Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Full escape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Additional electric arc heating copper backing board pre-heating aluminum alloy and magnesium alloy welding method

InactiveCN101264541AReduce crackingExtended cooldownArc welding apparatusWelding/soldering/cutting articlesButt jointCopper

The invention relates to a welding method, in particular to a welding method in which an electric arc is added to heat a copper padding plate and preheat aluminum alloy and magnesium alloy, aiming to reduce defects of blowholes and cracks at the joint, ensure good forming at the back of the joint, and finally obtain high quality joint which is suitable for aluminum alloy and magnesium alloy. In order to solve the problems that the aluminum alloy and magnesium alloy are liable to generate blowholes and cracks during welding and the forming at the back of the joint is poor, the invention provides the welding method in which the electric arc is added to heat the copper padding plate and preheat aluminum alloy and magnesium alloy. The copper padding plate is adopted when the butt joint is welded using aluminum alloy and magnesium alloy, and the electric arc is added at the back of the copper padding plate. The shape of the copper padding plate varies with the weldment. The method has the advantages of simple and easy practice, convenient operation, and obvious effect for improving the forming at the back of the joint and the quality of the joint.

Owner:HARBIN INST OF TECH

Gas protection welding method of 1000 MPa-level engineering machine high-strength steel thick plates

ActiveCN106270957AHigh strengthGuaranteed toughness and plasticityArc welding apparatusWelding/cutting media/materialsEngineeringSlow cooling

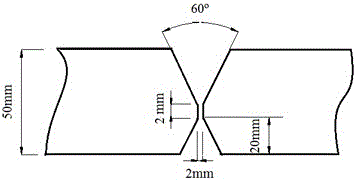

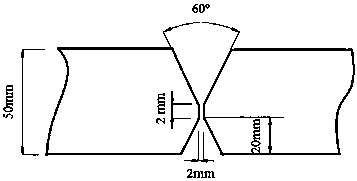

The invention provides a gas protection welding method of 1000 MPa-level engineering machine high-strength steel thick plates. Welding base materials are Rm1000-1100 MPa engineering machine quenched and tempered steel plates in equal-thickness flat plate butt joint, a groove is a double-side V-shaped asymmetric groove, the angle of the groove is 60 degrees, a truncated edge is 2-3 mm long, and an assembly gap is 2 mm wide. According to welding materials, bottoming welding wires are 700 MPa-level solid-core gas-protected welding wires with the diameter of 1.2 mm, and filling and surface covering welding wires are 1000 MPa-level solid-core gas-protected welding wires with the diameter of 1.2 mm. The welding method includes the welding steps that bottoming welding is conducted, filling welding is conducted, surface covering welding is conducted, slow cooling is conducted after welding, and joint areas in the range of 300 mm on the two sides of a weld joint are covered with asbestos cloth. Preheating is not needed, after-heating is not conducted, strength and toughness of a joint are ensured, the variety of welding gas and replacement frequency of equipment and the welding wires are reduced, the high-strength advantage of high-strength steel can be fully achieved, and maneuverability is high.

Owner:武汉钢铁有限公司

Self protection flux core welding wire of pipe line steel full position

InactiveCN1943965AImprove smoothnessReduce nitrogen and hydrogenWelding/cutting media/materialsSoldering mediaArc stabilityLine tubing

The self-protecting welding wire with flux core for pipeline steel has welding wire comprising BaF2, SrF2 and / or CaF2 7-12 wt%, LiF 0.8-3.0 wt%, CaO 0.2-0.8 wt%, SiO2 0.1-0.4 wt%, Al 1.2-2.0 wt%, Mg 1.2-2.0 wt%, Mn 0.6-1.2 wt%, Ni 0.6-1.2 wt%, C 0.05- 0.10 wt%, Zr 0.05-0.3 wt%, B 0.002-0.012 wt%, and Fe for the rest; and flux core accounting for 18-25 wt%. It contains water in 0.010-0.120 wt%, and has reduced current fluctuation and raised welding performance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Aluminum alloy thick plate vacuum electron beam three-step welding method capable of overcoming gas hole defect

The invention discloses an aluminum alloy thick plate vacuum electron beam three-step welding method capable of overcoming the gas hole defect. The aluminum alloy thick plate vacuum electron beam three-step welding method capable of overcoming the gas hole defect solves the problem that the bubble defect is easily generated during vacuum electron beam welding. A vacuum electron beam welding welding machine is adopted, and electron beam upper defocusing preheating welding is adopted for two butt welding faces of an aluminum alloy plate; large fusion depth hole penetrating welding is performed on the two butt welding faces of the aluminum alloy plate, and welding parameters of the vacuum electron beam welding welding machine are set as follows: a welding accelerating voltage is 40 kV, the welding beam current is 220 mA, the welding speed is 350 mm / min, the welding focus point is an upper focus point +0.13, the scanning pattern is in an O shape, the scanning frequency is 800 Hz, and the amplitude value is 1.0 mm; full penetration welding is implemented; and remelting modification welding is performed on the two butt welding faces of the aluminum alloy plate under a weld joint hot state, and a weld joint is subjected to heat preserving for 30 min under a vacuum state. Hydrogen holes formed in the weld joint are substantially lowered, and the weld joint quality is substantially improved.

Owner:SHANXI FENXI HEAVY IND

Chemical engineering sewage treatment front-mounted deodorization device

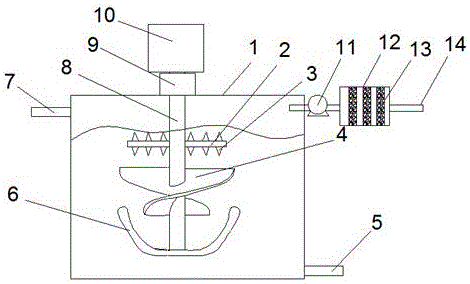

InactiveCN106365223AGood mixing effectSimple and reasonable structural designGas treatmentRotary stirring mixersDrive motorActivated carbon

The invention discloses a chemical engineering sewage treatment front-mounted deodorization device. The chemical engineering sewage treatment front-mounted deodorization device comprises a stirring tank body, wherein a driving motor is arranged at the upper end of the stirring tank body, and is connected with a rotating shaft through a speed reducer; the rotating shaft extends into the stirring tank body; anchor type stirring paddles are arranged at the bottom end of the rotating shaft; a spiral defoaming blades are arranged in the middle of the rotating shaft; two defoaming transverse shafts are symmetrically arranged at the upper part of the rotating shaft; a plurality of defoaming saw teeth are arranged on the defoaming transverse shafts; a water inlet tube is arranged at the upper end of the left side of the stirring tank body; a water outlet tube is arranged at the lower end of the right side of the stirring tank body. The chemical engineering sewage treatment front-mounted deodorization device is simple and reasonable in structural design and convenient to use, through multiple stirring and defoaming functions, odor in sewage can be sufficiently released, harmful smell substances can be adsorbed by using an activated carbon adsorption device and are discharged out later, and thus an ambient environment can be prevented from being affected by the odor.

Owner:GUANGXI UNIV

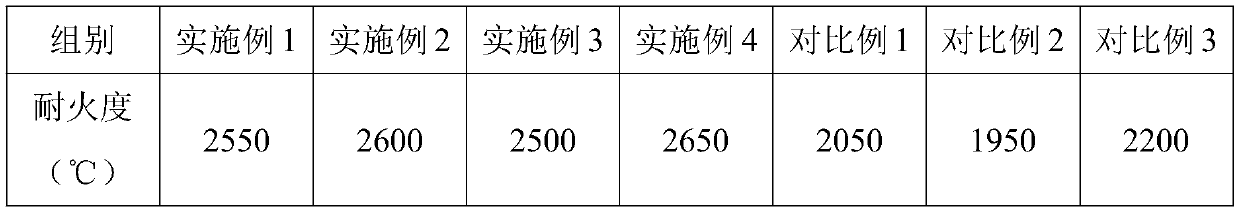

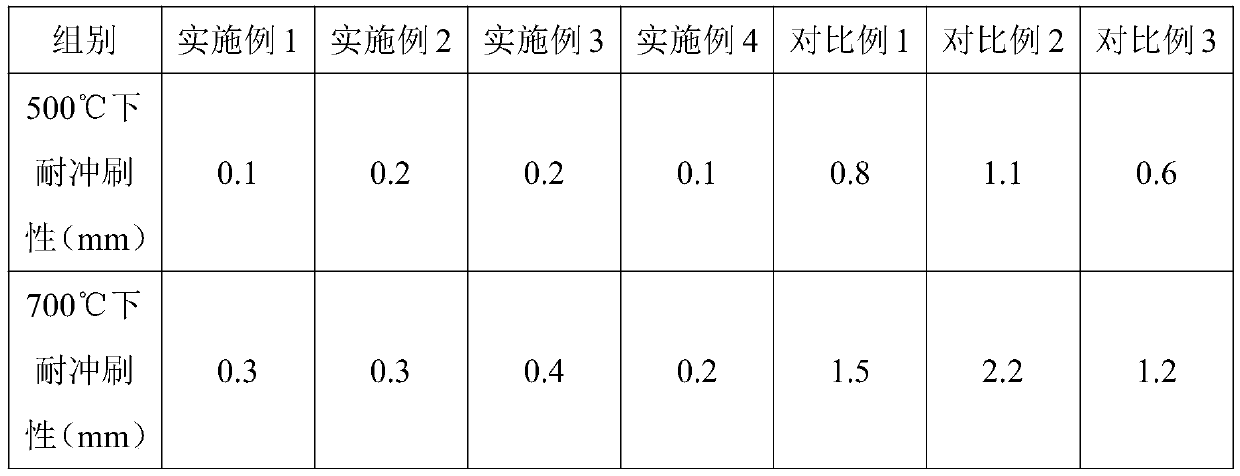

Preparation method for low-silicon, high-calcium and large-crystal fused magnesia

The invention discloses a preparation method for low-silicon, high-calcium and large-crystal fused magnesia. The preparation method comprises the following two steps: preparation of high-activity MgOand smelting with an electric arc furnace, i.e., during preparation of high-activity magnesium oxide powder, adding a sodium carbonate solution with a concentration of 3 to 8%, then adding high-puritygraphite powder into the prepared high-activity magnesium oxide powder as a reducing agent, carrying out balling with a device, after balling is completed, carrying out smelting with a fully-automatic electric arc furnace, carrying out cooling and crystallizing, and carrying out crushing and picking so as to obtain a finished product. According to the invention, through addition of the sodium carbonate solution, the point of melting is effectively reduced; the temperature of calcination is reduced; and energy is saved. Meanwhile, through a reaction between sodium carbonate with silicon dioxide impurities, sodium silicate and carbon dioxide can be generated; the silicon dioxide impurities in magnesite can be effectively removed; and the content of magnesium oxide is improved. The low-silicon, high-calcium and large-crystal fused magnesia provided by the invention reaches an MgO content of 99.90% or above, achieves a calcium-to-silicon ratio of 2.30 or above, has good high-temperature fire resistance and high-temperature scouring resistance, and can be used as a high-quality advanced refractory material to be applied in the industries of aerospace, electronics, steel and iron, metallurgy, etc.

