Production method of meta-aramid fiber paper-based material

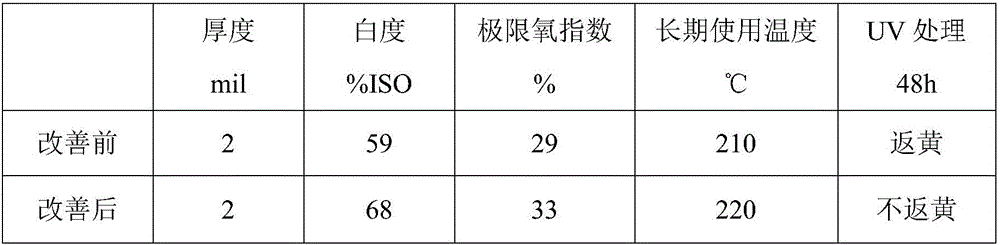

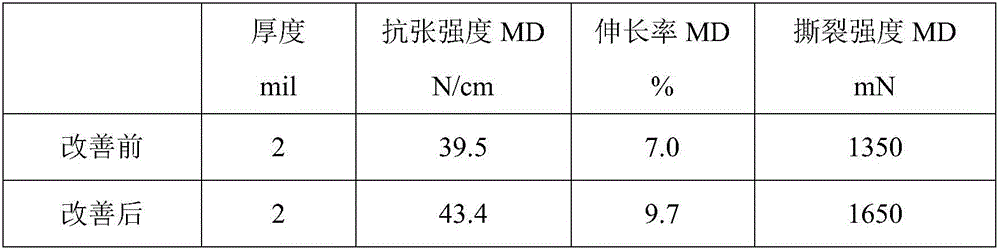

一种芳纶纤维、生产方法的技术,应用在纤维原料处理、合成纤维素/非纤维素材料纸浆/纸、纸涂料等方向,能够解决层间结合强度弱、易分层起泡等问题,达到提高机械强度、性能稳定性良好、性能稳定性提升的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

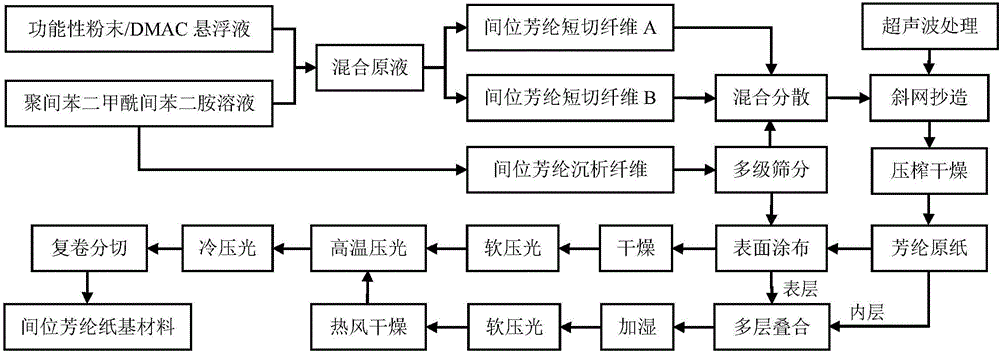

Method used

Image

Examples

Embodiment 1

[0042] (1) Mix and co-mill the functional powder with the DMAC solution to form a uniformly dispersed suspension, then add it to the polym-phenylene isophthalamide solution, and prepare a mixed stock solution through a static mixer, wherein the functional powder It is titanium oxide with a particle size below 200nm, and the total amount added is 0.1% of the mass of polym-phenylene isophthalamide;

[0043] (2) Take the mixed stock solution and prepare the meta-aramid chopped fiber A (high-strength and high-modulus fiber) with a length of 4mm, a fineness of 1.5D, and a modulus of 60CN / dtex and a length of 1mm, a fineness of 0.5D, and a modulus fiber by dry spinning. Amount of 40CN / dtex meta-aramid chopped fiber B (as-spun fiber), respectively dispelled to a concentration of 0.05%;

[0044] (3) Take the polym-phenylenediamine isophthalamide solution and prepare meta-aramid precipitated fibers in a sedimentation machine. After refining, pass through multi-stage sieving, and select...

Embodiment 2

[0050] (1) Mix and co-mill the functional powder with the DMAC solution to form a uniformly dispersed suspension, then add it to the polym-phenylene isophthalamide solution, and prepare a mixed stock solution through a static mixer, wherein the functional powder It is titanium oxide, aluminum oxide, and bismuth oxide with a particle size below 200nm, and the three are mixed according to a mass ratio of 1:1:1, and the total amount added is 1% of the mass of polym-phenylene isophthalamide;

[0051] (2) Take the mixed stock solution and prepare the meta-aramid chopped fiber A (high-strength and high-modulus fiber) with a length of 6mm, a fineness of 2.0D, and a modulus of 70CN / dtex and a length of 2mm, a fineness of 0.5D, and a modulus fiber by dry spinning. Amount of 30CN / dtex meta-aramid chopped fiber B (as-spun fiber), respectively dispelled to a concentration of 0.1%;

[0052] (3) Take the polym-phenylenediamine isophthalamide solution and prepare meta-aramid precipitated fib...

Embodiment 3

[0071] (1) Mix and co-mill the functional powder with the DMAC solution to form a uniformly dispersed suspension, then add it to the polym-phenylene isophthalamide solution, and prepare a mixed stock solution through a static mixer, wherein the functional powder It is alumina with a particle size below 200nm, and the total amount added is 2% of the mass of polym-phenylene isophthalamide;

[0072] (2) Take the mixed stock solution and prepare the meta-aramid chopped fiber A (high-strength and high-modulus fiber) with a length of 7mm, a fineness of 2.0D, and a modulus of 70CN / dtex and a length of 2mm, a fineness of 0.5D, and a modulus fiber by dry spinning. Amount of 30CN / dtex meta-aramid chopped fiber B (as-spun fiber), decomposed to a concentration of 0.2% respectively;

[0073] (3) Take the polym-phenylene isophthalamide solution and prepare the meta-aramid precipitated fiber in the sedimentation machine, pass through multi-stage screening after refining, and select ≤30 mesh, 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com