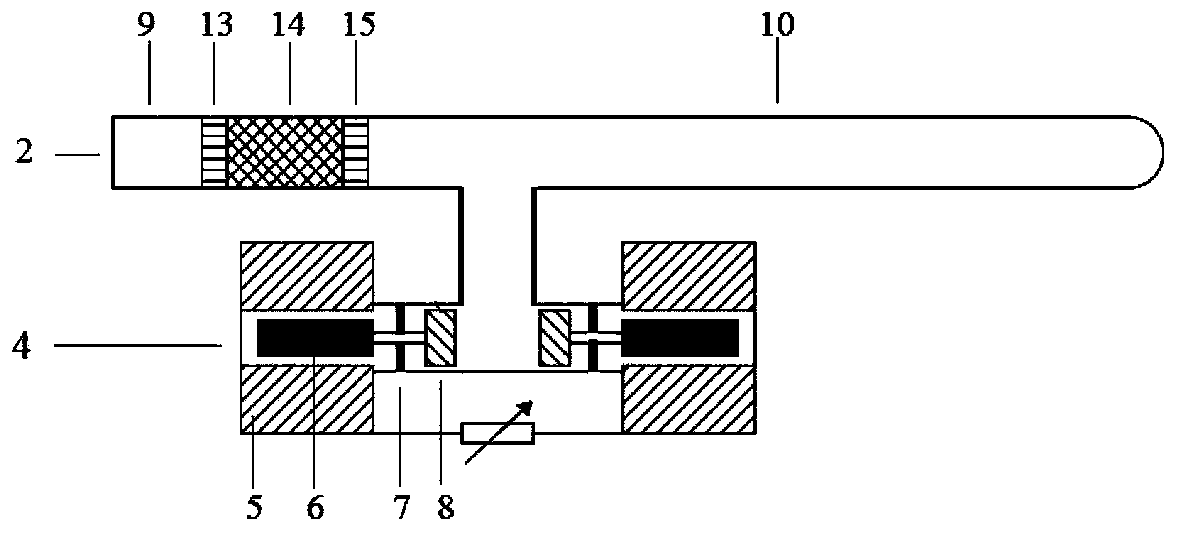

Sealed Cartridge for an Aerosol Delivery Device and Related Assembly Method

ActiveUS20150335071A1Reduce void volumeRespiratorsSteam generation heating methodsEngineeringAerosol delivery

The present disclosure relates to an aerosol delivery device. The aerosol delivery device may include a control body and a cartridge. The cartridge may include a base, a flow director, an outer body, a reservoir substrate, an outer body, and a mouthpiece. Heating elements may be molded into the flow director. The flow director may be welded to the base and the outer body, or the base and the flow director may include deformable ribs that engage the outer body. The flow director and the outer body may cooperatively define a reservoir compartment in which the reservoir substrate and the atomizer are received. The flow director and the base may define an electronics compartment in which an electronic control component is received. A related assembly method is also provided.

Owner:RAI STRATEGIC HLDG INC

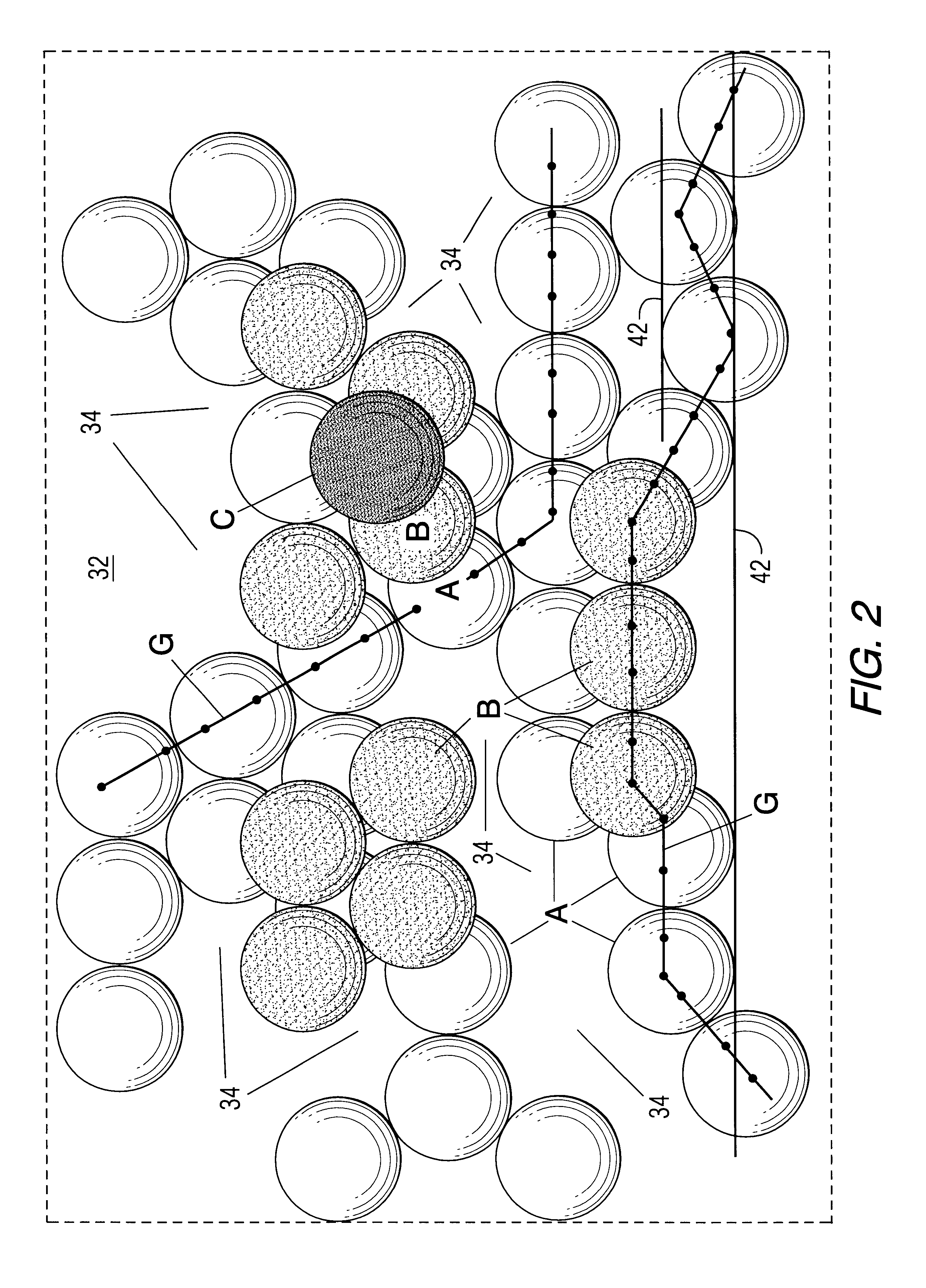

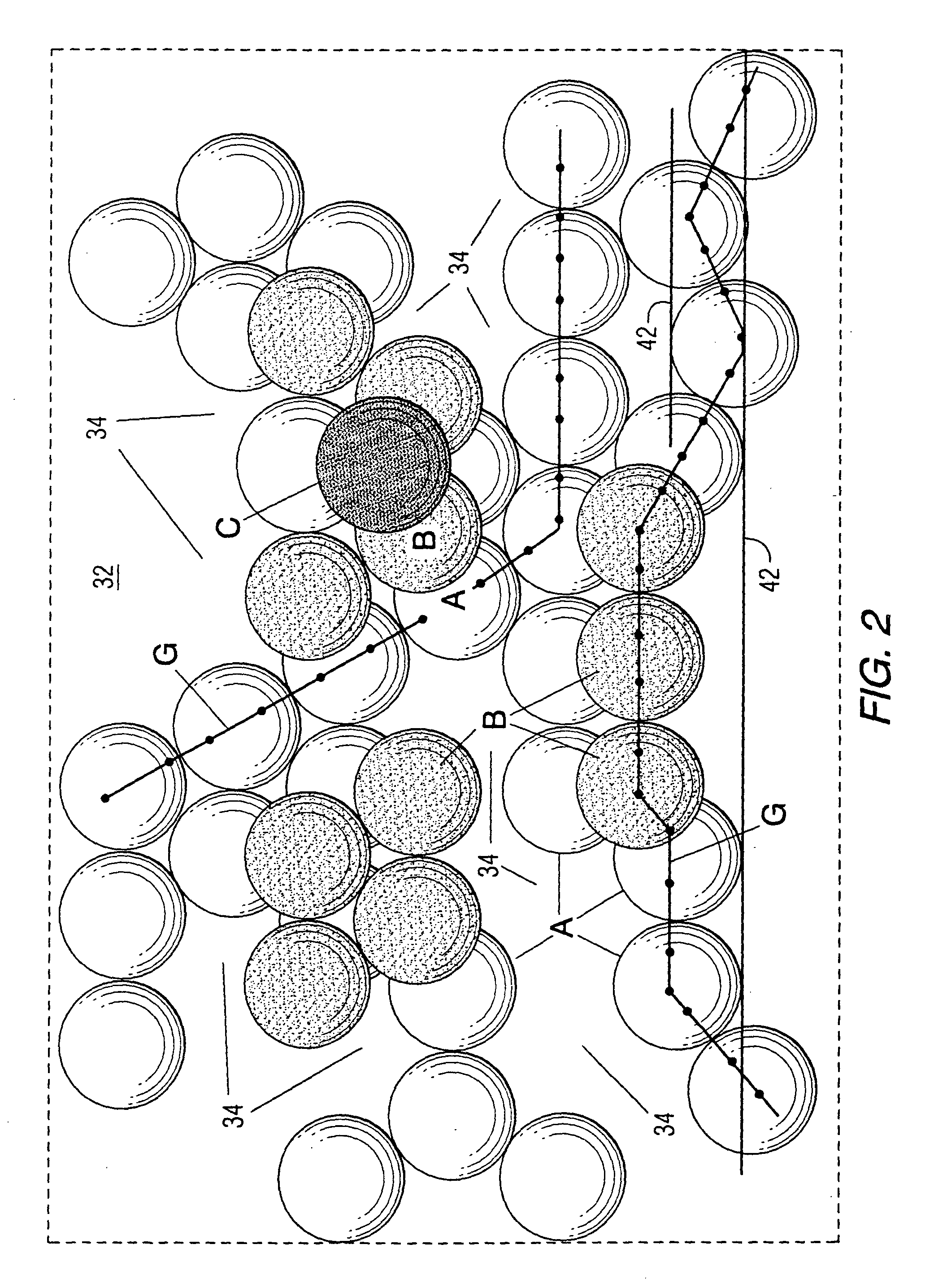

High temperature erosion resistant coating and material containing compacted hollow geometric shapes

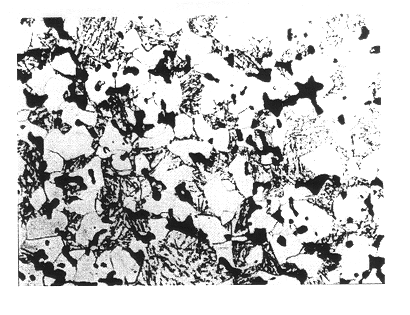

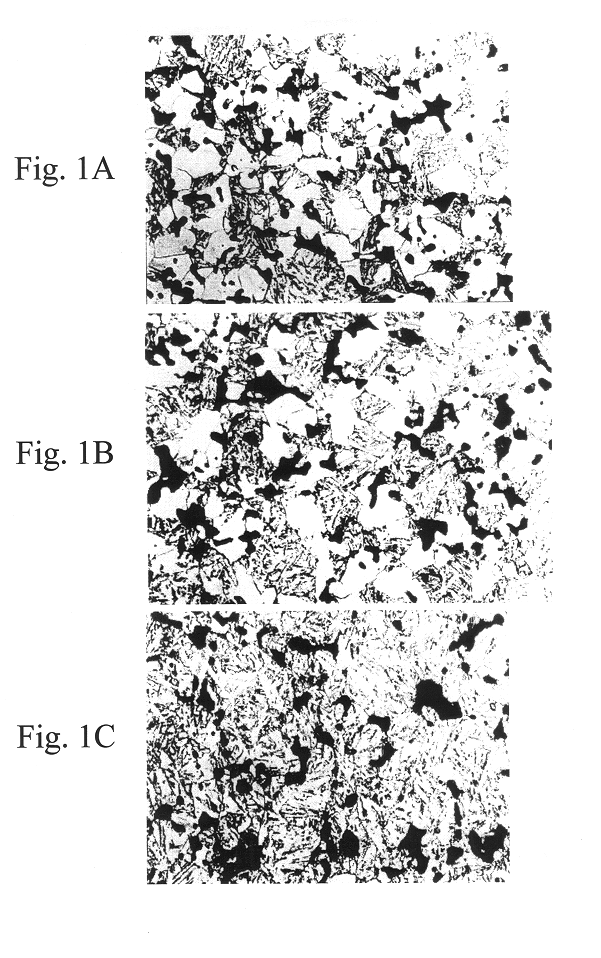

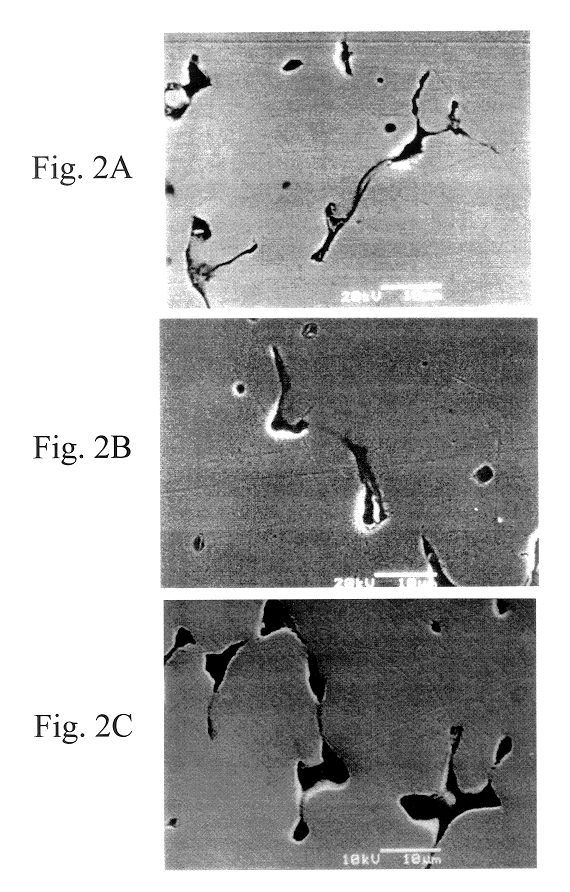

InactiveUS6641907B1Improve corrosion resistanceReduce void volumeEngine manufactureBlade accessoriesPorosityMetallurgy

A material system (60) contains close packed hollow shapes (50, 70) having a dense wall structure (52, 66), which are bonded together and which may contain a matrix binder material (56) between the shapes, where the system has a stable porosity, and is abradable and thermally stable at temperatures up to possibly 1700° C., where such systems are useful in turbine apparatus.

Owner:SIEMENS ENERGY INC

Polyolefin containing polyetheramine modified functionalized polyolefin

InactiveUS6093496AGood paintabilityExcellent mold flowabilityFilm/foil adhesivesSynthetic resin layered productsPolymer sciencePolyolefin

This invention concerns a composition comprising a blend of polyolefin with the reaction of a functionalized polyolefin and polyetheramine in which the polyetheramine is grafted into the functionalized polyolefin in a customary mixing apparatus. A process for producing the reaction product of functionalized polypropylene and polyetheramine by melting with polypropylene in a customary mixing apparatus is also disclosed. Blends of the present invention are advantageously useful to prepare paintable automotive body parts. This invention further includes dyeable polyolefin compositions containing the reaction product of functionalized polyolefin and polyetheramine. Dyeable polyolefin fibers, including polypropylene fibers, are disclosed, which may be made by melt spinning, and which may be employed to make woven and non-woven fabric. The polyolefin employed in the practice of this invention may be a flexible polyolefin.

Owner:HUNTSMAN PETROCHEMICAL LLC +1

Article manufacture using polyolefin containing polyetheramine modified functionalized polyolefin

InactiveUS6146574AIncrease stiffnessReduce void volumeSynthetic resin layered productsWood working apparatusPolyolefinPolymer science

This invention concerns a composition comprising a blend of polyolefin with the reaction of a functionalized polyolefin and polyetheramine in which the polyetheramine is grafted into the functionalized polyolefin in a customary mixing apparatus. A process for producing the reaction product of functionalized polypropylene and polyetheramine by melting with polypropylene in a customary mixing apparatus is also disclosed. Blends of the present invention are advantageously useful to prepare paintable automotive body parts. This invention further includes dyeable polyolefin compositions containing the reaction product of functionalized polyolefin and polyetheramine. Dyeable polyolefin fibers, including polypropylene fibers, are disclosed, which may be made by melt spinning, and which may be employed to make woven and non-woven fabric.

Owner:HUNTSMAN PETROCHEMICAL LLC +1

Dyeable polyolefin containing polyetheramine modified functionalized polyolefin

InactiveUS6127480AGood paintabilityExcellent mold flowabilityEngine sealsCellulosic plastic layered productsPolymer sciencePolyolefin

This invention concerns a composition comprising a blend of polyolefin with the reaction of a functionalized polyolefin and polyetheramine in which the polyetheramine is grafted into the functionalized polyolefin in a customary mixing apparatus. A process for producing the reaction product of functionalized polypropylene and polyetheramine by melting with polypropylene in a customary mixing apparatus is also disclosed. Blends of the present invention are advantageously useful to prepare paintable automotive body parts. This invention further includes dyeable polyolefin compositions containing the reaction product of functionalized polyolefin and polyetheramine. Dyeable polyolefin fibers, including polypropylene fibers, are disclosed, which may be made by melt spinning, and which may be employed to make woven and non-woven fabric.