Owner:LIAONING XINFAZHAN REFRACTORY MATERIAL GRP

Halogenated hydrocarbon-contaminated soil remediation device

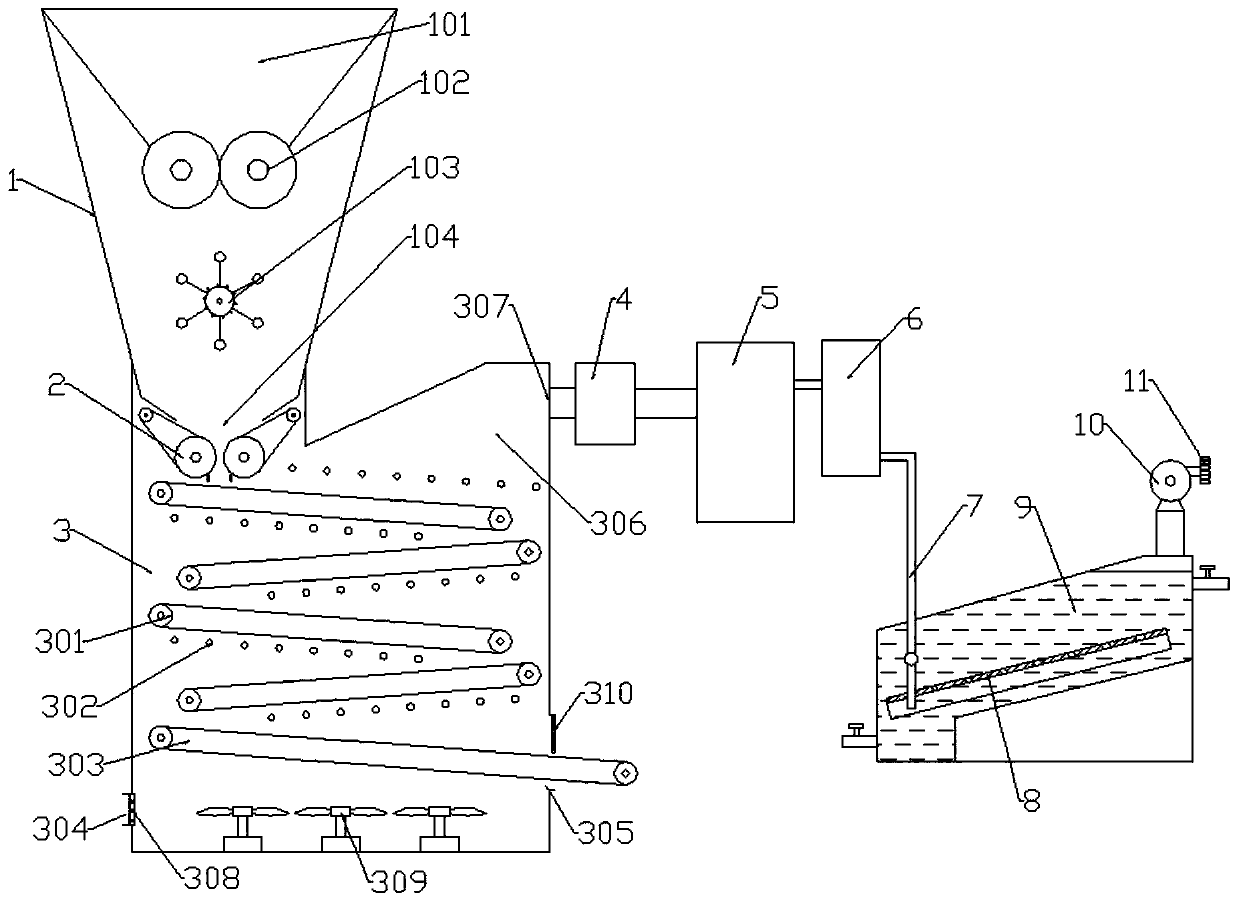

InactiveCN109967506AFully break upFully heatedDispersed particle separationContaminated soil reclamationHeating timeSoil remediation

The invention discloses a halogenated hydrocarbon-contaminated soil remediation device. The halogenated hydrocarbon-contaminated soil remediation device comprises a halogenated hydrocarbon removal box, wherein a hopper is arranged on the upper left portion of the halogenated hydrocarbon removal box, a plurality of soil conveyor belts are obliquely arranged in the halogenated hydrocarbon removal box from top to bottom alternatively in a Z-shaped mode, a soil discharging conveyor belt is arranged on the bottom of the interior of the halogenated hydrocarbon removal box, infrared ray heating modulator tubes are distributed above the soil conveyor belts and the soil discharging conveyor belt, a gas collecting cavity used for collecting hot gas flows is formed in the upper right portion of the halogenated hydrocarbon removal box, a first exhausting fan is connected with the outer portion of the gas collecting cavity, the first exhausting fan is connected with a halogenated hydrocarbon catalytic combustion furnace, the halogenated hydrocarbon catalytic combustion furnace is connected with a heat exchanger, the heat exchanger is connected with a gas inlet pipe assembly, the gas inlet pipeassembly introduces tail gas into a tail gas purification box in which an alkaline solution is placed, a gas outlet is formed in the upper right portion of the tail gas purification box, and a secondexhausting fan is arranged on the gas outlet. The halogenated hydrocarbon-contaminated soil remediation device uses infrared ray, soil heating time is long, a heated surface of soil is large, and theremediation efficiency is high.

Owner:泰顺县王日飞家庭农场

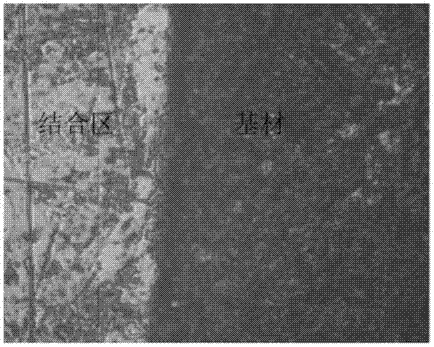

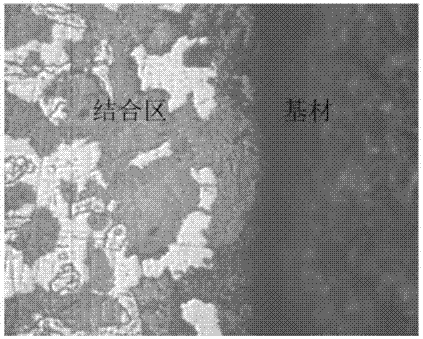

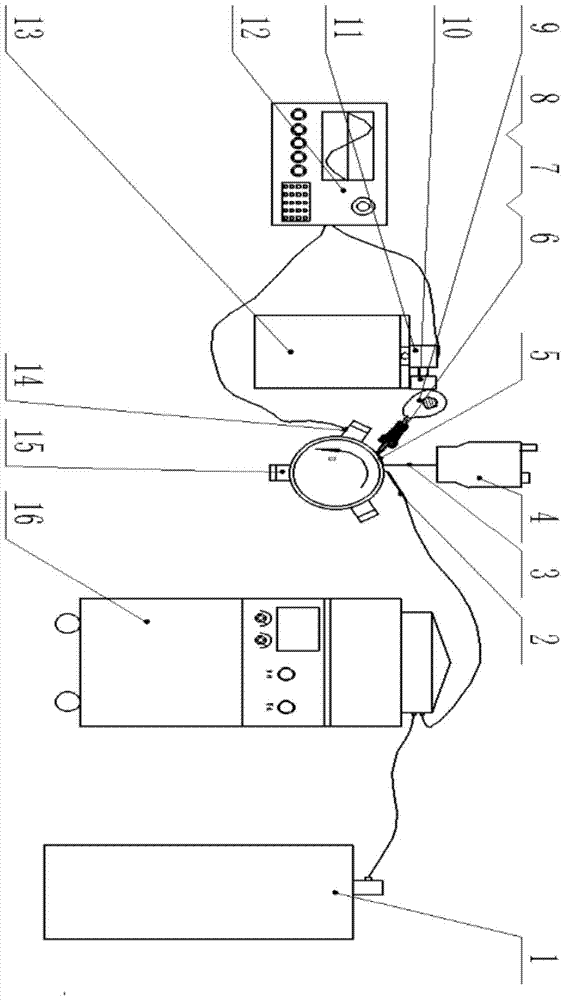

Mechanical shock method and device for effectively reducing laser cladding cracks

ActiveCN105088225AReduce in quantityHigh strengthMetallic material coating processesNumerical controlSemiconductor

A mechanical shock device for effectively reducing laser cladding cracks mainly comprises a powder feeding type high-power semiconductor laser cladding device, a numerical control device and a mechanical shock assembly. According to the mechanical shock device, a workpiece to be subjected to fusion cladding is clamped through a three-jaw chuck or a four-jaw chuck, powder is fed to the workpiece in a preset powder feeding mode, mechanical shock with a certain frequency is applied to a single channel where laser cladding is completed, and a fusion cladding layer with excellent quality is obtained. Since dendritic crystals which are separated out preferentially in a molten pool can be effectively broken into pieces through mechanical vibration caused by the shock, crystal grains are refined, the plasticity of solidified crystals is improved, and heat cracks are avoided; moreover, under the hammering action of a mechanical shock hammer on the cladding single channel, residual tension produced in the cooling process of the molten pool can be partially balanced out, cold cracks are reduced, and the fusion cladding layer with the excellent quality is obtained.

