Metal polishing liquid and polishing method

A technology for grinding fluid and metal, which is applied in grinding devices, grinding machine tools, metal processing equipment, etc., and can solve the problems of grinding scars, poor electrical characteristics, and insufficient cleaning of the ground surface.

Active Publication Date: 2009-12-23

RESONAC CORP

View PDF9 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to increase the polishing speed of the interlayer insulating film, a method of polishing by increasing the particle size of the abrasive grains contained in the metal polishing liquid has been proposed. However, there are polishing scratches on the surface to be polished, resulting in poor electrical characteristics. The reason for such problems

In addition, there is a problem that such poor electrical characteristics occur due to insufficient cleaning after CMP.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

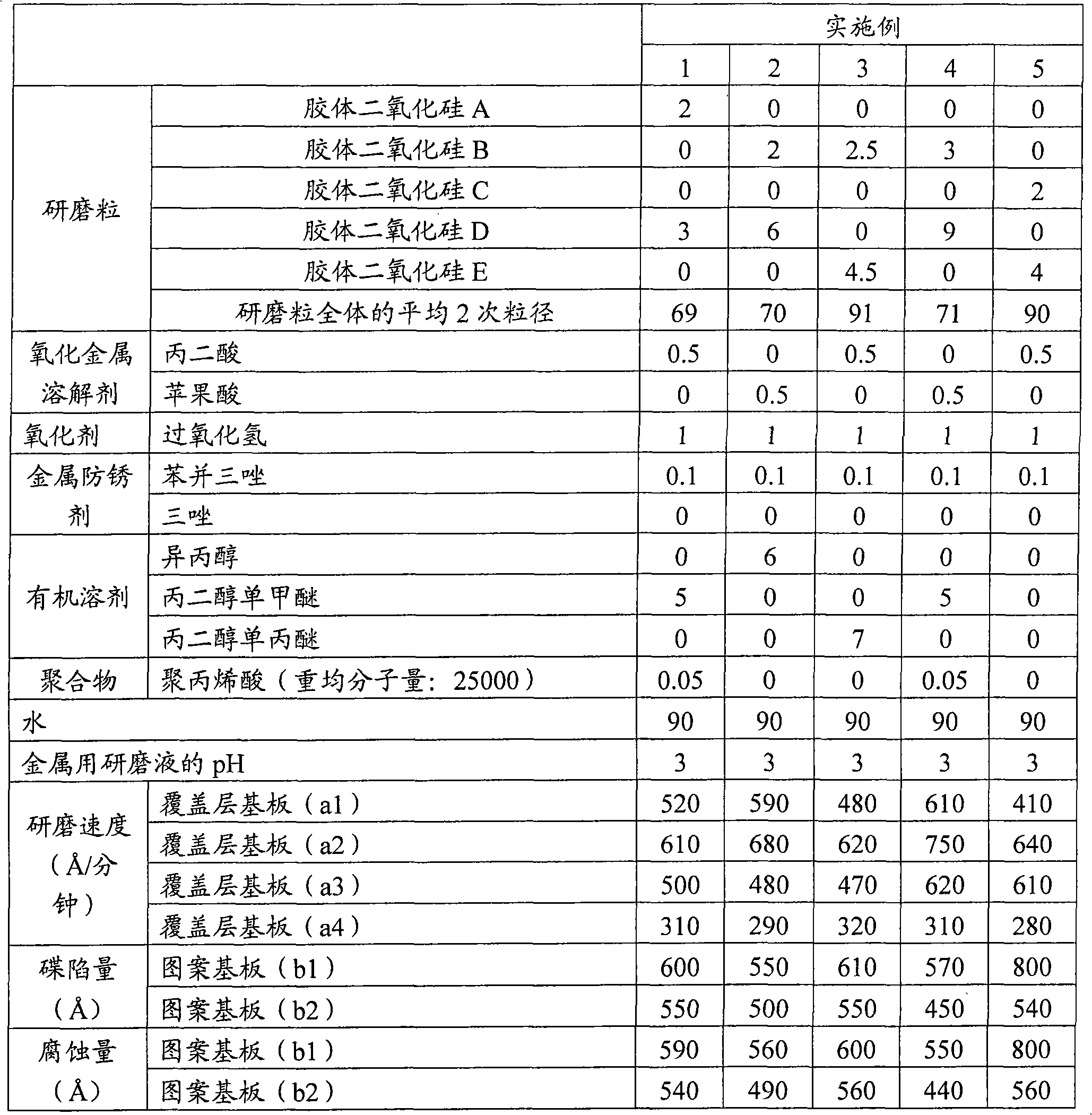

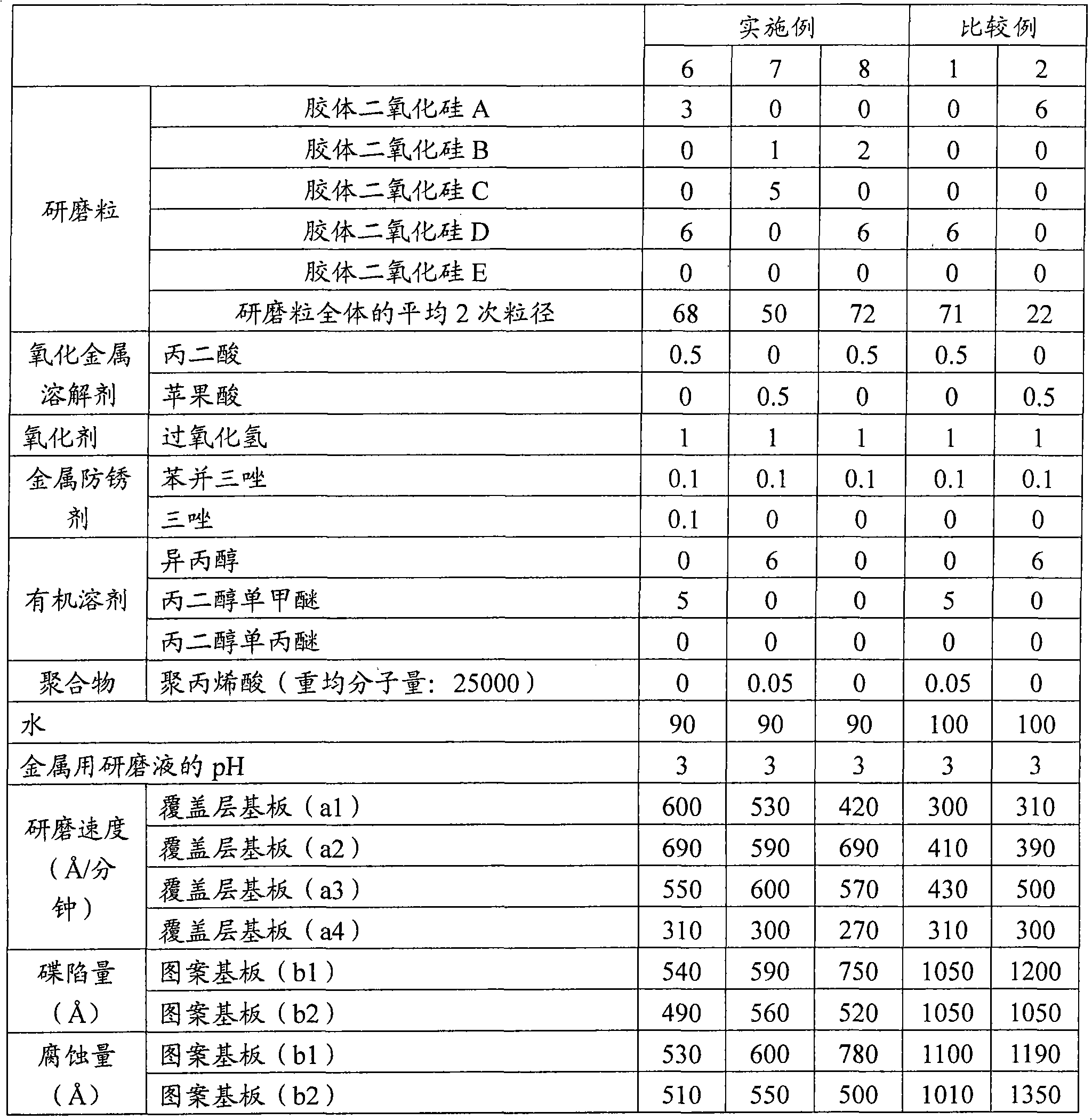

Embodiment 1~8、 comparative example 1~2

[0091] (Manufacturing method of polishing liquid)

[0092] The materials shown in Table 1 were mixed in respective mixing ratios (parts by mass) to prepare polishing liquids for metals used in Examples 1-8 and Comparative Examples 1-2. The substrate produced as described below was polished using this polishing liquid for metal under the following polishing conditions.

[0093] (Measurement method of average secondary particle size)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

Disclosed is a metal polishing liquid containing abrasive grains, a metal oxide dissolving agent and water. This metal polishing liquid is characterized by containing two or more kinds of abrasive grains having different average secondary particle diameters. Also disclosed is a polishing method using such a metal polishing liquid, which enables to polish an interlayer insulating film at a high polishing rate while ensuring high flatness in the polished surface. This polishing method is suitable for a highly reliable low-cost semiconductor device which is excellent in miniaturization, reduction of film thickness, dimensional accuracy and electrical characteristics.

