Gas protection welding method of 1000 MPa-level engineering machine high-strength steel thick plates

A technology of construction machinery and gas protection, applied in welding medium, welding equipment, welding equipment and other directions, can solve problems such as unfavorable field operation, small thickness of steel plate, low matching, etc., to avoid cold cracks in welding, ensure weld toughness, practical strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A gas-shielded welding method for a 1000MPa grade construction machinery high-strength steel thick plate, the steps of which are:

[0036]1) Welding conditions: mechanical properties of steel plates for construction machinery to be welded: yield strength R el =955MPa, tensile strength R m =1020MPa, Elongation A=17%, Longitudinal -20°C Impact Energy KV 2 =120J, the delivery state is quenched and tempered; the size of the welding test plate is 500mm×150mm×30mm, the joint form is flat butt joint, the welding test equipment is 455 Lincoln welding machine, the ambient temperature is 25ºC, and the humidity is 70%;

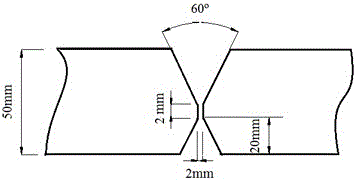

[0037] 2) Welding groove form: double-sided V-shaped asymmetric groove, the groove angle is 60º, the blunt edge size is 2.2mm, and the assembly gap is 2mm; the groove is polished and cleaned before welding;

[0038] 3) Matching welding materials: the bottom welding wire is 700MPa solid core gas shielded welding wire; the diameter of the welding wire is 1.2mm; th...

Embodiment 2

[0048] A gas-shielded welding method for a 1000MPa grade construction machinery high-strength steel thick plate, the steps of which are:

[0049] 1) Welding conditions: mechanical properties of steel plates for construction machinery to be welded: yield strength R el =965MPa, tensile strength R m =1070MPa, Elongation A=16%, Longitudinal -20°C Impact Energy KV 2 =110J, the delivery state is quenched and tempered; the size of the welding test plate is 500mm×150mm×40mm, the joint form is flat butt joint, the welding test equipment is 455 Lincoln welding machine, the ambient temperature is 25ºC, and the humidity is 60%;

[0050] 2) Welding groove form: double-sided V-shaped asymmetric groove, the groove angle is 60º, the blunt edge size is 2.5mm, and the assembly gap is 2mm; the groove is polished and cleaned before welding;

[0051] 3) Matching welding materials: the bottom welding wire is 700MPa solid core gas shielded welding wire; the diameter of the welding wire is 1.2mm; t...

Embodiment 3

[0061] A gas-shielded welding method for a 1000MPa grade construction machinery high-strength steel thick plate, the steps of which are:

[0062] 1) Welding conditions: mechanical properties of steel plates for construction machinery to be welded: yield strength R el =960MPa, tensile strength R m =1080MPa, Elongation A=16%, Longitudinal -20°C Impact Energy KV 2 =110J, the delivery state is quenched and tempered; the size of the welding test plate is 500mm×150mm×50mm, the joint form is flat butt joint, the welding test equipment is 455 Lincoln welding machine, the ambient temperature is 25ºC, and the humidity is 70%;

[0063] 2) Welding groove form: a double-sided V-shaped asymmetric groove, the groove angle is 60º, the blunt edge size is 3mm, and the assembly gap is 2mm; the groove is polished and cleaned before welding;

[0064] 3) Matching welding materials: the bottom welding wire is 700MPa solid core gas shielded welding wire; the diameter of the welding wire is 1.2mm; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com