Owner:YANSHAN UNIV

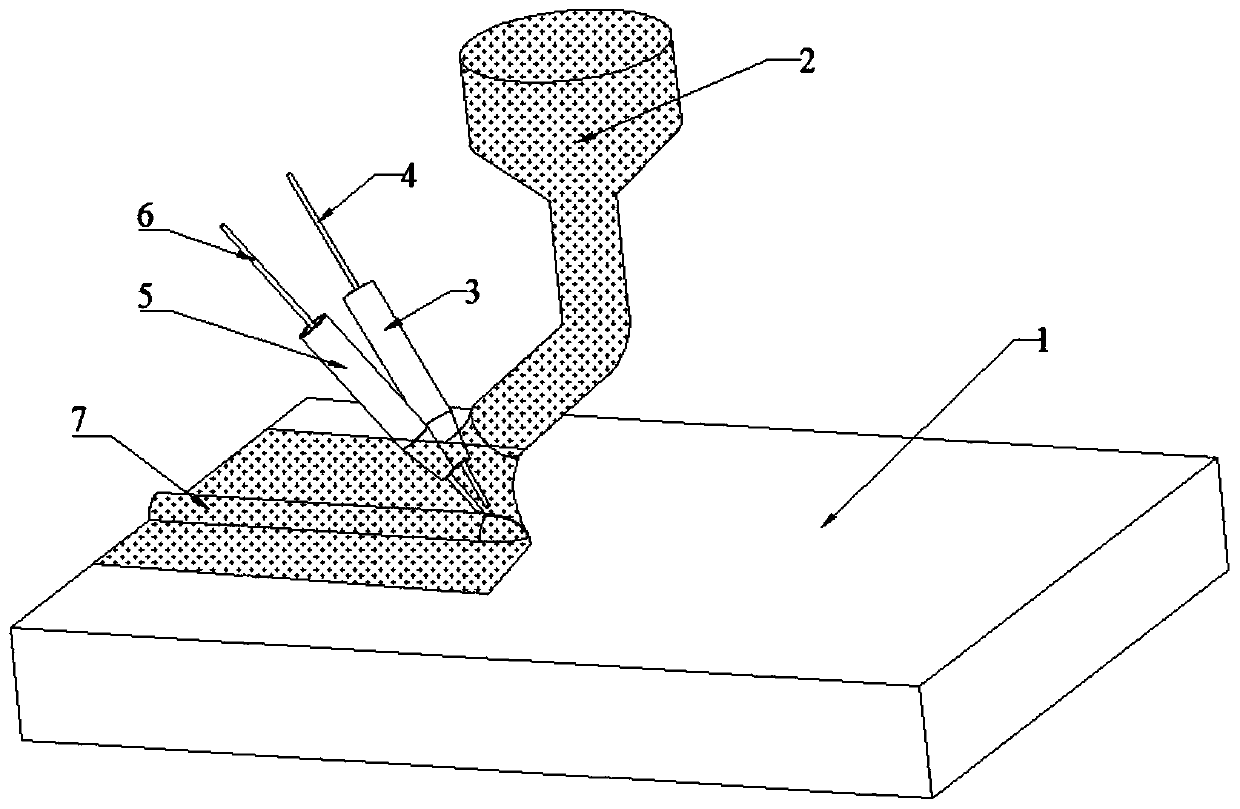

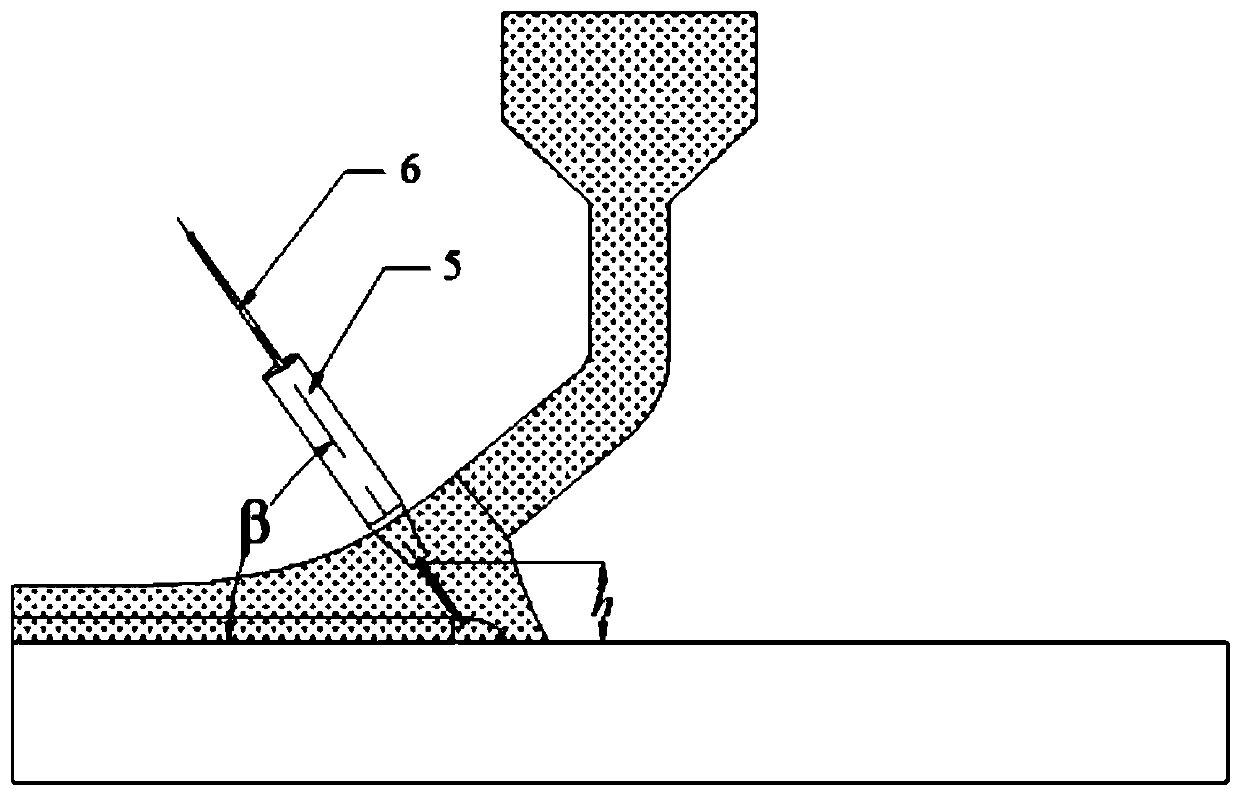

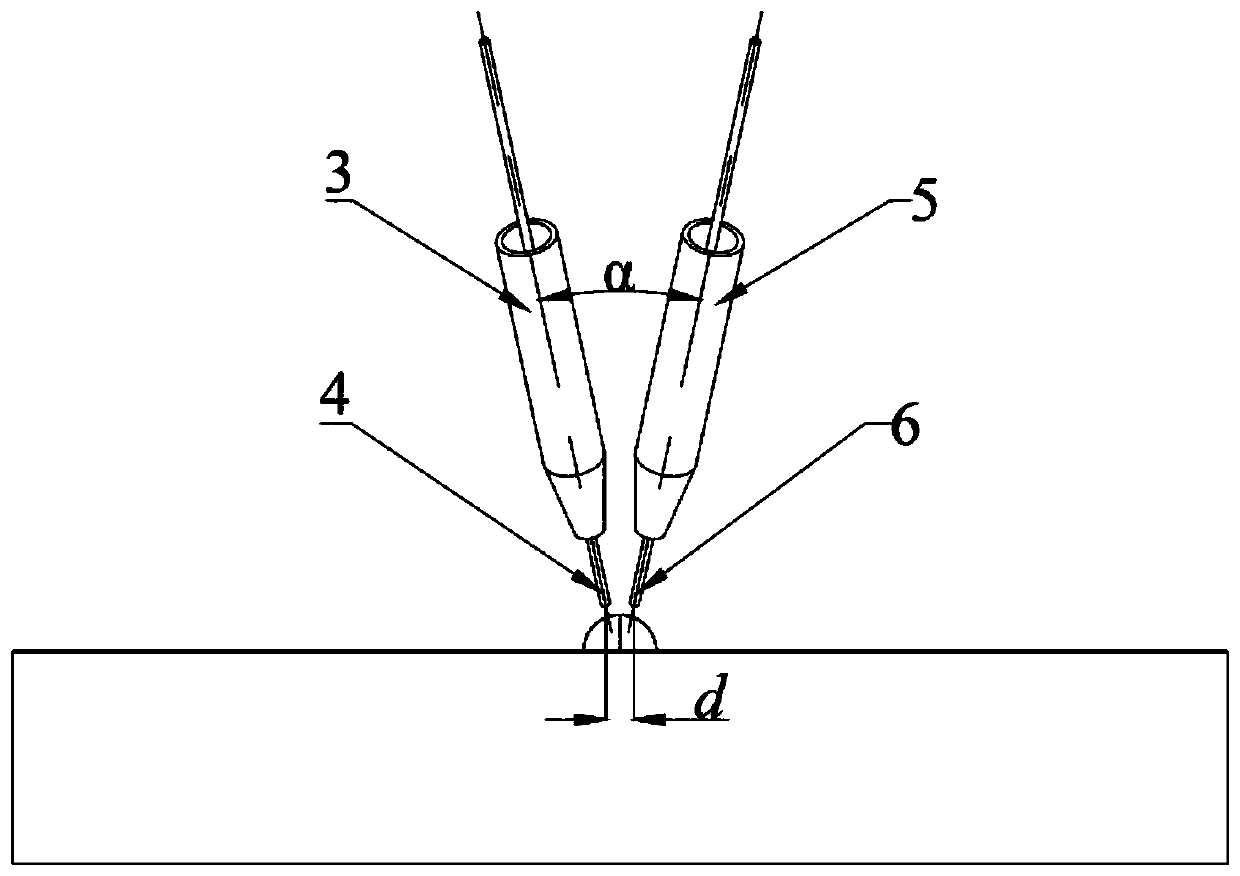

Dual-MAG heat source dual-filament submerged arc build-up welding method

InactiveCN111496346AAvoid poisoningLess welding spatterArc welding apparatusMelting tankSlag (welding)

The invention discloses a dual-MAG heat source dual-filament submerged arc build-up welding method which aims to solve the problems such as gas holes in aluminum bronze MAG build-up welding, incomplete fusion, slag inclusion, welder poisoning caused by copper welding smoke gas, and the like. The dual-MAG heat source dual-filament submerged arc build-up welding method comprises the following steps:I, removing spray nozzles for dual welding guns connected to a dual-MAG power supply, adopting dual conductive nozzles to separately clamp dual welding wires, embedding protective soldering flux, andadopting direct-current reverse connection for the dual-MAG power supply; II, enabling the dual welding guns to simultaneously arc and feed wires, enabling end parts of dual wires to define an included angle to advance side by side, and enabling two electric arcs to define a congruent melting tank; III, regulating current of the dual-MAG power supply to be 160A-200A, enabling voltage to be 24V-28V, enabling welding speed to be 30 cm / min to 40cm / min, enabling offset of adjacent two welding beads to be 1 / 3-1 / 2 of width of an upper welding seam (7), performing build-up welding on 3-4 wear-resisting layers, and enabling the thickness of a bottoming layer to be not greater than 3 mm. The welding method disclosed by the invention can be applied to the field of aluminum bronze build-up welding engineering of a water turbine.

Owner:HARBIN ELECTRIC MASCH CO LTD

60mm steel plate with excellent performance in thickness direction for ocean platform and production method thereof

The invention belongs to the technical field of structural steels for ship and ocean engineering, and particularly relates to a 60mm steel plate with excellent performance in a thickness direction for an ocean platform and a production method thereof. The 60mm steel plate with excellent performance in the thickness direction for the ocean platform comprises the following chemical components by mass percent: 0.09-0.14% of C, 0.20-0.50% of Si, 1.10-1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.030-0.060% of Nb, 0.010-0.020% of Ti, 0.015-0.050% of Als, the balance of Fe, and inevitable impurities. The steel plate has excellent performances in the thickness direction, steelmaking production adopts a single slag process, and the production method is simple and feasible.

Owner:JIGANG GRP

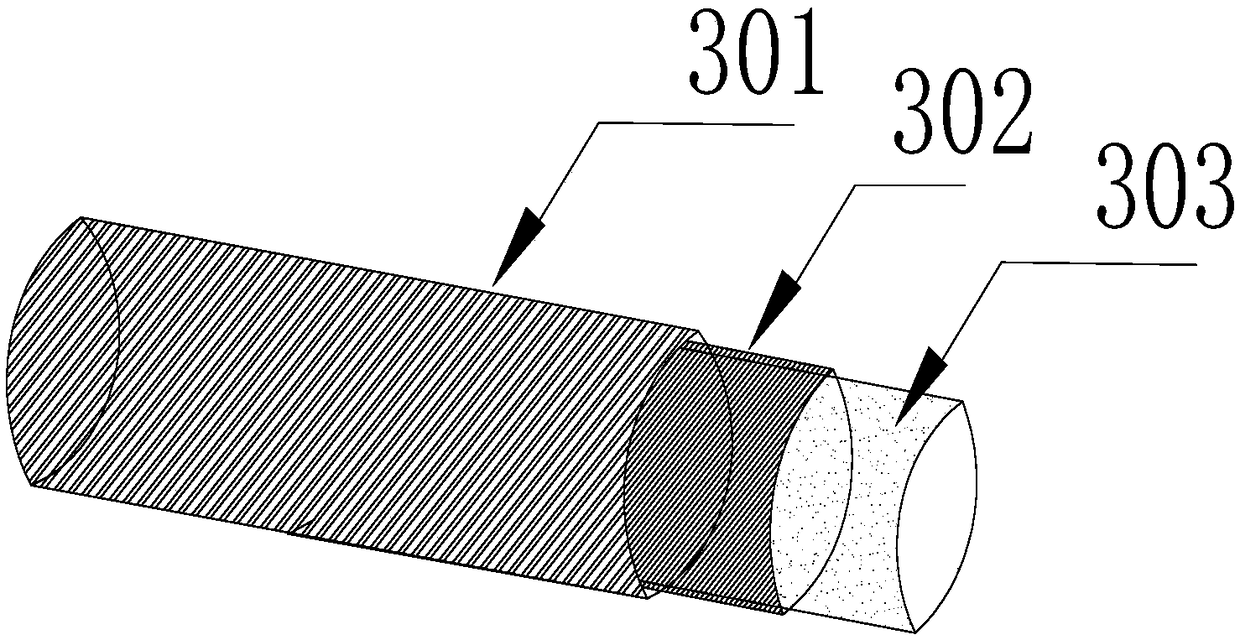

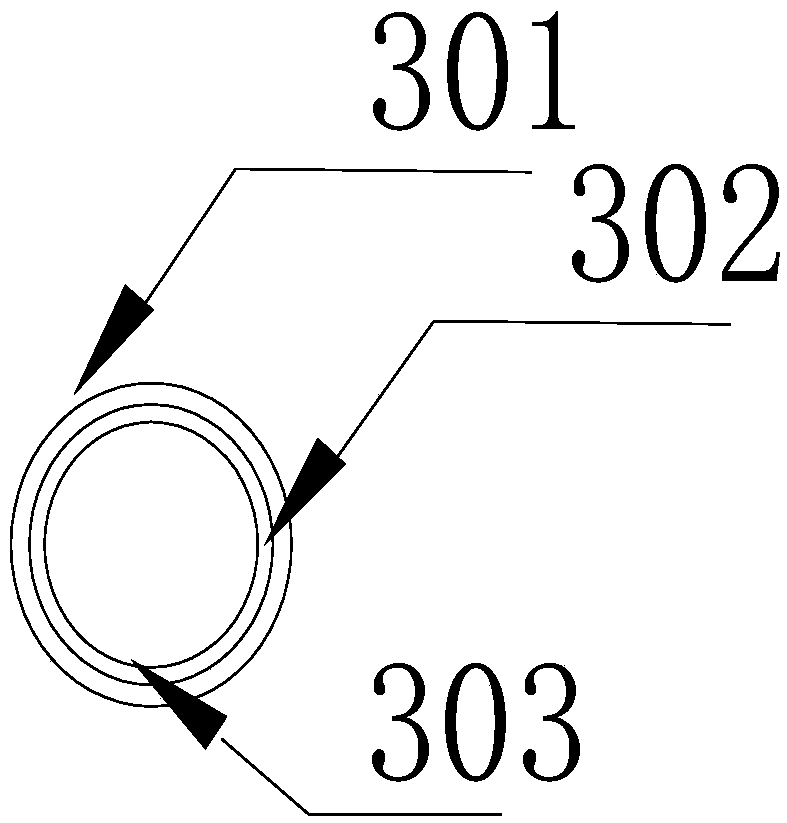

Low-temperature heatable cigarette having mint taste

ActiveCN109497610AImprove cooling effectExtended Airflow PathTobacco smoke filtersTobacco devicesFlavorAdhesive