Owner:JPMORGAN CHASE BANK N A AS COLLATERAL AGENT

Dyeable polyolefin containing polyetheramine modified functionalized polyolefin

InactiveUS6420482B1Easy to optimizeImprove washabilityFibre treatmentDyeing processPolymer sciencePolyolefin

This invention concerns a composition comprising a blend of polyolefin with the reaction of a functionalized polyolefin and polyetheramine in which the polyetheramine is grafted into the functionalized polyolefin in a customary mixing apparatus. A process for producing the reaction product of functionalized polypropylene and polyetheramine by melting with polypropylene in a customary mixing apparatus is also disclosed. Blends of the present invention are advantageously useful to prepare paintable automotive body parts. This invention further includes dyeable polyolefin compositions containing the reaction product of functionalized polyolefin and polyetheramine. Dyeable polyolefin fibers, including polypropylene fibers, are disclosed, which may be made by melt spinning, and which may be employed to make woven. and non-woven fabric.

Owner:JPMORGAN CHASE BANK N A AS COLLATERAL AGENT

High temperature erosion resistant coating and material containing compacted hollow geometric shapes

InactiveUS20040219010A1Improve corrosion resistanceReduce void volumeEngine manufacturePump componentsThermodynamicsEngineering

A material system (60) contains close packed hollow shapes (50, 70) having a dense wall structure (52, 66), which are bonded together and which may contain a matrix binder material (56) between the shapes, where the system has a stable porosity, and is abradable and thermally stable at temperatures up to possibly 1700° C., where such systems are useful in turbine apparatus.

