Fabricated spacing adjustable steel stand column connecting hoop structure

A technology of assembly spacing and steel columns, which is applied in building construction, construction, and building materials processing, etc., can solve problems such as damage, waste of steel pipes, impact on structure and bearing capacity, etc., to achieve easy operation, eliminate material waste, and overall stiffness. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

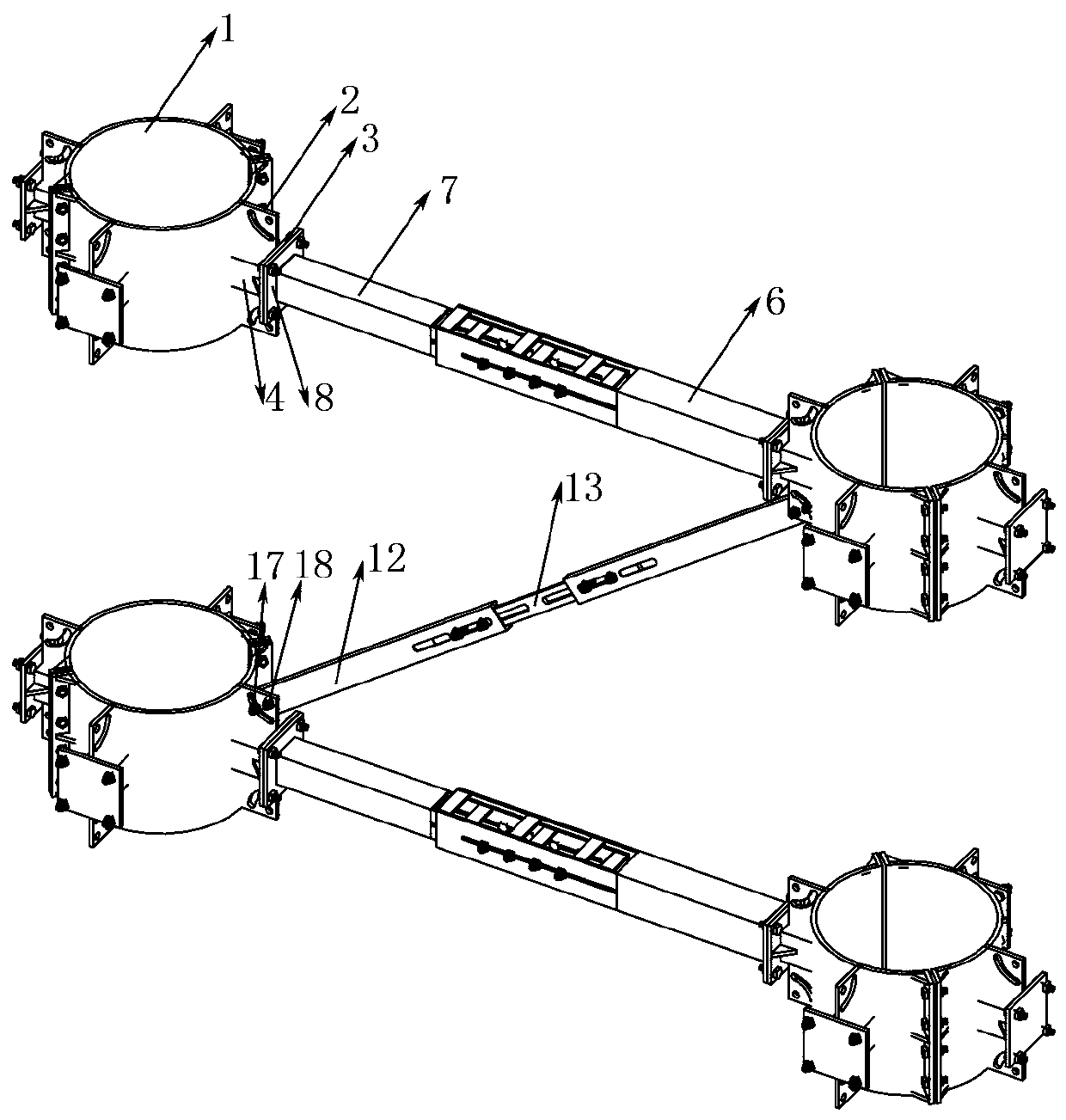

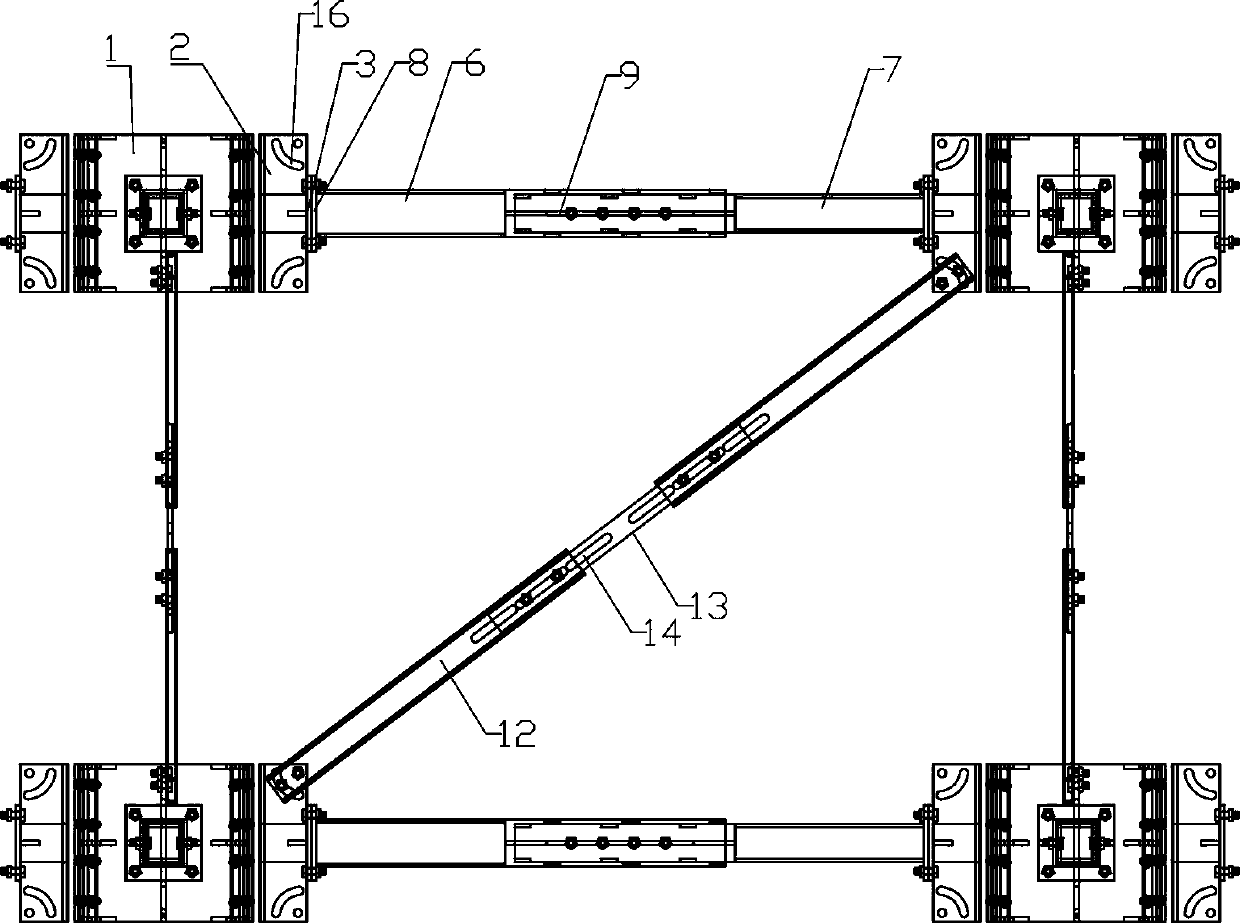