The invention provides a low-temperature heatable cigarette having mint taste. The low-temperature heatable cigarette comprises an atomization substrate section and a cooling cigarette holder connected with each other, the structure of the cooling cigarette holder is a hollow cylindrical tubular structure and sequentially comprises a shell, an adhesive layer and a cooling layer from outside to inside, the adhesive layer enables the shell and the cooling layer bonded together, the adhesive layer is provided with an internally contained dissolution agent and a thermosensitive microcapsule for tobacco flavor containing mint, the thermosensitive microcapsule begins to release the dissolution agent and the tobacco flavor after response temperate is reached, accordingly the bonding state and flavor state between the shell and the cooling layer are changed, and the surface area of the cooling layer and a smoke flow path is changed. Under the influence of multiple effects of lubrication, dissolution and the like of the dissolution agent released by the thermosensitive microcapsule on an adhesive, the stickiness of the cooling layer and the shell is reduced, accordingly the effect of makingthe cooling layer shedding from the shell is achieved, a smoke cooling effect is remarkable, meanwhile the tobacco flavor containing mint fragrance, and a sensory cooling effect is better.

Owner:HUBEI CHINA TOBACCO IND

A steel plate for offshore platforms with excellent performance in the thickness direction of 60mm and its production method

InactiveCN103451534BFull escapeGuaranteed floatManufacturing convertersSteelmakingChemical composition

Owner:JIGANG GRP

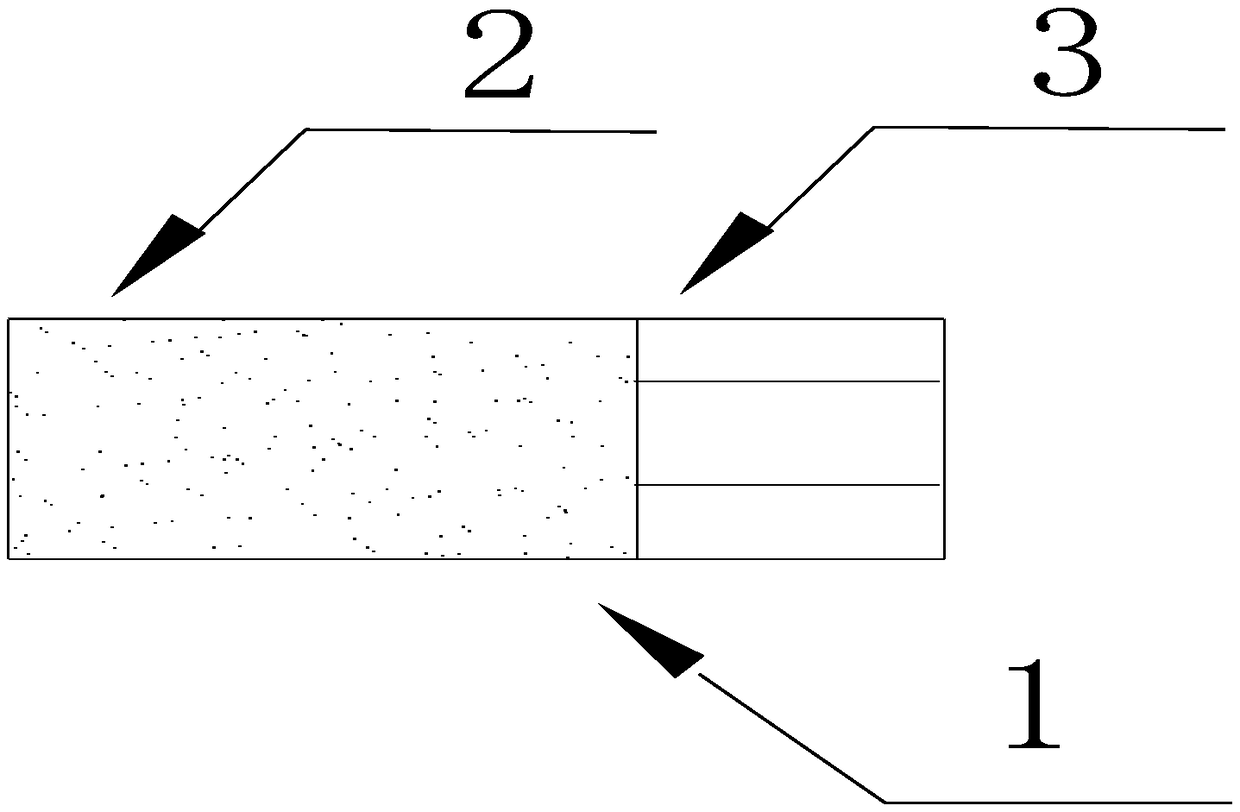

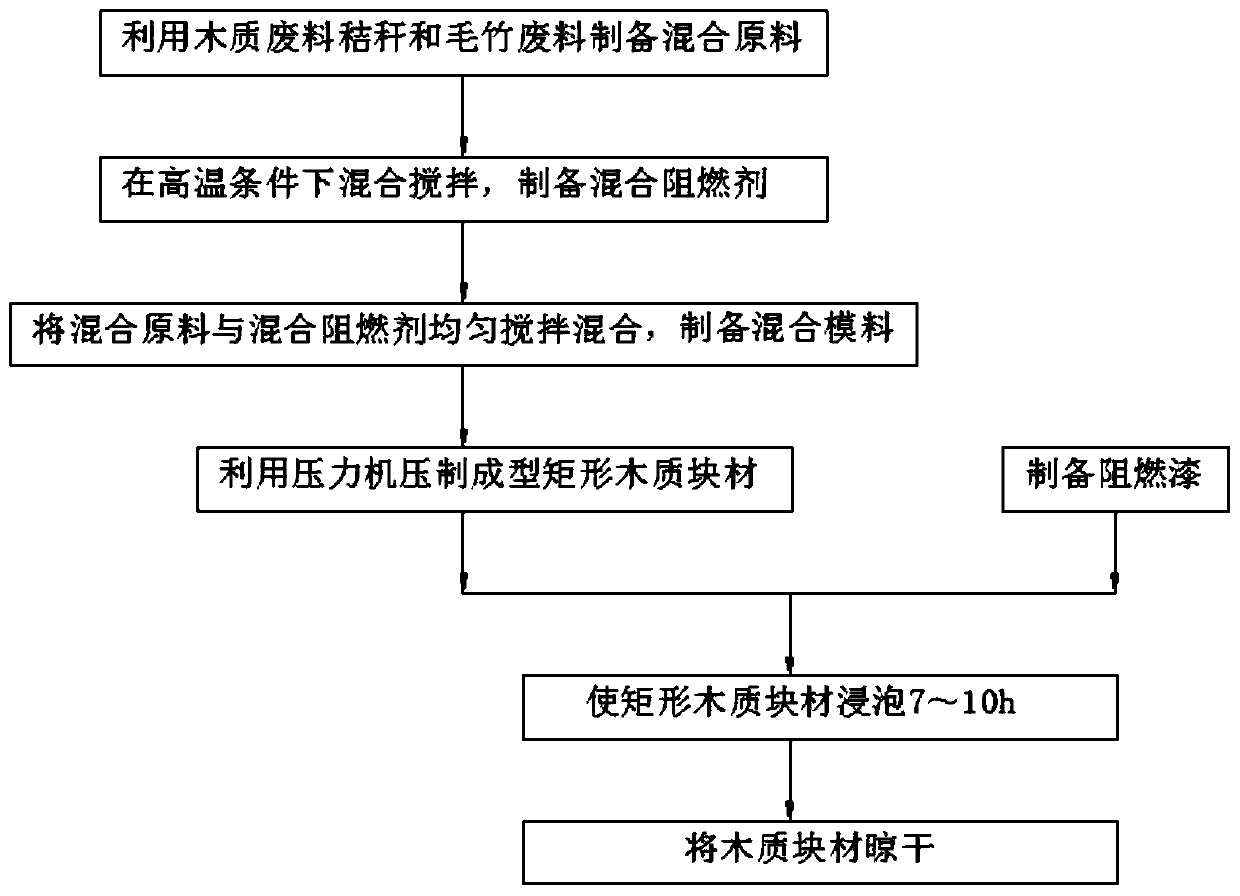

Manufacturing method of flame-resistant wood floor in architectural decoration and finishing

InactiveCN110105780AIncrease profitImprove product qualityCovering/liningsWood treatment detailsMaterials preparationRenewable resource

The invention provides a manufacturing method of flame-resistant wood floor in architectural decoration and finishing. The manufacturing method comprises following steps: wood waste material straw andPhyllostachys edulis waste material are adopted to prepare a mixed raw material, mixing stirring is carried out under high temperature conditions, a mixed flame retardant is prepared, the mixed raw material and the mixed flame retardant are mixed through stirring so as to obtain a mixed mould material, the mixed mould material is subjected to pressing so as to obtain rectangular wood sheet materials, a mixed flame-resistant paint is prepared, and the rectangular wood sheet materials are immersed in the mixed flame-resistant paint. According to the technology, renewable resources are adopted to prepare the wood sheet material, so that resource waste is reduced; the prepared flame retardant is subjected to full mixing stirring with the raw material under high temperature conditions, flame retardant activity is increased; full stirring is adopted in the mixed mould material preparation process, so that uniform distribution of the flame retardant in the mixed mould material is realized, wood sheet material manufacturing quality is increased; and wood sheet material immersion in the mixed flame-resistant paint is capable of improving the flame resistance of the surface of the wood sheet material, and eliminating fire hazard hidden troubles completely.