Owner:SIEMENS ENERGY INC

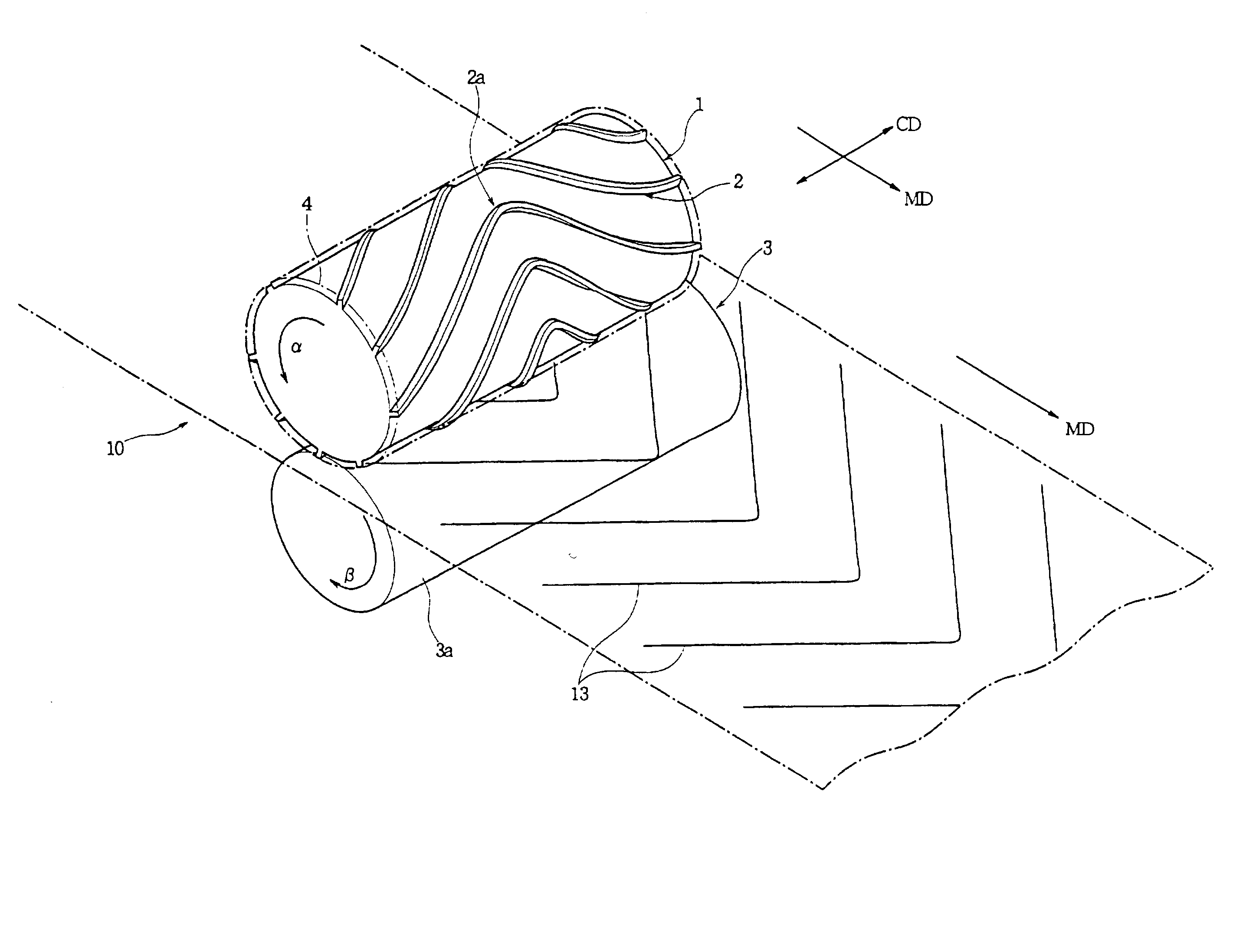

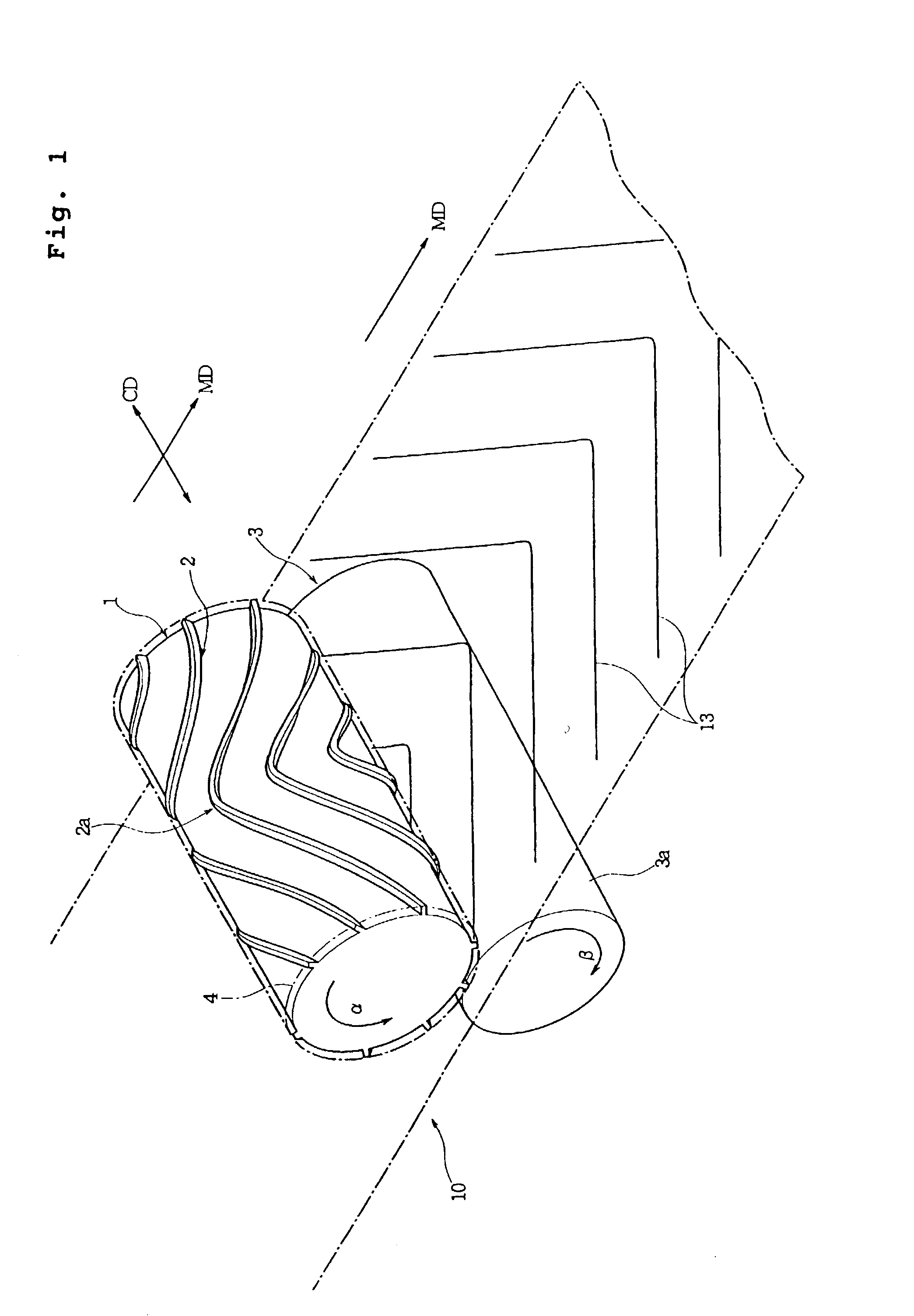

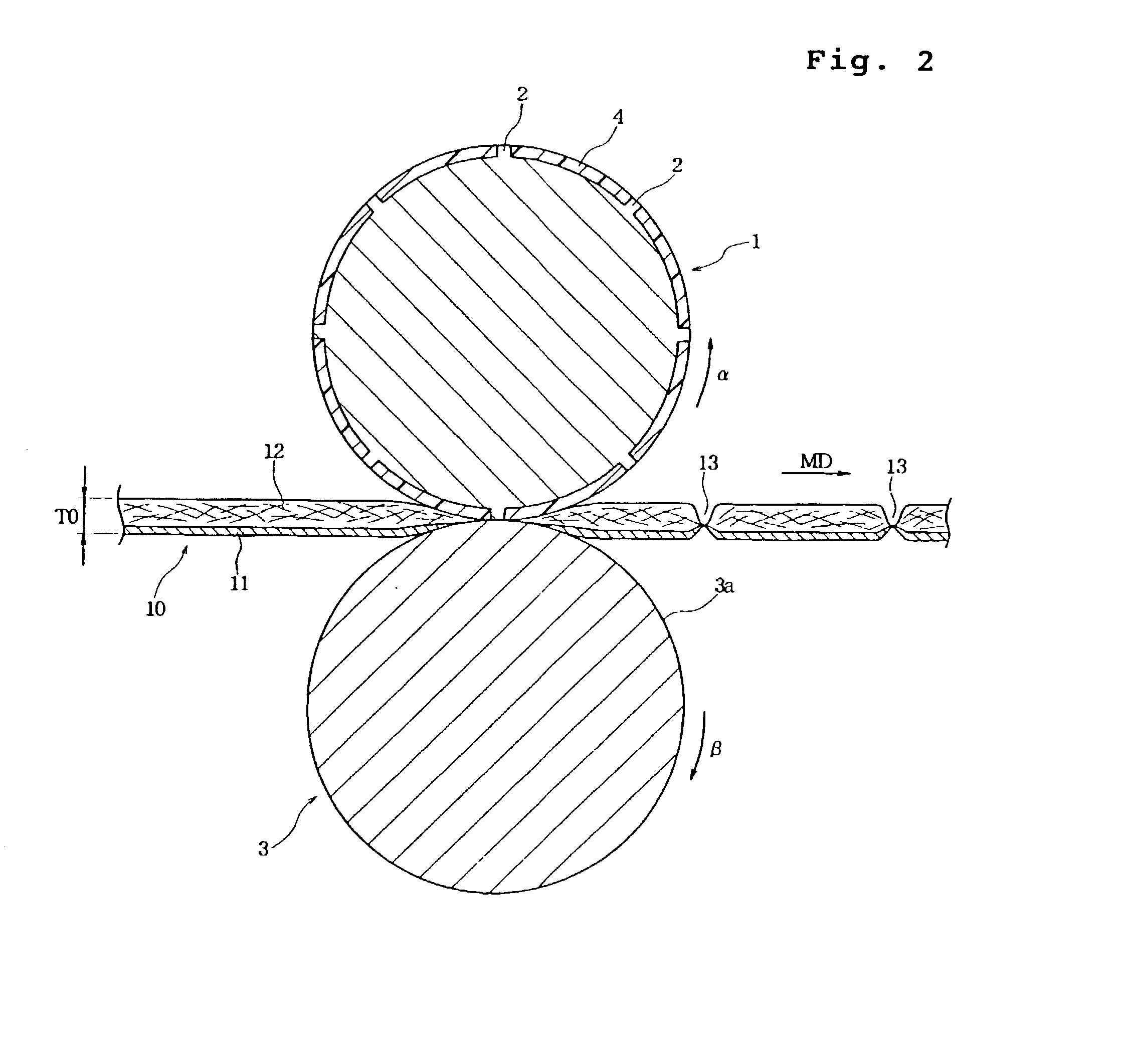

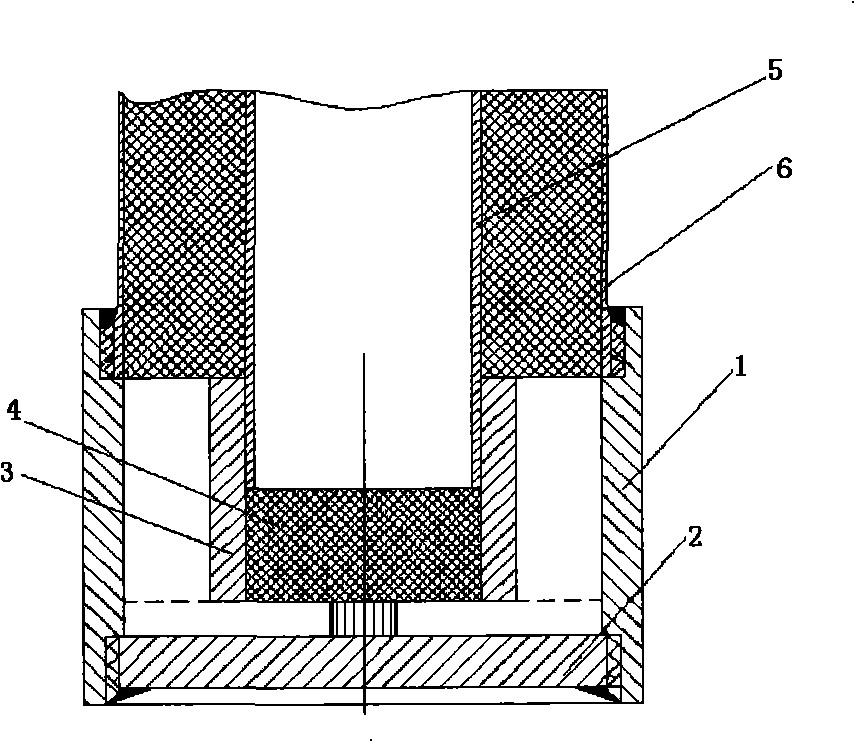

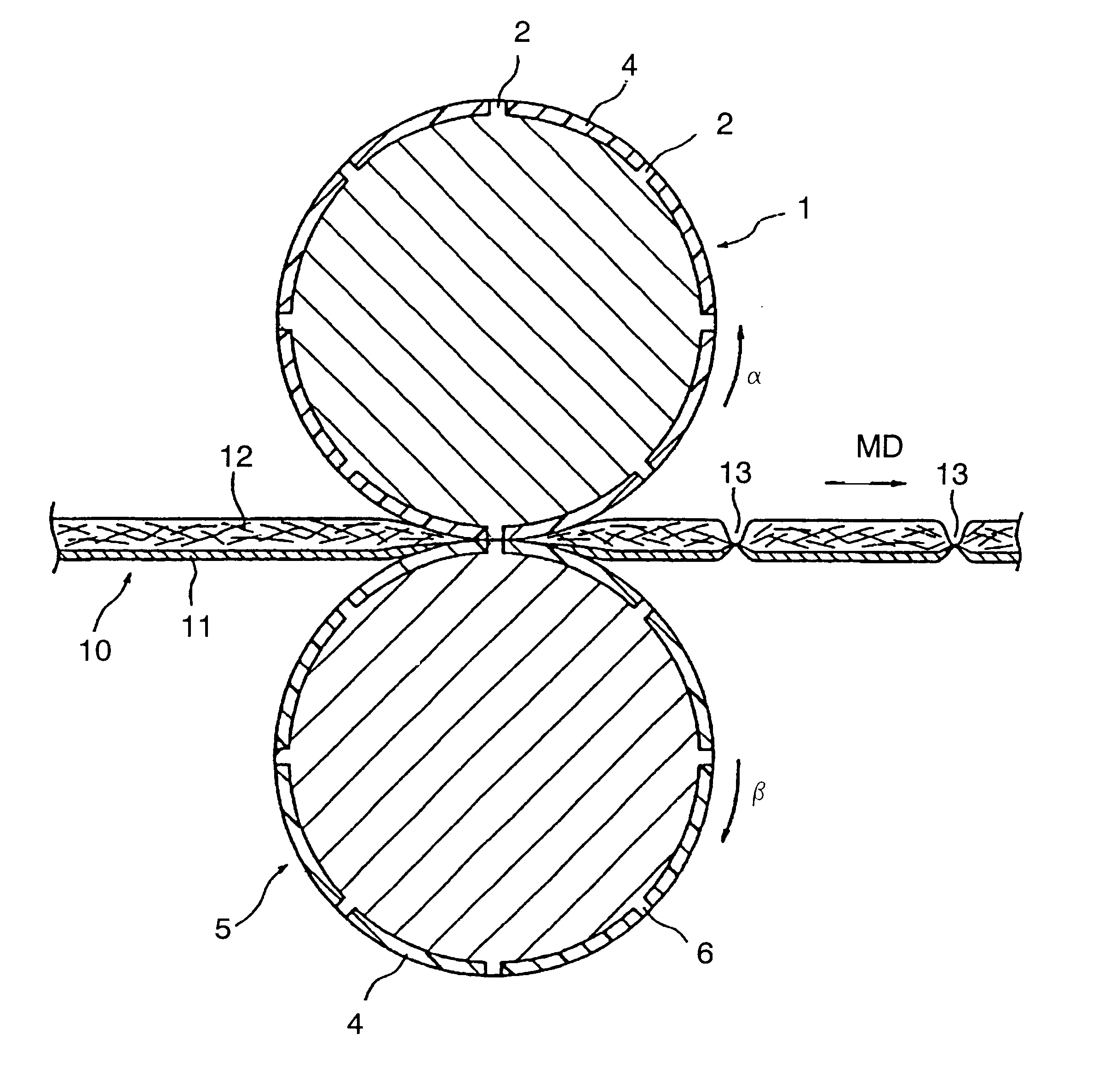

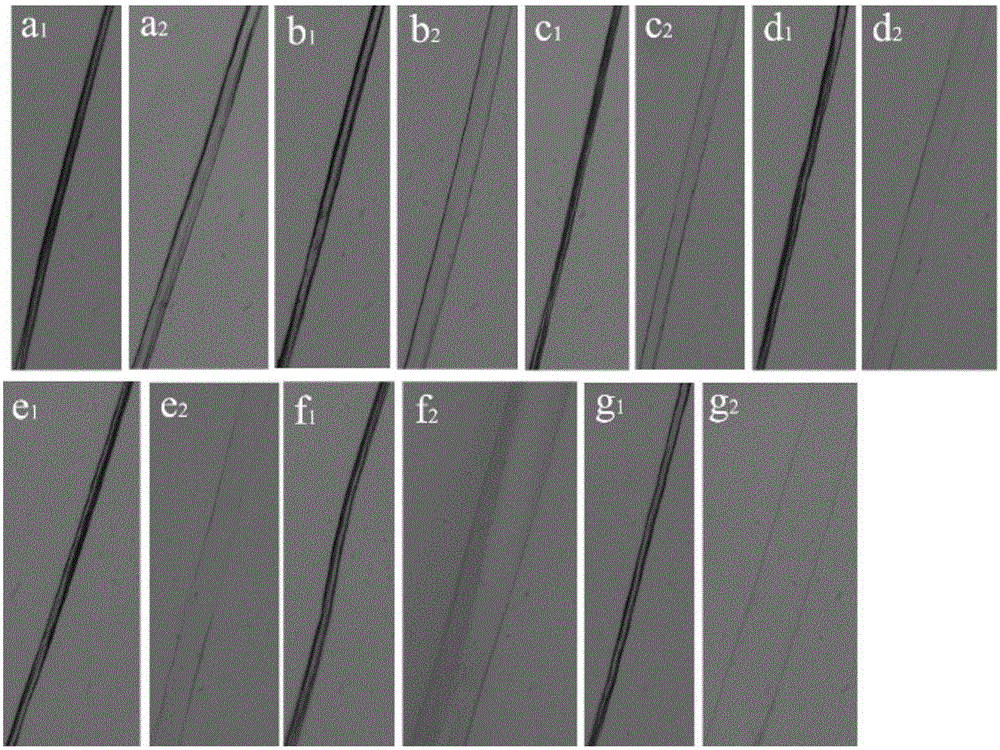

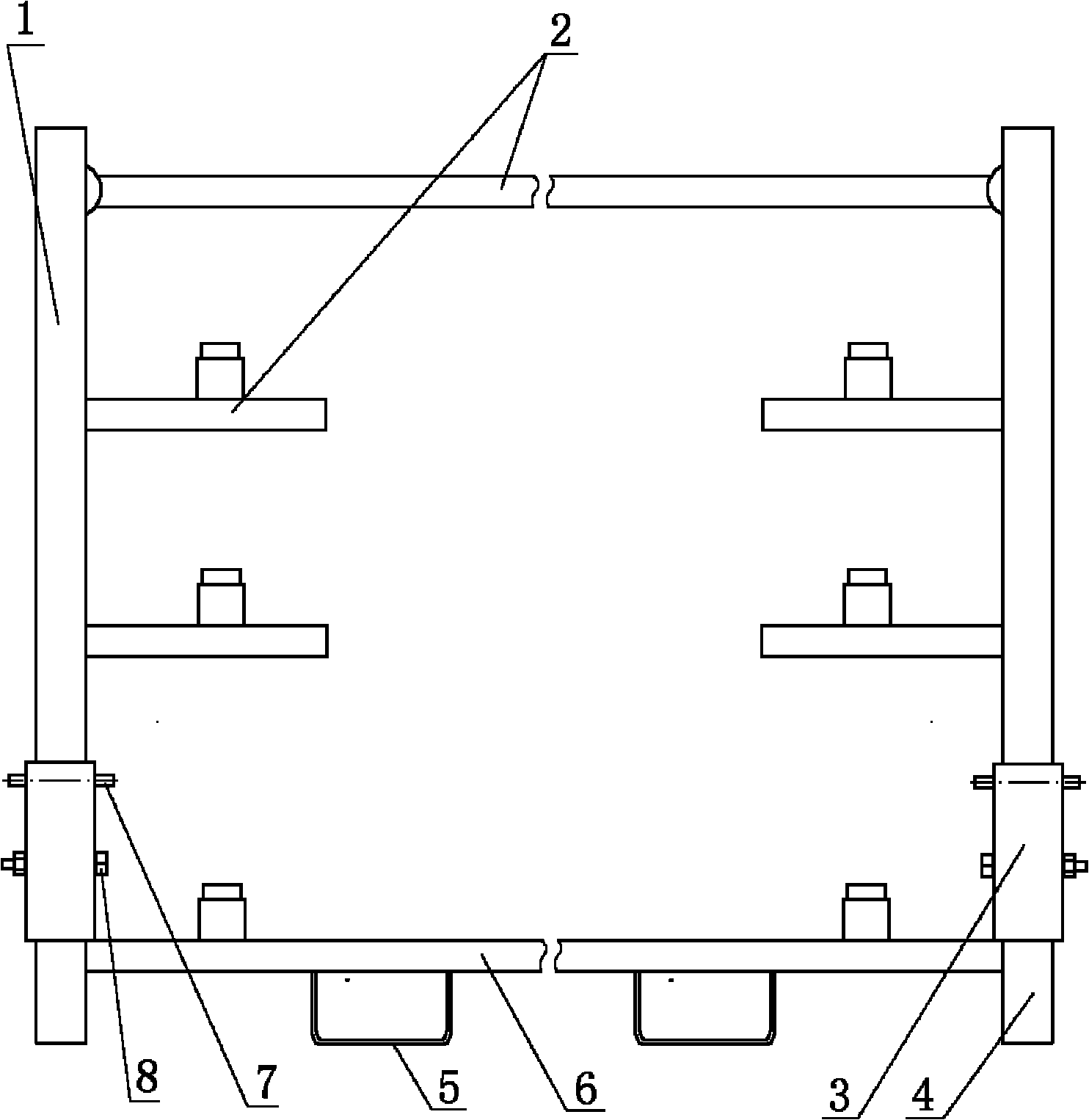

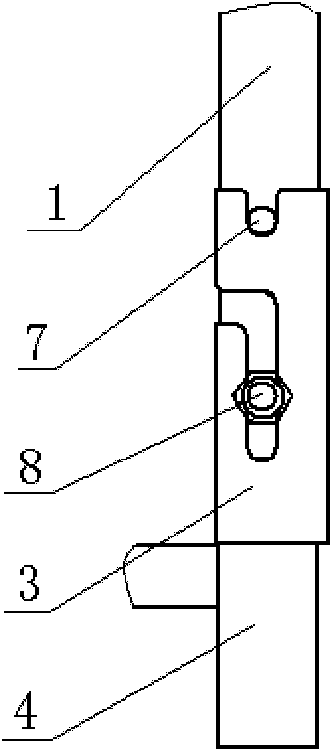

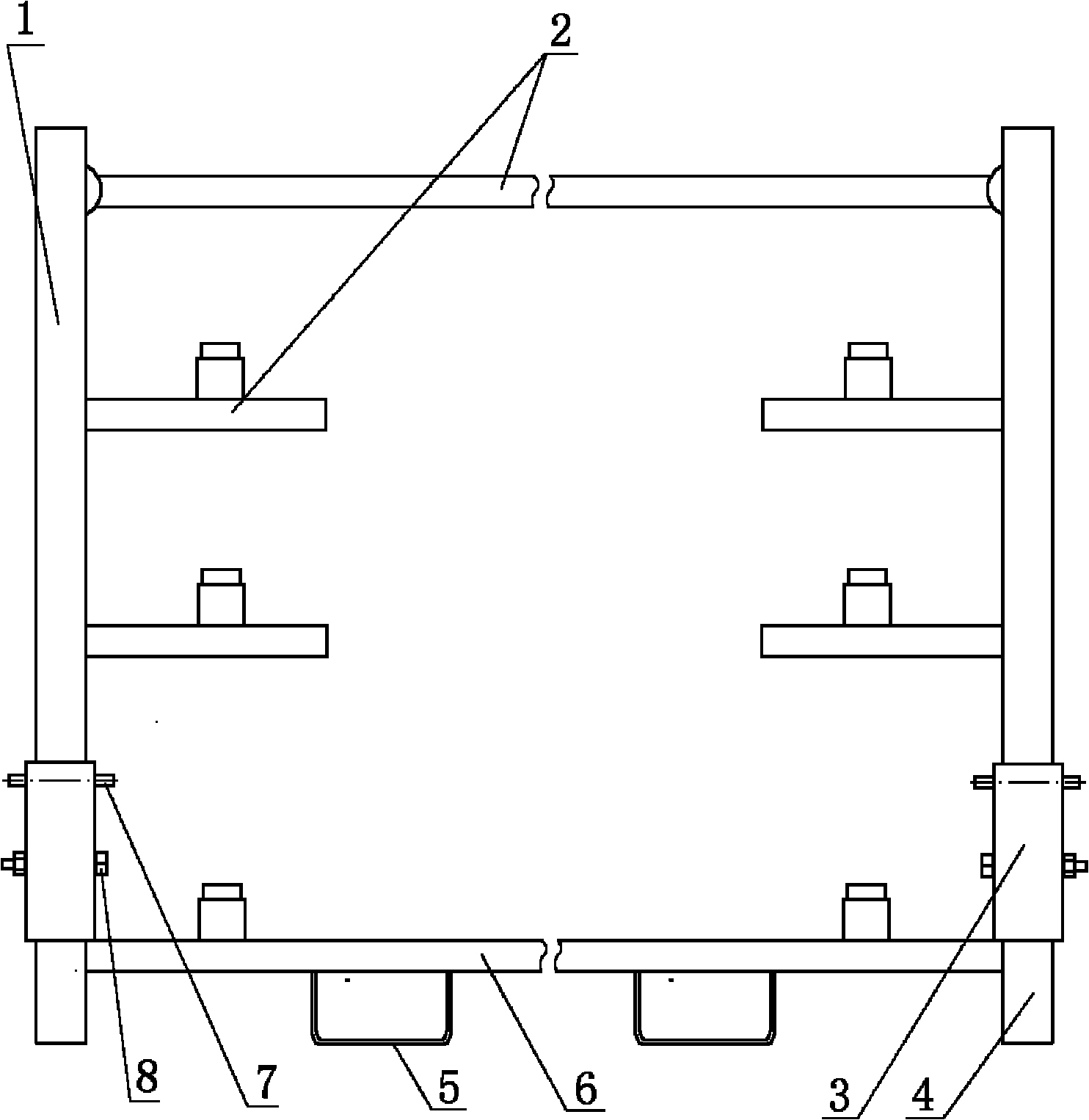

Heat-sealing method and apparatus for fiber sheets

InactiveUS20030000934A1Reduce void volumeReliable heat sealingMechanical working/deformationLaminationFiberMechanical engineering

There is disclosed a heat-sealing method including: feeding a fusible fiber sheet (12) into the clearance between a pair of rolls (1, 5), at least one of which has sealing ridges (2, 6) of a predetermined pattern on its outer circumference; and heating and pressing the fiber sheet (12) with the sealing ridges (2, 6), to form fused portions corresponding to the pattern of the sealing ridges (2, 6), in the fiber sheet (12). An insulator (4) is disposed to cover the outer circumference of the rolls (1, 5), as lacking the sealing ridges. The insulator (4) is made of a material which has a lower thermal conductivity than that of the sealing ridges and which can be elastically contracted by the pressure of the rolls (1, 5). The fiber sheet (12) to be fed into the clearance between the rolls (1, 5) rotating is compressed by the insulator (4) to discharge its internal air and is then heated and pressed by the sealing ridges (2, 6) so that it is heat-sealed.