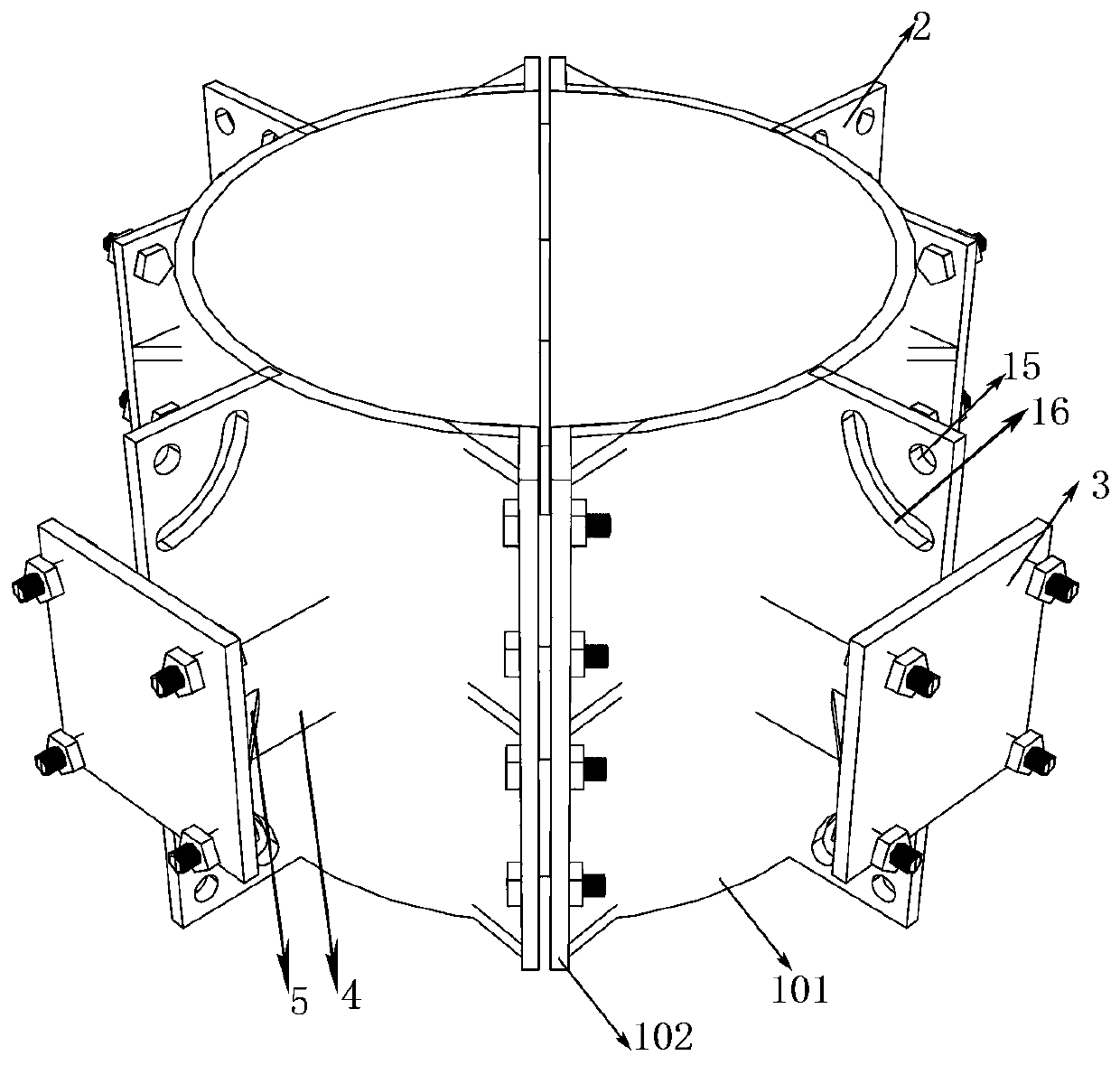

[0026] Embodiment 1: A steel column connection hoop structure with adjustable assembly spacing, such as Figure 1-7 As shown, the steel columns in this embodiment are φ609mm steel pipes, and each steel column is equipped with a hoop 1 at intervals of a certain length. Two semi-annular sub-clamps 101 are fastened to each other, and the two sides of the sub-clamps 101 are respectively vertically connected with connecting edges 102. The bolts pass through the through holes, and the bolts are tightened to make the two sub-clamps 101 hug each other and be fixedly set on the steel column. On the outer wall of the hoop 1, there are four installation seats evenly fixed along the ring, that is, the four installation seats are distributed in a "cross shape", and each installation seat includes the first wing plate 2 and the second wing plate 3 respectively. and the center base block 4, the center base block 4 is a direction column, the center base block 4 is convexly welded to the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com