Owner:贵州力宏建筑工程有限公司

A gas-shielded welding method for high-strength steel thick plates of 1000mpa engineering machinery

ActiveCN106270957BAvoid cold cracksFull escapeArc welding apparatusWelding/cutting media/materialsEngineeringSlow cooling

Owner:武汉钢铁有限公司

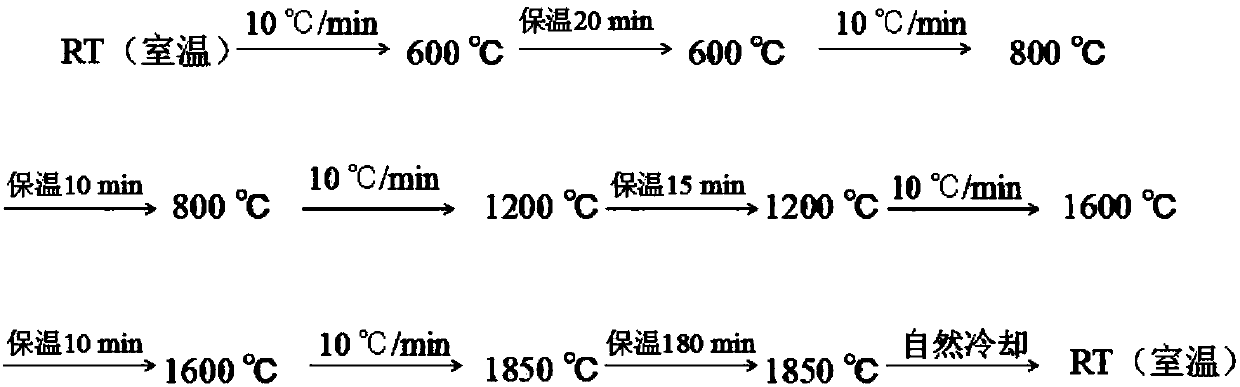

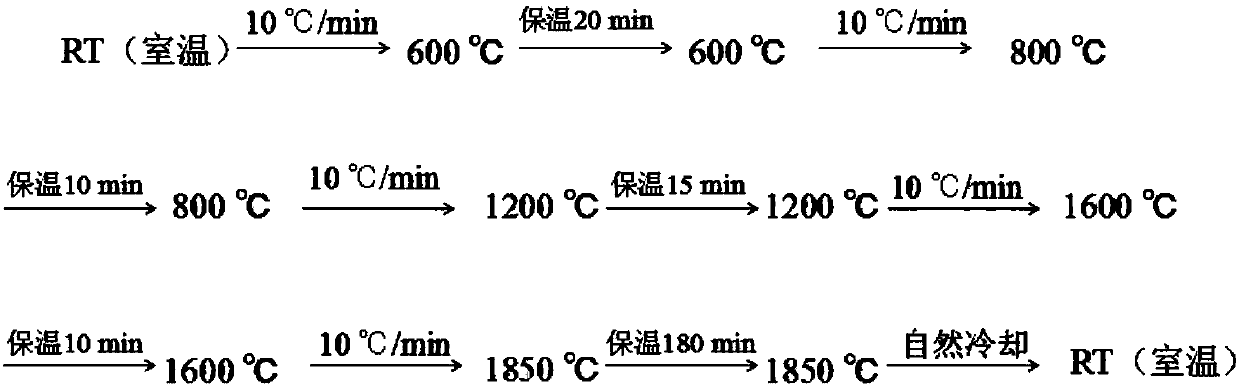

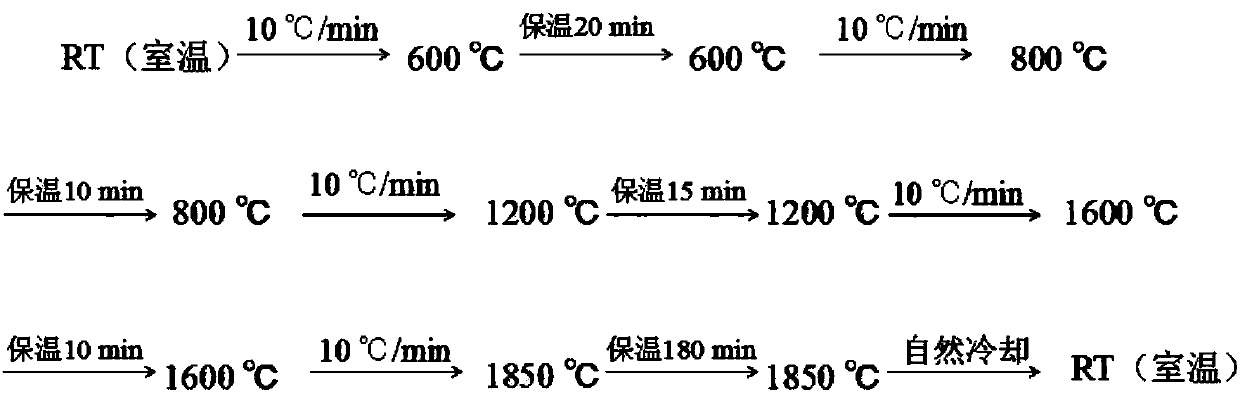

A preparing method of a polycrystalline sapphire transparent thin plate

InactiveCN107747123ASolve processabilitySolve the yieldPolycrystalline material growthSingle crystal growth detailsEmulsionOrganic solvent

An environmentally friendly tape casting method of a polycrystalline sapphire transparent thin plate is provided. High-purity submicron-order spherical aluminum oxide is adopted as a main raw material, a sintering auxiliary agent is added, and polyvinyl alcohol, waterborne acrylic resin, styrene-acrylic emulsion, and the like are adopted as main adhesives, and deionized water is adopted in place of an organic solvent. The method overcomes problems, namely difficult production and processing, a low yield and a small manufacturing dimension in present sapphire production. The dimension of a polycrystalline sapphire thin plate blank manufactured by the method can be 450*450 mm that is an ultrahigh dimension, and most monocrystal sapphire products can be replaced. The waterborne adhesives areadopted and the water is adopted to replace the organic solvent in the method, thus reducing environment pollution.

Owner:宁夏钜晶电子材料科技有限公司

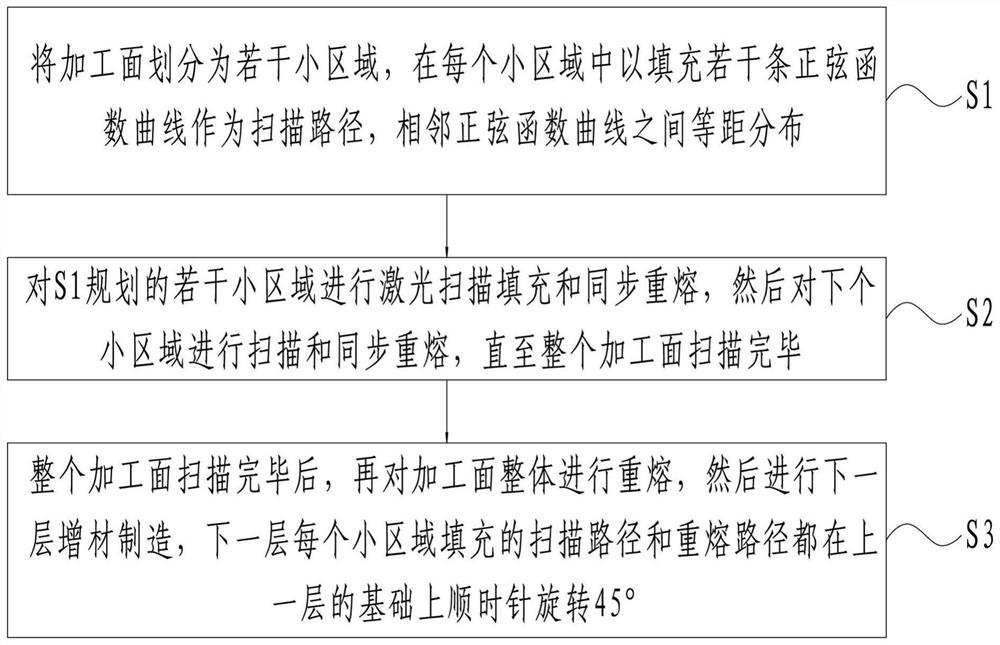

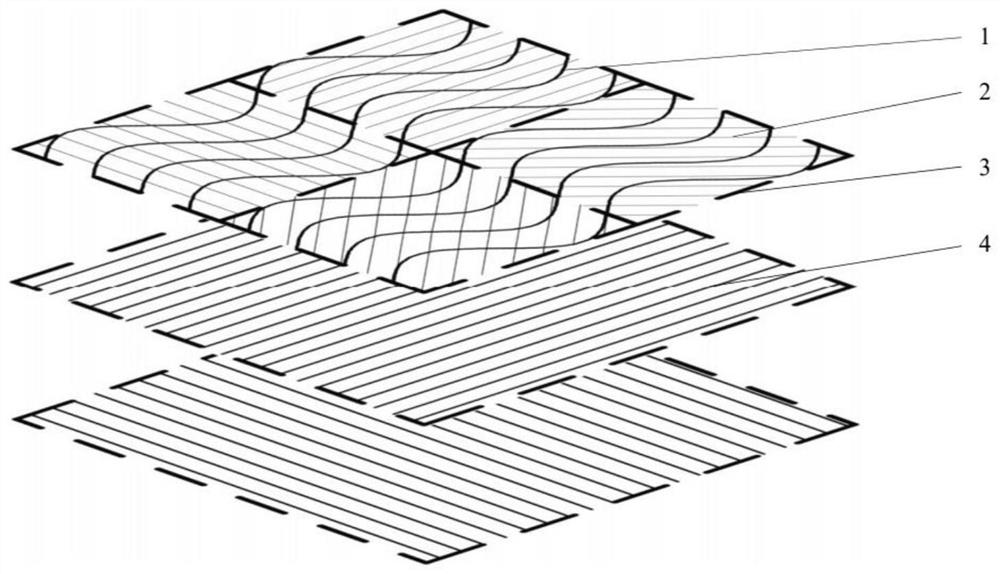

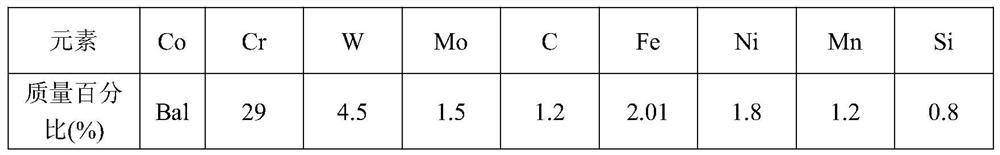

Laser additive manufacturing isotropic scanning method for scanning galvanometer

PendingCN114535607AShort timeExtension of timeTurbinesAdditive manufacturing apparatusMachined surfaceGalvanometer

The invention discloses a laser additive manufacturing isotropic scanning method for a scanning galvanometer, which comprises the following steps of: dividing a processing surface into a plurality of small areas, filling a plurality of sine function curves in each small area as a scanning path, and equidistantly distributing adjacent sine function curves; s2, laser scanning filling and synchronous remelting are conducted on the multiple small areas planned in the S1, and then scanning and synchronous remelting are conducted on the next small area till the whole machining face is scanned; and after the whole machined surface is scanned, the whole machined surface is remelted, then additive manufacturing of the next layer is carried out, and the scanning path and the remelting path for filling each small area of the next layer are clockwise rotated by 45 degrees on the basis of the upper layer. According to the method, through curve path scanning and synchronous remelting, due to the fact that the grain growth direction is disturbed, grains are arranged disorderly, and the overall mechanical property of the additive manufacturing layer tends to be isotropic.