Owner:UNI CHARM CORP

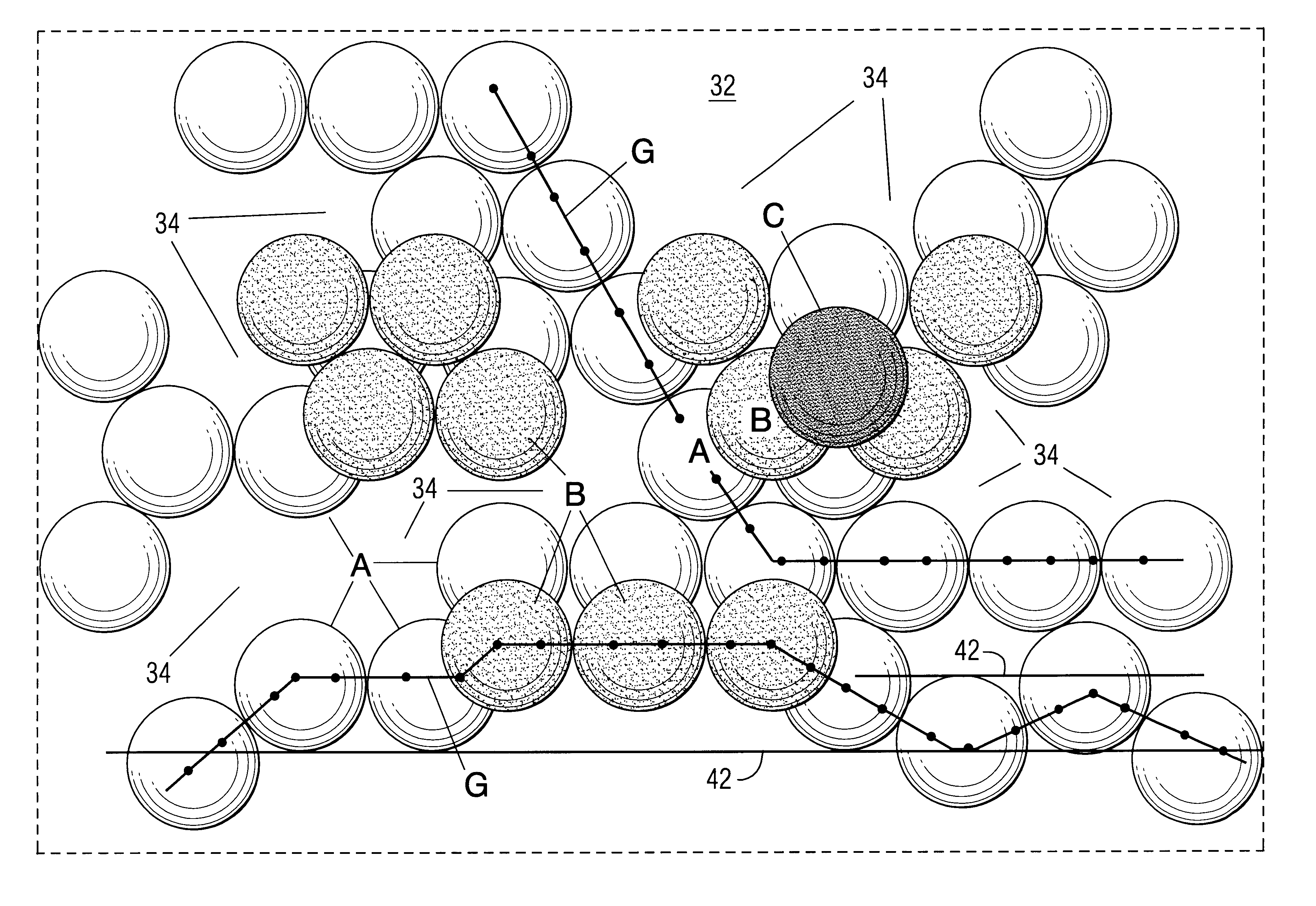

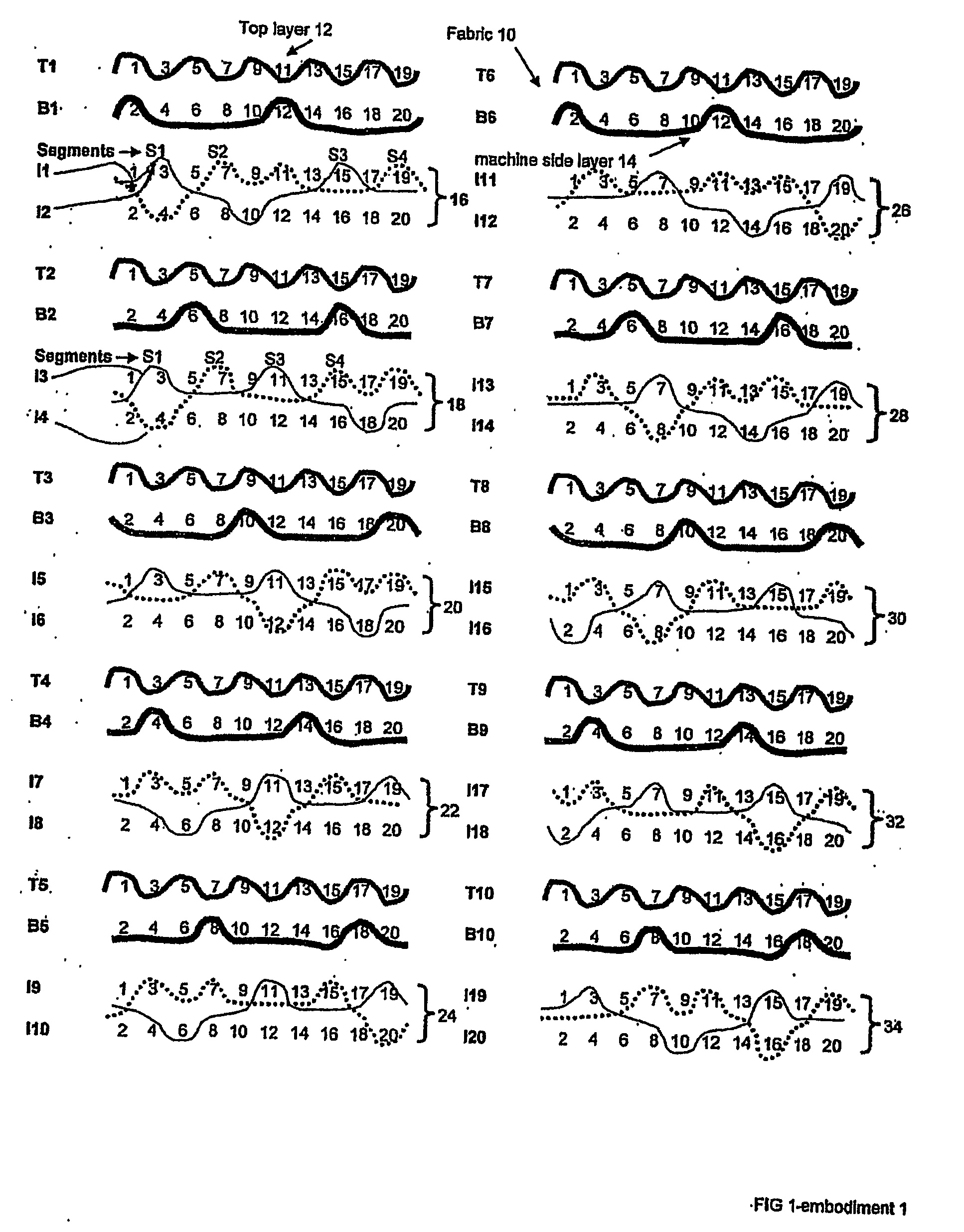

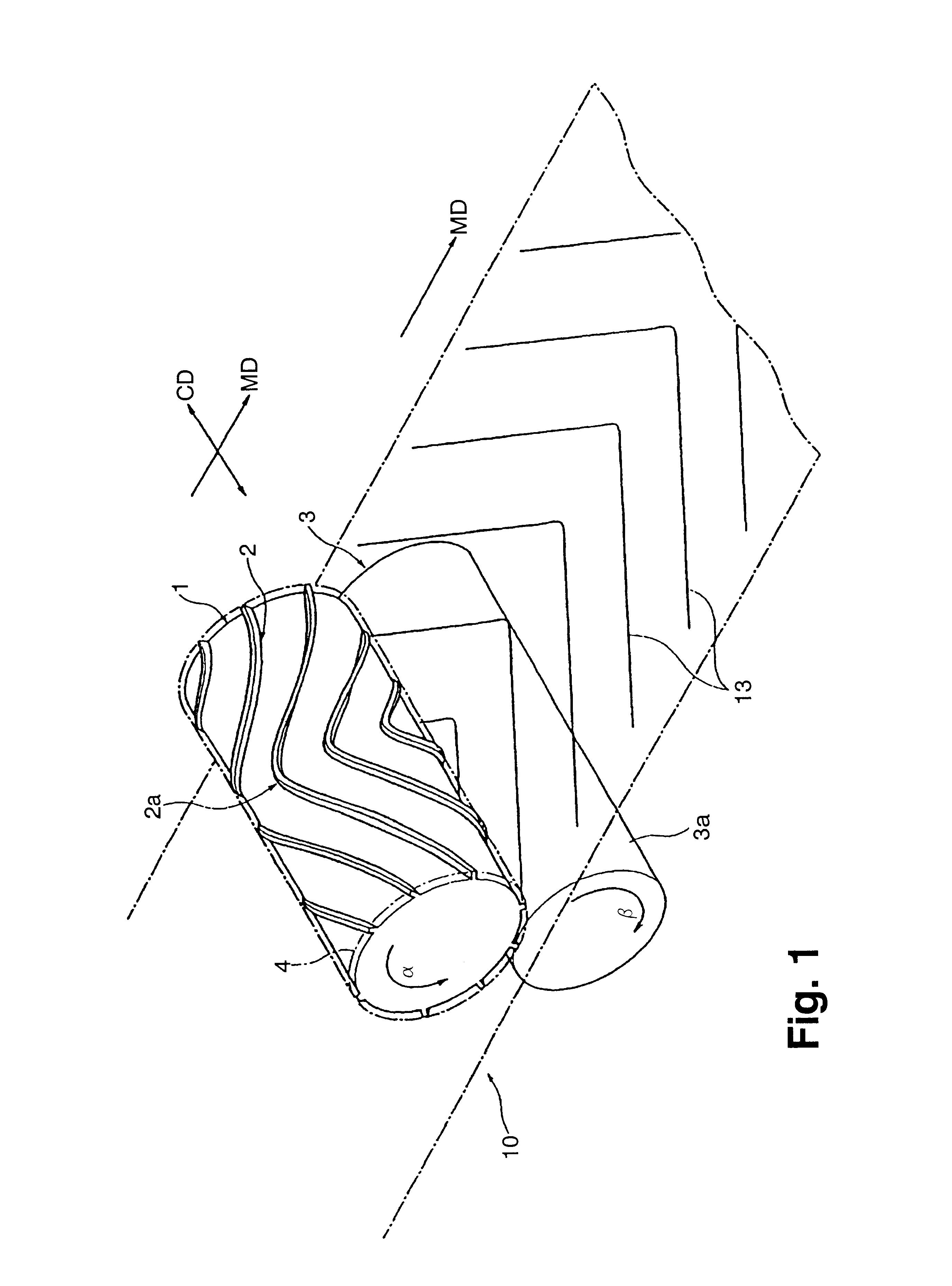

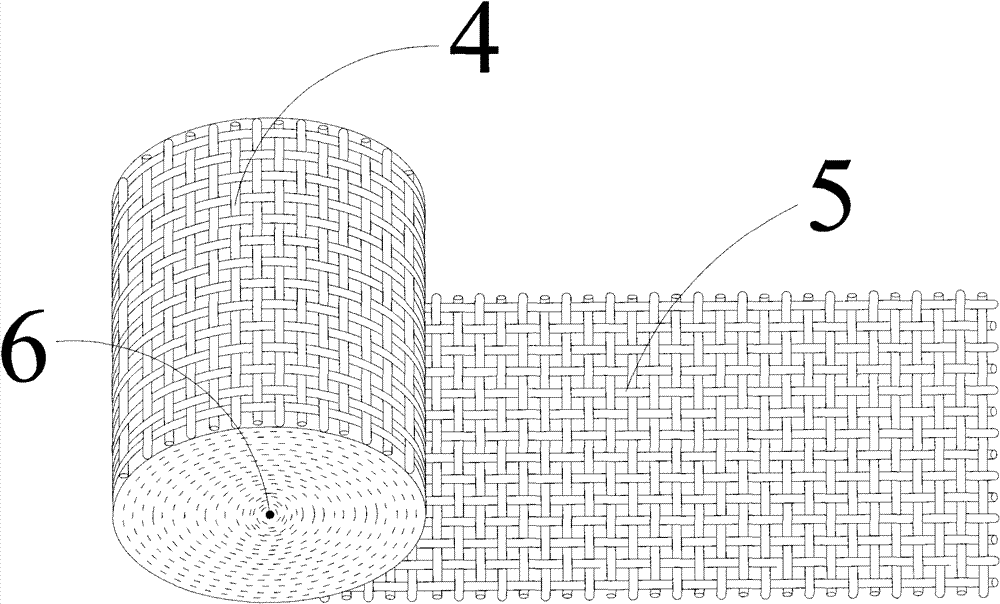

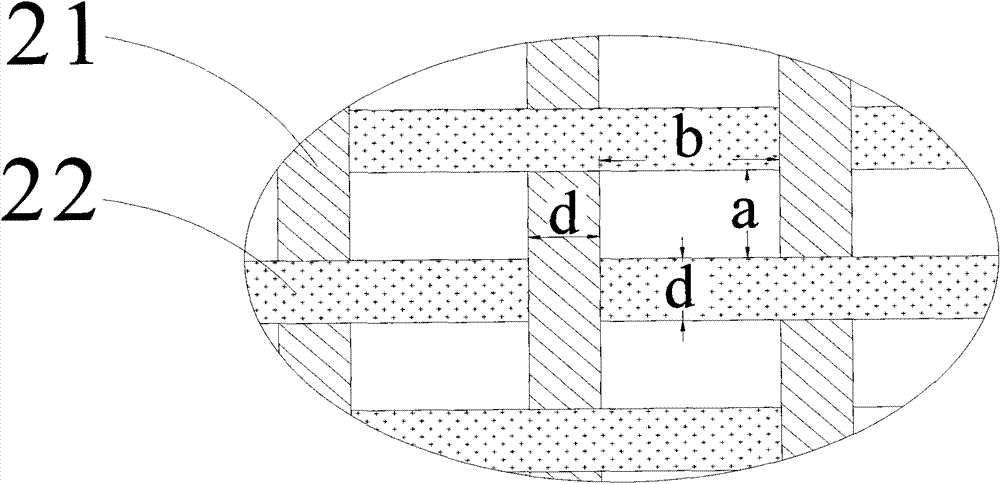

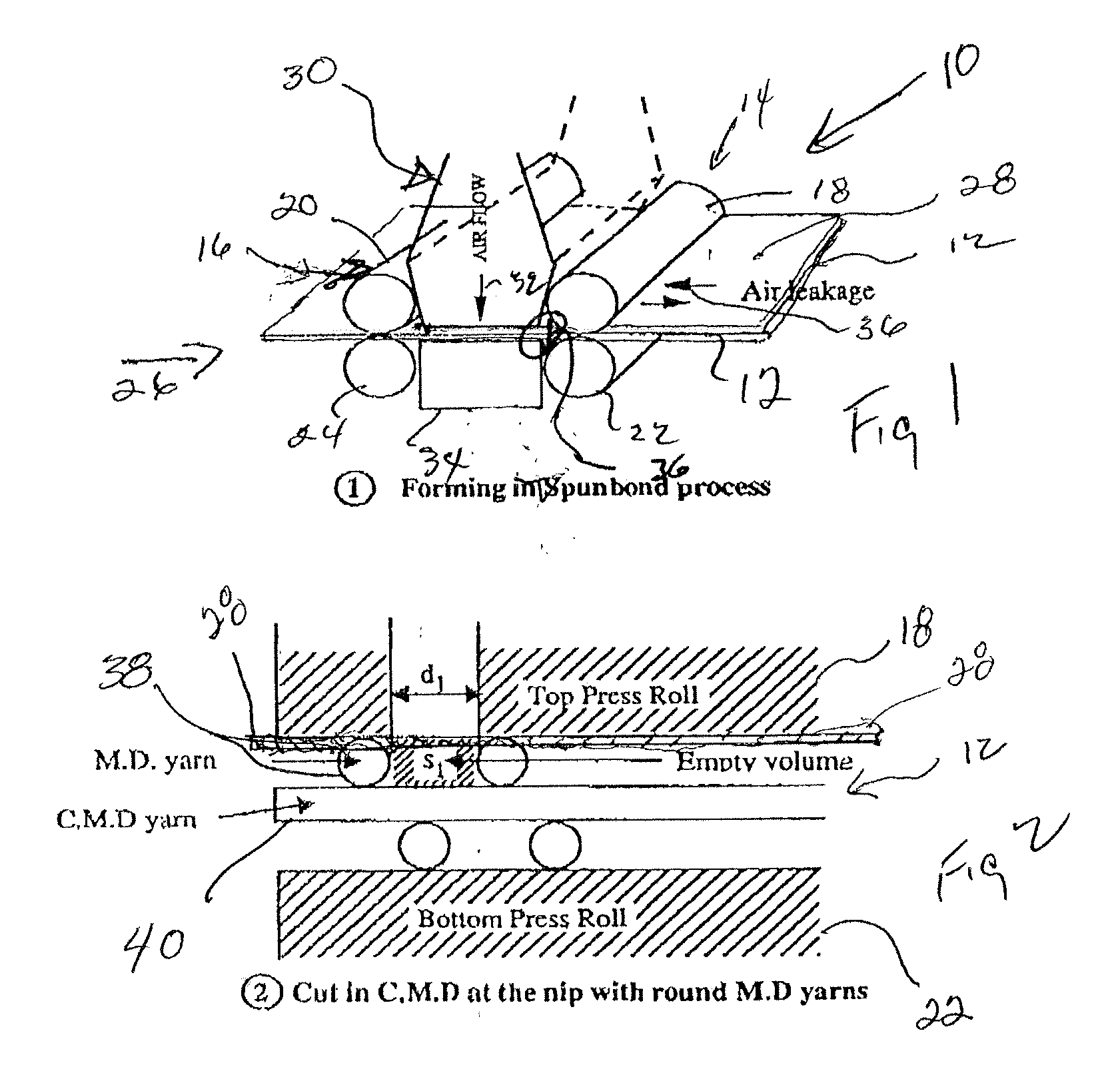

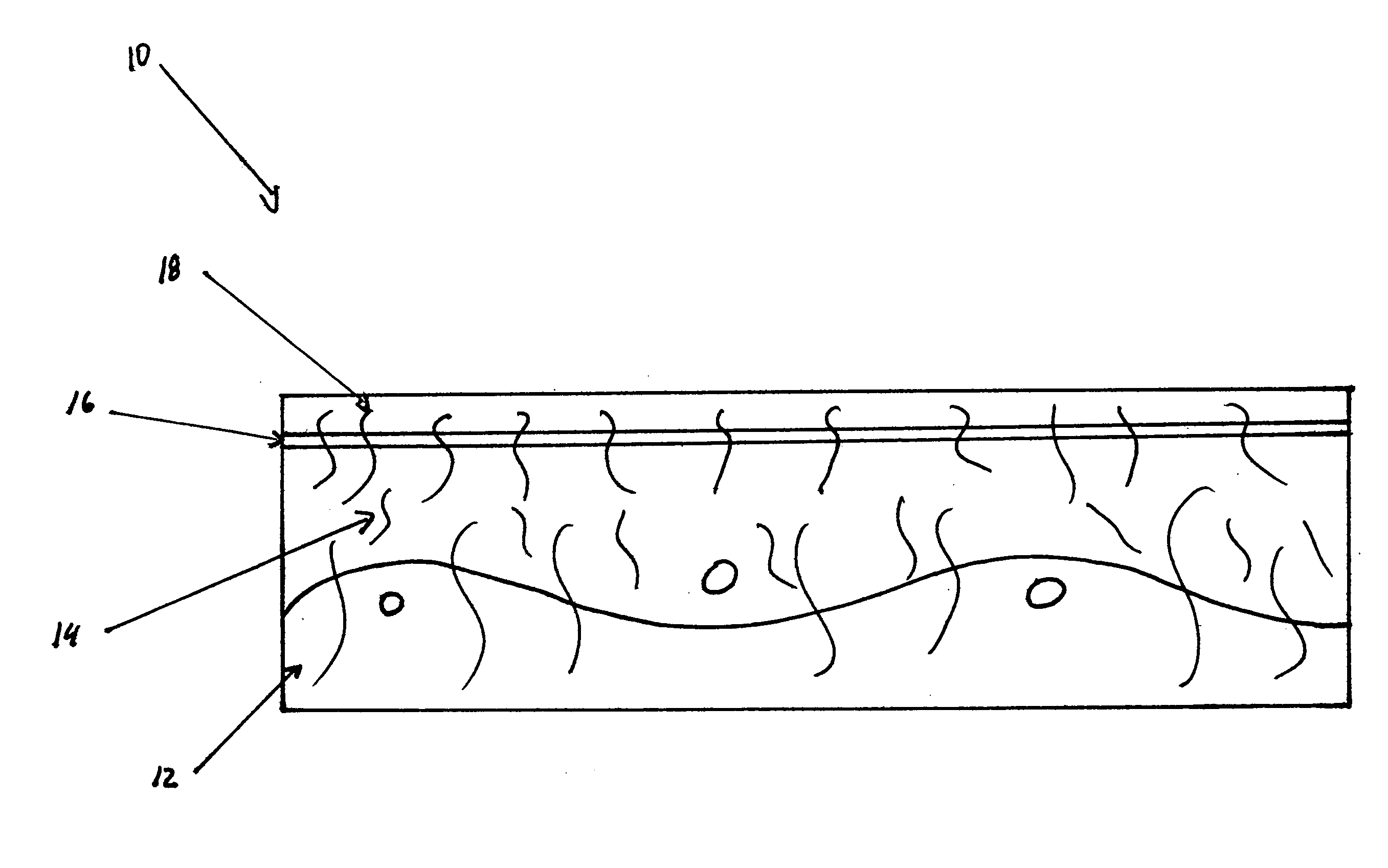

Fabrics with multi-segment, paired, interchanging yarns

ActiveUS20060219312A1Reduce thicknessReduce void volumePaper/cardboardMachine wet endWeft yarnEngineering

A composite forming fabric (10) comprising a paper side layer (12) having a paper side surface, a machine side layer (14) having a bottom wear side surface, and a plurality of pairs of first and second intrinsic, interchanging weft binder yarns (16, 18, 20, . . . 34) for binding together the paper side layer (12) and the machine side layer (14). At least of said plurality of pairs of first and second intrinsic, interchanging weft binder yarns have at least four segments (S1-S4) in the paper side layer (12) within each repeat of the weave pattern in the fabric, and these segments provide an unbroken weft path in the paper side surface. Each of the first and second intrinsic, interchanging weft binder yarns (16, 18, 20, . . . 34) of each binder pair having at least four segments (S1-S4) in the paper side layer (12) within each repeat of the weave pattern binds to at least one warp yarn (2-20) in the machine side layer (14) vertically underlying one of the segments (S1-S4).

Owner:VOITH PATENT GMBH

Process for preparing high performance copper-clad polytetrafluoroethylene plate

InactiveCN1586876AReduce void volumeLow dielectric dissipation factorSynthetic resin layered productsCopper foilPTFE - Polytetrafluoroethylene

The preparation process of novel high performance copper-clad PTFE plate includes the following steps: preparing inner layer of glass fiber fabric; preparing outer layer of glass fiber fabric; and cladding copper foil on two sides of the outer layer of glass fiber fabric. The copper-clad PTFE plate of the present invention has excellent electric performance, heat performance and mechanical performance, high bending strength, high size stability and high comprehensive performance.

