Gear measuring system, gear measuring method and special handheld movable optical reverse reflector

A gear measurement and reflector technology, applied in the direction of using optical devices, measuring devices, measuring/indicating equipment, etc., can solve the problems of adverse effects of measurement results, and the accuracy cannot meet the requirements of such gear measurement, and achieve the effect of improving the manufacturing level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

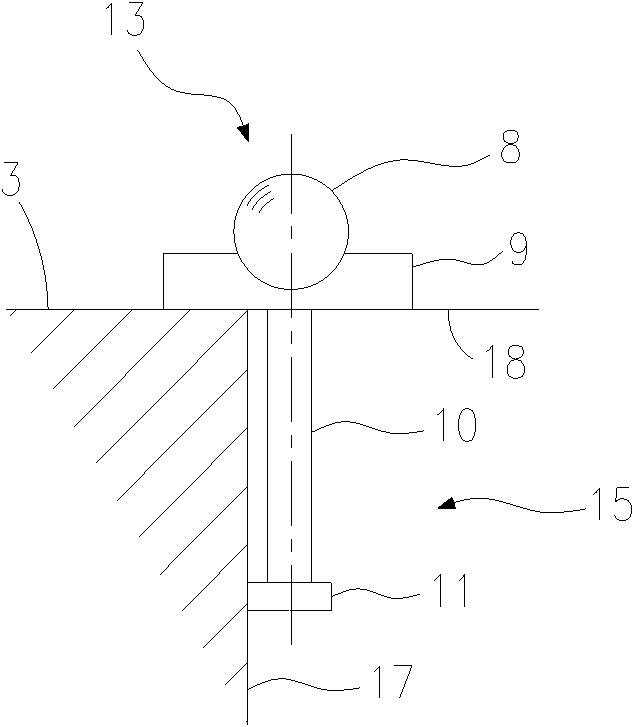

[0058] Such as Figure 5 As shown, the positioning body 15 is a long cylindrical structure with the positioning seat 9 installed on one upper end and coaxial with the reflector 8 . In use, the outer cylindrical surface of the elongated cylindrical structure is tangent to the inner cylindrical surface of the hole wall of the central hole 17 of the gear 3 to be tested for radial positioning. Since the tangent between the outer cylindrical surface of the long cylindrical structure and the inner cylindrical surface of the hole wall of the central hole 17 of the gear 3 under test is in most cases a straight line, the straightness error will have a certain impact on the measurement results.

Embodiment 2

[0060] Such as Image 6 As shown, the positioning body 15 includes a support rod 10 on which the positioning seat 9 is installed at the upper end, and a rotating body 11 arranged at the lower end of the supporting rod 10, and the positioning body 15 is connected to the measured gear through the rotating body 11 The hole wall of the central hole 17 of 3 is in contact, and the rotating body 11 is arranged coaxially with the reflector 8; wherein, the rotating body 11 is spherical. During the measurement, the rotating body 11 is in point contact with the inner cylindrical surface of the hole wall of the central hole 17 of the gear 3 under test, so the contact point may be located at the contour peak or contour valley of the surface roughness of the hole wall, so the measured The surface roughness of the hole wall of the central hole 17 of the gear 3 will have a certain influence on the measurement result.

Embodiment 3

[0062] Such as image 3 As shown, the positioning body 15 includes a support rod 10 on which the positioning seat 9 is installed at the upper end, and a rotating body 11 arranged at the lower end of the supporting rod 10, and the positioning body 15 is connected to the measured gear through the rotating body 11 The hole walls of the central hole 17 of 3 are in contact with each other, and the rotating body 11 is arranged coaxially with the reflector 8; wherein, the rotating body 11 is disc-shaped. In this way, the rotating body 11 and the inner cylindrical surface of the hole wall of the central hole 17 of the gear under test 3 are in surface contact with a small contact area, which can avoid the influence of the straightness error on the measurement results in Embodiment 1, It can also avoid the impact of the contact surface roughness on the measurement results in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com