Tab material of flexible-packaging lithium battery as well as electroplating method and application method thereof

A technology of a soft-pack lithium battery and its application method, which is applied to the tab material of the soft-pack lithium battery and its electroplating and application fields. It can solve problems such as bulging, damage to aluminum-plastic films, and troublesome operation of converting nickel, so as to reduce heat generation, The effect of increasing the welding strength and increasing the welding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

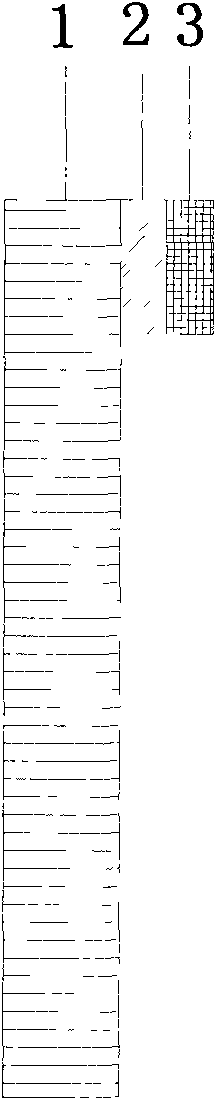

[0062] Welding of 0.45mm thick soft pack lithium battery and ultra-thin circuit board.

[0063] The lug material of this embodiment is that one end of the SUS430 stainless steel strip substrate 1 side with a thickness of 0.05mm is first coated with a layer of nickel coating 2, and then coated with a layer of tin coating 3 on the nickel coating 2, and the thickness of the nickel coating 2 is is 1 μm; the thickness of the tin plating layer 3 is 5 μm.

[0064] Its specific preparation process is as follows:

[0065] (1) Surface pretreatment before plating:

[0066] In order to make the coating and the substrate well bonded, the above-mentioned steel strip is subjected to the following surface pretreatment before electroplating. Since the surface of the steel strip used is relatively smooth, there is no need for grinding and mechanical polishing before nickel plating, and the degreasing treatment is carried out directly. In this example, the chemical high temperature degreasing...

Embodiment 2

[0107] Welding of 0.45mm thick soft pack lithium battery and ultra-thin circuit board;

[0108] In this embodiment, the tab material is coated with a layer of tin coating 3 on one end of the base 4 side of the nickel strip with a thickness of 0.05 mm; the thickness of the tin coating 3 is 3-10 μm. Its electroplating and laser welding treatment conditions and steps are the same as in Example 1, except that there is no step of DC electroplating nickel coating.

[0109] Performance Testing

[0110] A sample was produced as a comparative example in the following manner.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com