Owner:SOUTH CHINA UNIV OF TECH

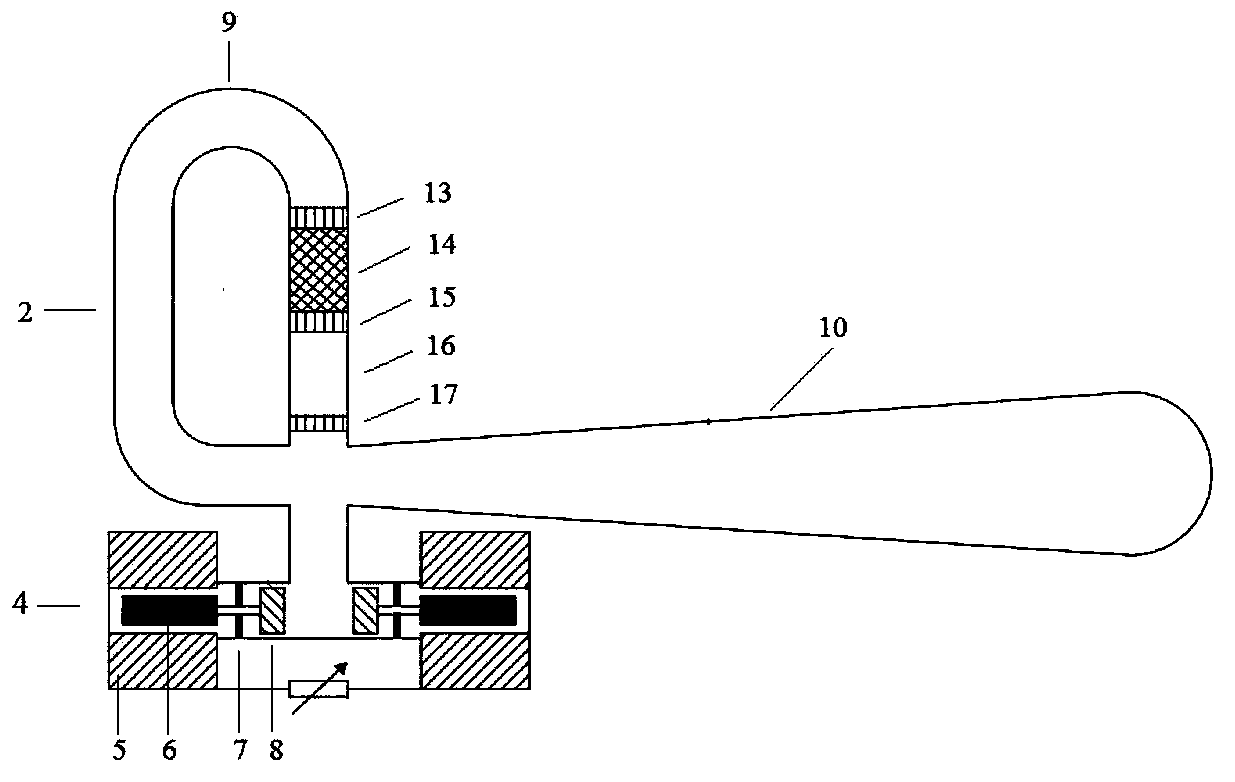

Screw thread welding integral narrow slit type cold junction for coaxial pulse-tube refrigerator

InactiveCN101298948AIncrease the heat exchange areaSmall pressure lossCompression machinesGas cycle refrigeration machinesCopper wirePulse tube refrigerator

The invention discloses a thread weld integral slit type cold head of the coxial vessle refrigerator in the refrigeration technology field, including an upper cold head, a lower cold head, a cold end baffle and a copper wire, wherein the upper cold head and the lower cold head are welded again after the threaded connection, the cold baffle is arranged at the middle of the cold head integer, and the cold baffle is filled with the copper wire, wherein the lower cold head is divided into a base seat and a boss having the uniformly distributed slots in the axial symmetry. The depth of the slot is the same with the height of the boss, and the external thread is arranged at the cirumferential of the base seat; a cylinder is arranged on the upper cold head, a round hole at the center and radial slots in the distributed uniformly arranged at the cirumferential of the round hole. The width of the slot is consistent with the slot of the lower cold head; the internal thread structure of the upper cold head is matched with the external thread of the lower cold head, with the other end in the thread match with the cold accumulator, and is left with the margin for welding after being matched. The invention has large heat exchange area, and the welding structure ensures the leak detection safety of the pressure gas the welding reliability.

Owner:SHANGHAI JIAO TONG UNIV

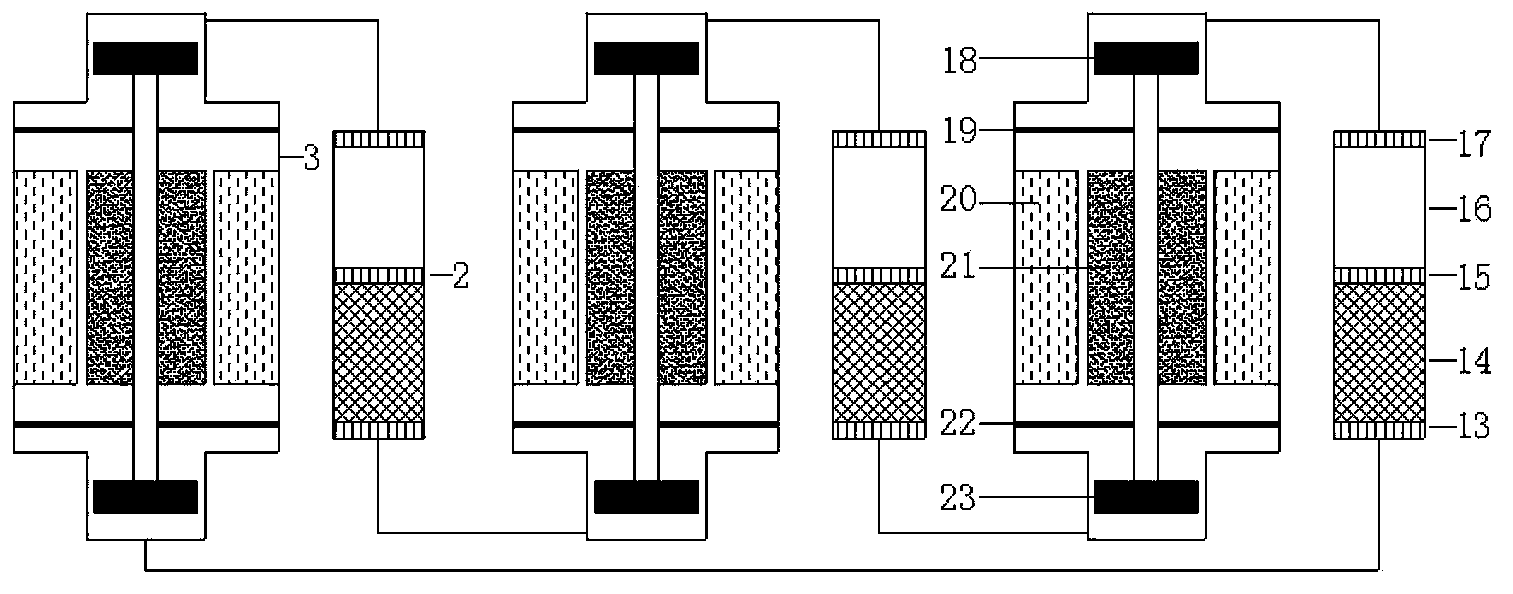

Linear double-acting thermo-acoustic power generation system

ActiveCN103352817AImprove efficiencyImprove voiceMachines/enginesMechanical power devicesEngineeringToxic industrial waste

The invention provides a linear double-acting thermo-acoustic power generation system. The linear double-acting thermo-acoustic power generation system is composed of N thermo-acoustic engines and N-1 linear double-acting generators, wherein the thermo-acoustic engines and the linear double-acting generators are sequentially connected in series between the linear compressor and a linear generator at intervals. The linear compressor is arranged at the initial end of the system and the linear generator is arranged at the tail end of the system. The linear compressor and the linear generator are both work with a single piston. Two pistons of each linear double-acting generator can work at the same time. N is a positive integer ranging from 2 to 20. A resonant tube structure is removed in the system so that the empty size of the system is greatly reduced, power density is improved, and frequency characteristics of linear motors at the two ends of the thermo-acoustic engine are adjusted to achieve required phases. The acoustic power generated by the thermo-acoustic engine is not consumed by the resonant tube, but absorbed by expansion pistons of the linear motors and a higher efficiency is obtained. In addition, a heat source of the thermo-acoustic engine can utilize low-grade energy sources such as solar energy, industrial waste gas and smoke, and the energy utilization rate is improved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Heat-sealing method and apparatus for fiber sheets

InactiveUS6713726B2Reduce void volumeReliable heat sealingMechanical working/deformationLaminationFiberEngineering

Owner:UNI CHARM CORP

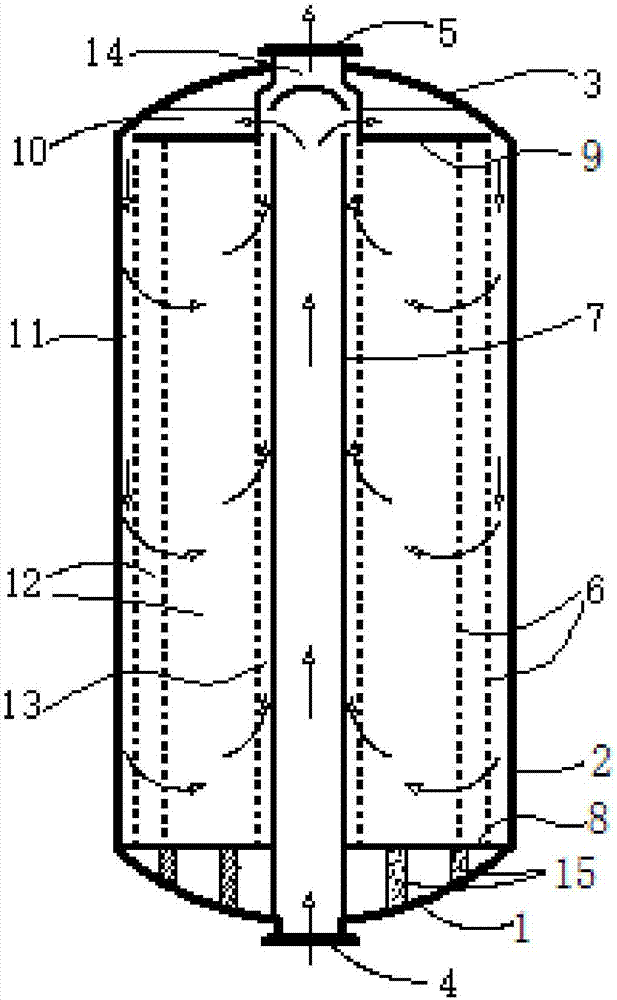

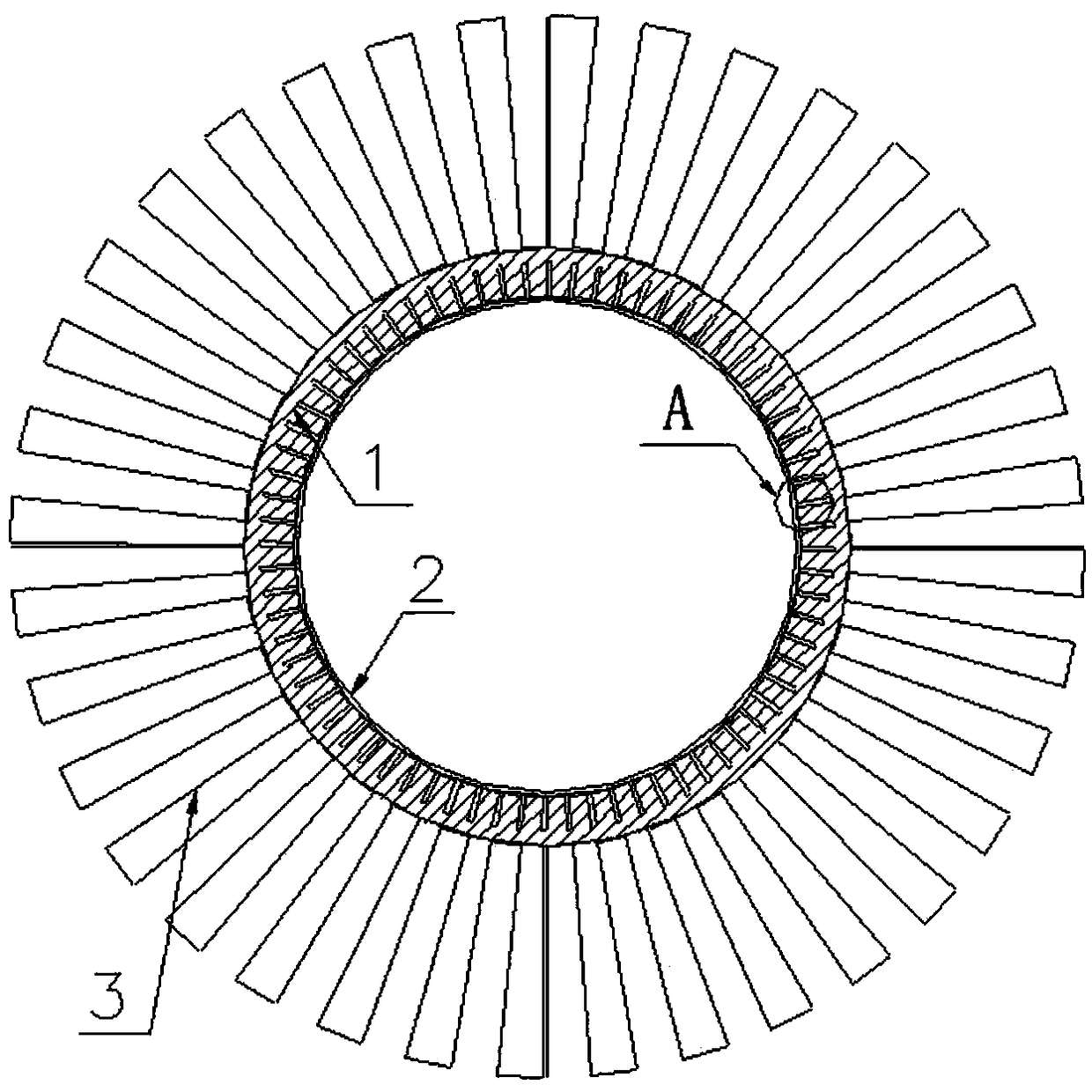

Novel radial flow adsorption tower for pressure swing adsorption

ActiveCN107126814AEvenly distributedReduce driftGas treatmentDispersed particle separationEngineeringTower

The invention provides a novel radial flow adsorption tower for pressure swing adsorption, and belongs to the technical field of adsorption tower. The novel radial flow adsorption tower comprises an upper seal head, a lower seal head, a tower cylinder body, an isolation drum and a center pipe, wherein the tower cylinder body, the isolation drum and the center pipe are distributed in a concentric circle way; an annular outer passage is formed between the outer drum wall of the isolation drum and the tower cylinder body, and an annular inner passage is formed between the inner drum wall of the isolation drum and the outer wall of the center pipe; a flow distributing pipe and an air exhaust pipe are arranged at the top part of the interior of the adsorption tower, the flow distributing pipe is used for communicating the center pipe and the annular outer passage, and the air exhaust pipe is connected and communicated with the annular inner passage; air flow hole passages are distributed on a drum body of the isolation drum, and an adsorbent is filled into the drum body. The novel radial flow adsorption tower has the advantages that the raw gas is guided into the annular outer passage by the center pipe passage via the flow distributing pipe, flown into the adsorbent layer in the radial way, and sent into the annular inner passage after adsorbing and separating; the gas flows outside the adsorption tower and in the inner passage to form the U-shaped flowing type, so that the change trends of static pressures in the inner passage and the outer passage are basically the same in the axial flowing direction of gas flow, and the uniform distribution of the gas flow is realized.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

