Hot-pressed mounting paper capable of being lifted off and re-mounted with water and manufacturing method thereof

A production method and a mounting technique, which are applied to chemical instruments and methods, paper, papermaking, etc., can solve the problems of damage to precious calligraphy and painting, failure to unmount and repair, and irreplaceable calligraphy and painting, and achieve the effect of convenient mounting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

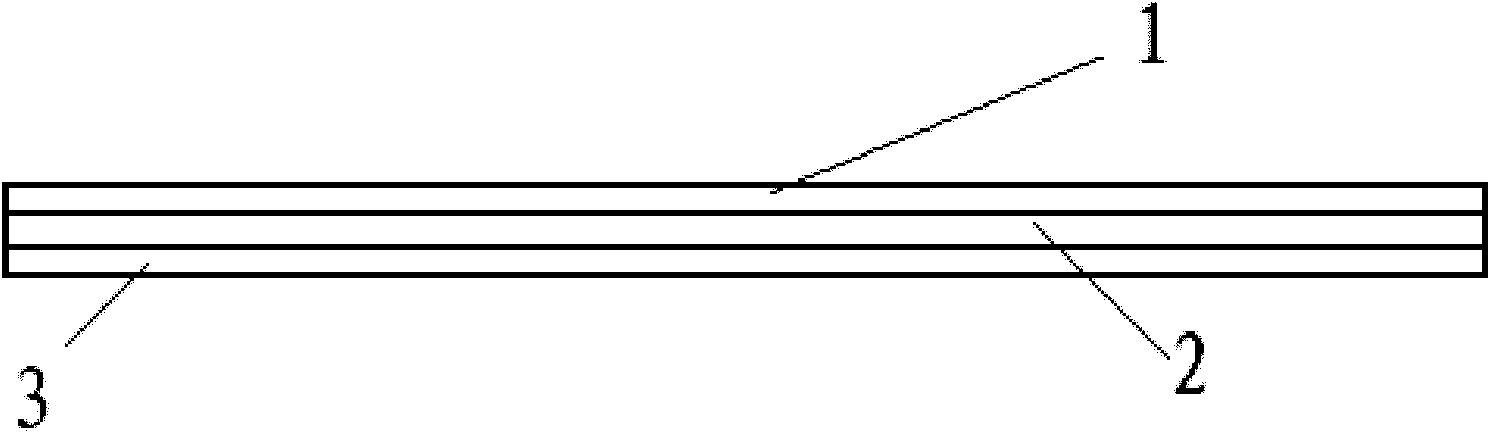

[0043] The technical solution of the first water-mountable hot-pressed mounting paper of the present invention is: the base paper 3 has a water-absorbable mountable coating 2; the water-absorbable mountable coating 2 has a hot-melt adhesive coating 1 on it. Base paper 3 can be rice paper, leather paper, and other base papers.

[0044] On the surface of rice paper, leather paper or other base paper 3, first coat a layer of water-absorbable detachable coating 2, and then coat a layer of hot-melt adhesive coating 1 for mounting paper, see figure 1 . This kind of painting paper can be directly mounted with calligraphy and painting by hot pressing, that is, hot mounting; it can also be uncovered by soaking in water, that is, water exposing and mounting.

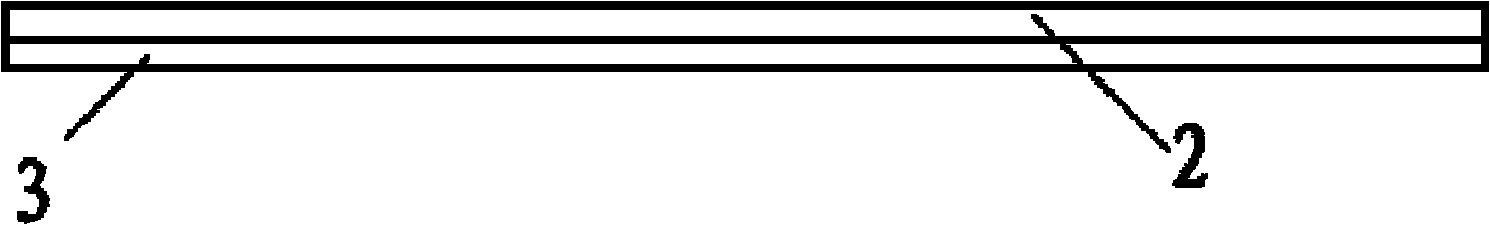

[0045] The technical scheme of the second water-removable hot-pressed mounting paper of the present invention is: the base paper 3 has a water-absorbable and releasable coating 2 . Base paper 3 can be rice paper, leather paper, ...

