Air bubble liquid membrane method for producing nanometer granule material

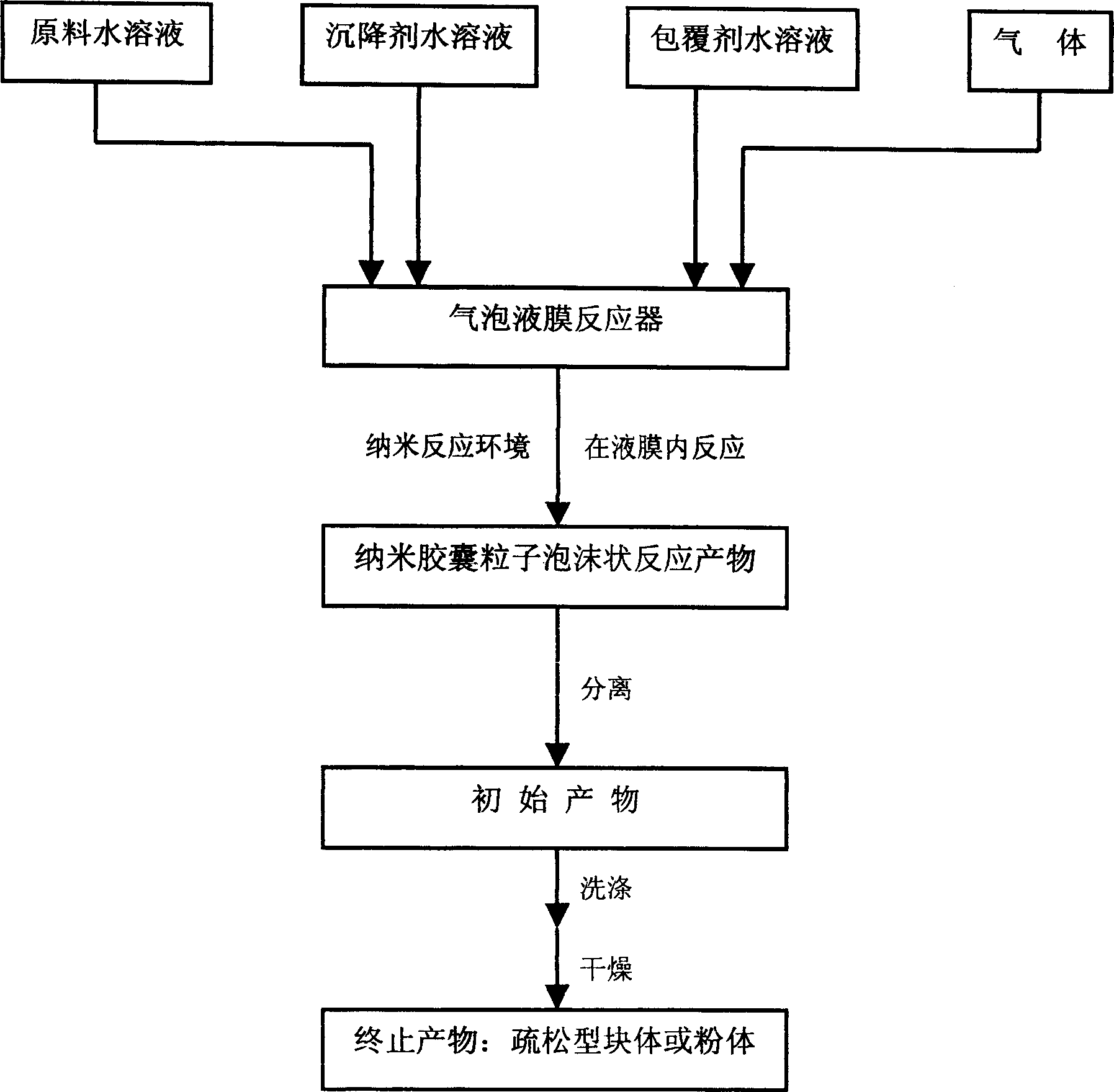

A technology of nanoparticles and bubbles, which is applied in chemical methods, chemical instruments and methods, chemical/physical/physicochemical processes, etc. to make liquids react with liquids, and can solve environmental pollution, in-situ surface modification, and equipment costs advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0080] Start the bubble-cap disc stirrer, introduce gas, and mix the MgCl with a concentration of 2mol 2 -6H 2 O aqueous solution, at a speed of 1L / min, a NaOH aqueous solution with a concentration of 4mol, at a speed of 1L / min, a sodium oleate aqueous solution with a concentration of 0.2mol, at a speed of 0.5L / min, at 20-50°C, use The metering pump is fed into the continuous bubble liquid film reactor in parallel, and the foamy reaction product flows out. After filtering, washing and drying, the nano-Mg with a particle size of 30nm-50nm and a surface modified by oleic acid radicals is obtained. (OH) 2 Capsule particle loose block.

example 2

[0082] Start the bubble-cap disc stirrer, introduce gas, and mix the MgCl with a concentration of 0.3mol 2 -6H 2 O aqueous solution, at a speed of 1L / min, a NaOH aqueous solution with a concentration of 0.6mol, at a speed of 1L / min, a sodium oleate aqueous solution with a concentration of 0.03mol, at a speed of 0.5L / min, at 20-50°C, respectively A metering pump is used to co-flow into the continuous bubble liquid film reactor, and the foamy reaction product flows out. After filtering, washing and drying, the obtained particle size is 30nm-50nm, and the surface is modified by oleate. Oh) 2 Capsule particle loose block.

example 3

[0084] Start the bubble-cap disc stirrer, introduce gas, and mix the MgCl with a concentration of 2mol 2 -6H 2 O aqueous solution, at the speed of 1L / min, the concentration of 4mol NaOH aqueous solution, at the speed of 1L / min, the concentration of 0.2mol sodium stearate aqueous solution, at the speed of 0.5L / min, at 20-60°C, respectively Add it into the continuous bubble liquid film reactor in parallel flow with a metering pump, and the foamy reaction product flows out. After filtering, washing and drying, the nano-Mg with a particle size of 30nm-80nm and a surface modified by stearate is obtained. (OH) 2 Capsule particle loose block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com