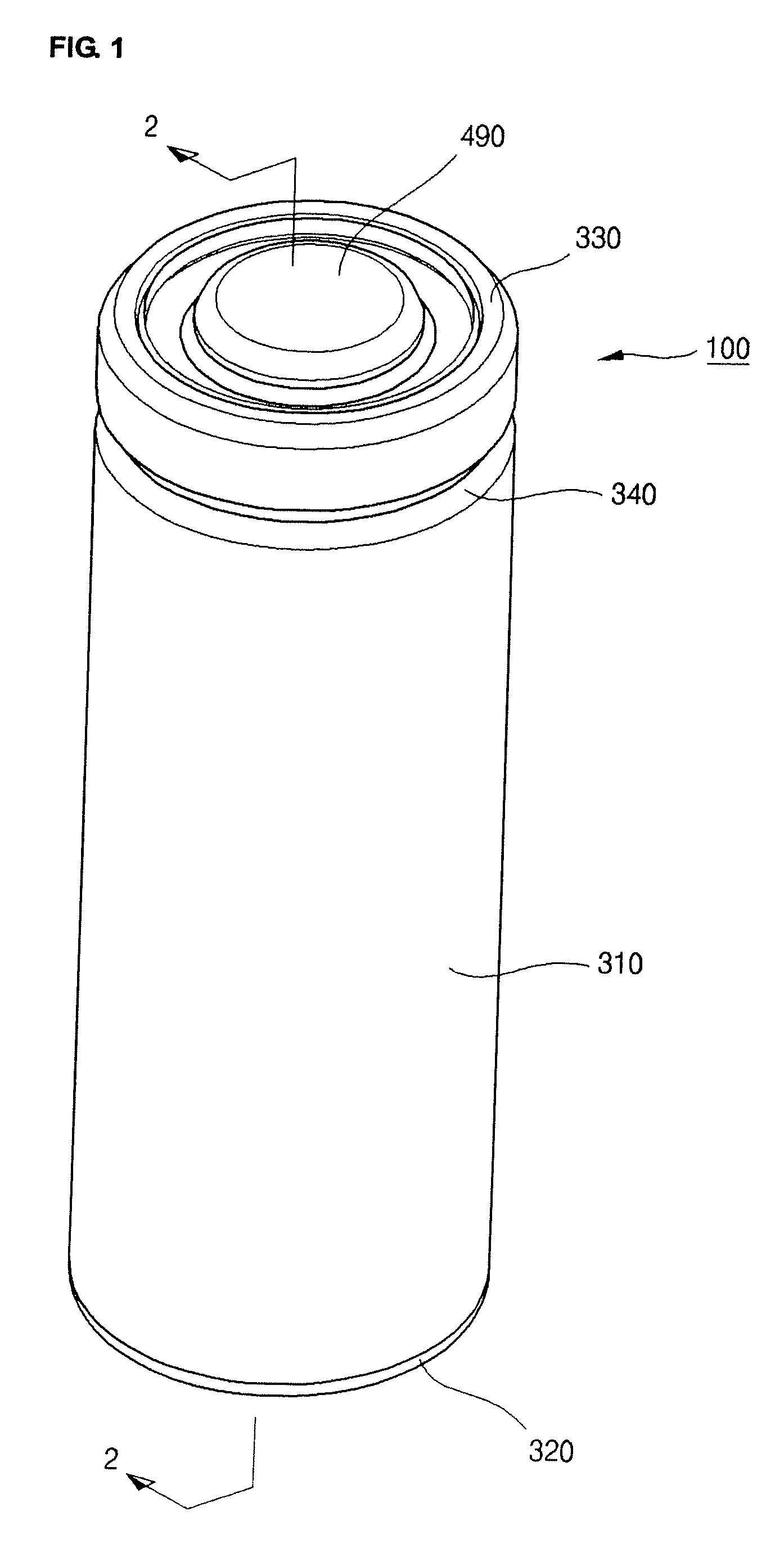

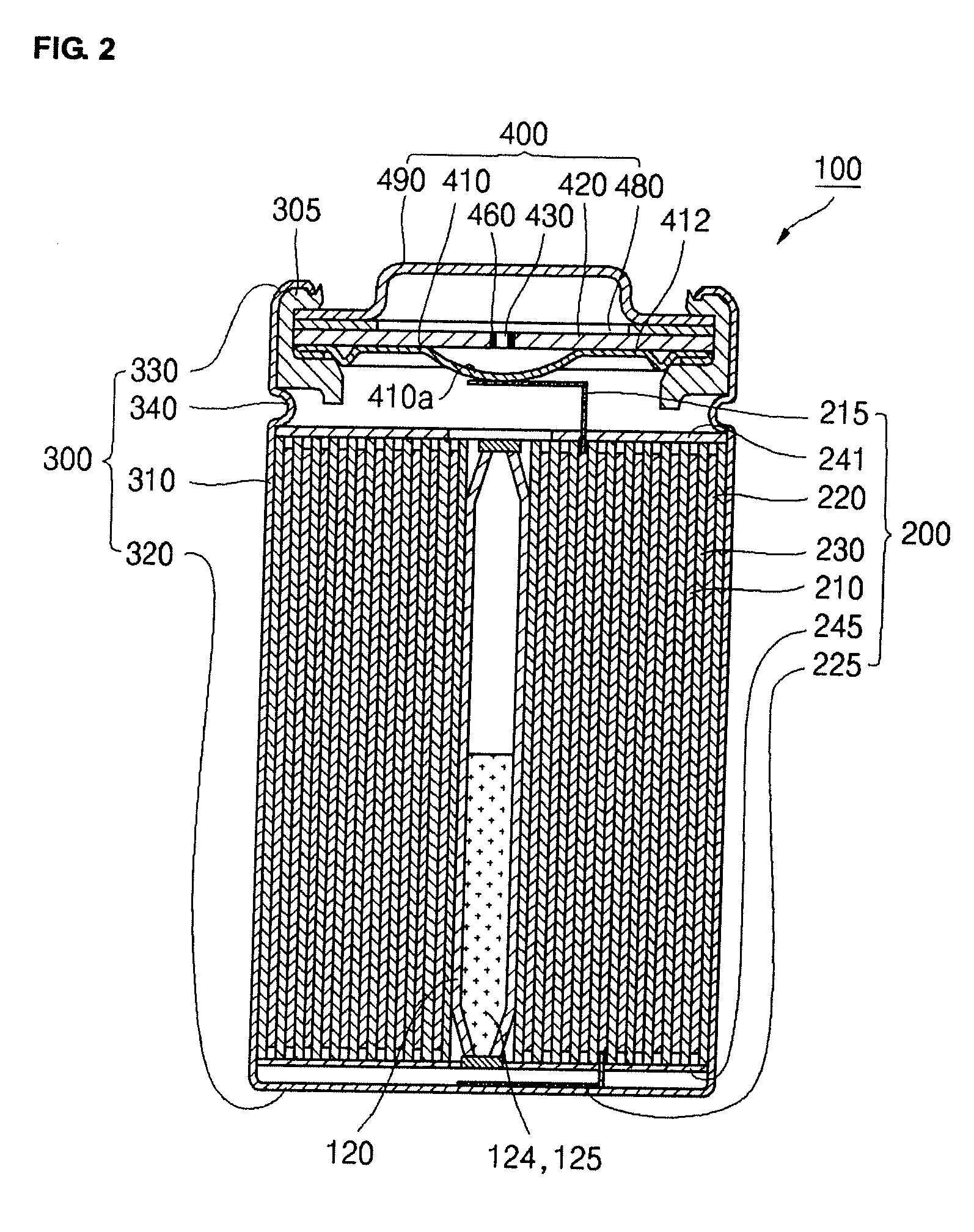

Lithium Rechargeable Battery

ActiveUS20090246605A1Improve securityReduce void volumeFinal product manufactureCell temperature controlLithiumEngineering

Lithium rechargeable batteries having functional center pins are provided. A lithium rechargeable battery has a center pin whose top and bottom ends are blocked by a thermal cut-off composition to reduce the void volume inside a bare cell during initial overcharge. The thermal cut-off composition melts at a temperature within a specific temperature range, e.g. between about 80 and about 250° C. This prevents the battery from exploding and igniting. Thus, the inventive lithium rechargeable batteries have improved thermal stability.

Owner:SAMSUNG SDI CO LTD

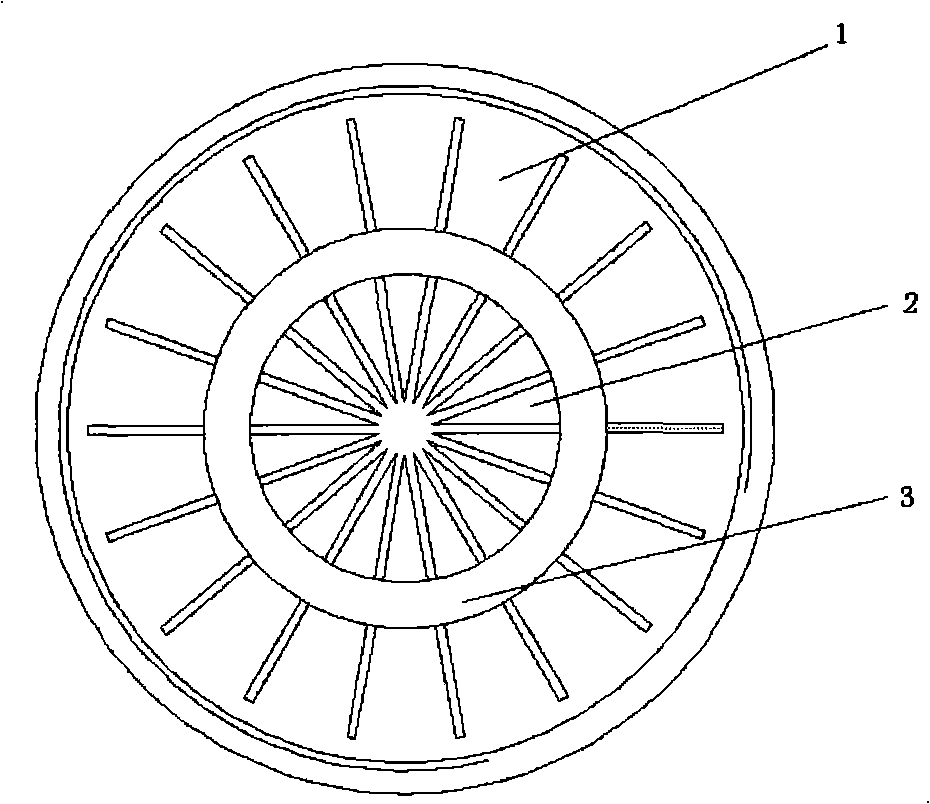

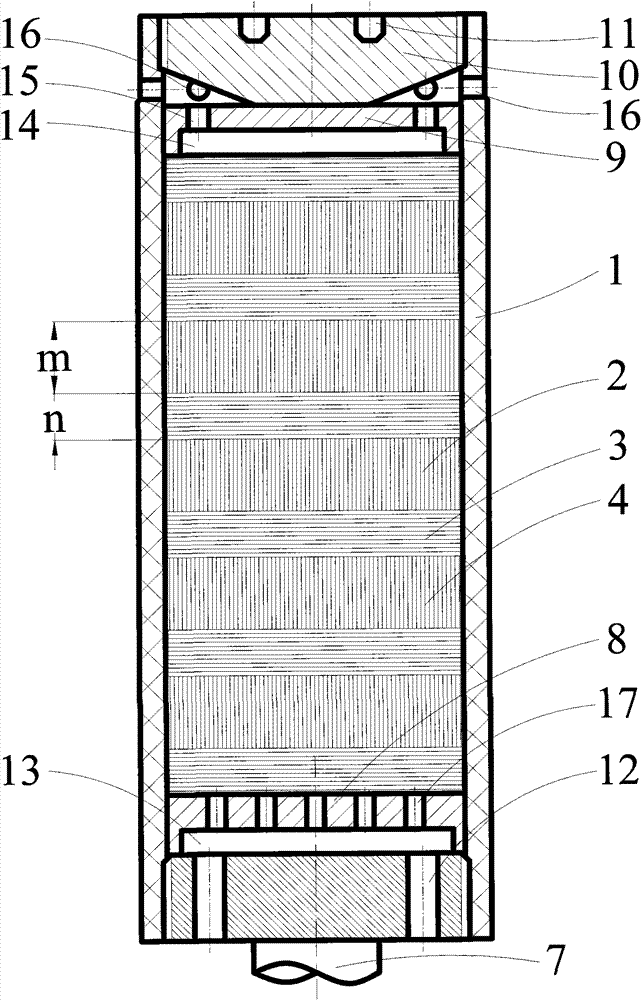

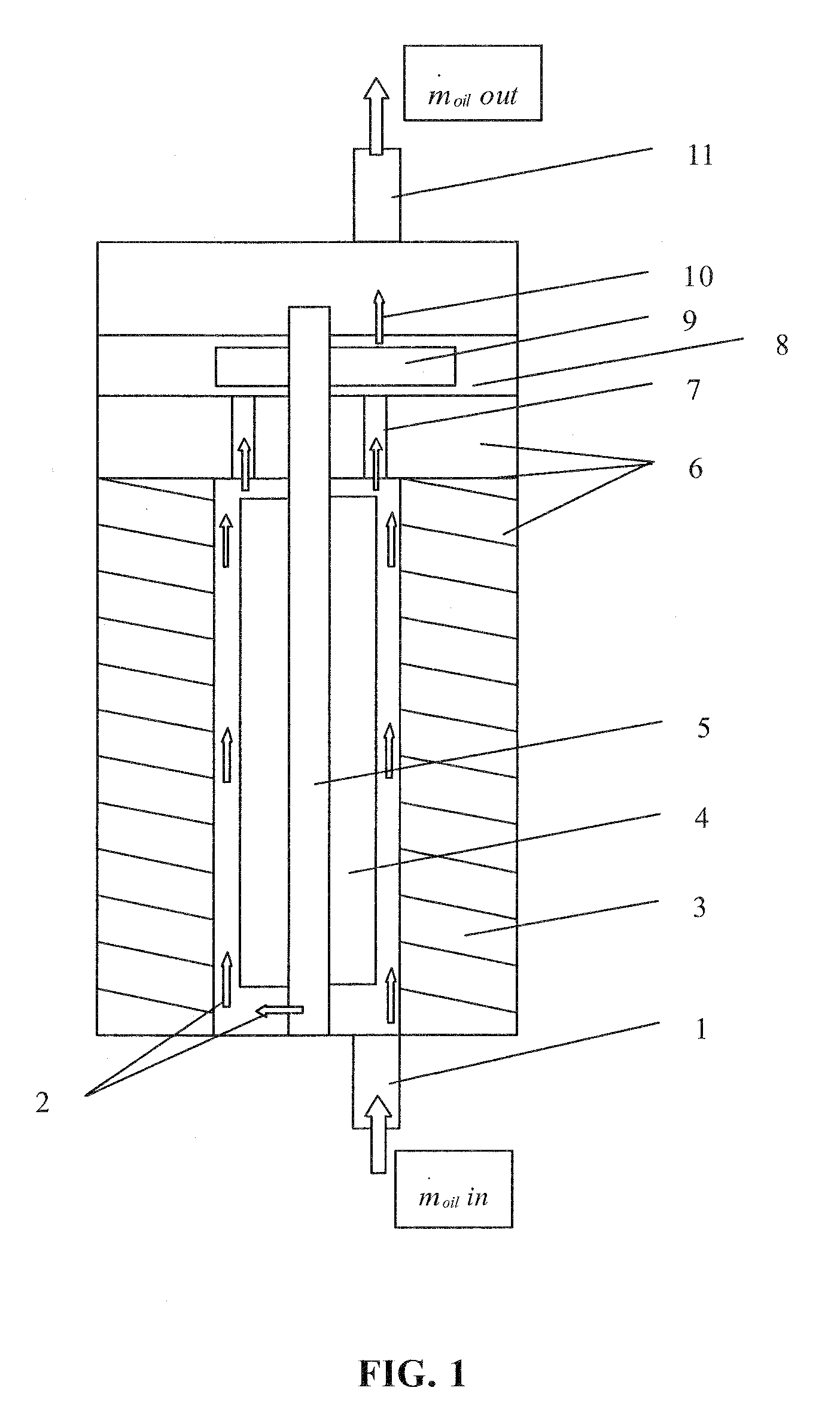

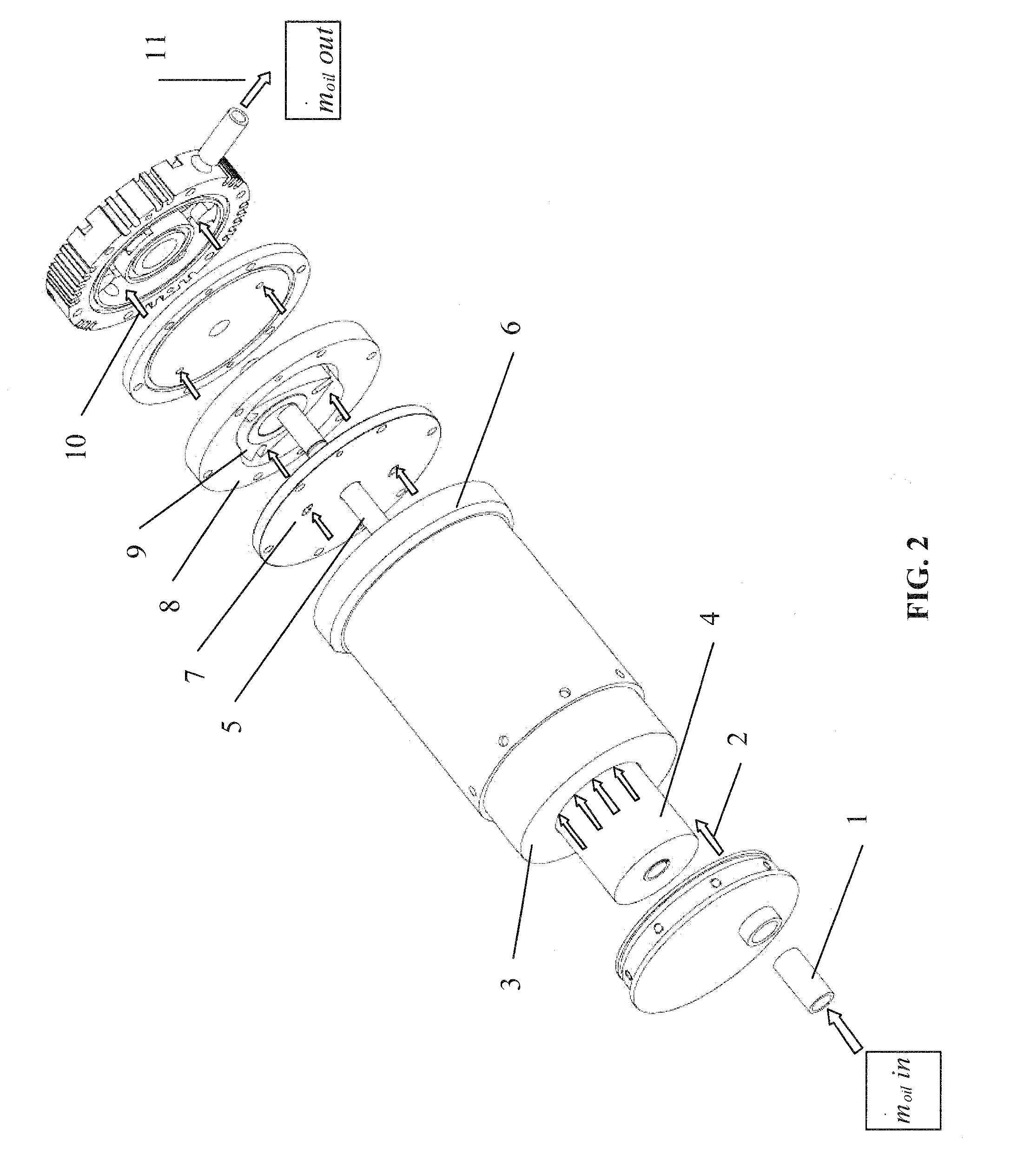

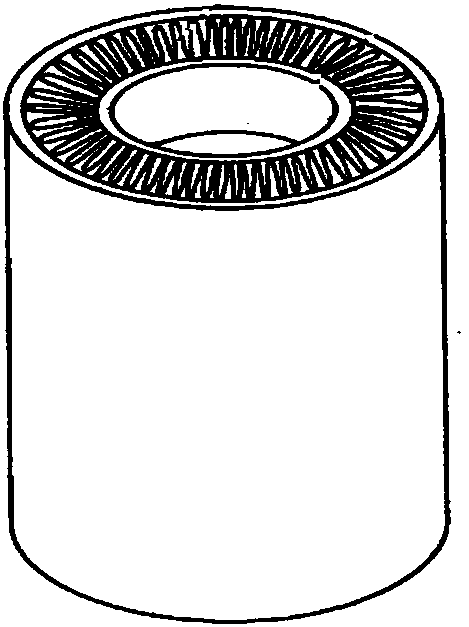

Heat regenerator of heat-regenerating type low-temperature refrigerator

ActiveCN101799229BReduce void volumeSmall empty volumeSuperheatersEngineeringRefrigerated temperature

The invention discloses a heat regenerator of a heat-regenerating type low-temperature refrigerator, which comprises a sleeve of a heat regenerator and a filler of the heat regenerator. The heat regenerator is characterized in that the sleeve of the heat regenerator is firstly filled with the radial filler and secondly filled with the axial filler, which are alternately filled, and finally with the radial filler; the radial filler is formed by tightly paving and overlapping 20-40 pieces of circular metal nets layer by layer, wherein the diameter of each piece of the circular metal net is equal to the inner diameter of the sleeve of the heat regenerator; the axial filler is formed by tightly winding through a square metal net piece along an edge metal wire; and the radial filler and the axial filler are tightly contacted with the inner wall of the sleeve of the heat regenerator. The depth m of the axial filler is larger than the depth n of the radial filler, and the voidage of the axial filler is less than that of the radial filler. The heat regenerator can realize high heat regenerating efficiency, low flow resistance, small axial heat-guiding loss and smaller empty cubage, and greatly improves the efficiency of the heat-regenerating type low-temperature refrigerator.

