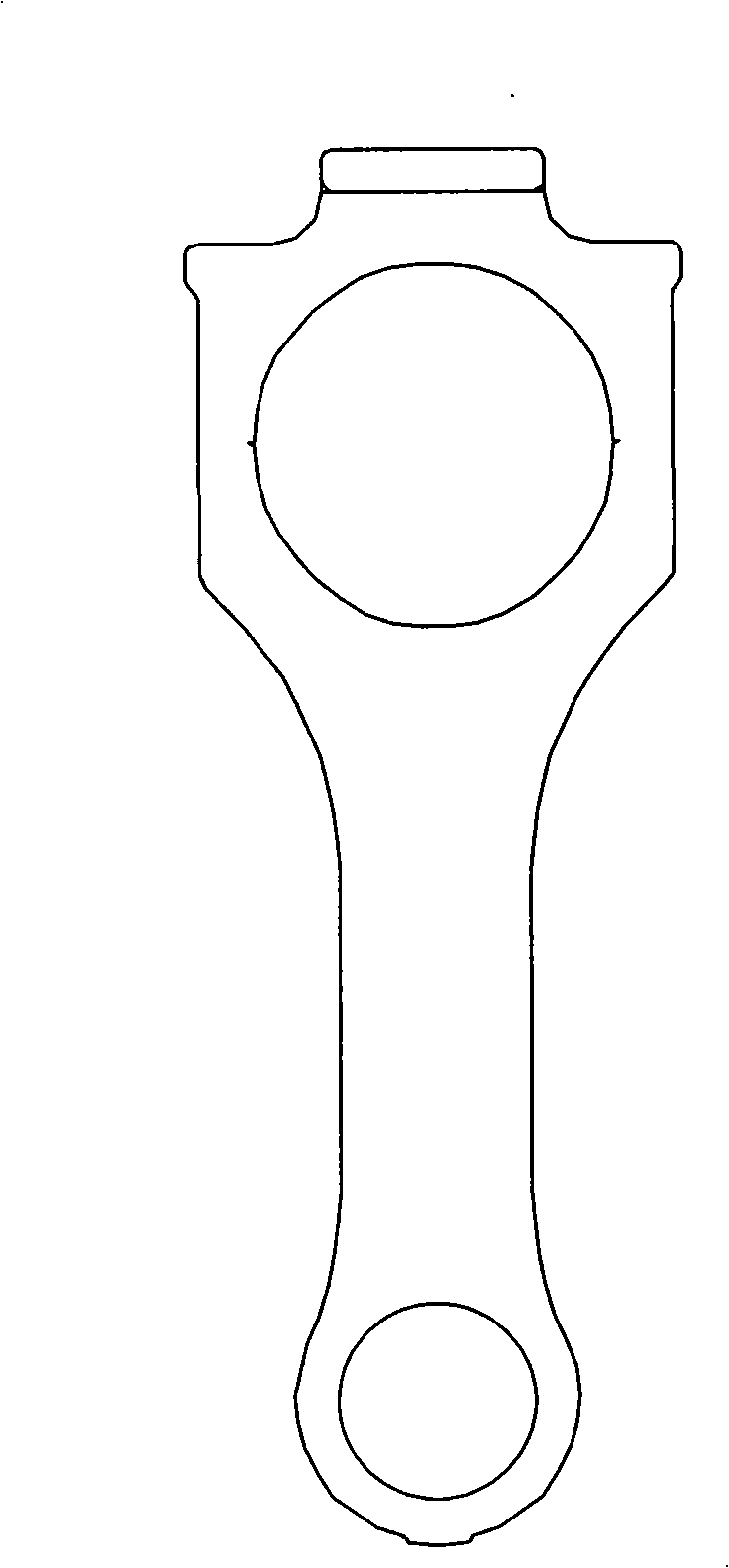

High intensity alloyed steel linkage rod deep cooling embrittlement bulge-breaking process