Embodiment 2

[0048] The making method of the first kind of water detachable hot-pressed mounting paper comprises the following methods:

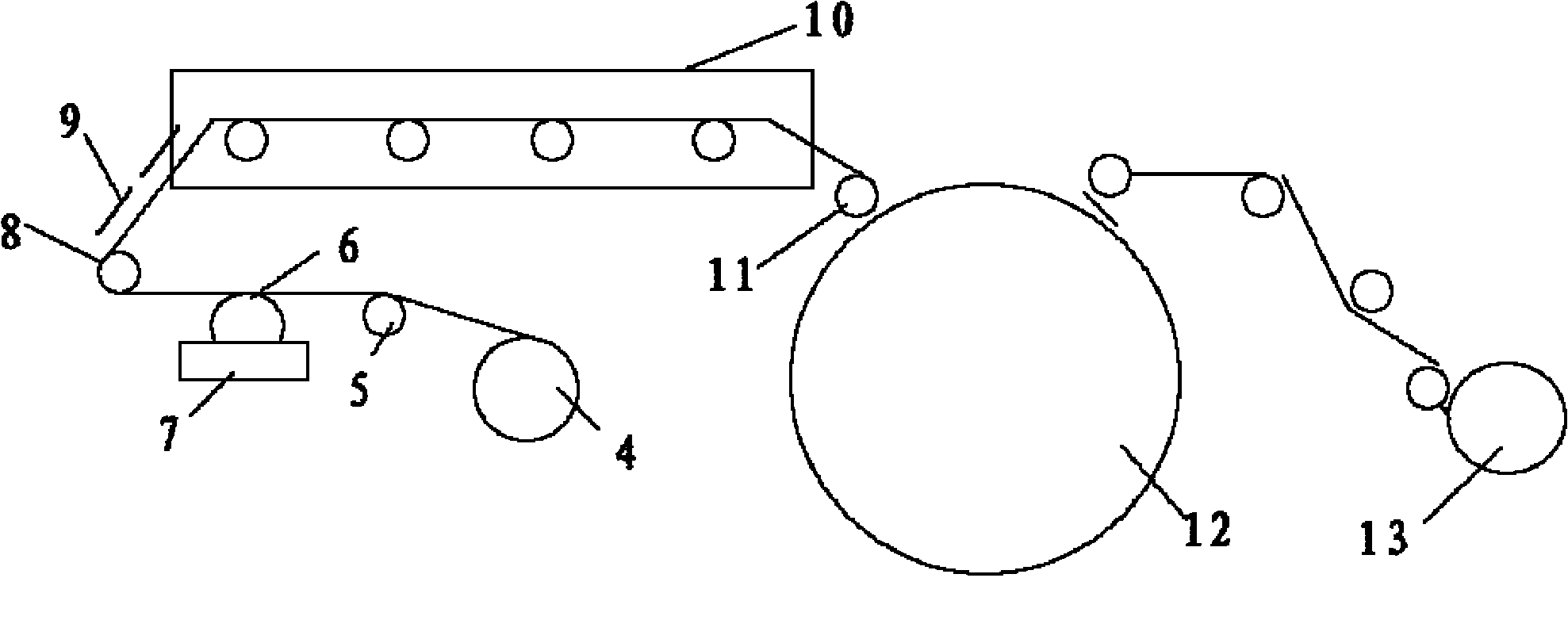

[0049] (1) Apply the water-absorbable and demountable coating evenly to the surface of rice paper, leather paper or other base paper through a coating machine; After being dried to form a hot-melt adhesive coating, it is then flattened, rolled, and cut to make roll or sheet hot-pressed painting paper that can be exposed and mounted by water. See image 3 .

[0050] (2) Apply the water-absorbable and demountable coating evenly to the surface of rice paper, leather paper or other base paper through a coating machine; after drying, apply the hot-melt adhesive water-based coating to the water-absorbable and demountable coating After being dried to form a hot-melt adhesive coating, it is then flattened, rolled, and cut to make roll or sheet hot-pressed painting paper that can be exposed and mounted by water. See Figure 4 .

[0051] (3) Apply the water-abs...

Embodiment 3

[0060] Embodiment 3: The preparation method 1 of the heat-pressed mounting paper that can be demounted by water:

[0061] (1) Coating of water release mountable coating. Such as image 3 As shown, a continuous base paper 4 rolled into a tube is installed on the unwinding frame of the coater, and the continuous base paper 4 passes through the feed roller 6 of the coater under the traction of the coater, and the feed roll 6 of the coater will The water-mountable paint in the coater feed tank 7 is transferred to the surface of the continuous base paper 4, and the coater scraper bar 8 scrapes off the excess paint so that the continuous base paper 4 surface is coated with a uniform coating;

[0062] (2) Powder coating of hot melt adhesive. Such as image 3 As shown, the hot-melt adhesive duster 9 evenly spreads the hot-melt adhesive powder on the wet coating on the surface of the continuous base paper 4; Cloth machine oven 10 is dried, then passes through coating machine pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com