Owner:ZHEJIANG UNIV OF TECH

Self protection flux core welding wire of pipe line steel full position

InactiveCN100420539CImprove smoothnessReduce nitrogen and hydrogenWelding/cutting media/materialsSoldering mediaArc stabilityLine tubing

The self-protecting welding wire with flux core for pipeline steel has welding wire comprising BaF2, SrF2 and / or CaF2 7-12 wt%, LiF 0.8-3.0 wt%, CaO 0.2-0.8 wt%, SiO2 0.1-0.4 wt%, Al 1.2-2.0 wt%, Mg 1.2-2.0 wt%, Mn 0.6-1.2 wt%, Ni 0.6-1.2 wt%, C 0.05- 0.10 wt%, Zr 0.05-0.3 wt%, B 0.002-0.012 wt%, and Fe for the rest; and flux core accounting for 18-25 wt%. It contains water in 0.010-0.120 wt%, and has reduced current fluctuation and raised welding performance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

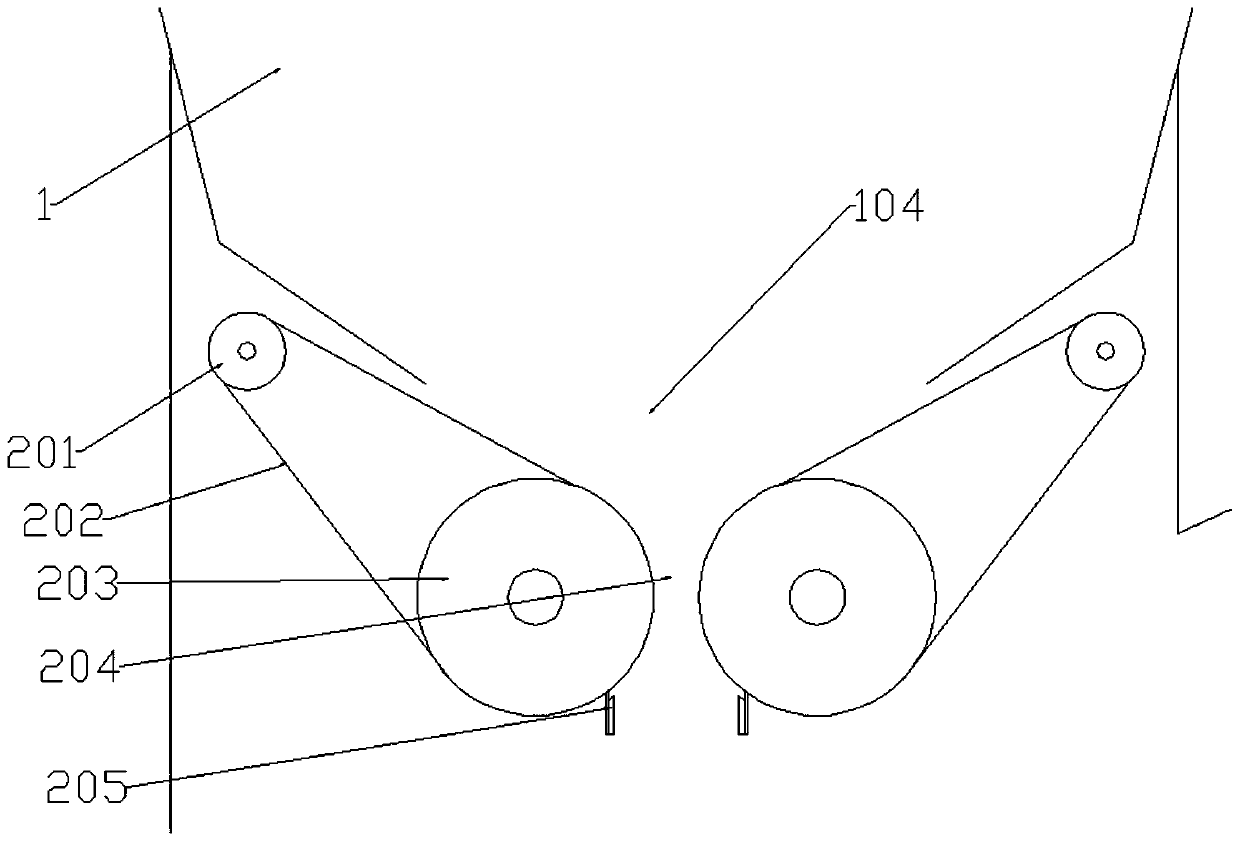

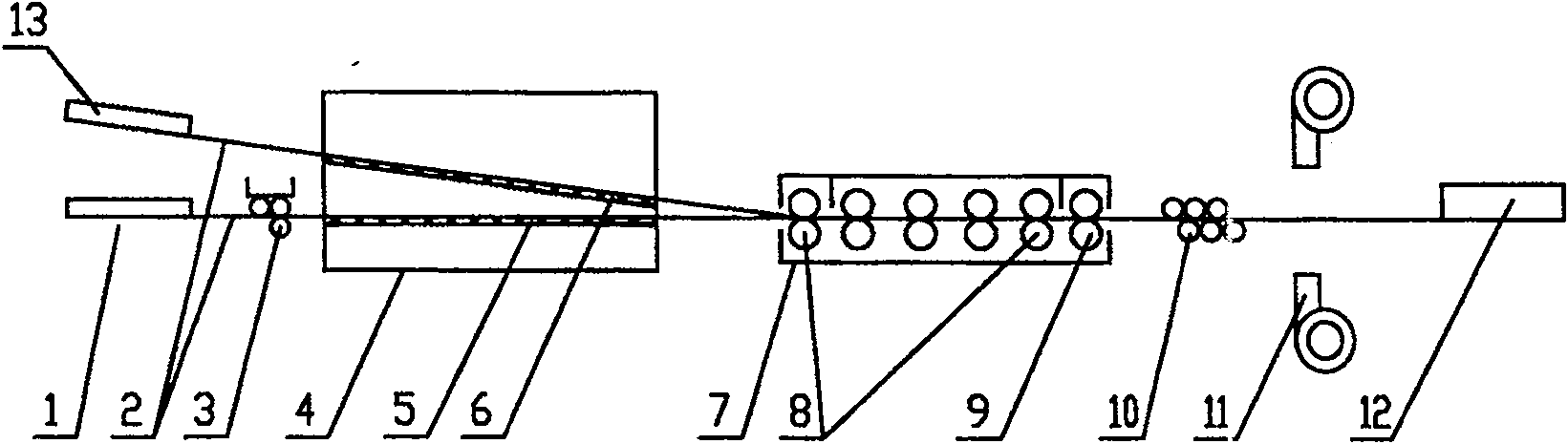

Compound damping steel plate making process and apparatus

InactiveCN100579776CImprove composite effectHigh peel strengthLamination ancillary operationsLaminationSheet steelHeating furnace

The compound damping steel plate making process and apparatus adopts one identical heating furnace with upper stoving channel and lower stoving channel for preheating steel plate and heating glued steel plate separately, and five pairs of heating and laminating rolls to roll and combine two steel plates, with the damping resin layer between two steel plates being heated, pressurized and cured simultaneously. The present invention has effectively lowered power consumption, excellent steel plate laminating performance and simplified technological process, and may be applied widely in making compound damping steel plate with high molecule resin as the damping and adhering layer.

Owner:黄云龙 +1

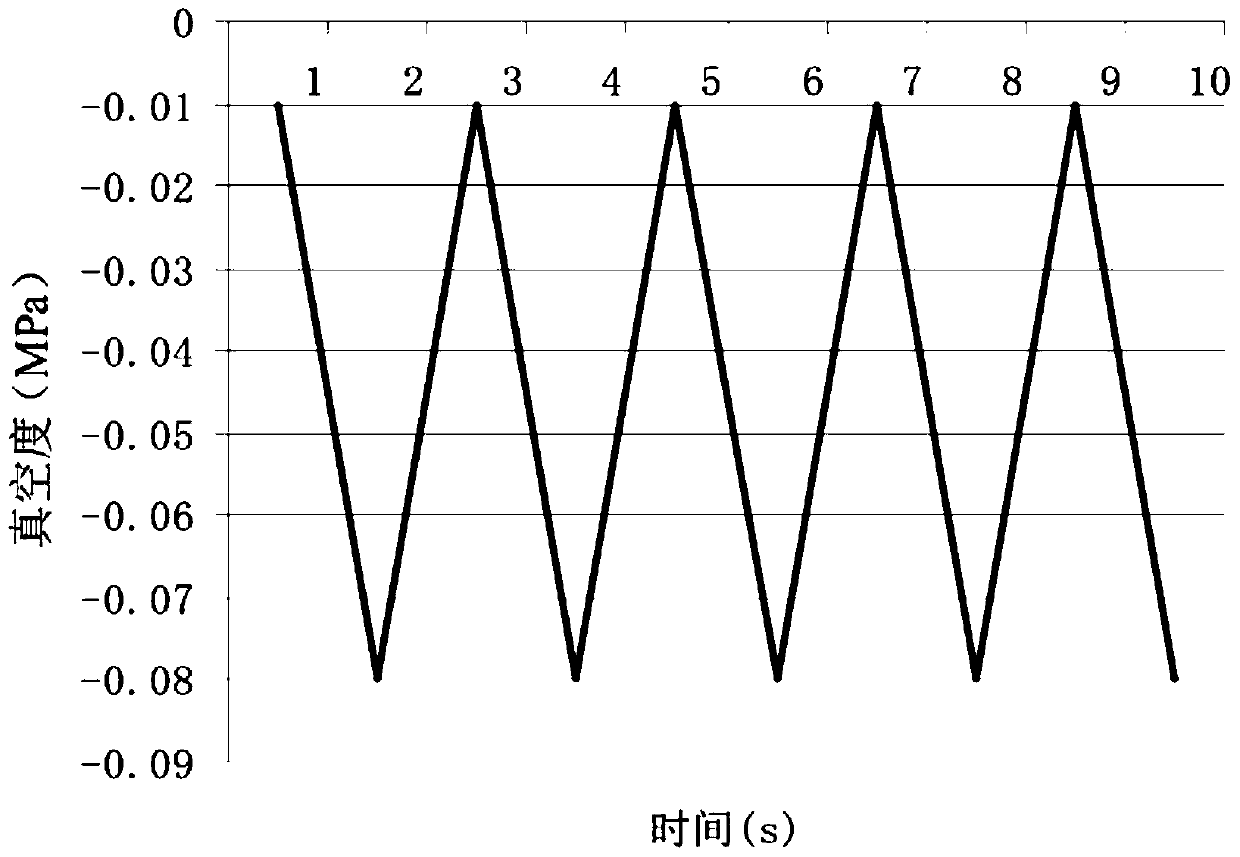

A method for accelerating the absorption of soft-pack lithium-ion battery injection and soft-pack lithium-ion battery

ActiveCN105428721BSpeed up entryMove with easeFinal product manufactureCell component detailsPressure cyclePhysical chemistry

The invention relates to a liquid-injecting accelerated absorption method for a soft-pack lithium-ion battery and a soft-pack lithium-ion battery, belonging to the technical field of lithium-ion batteries. The method for accelerating the absorption of soft-pack lithium-ion battery injection according to the present invention comprises: under the protection of a dry inert gas, inject the electrolyte solution into the soft-pack lithium-ion battery three times in a glove box at 45-50°C, and after each injection, Squeeze the soft-packed lithium-ion battery sequentially and leave it in a negative pressure cycle; seal the soft-packed lithium-ion battery; the degree of vacuum during the negative pressure cycle is continuously changed between -0.08~-0.01MPa, and the The time for standing under negative pressure is 2-8s; the sealed soft-pack lithium-ion battery is kept at 70-80°C for 4-5h, and the soft-pack lithium-ion battery is pressed at least once during the standing process and turned upside down . The method of the invention promotes the absorption of the electrolyte in the battery core, and improves the consistency of the absorption of the electrolyte in the soft pack lithium ion battery.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

A mechanical impact method and device for effectively reducing laser cladding cracks

ActiveCN105088225BReduce in quantityHigh strengthMetallic material coating processesNumerical controlMechanical impact

A mechanical impact device for effectively reducing laser cladding cracks mainly includes: a powder-feeding high-power semiconductor laser cladding device, a numerical control device and a mechanical impact assembly. In the present invention, the workpiece to be clad is clamped with a three-jaw or four-jaw chuck, powder is fed to the workpiece by a preset powder feeding method, and a mechanical impact of a certain frequency is applied to a single pass of laser cladding to obtain a cladding layer with excellent quality . The mechanical vibration caused by the impact can effectively break the dendrites that are preferentially precipitated in the molten pool, the grains are refined, the plasticity of the solidified crystals is improved, and thermal cracks are avoided. Secondly, the hammering effect of the mechanical impact hammer on the cladding single pass , can partially balance the residual tensile stress generated during the cooling process of the molten pool, reduce the appearance of cold cracks, and obtain a cladding layer with excellent quality.

