Injection molding process of plastic microfluidic chip

An injection molding process and microfluidic chip technology, applied in laboratory containers, laboratory utensils, chemical/physical/physicochemical processes, etc., to solve the problem of incomplete replication of microchannels, promote applications, and improve manufacturing levels Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

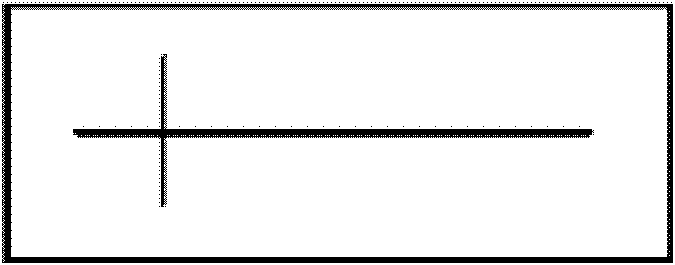

Embodiment 1

[0020] Single cross microfluidic chip, the product is 80mm long, 30mm wide, and 1.2mm thick, with 2 cavities in one mold, the cross-sectional depth of the microchannel is 50μm, and the width is 70μm. The material is PMMA.

[0021] (A) Put the dried PMMA into the hopper of the injection molding machine, set the temperature of the barrel: 230°C for the nozzle, 250°C for the first zone, 245°C for the second zone, and 220°C for the third zone;

[0022] (B) The mold temperature is set to 89°C;

[0023] (C) The mold is closed and enters the injection stage. The injection pressure is: 100MPa for the first stage, 110MPa for the second stage, and 110MPa for the third stage. The injection time is 2.6s. The injection speed adopts the form of slow-fast-slow. The injection speed is set as: the first stage 90mm / s, the second section 140mm / s, the third section 60mm / s;

[0024] (D) Entering the pressure-holding stage, the pressure-holding pressure is 70MPa, and the pressure-holding time is 4...

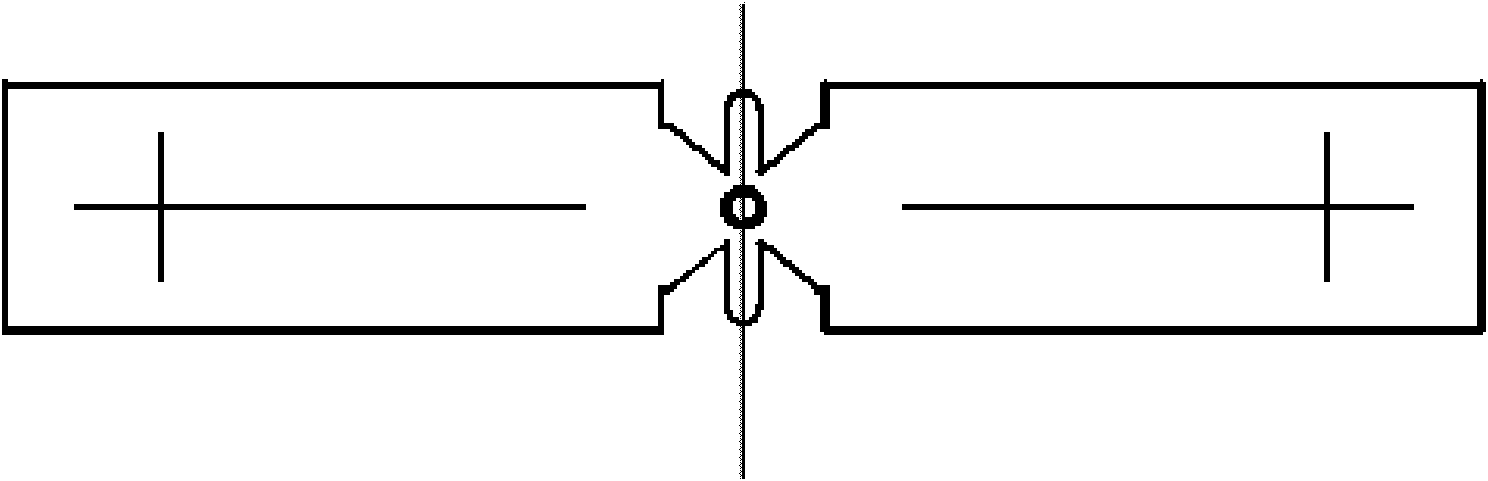

Embodiment 2

[0029] Double cross microfluidic chip (two cross microchannels on each chip), the product is 62mm long, 60mm wide, and 1.2mm thick, with 2 cavities in one mold, the cross-sectional depth of the microchannel is 50μm, and the width is 50μm. The material is PMMA.

[0030] (G) Put the dried PMMA into the hopper of the injection molding machine, set the temperature of the barrel: 230°C for the nozzle, 250°C for the first zone, 245°C for the second zone, and 220°C for the third zone;

[0031] (H) mold temperature is set to 89 ℃;

[0032] (1) The mold is closed and enters the injection stage. The injection pressure is: 100MPa for the first stage, 110MPa for the second stage, and 120MPa for the third stage. The injection time is 2.6s. The injection speed adopts the form of slow-fast-slow, and the injection speed is set as: the first stage 90mm / s, the second section 140mm / s, the third section 60mm / s;

[0033] (J) Enter the pressure-holding stage, the pressure-holding pressure is 70MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com