An alloy steel, high-strength technology, applied in the direction of connecting rods, shafts and bearings, mechanical equipment, etc., can solve the problems that the connecting rods of high-power engines cannot be broken by expansion technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

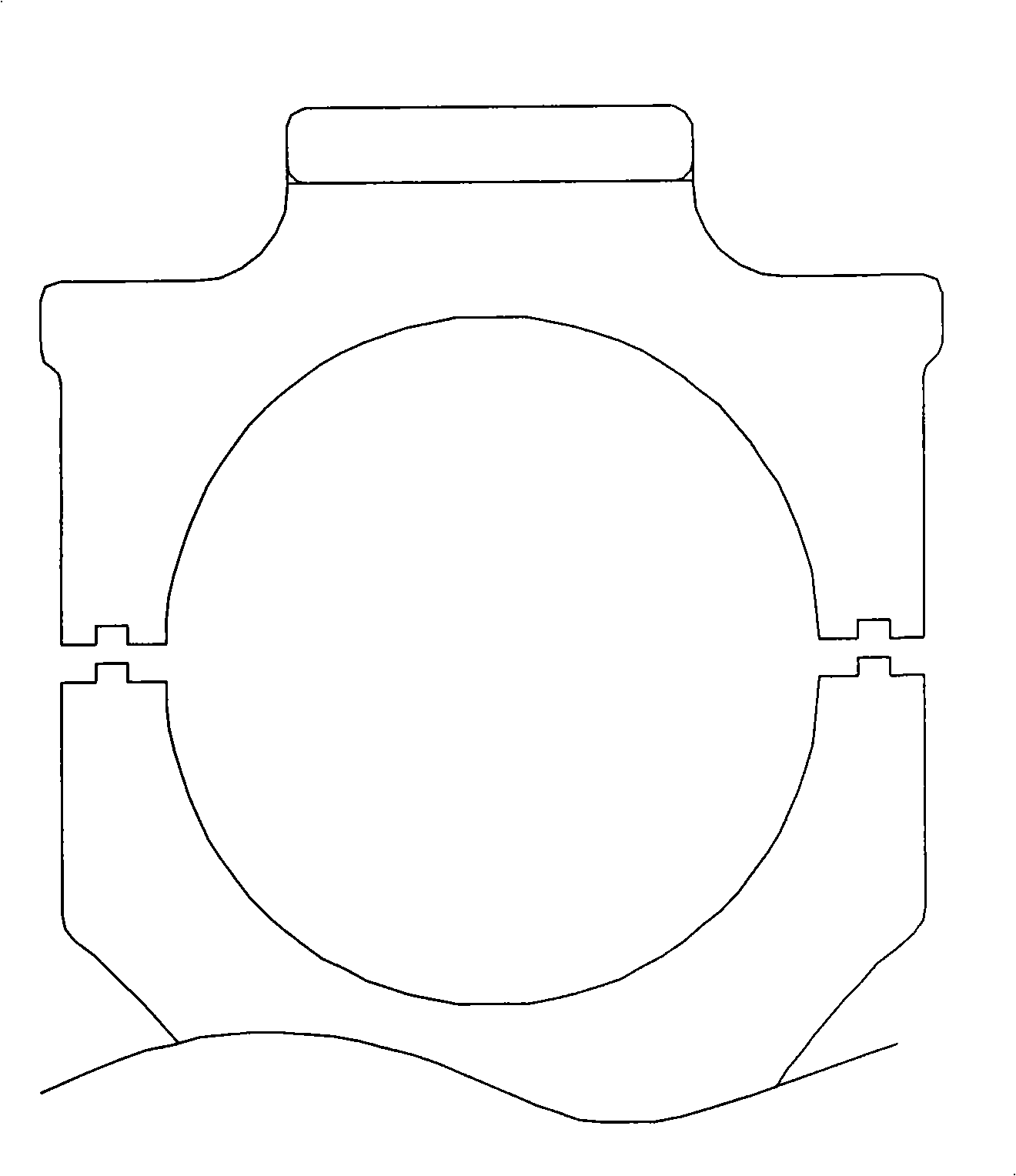

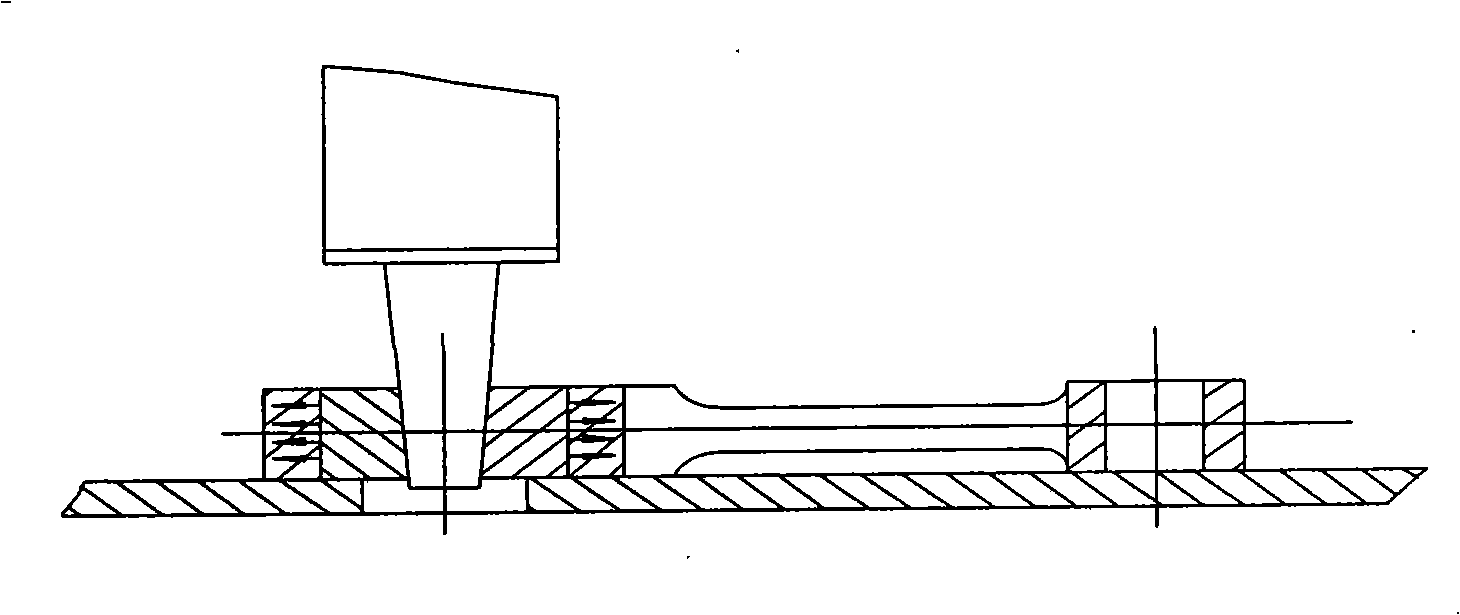

[0024] like Image 6 , 7 As shown, wherein, 1 is the connecting rod, 2 is the expansion head, 3 is the expansion sleeve, and 4 is the back pressure spring.

[0025] 1. Connecting rod bursting—brittle deformation

[0026] The connecting rod bursting processing technology is based on the fact that the connecting rod material itself can achieve brittle deformation, while the high-strength alloy steel used for the high-power engine connecting rod cannot achieve brittle deformation by conventional means, which is also the connecting rod bursting technology. The main reason why it cannot be popularized in the processing technology of high-power engine connecting rods. The key technology adopted in the invention is to carry out liquid nitrogen cryogenic cooling on the connecting rod, which can realize the brittle deformation of the high-strength alloy steel.

[0027] 2. Solution

[0028] Through process tests, the plastic deformation of the separation surface of the high-strength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com