Owner:YANSHAN UNIV

A low temperature heating cigarette with mint flavor

ActiveCN109497610BImprove cooling effectExtended Airflow PathCigar manufactureTobacco smoke filtersMentholMentha spicata

The invention provides a low-temperature heating cigarette with a mint flavor, which comprises interconnected atomization matrix segments and a cooling nozzle rod; the structure of the cooling nozzle rod is a hollow cylindrical tubular structure, which sequentially includes a shell, an adhesive layer, and a cooling nozzle from outside to inside. layer, the adhesive layer bonds the shell and the cooling layer together, and the adhesive layer contains heat-sensitive microcapsules containing a solvent and mint-containing tobacco flavor, and the heat-sensitive microcapsules begin to release and dissolve after reaching the response temperature To change the bonding state and aroma state between the casing and the cooling layer, increase the surface area of the cooling layer and change the airflow path of the smoke. In the present invention, the dissolving agent released by the heat-sensitive microcapsules can reduce the viscosity of the cooling layer and the casing under the influence of multiple effects such as lubrication and dissolution of the adhesive, thereby achieving the effect that the cooling layer falls off from the casing and the flue gas cooling effect Significantly, at the same time, the tobacco flavor contains mint aroma, and the sensory cooling effect is better.

Owner:HUBEI CHINA TOBACCO IND

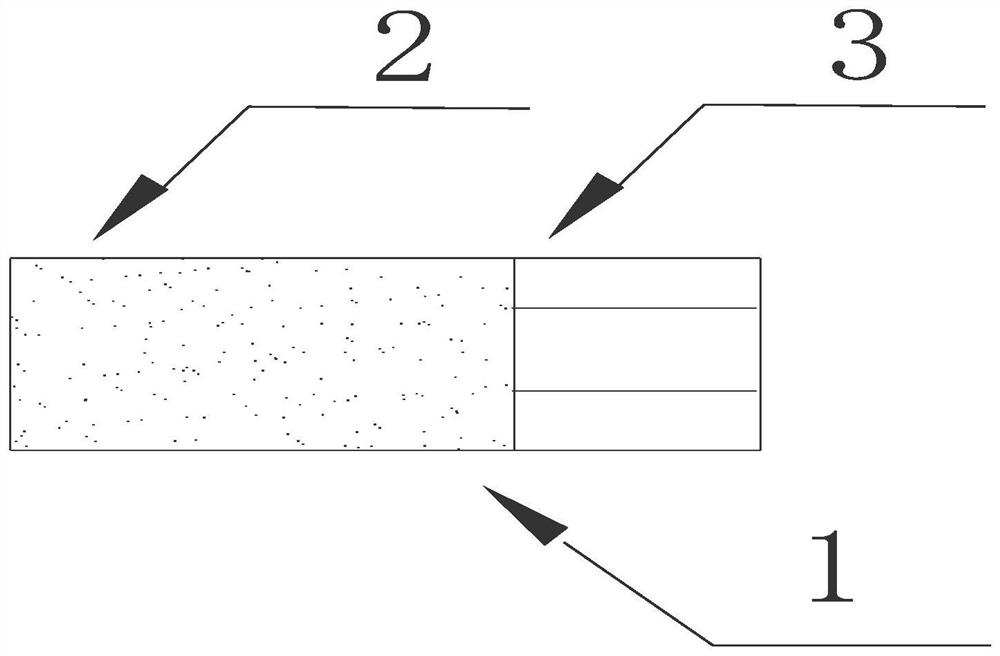

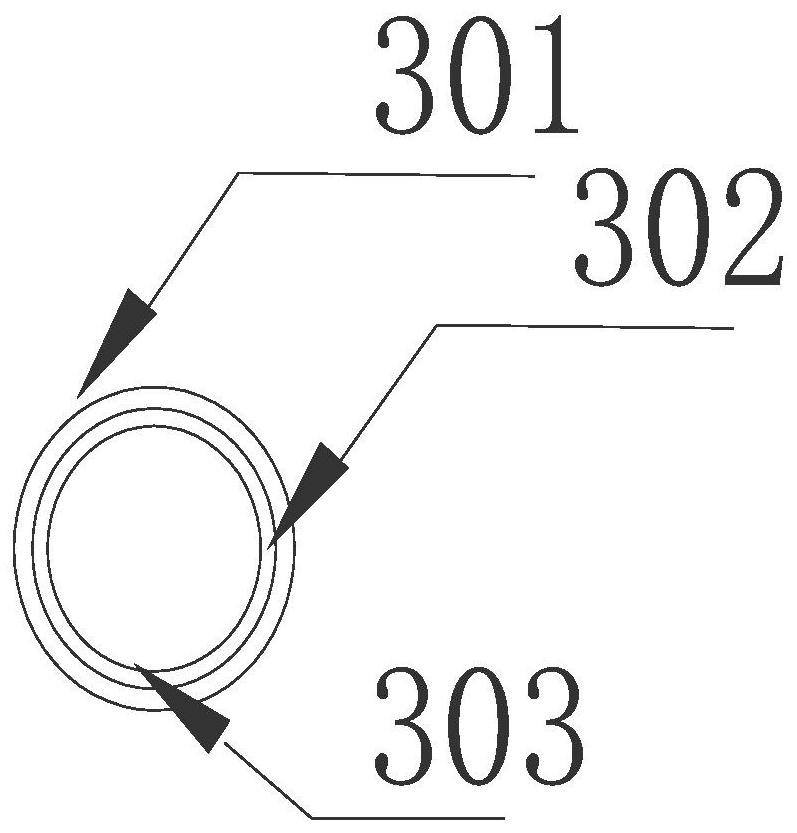

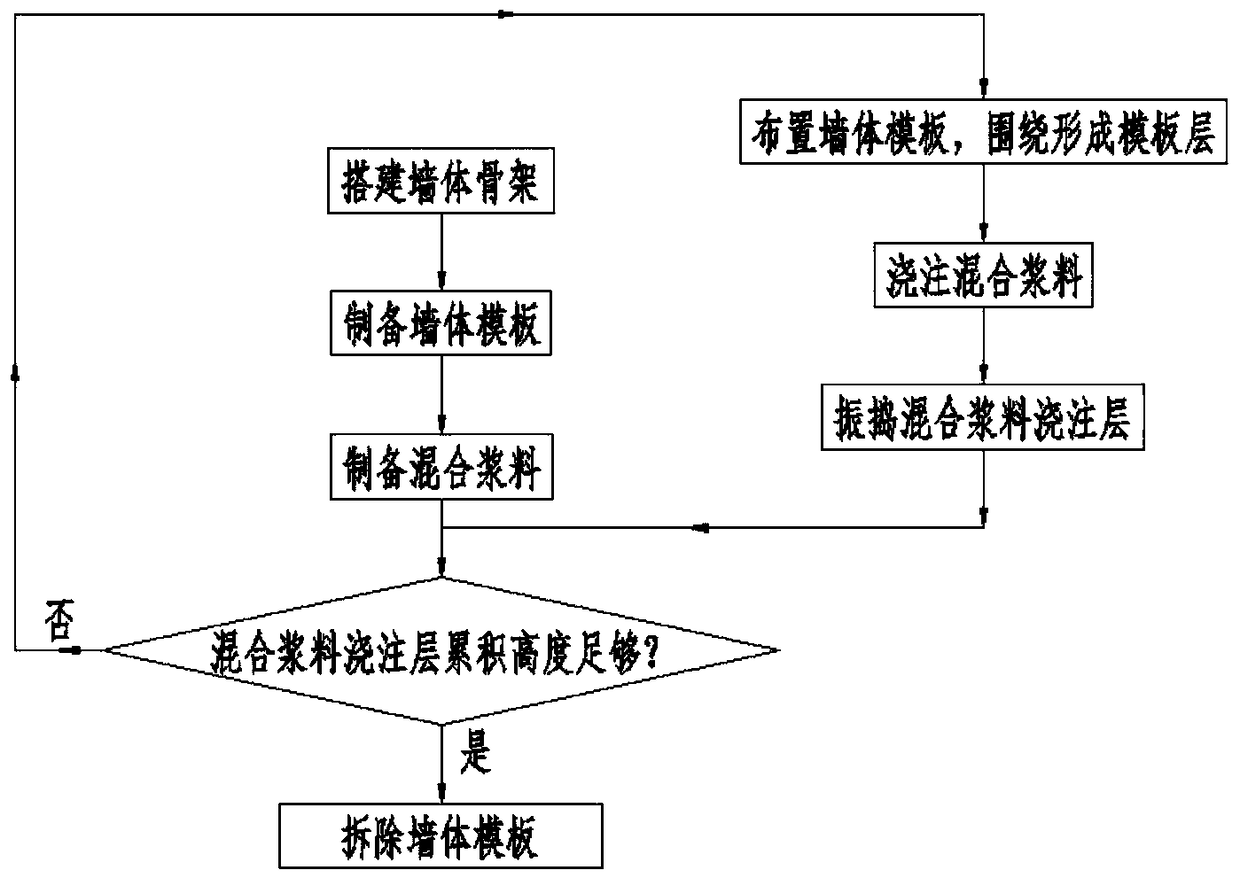

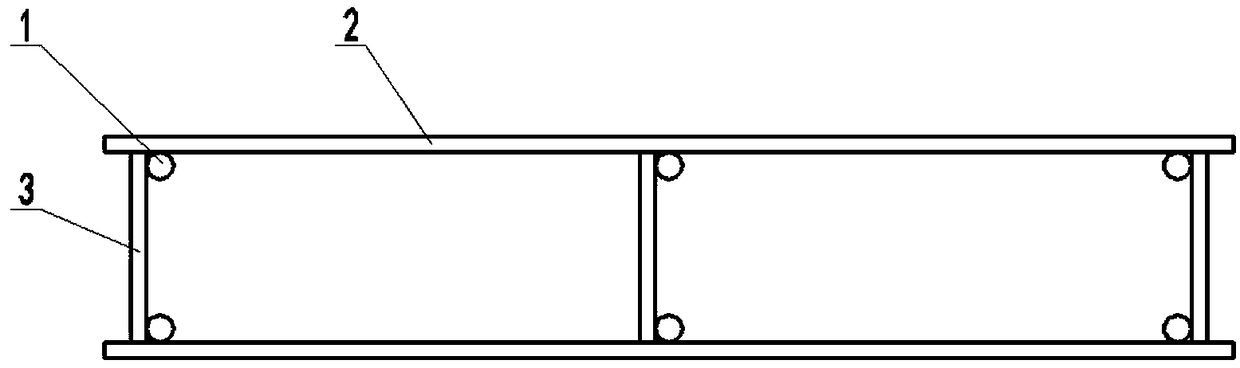

Construction method of cast-in-place bearing wall

PendingCN109025283AHigh flatness of the side surfaceImprove carrying capacityWallsBuilding material handlingSlurryEngineering

The invention provides a construction method of a cast-in-place bearing wall. The construction method comprises the steps of building a wall framework, preparing a wall template, preparing a mixed slurry, arranging a wall template in a surrounding mode to form a template layer, enabling wall templates within the template layer to be connected together, pouring mixed slurry into the template layerin a layer-by-layer casting manner, allowing the template layers to be connected together during pouring, vibrating the mixed slurry, and disassembling a wall template. According to the technical scheme, a lot of gypsum raw materials are reasonably applied in the field of construction engineering. In the pouring construction process, the wall templates are always kept in a posture perpendicular tothe ground, so that the flatness of the surface of the bearing wall formed by final pouring is higher. The side surface of the bearing wall is perpendicular to the ground, and the construction quality is improved. Full vibration is carried out in the pouring process, so that the concrete is condensed and dense, the bearing capacity of the bearing wall is improved, and the construction quality isimproved.

