Oversized-section bainite pre-hardening plastic die steel and manufacturing method

A plastic mold and bainite technology, applied in the field of alloy steel, can solve the problems of long manufacturing cycle and high manufacturing cost, and achieve the effect of reducing alloy cost, shortening manufacturing cycle and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The composition and weight percentage of the hot work die steel are as follows:

[0047] C is 0.28%, Si is 0.20%, Mn is 2.30%, Cr is 1.30%, Mo is 0.20%,

[0048] V is 0.20%, P is 0.020%, S is 0.015%, Ni is 0.20%, Nb is 0.08%, and Fe is the balance.

[0049] The process and steps of super-large cross-section bainitic pre-hardened plastic mold steel are as follows:

[0050] 1) Electric furnace smelting: smelting in an electric arc furnace according to the above alloy element ratio, then refining outside the furnace and vacuum degassing, casting into ingots and sending them to the forging heating furnace;

[0051] 2) High-temperature diffusion heat treatment: the heating temperature is 1200-1250°C, and the holding time is 15-20h;

[0052]3) Forging hot processing: the steel ingot that has undergone high-temperature diffusion heat treatment is cooled to a temperature range of 1150-1200 ° C for multi-directional forging processing, using two upsetting and two drawing forgi...

Embodiment 2

[0065] The composition and weight percentage of the hot work die steel are as follows:

[0066] C is 0.15%, Si is 0.10%, Mn is 3.00%, Cr is 1.00%, Mo is 0.30%,

[0067] V is 0.10%, P is 0.015%, S is 0.025%, Ni is 0.10%, Nb is 0.14%, and Fe is the balance.

[0068] The preparation method of the ultra-large cross-section bainite pre-hardened plastic mold steel in this embodiment is the same as that in Embodiment 1, wherein the tempering is heated to 450-500°C.

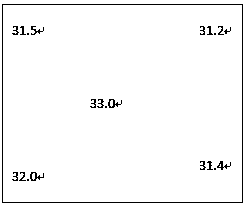

[0069] After the above-mentioned smelting, thermal processing and heat treatment of the ultra-large cross-section bainitic pre-hardened die steel in this example, the final product specification is (length×width×thickness) 2500mm×1300mm×1200mm module, and samples are taken for performance testing:

[0070] A phase change characteristics:

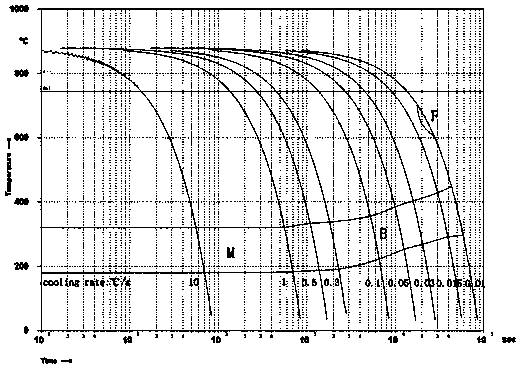

[0071] The CCT curve of present embodiment steel is as attached Figure 5 shown.

[0072] B Microstructure:

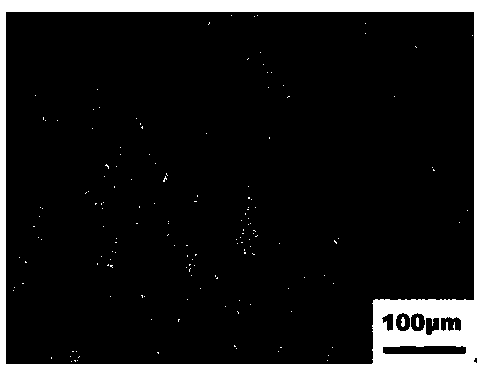

[0073] The microstructure of the steel in this embodiment is as attac...

Embodiment 3

[0079] The composition and weight percentage of the hot work die steel are as follows:

[0080] C is 0.30%, Si is 0.30%, Mn is 2.00%, Cr is 2.00%, Mo is 0.10%,

[0081] V is 0.30%, P is 0.03%, S is 0.03%, Ni is 0.30%, Nb is 0.10%, and Fe is the balance.

[0082] The preparation method of the ultra-large cross-section bainite pre-hardened plastic mold steel in this embodiment is the same as that in Embodiment 1.

[0083] After the above-mentioned smelting, thermal processing and heat treatment of the ultra-large cross-section bainitic pre-hardened die steel in this example, the final product specification is (length×width×thickness) 2500mm×1300mm×1200mm module, and samples are taken for performance testing:

[0084] A phase change characteristics:

[0085] The CCT curve of present embodiment steel is as attached Figure 9 shown.

[0086] B Microstructure:

[0087] The microstructure of the steel in this embodiment is as attached Figure 10 shown.

[0088] C hardness unif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com