Fast connecting and positioning device for L-shaped rotary tire and follow fixture of robot and working method of fast connecting and positioning device

A technology of accompanying fixtures and positioning devices, applied in auxiliary devices, manufacturing tools, welding equipment, etc., to achieve the effects of achieving diversity, reducing the number of tooling manufacturing, reducing deformation and robot positioning errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in conjunction with specific embodiments now.

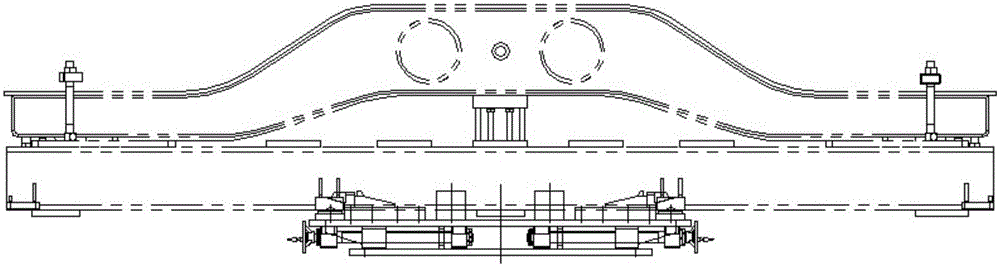

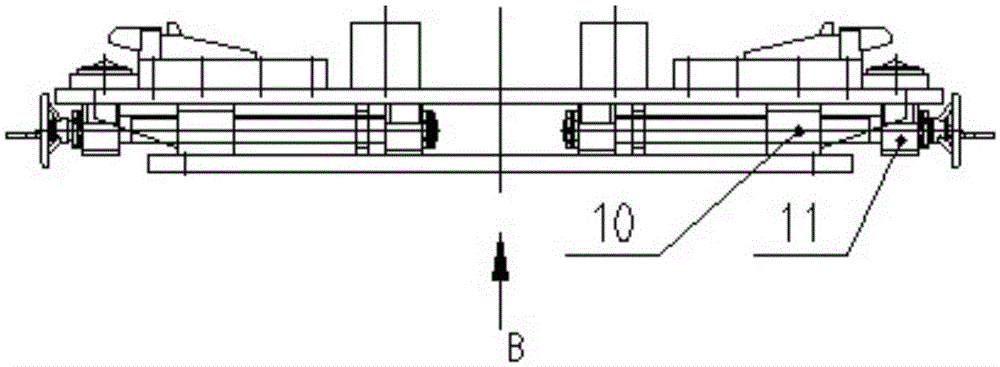

[0044] As shown in the figure, 1 base; 2 positioning block; 3 countersunk screw; 4 bayonet; 6 bayonet seat; 7 slide rail; 9 stopper; 10 movable block; 11 self-locking screw mechanism; 100 accompanying fixture; 101 workpiece; 102 wedge-shaped pressing seat of accompanying fixture.

[0045] The object of the present invention is realized by following preferred embodiments, and structure and composition are as follows:

[0046] (1) The base 1 is connected with the transition plate of the robot L rotating tire positioner, and the self-locking screw mechanism is used to build and connect the front wedge block to move with the screw and position and tighten along the slide rail.

[0047] (2) The main structure includes piece 1 base, piece 2 positioning block, piece 4 bayonet, piece 6 bayonet seat, piece 7 slide rail, piece 9 stopper, piece 10 movable block, piece 11 self-locking s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com