Description

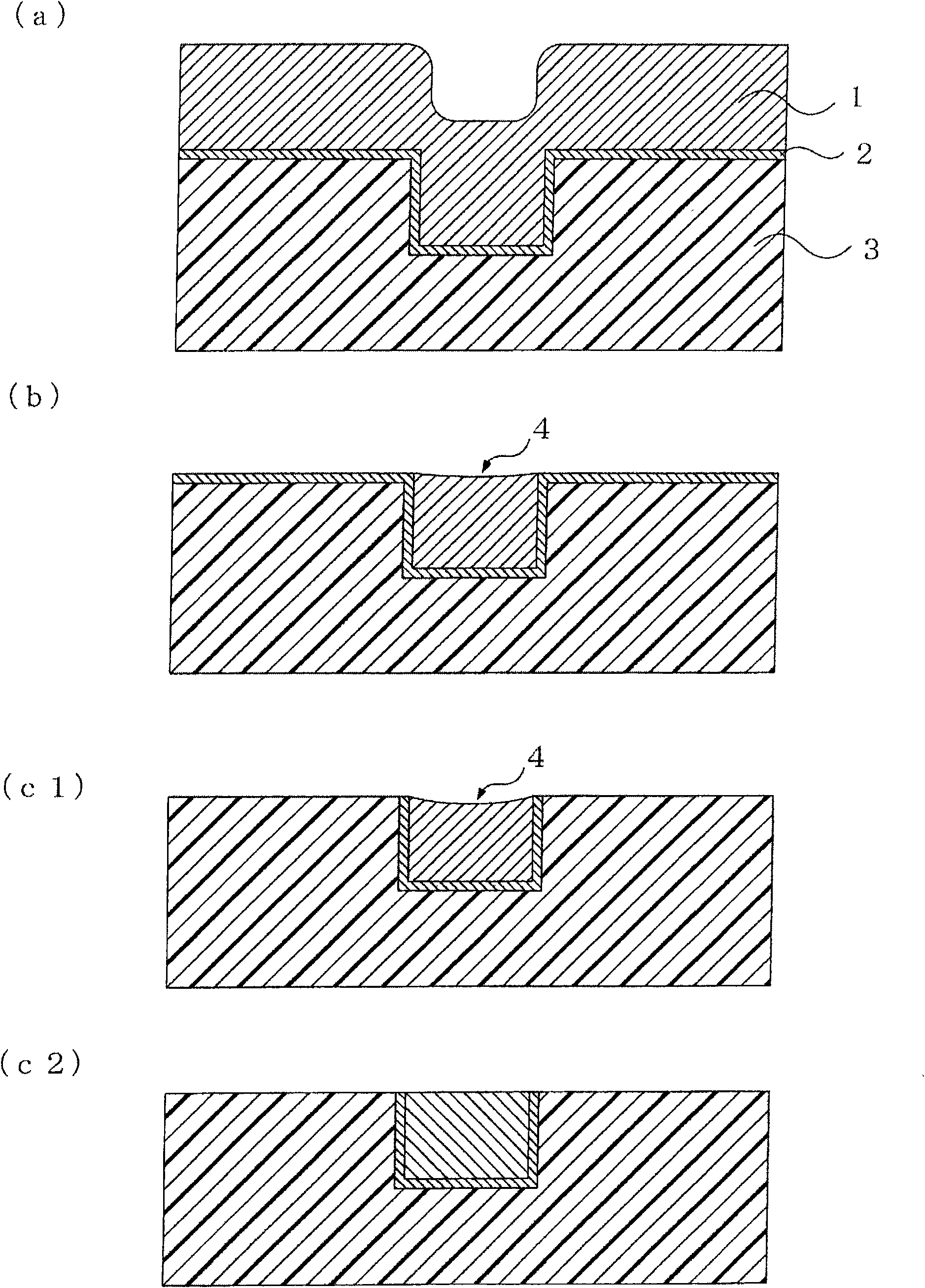

technical field [0001] The invention relates to a metal grinding liquid and a grinding method. Background technique [0002] In recent years, along with the high integration and high performance of semiconductor integrated circuits (hereinafter referred to as LSI), new microfabrication technologies have been developed. The chemical mechanical polishing (hereinafter, referred to as CMP) method is one of them, and is a method frequently used in the LSI manufacturing process, especially in the planarization of the interlayer insulating film in the multilayer wiring formation process, and the metal plug (plug) ) formation, technology in the formation of embedded wiring. This technique is disclosed in, for example, US Patent No. 4,944,836. [0003] In addition, recently, in order to improve the performance of LSIs, it has been attempted to use copper or copper alloys as conductive substances of wiring materials. However, it is difficult to use copper or a copper alloy for micr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L21/304B24B37/00C09K3/14

CPCC09G1/02C09K3/1409C09K3/1463C23F3/06H01L21/3212C09K3/14C23F1/18H01L21/302H05K3/02C23F1/26H01L21/30625

Inventor 天野仓仁樱田刚史安西创筱田隆野部茂

Owner RESONAC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com