Owner:江苏热声机电科技有限公司

Method and apparatus for orientation independent compression

ActiveUS20100132382A1Adequate oil-vapor mixture velocityMinimizing internal volumeCompressorFlexible member pumpsPolyesterWorking fluid

The subject invention pertains to a method and apparatus for an orientation independent compressor. The subject compressor can be part of a vapor compression cycle system, and can use one or more of a variety of working fluids, including, but not limited to, refrigerants such as r-134a, r-22, CO2, and NH3. Embodiments of the compressor can utilize positive displacement means to compress the vapor. In a specific embodiment, the compressor can incorporate an oil-lubricated rotary lobed type positive displacement compressor. In a further specific embodiment, the working fluid can be a refrigerant, such as r-134a, incorporating entrained oil, such as miscible lubricating oils. An example of such a miscible lubricating oil that can be used is polyester (POE) oil.

Owner:RINI TECH

Sintered sprocket

InactiveUS6670048B2Improve surface pressure resistanceReduce void volumePig casting plantsExtrusion containersMetallurgySprocket

A sintered sprocket is provided in which surface pressure resistance can be improved without using a forging processing. An Fe-based sintered alloy which contains C at 0.2 to 0.5% by weight, Mo at 0.2 to 1.0% by weight, and Ni at 0.2 to 1.0% by weight, and which exhibits a metallic structure in which an internal base layer comprises ferrite and bainite and in which the ferrite adjoins voids, is subjected to a rolling and is then subjected to carburizing and hardening.

Owner:HONDA MOTOR CO LTD

Wound treatment material

The invention discloses a wound treatment material which comprises a fiber. The wound treatment material is characterized in that the fiber comprises a polymer shown as the following structural formula (please see the formula in the description), wherein R is at least one selected from a group composed of -NH2, -OCH2CH2OH, -OCH2CH2CH2OH, -OH, -ONa, -OK and -OCa, m, n and p represent the quantity percentages of corresponding repetitive units in a polymer molecule respectively and meet the following relational expressions that m+n+p=1 and p / (m+n+p)=0.05-0.30, the substitution degree D is defined to be equal to m / (m+n+p), the overall substitution degree of the fiber is defined as Ds, the substitution degree of the polymer at the center point of the cross section of the fiber is defined as Do, the substitution degree of the polymer at the edge of the cross section of the fiber is defined as Dx, and Ds, Do and Dx meet the following relational expressions that Ds=0.09-0.8 and Do / Dx=0-0.7.

Owner:JIANGSU NEWVALUE MEDICAL PROD CO LTD +1

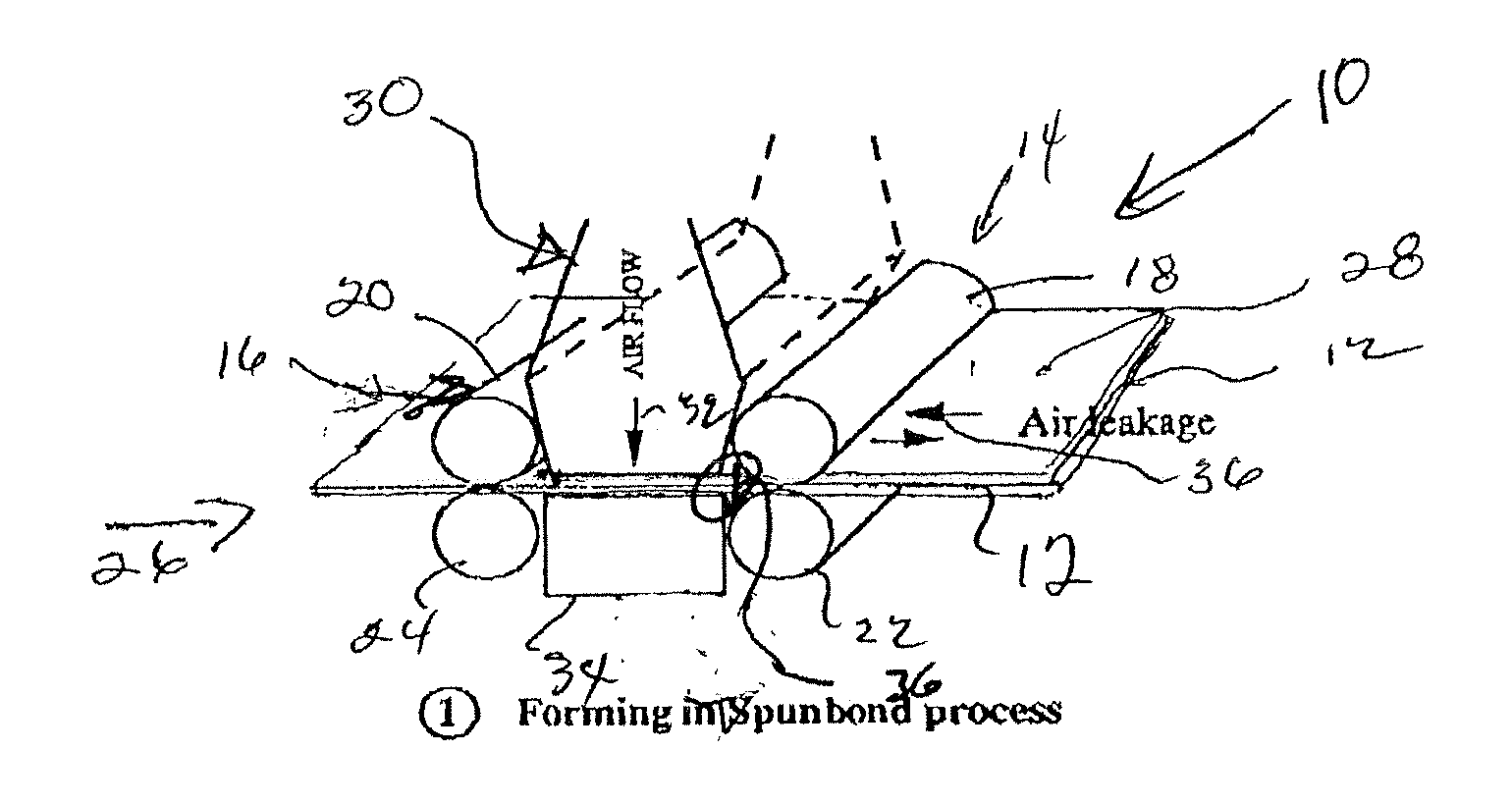

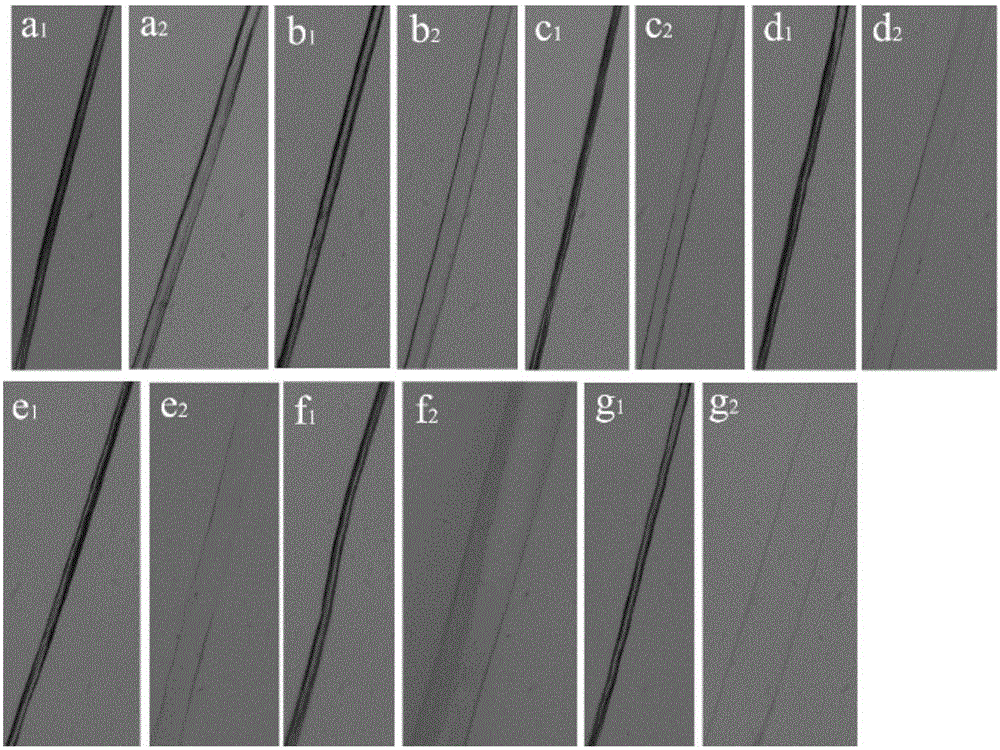

Fabric Comprising Shaped Conductive Monofilament Used in the Production of Non-Woven Fabrics

InactiveUS20110121481A1Minimize air leakageMinimizes and eliminates web flutterLiquid surface applicatorsCeramic shaping apparatusYarnBonding process

In an apparatus for the production of a non-woven web, structure, or article using a spun-bonding process in combination with a forming fabric which is woven having flat CMD yarns, flat MD yarns or both with some or all of such yarns being conductive so as to dissipate static electricity.

Owner:MONNERIE JEAN LOUIS +1

Hemostatic material

ActiveCN106267305ASimple processLow costSurgical adhesivesPharmaceutical delivery mechanismFiberMedicine

The invention aims to provide fiber suitable for clinical application, in particular to the application of hemostasis, scalding, chronic wound treatment and others. The invention is a hemostatic material, wherein the hemostatic material includes fiber, and the material is possessed of biodegradability; the hemostatic material is characterized in that the fiber includes a polymer expressed by the following structural formula: FORMULA, wherein R is at least one of groups consisting of -NH2, -CH2CH20H, -OCH2CH2CH2OH, -OH, -ONa, -OK, -OCa; m, n and p respectively represent the quantity percent of corresponding repeat unit in the polymer molecule and can meet the following relationship formula: m+n+p=1, p / (m+n+p)=0.05-0.30; the degree of substitution D is defined as m / (m+n+p), the total degree of substitution of fiber is defined as Ds, and the degree of substitution of polymer at the center of the fiber cross section is defined as D0; when the degree of substitution of the edge of the fiber cross section is defined as D, the following relationship formula can be satisfied: Ds=0.09-0.8, Do / D=0-0.7.

Owner:JIANGSU NEWVALUE MEDICAL PROD CO LTD +1

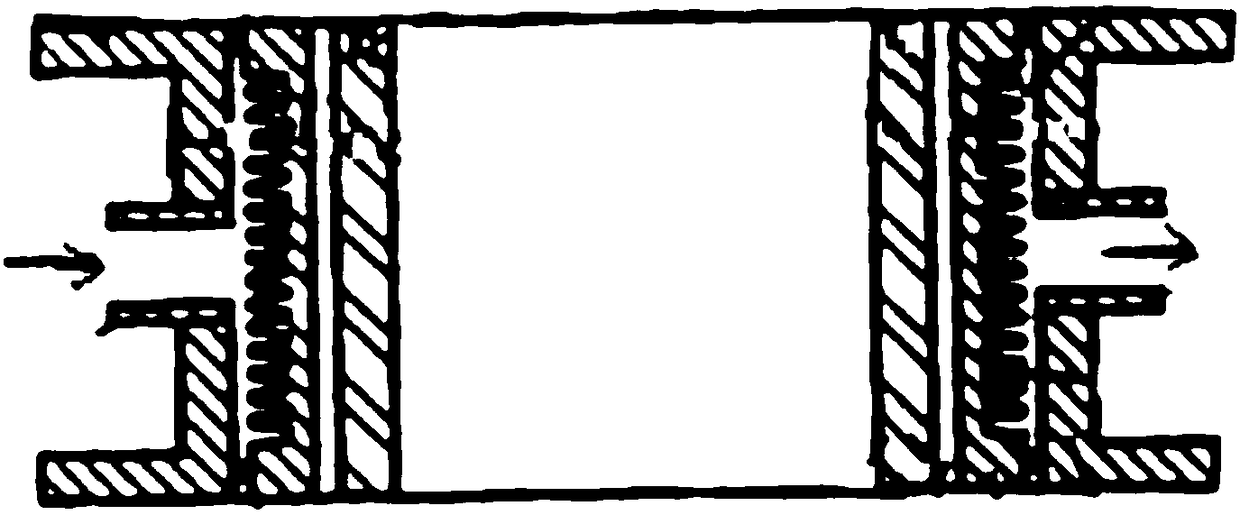

Heat exchanger provided with annular slots and used for sound-energy refrigerating machine

PendingCN108195214AImprove cooling effectImprove heat transfer coefficientCompression machinesIndirect heat exchangersInterference fitSound energy

The invention discloses a heat exchanger provided with annular slots and used for a sound-energy refrigerating machine, and belongs to the technical field of heat exchangers. The heat exchanger provided with the annular slots and used for the sound-energy refrigerating machine comprises an inner rib body and an inner sleeve. The inner rib body is an annular cylinder with the inner annular surfaceopen towards the outer annular surface. The inner sleeve is arranged in the inner rib body in a sleeved mode and is in interference fit with the inner rib body. The multiple slots are formed in the inner annular surface of the inner rib body at intervals, so that a slot channel allowing air to flow therein is formed between the inner rib body and the inner sleeve. According to the heat exchanger provided with the annular slots and used for the sound-energy refrigerating machine, forced-convection heat change between alternately-flowing working medium gas and the inner wall of the heat exchanger is achieved, and the heat exchange coefficient is large; in the heat conduction direction towards the outside, through interference fit between the inner rib body and the inner sleeve as well as a welding structure of the inner rib body and outer fins, contact heat resistance is eliminated; and in addition, the inner rib body is made of red copper with small heat conduction resistance, and thusthe heat exchanger provided with the annular slots in the hot end has a good cooling effect.

Owner:陕西仙童科技有限公司

Industrial fabric having a layer of a fluoropolymer and method of manufacture

InactiveUS20050136763A1Reduced dimensionHigh degree of controlFibre treatmentSynthetic resin layered productsFluoropolymerContamination

The present invention is directed to an industrial fabric that is rendered contamination resistant and maintains good permeability as a result of a durable anti-contaminate material that lasts the entire life of the fabric. A fluoropolymer material will render the fabric contamination resistant over the entire fabric lifetime.

Owner:ALBANY INT CORP

Automobile dashboard crossbeam transfer device

The invention discloses an automobile dashboard crossbeam transfer device, which consists of an underframe and a supporting frame, wherein the underframe comprises an underframe body, four underframe upright posts and four upright post connecting pieces; the supporting frame comprises a supporting frame body and four supporting frame upright posts; the upper part of each underframe upright post is provided with upright post connecting pieces connected into a whole; and each supporting frame upright post of the supporting frame is rotationally connected with a corresponding connecting piece of the underframe. When an automobile dashboard crossbeam is not arranged on a transfer rack, the automobile dashboard crossbeam transfer device with the structure can be folded and stacked, the vacant volume of the transfer rack is reduced, and the inventory cost and the logistics cost are reduced.

Owner:ANHUI DACHANG TECH

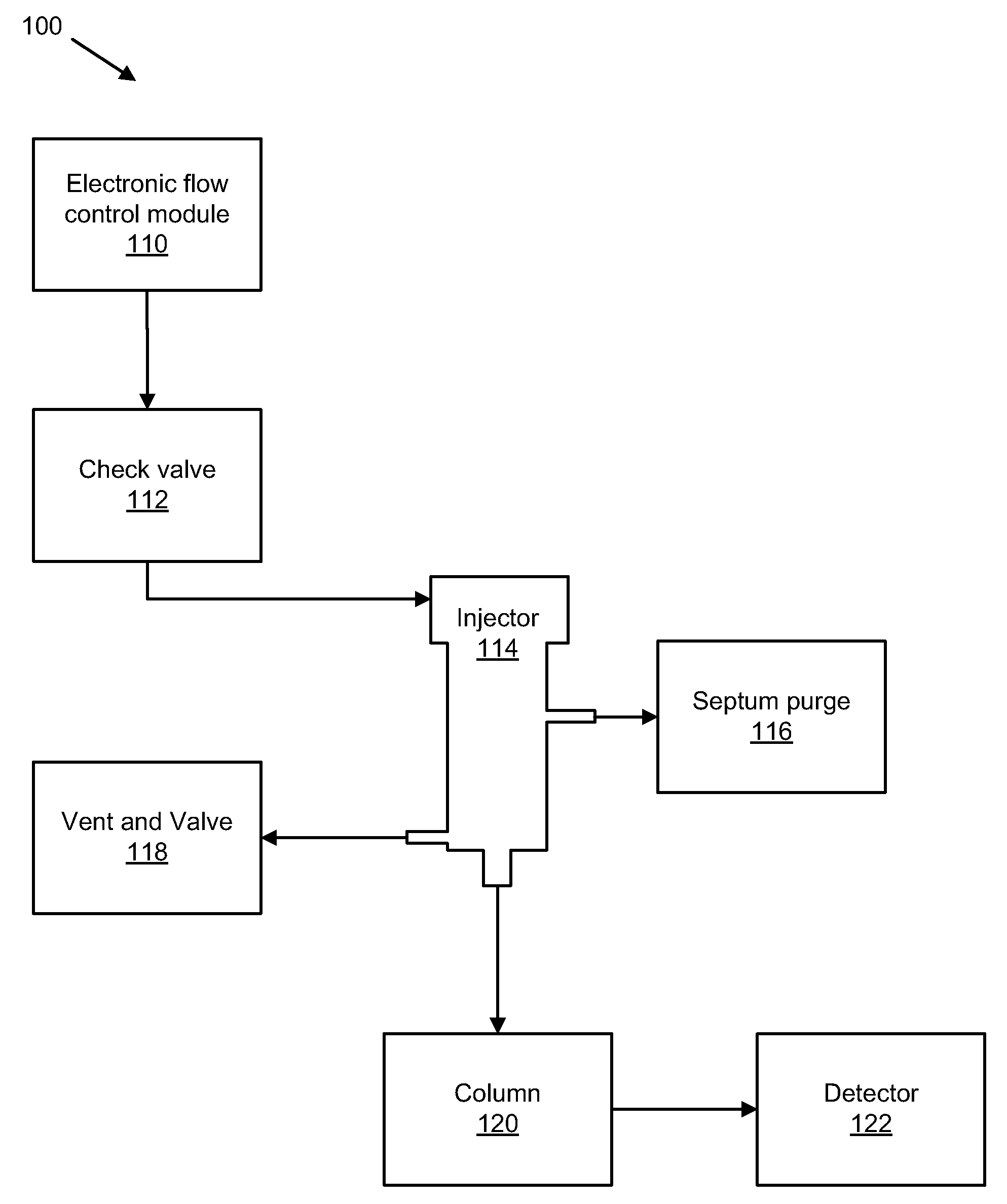

Gas chromatography check valve and system

ActiveUS20100251896A1Reduce void volumePrevent backflowComponent separationDispersed particle separationLine tubingGas liquid chromatographic

An apparatus, system, and method are disclosed for a gas chromatography (GC) system with a check valve. The check valve is situated downstream from the electronic flow control module and upstream of the injector. When a sample is volatized in the injector, the check valve closes into a checked position and prevents solvent and sample from backing into the gas delivery line. In certain embodiments, the check valve has a conical plug that fits into a seat that has an aperture. When the conical plug is depressed, the conical plug engages the sides of the aperture and seals the check valve, preventing solvent and sample from backing through the check valve. In certain embodiments, the change in pressure caused by over-pressurization in the injector, combined with the force applied by a spring on the conical plug, depresses the plug such that it seals the aperture.

Owner:BRUKER DALTONIK GMBH & CO KG

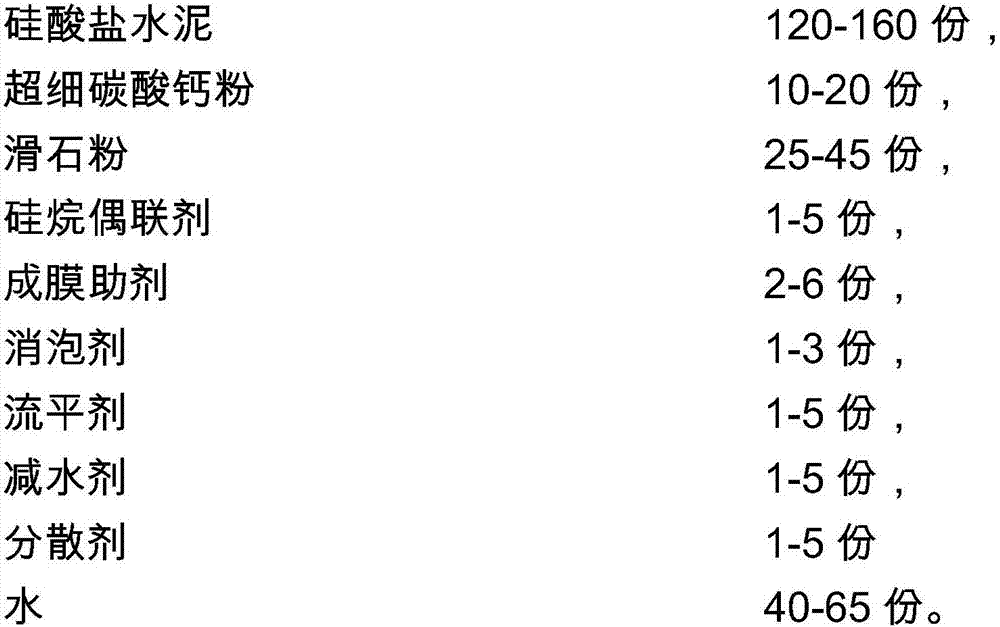

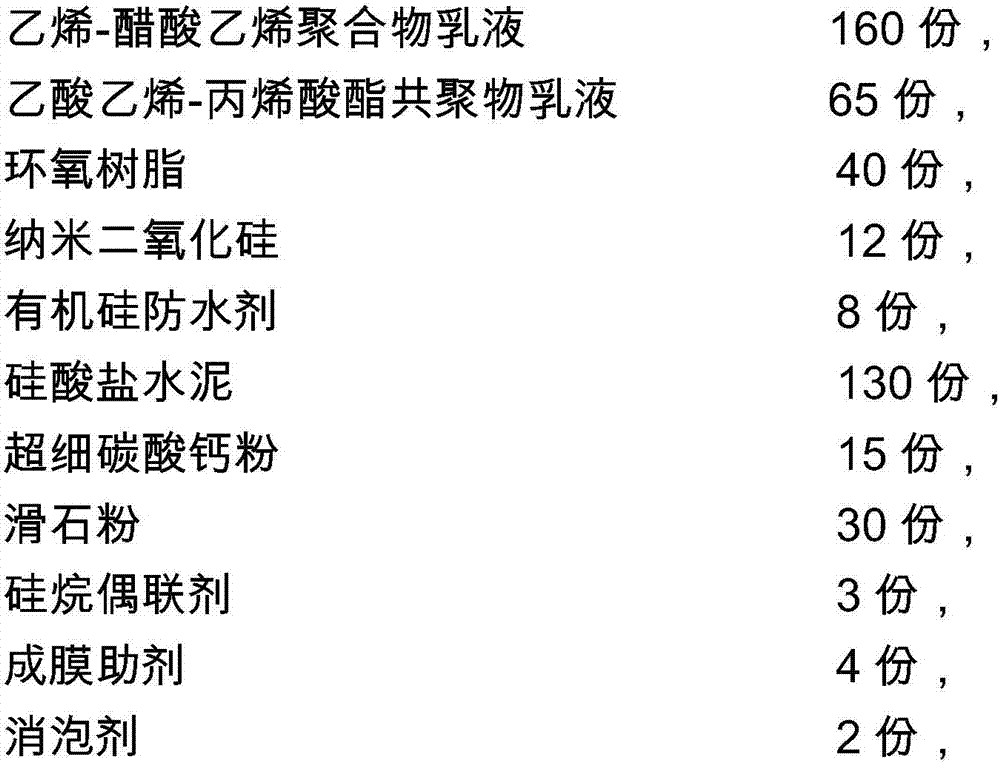

Polymer cement-based waterproof coating

InactiveCN107964287AHigh strengthImprove physical organizationEpoxy resin coatingsEpoxyPolymer science

The invention discloses a polymer cement-based waterproof coating. The polymer cement-based waterproof coating comprises an ethylene-vinyl acetate polymer emulsion, a vinyl acetate-acrylate copolymeremulsion, epoxy resin, nanometer silicon dioxide, an organic silicon waterproof agent, Portland cement, ultrafine calcium carbonate powder, talcum powder and filming additives. Through use of the mixed emulsion of the ethylene-vinyl acetate polymer emulsion and the vinyl acetate-acrylate copolymer emulsion, good synergistic promoting effects are obtained, the compactness and mechanical propertiesof the polymer waterproof coating are improved, elasticity is good, elongation is good, anti-permeability, durability and aging resistance are good, a service life is long and waterproof effects are good.

Owner:SUZHOU BIZUNION ARCHITECTURAL ENG CO LTD

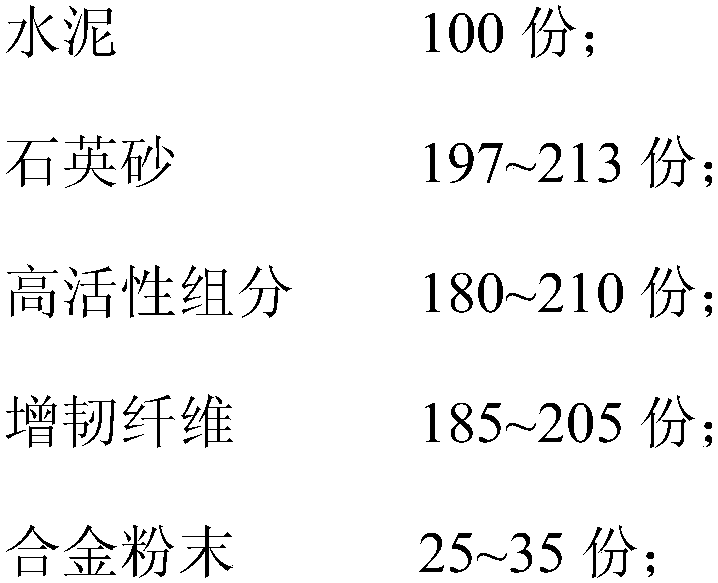

Eco-friendly composite concrete grinding body for grinding and preparation method thereof

The invention relates to an eco-friendly composite concrete grinding body for grinding and a preparation method thereof. The grinding body comprises 100 parts of cement; 197-213 parts of quartz sand;180-210 parts of high active components; 185-205 parts of toughening fibers; 25-35 parts of alloy powder; the high active components include any one of silicon powder, construction waste reclaimed powder, zeolite powder, ferrite powder, nano graphene oxide and ceramic waste powder, or combination of at least two kinds of the above components; the toughening fibers include any one of steel fiber, silicon carbide fiber, calcium carbonate whisker, basalt fiber and boron nitride fiber or combination of at least two kinds of the above fibers; the alloy powder includes aluminum zinc alloy powder and / or aluminum titanium alloy powder. The grinding body integrates high strength, high toughness, high hardness, high durability, low cost, and ecological and environmental protection as a whole, and the grinding body has universality and is applicable to design and development of various wear-resistant composite products.

Owner:广州基业长青新材料股份有限公司

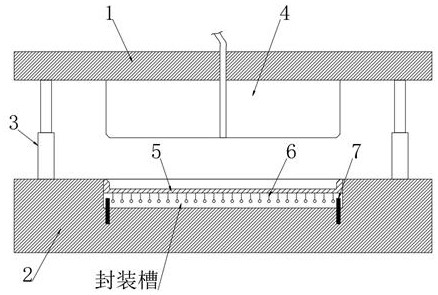

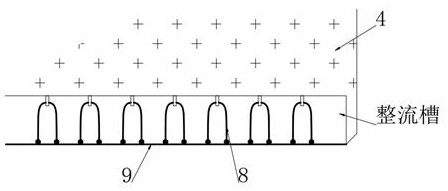

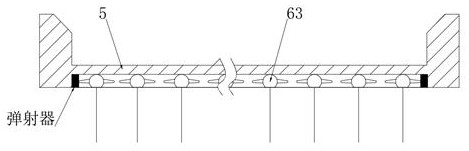

Transmission type chip packaging device

ActiveCN113601773AReduce void contentGuaranteed cooling effectSemiconductor/solid-state device manufacturingEpoxyMechanical engineering

The invention discloses a transmission type chip packaging device, and belongs to the field of chip packaging. The transmission type chip packaging device is characterized in that two electromagnetic plates are controlled to be powered on and powered off after molten epoxy resin is injected through arrangement of opposite control change ropes and a transmission magnetic guide module, the opposite control change ropes are gradually subjected to downward attraction force in the direction away from the electrified electromagnetic plates, downward pulling force is generated on recombination moving pieces, the recombination moving pieces are deformed towards a glue sealing layer, wave type extrusion force is generated on the glue sealing layer, internal gaps collapse, the molten epoxy resin is forced to be redistributed, and the gaps are effectively eliminated. Compared with the prior art, the chip packaging device has the advantages that the content of gaps in the glue sealing layer after curing is greatly reduced, and the heat dissipation performance of a chip after glue sealing and the use stability of the chip are effectively guaranteed.

Owner:南通鑫晶电子科技有限公司

Sand-stone terrazzo

InactiveCN106045387AReduce void volumeHigh strengthSolid waste managementTerrazzoUltimate tensile strength

The invention provides sand-stone terrazzo. The sand-stone terrazzo is prepared from the following raw materials in parts by weight: 300 parts of cement, 2-3 parts of sand and stones, 1.2 parts of glass granules, 1.5 parts of silica sand, 1.2 parts of shell granules, 7 parts of strength strengthening agent, 4 parts of polymer binder and water, wherein the grain size of the sand and stones is 5mm to 10mm, the glass granules are made from common glass through crushing and have the grain size of 3mm to 5mm, the silica sand has the grain size of 1.5mm to 3mm, granules of the silica sand are elliptical, the shell granules are made from shells through crushing and have the grain size of 1mm to 3mm, and the weight ratio of the water to the concrete is (1: 0.27) to (1: 0.33). According to the sand-stone terrazzo provided by the invention, the voidage generated during forming is low, the strength is high, and the dirt-removing power is improved; and due to the introduced polymer binder, the terrazzo has certain flexibility, is good in resistance to deformation and has relatively good freezing resistance.

Owner:江多忠

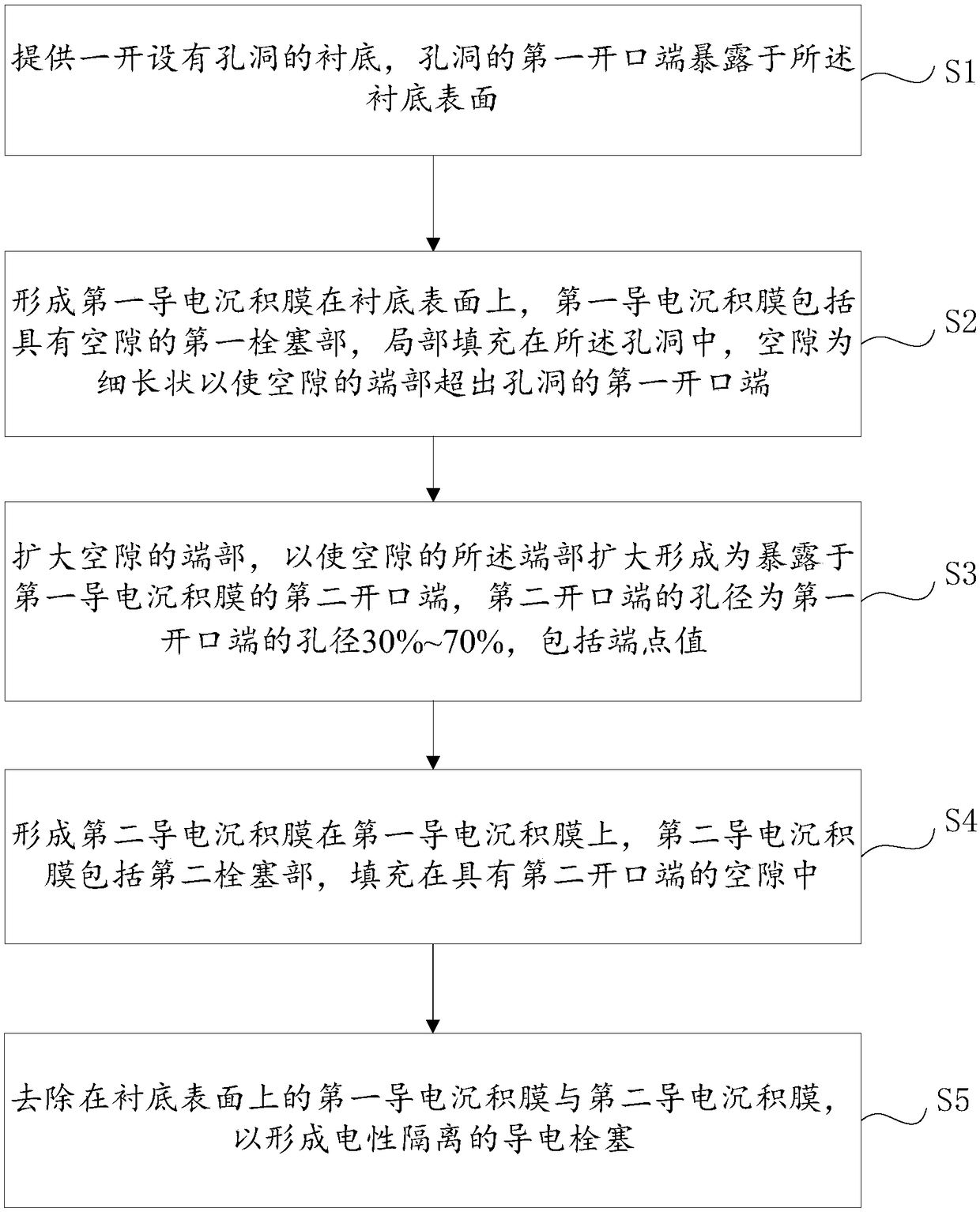

Preparation method of a conductive embolism and a semiconductor device with the conductive embolism

ActiveCN109256358ALower resistanceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesSemiconductorMaterials science

The invention discloses a preparation method of a conductive plug, comprising the steps of: providing a substrate with a hole, wherein a first open end of the hole is exposed to the surface of the substrate; forming a first conductive deposition film on the surface of the substrate, the first conductive deposition film including a first plug portion having a void partially filled in the void, thevoid being elongated such that the end of the void extends beyond the first open end of the void; enlarging an end portion of the void such that the end portion of the void is enlarged to be exposed to a second open end of the first conductive deposition film, the aperture of the second open end being 30% to 70% of the aperture of the first open end, including an endpoint value; forming a second conductive deposition film on the first conductive deposition film, the second conductive deposition film including a second plug portion filled in a gap having a second open end; and removing the first conductive deposition film and the second conductive deposition film on the surface of the substrate to form electrically isolated conductive plugs. The method reduces the volume of the voids or eliminates the voids so as to obtain a conductive plug with low resistance and high reliability.

Owner:CHANGXIN MEMORY TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com