Owner:NANNING UNIV

Spillway tunnel bottom plate construction method

InactiveCN112281766AReduce disturbancePrevent water seepageBarrages/weirsFoundation engineeringWater seepageStructural engineering

The invention provides a spillway tunnel bottom plate construction method. The spillway tunnel bottom plate construction method comprises the following steps that underground earthwork is gradually excavated in a target area section by section to form a plurality of linear tunnel sections and a plurality of bent tunnel sections, all the linear tunnel sections and all the bent tunnel sections are finally communicated in sequence according to the excavation sequence to form a spillway tunnel, meanwhile, bottom plate units are built in a segmented mode in sequence in the extending direction of the spillway tunnel, all the bottom plate units are finally and sequentially connected according to the building sequence to form the spillway tunnel bottom plate, and when the bottom plate units are located in the linear tunnel sections, the corresponding bottom plate units are shorter than 8m, and when the bottom plate units are located in the bent tunnel sections, the corresponding bottom plate units are shorter than 4m. By the adoption of the technical scheme, disturbance to surrounding rock of the spillway tunnel is reduced, the surrounding rock is reinforced in time, water seepage is effectively prevented by excavating the spillway in a segmented mode, building the bottom plate units in a segmented mode and pouring concrete in a layered mode, and the safety protection performance is enhanced by building side wall units on the left sides and the right sides of the bottom plate units; and the concrete engineering construction quality is improved.

Owner:SINOHYDRO BUREAU 9

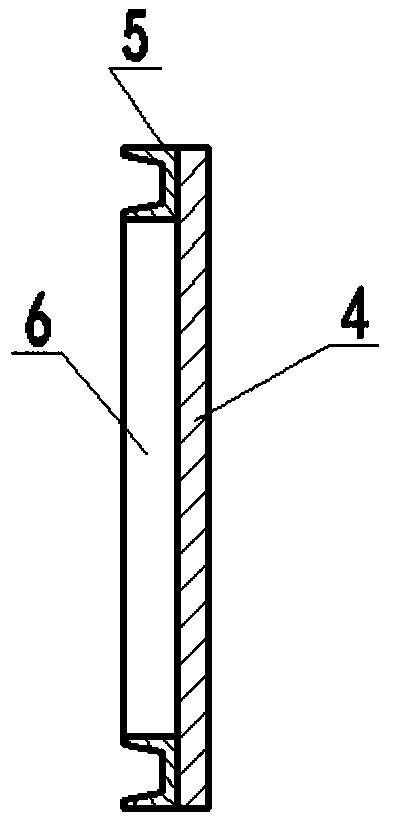

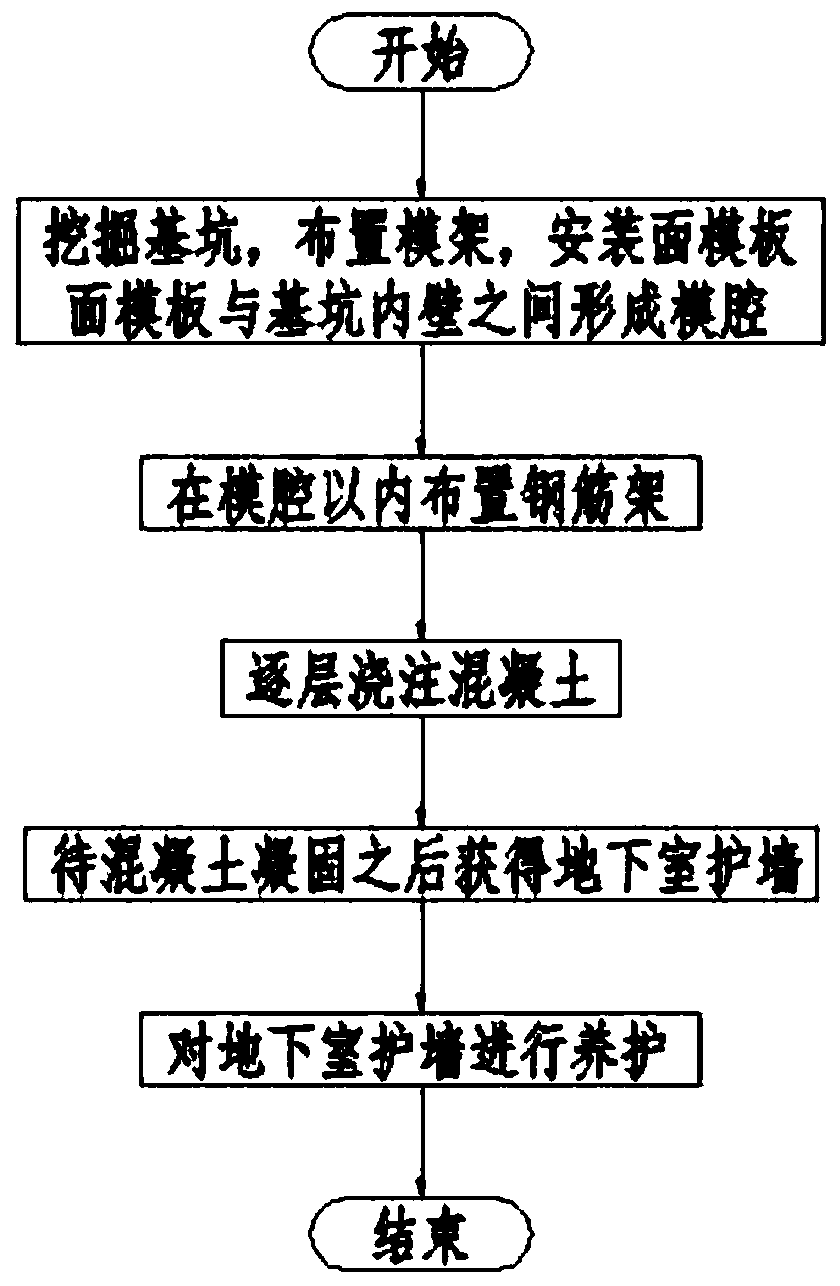

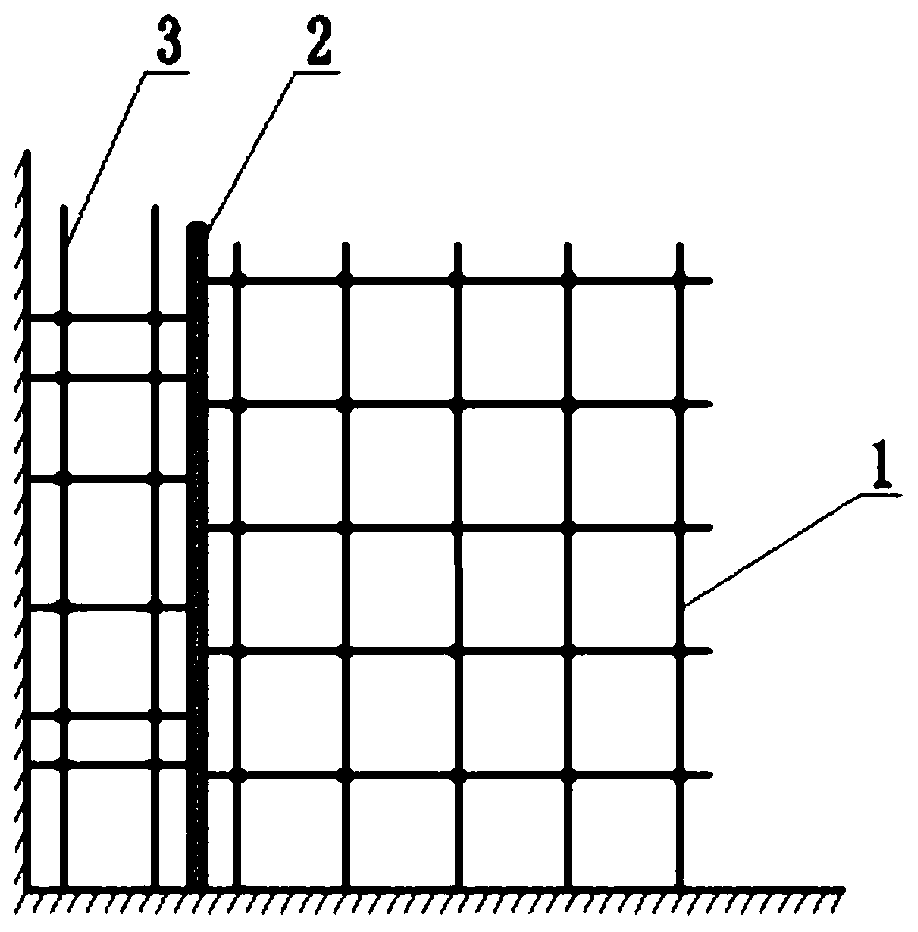

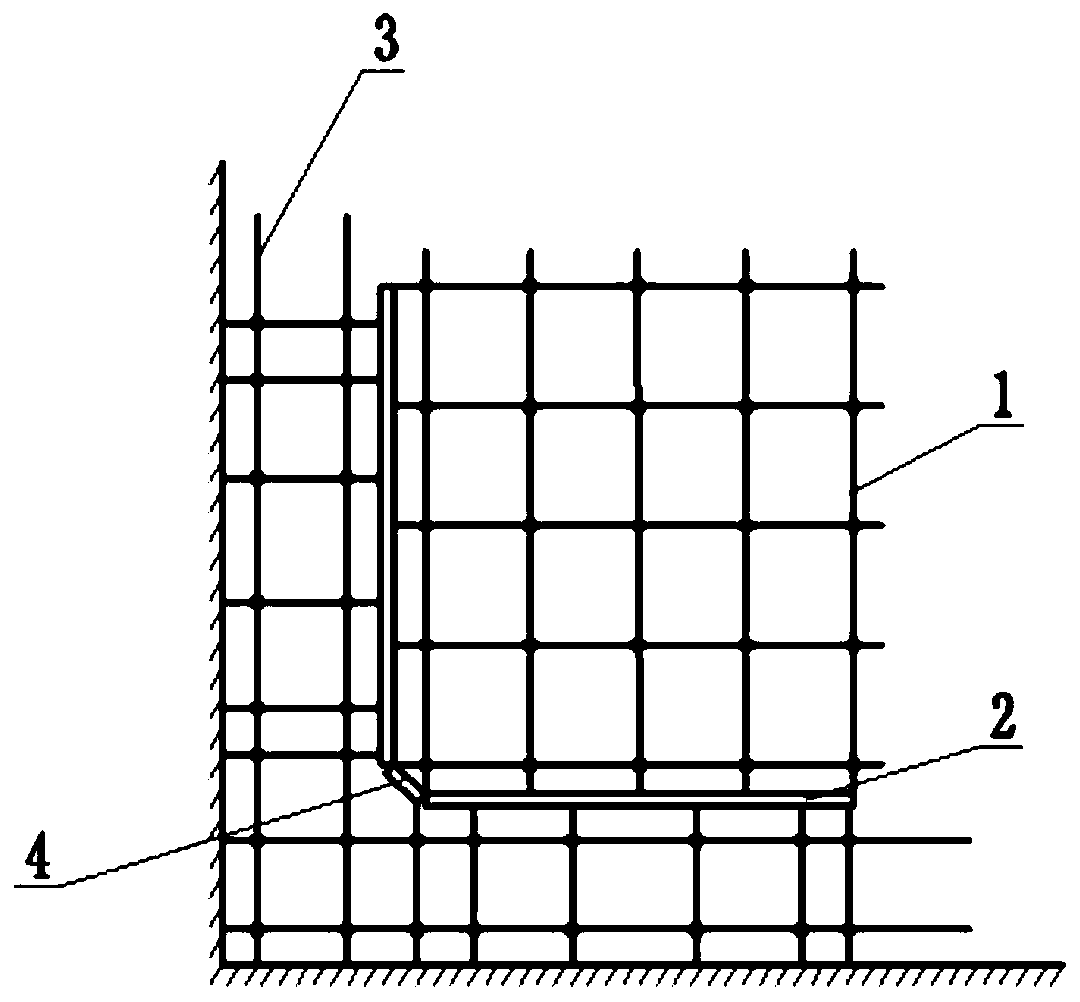

Basement protection wall concrete pouring construction technology

InactiveCN110847230AReduce surface roughnessImprove structural strengthArtificial islandsCellarsArchitectural engineeringRebar

The invention provides a basement protection wall concrete pouring construction technology. The technology comprises the following steps that a foundation pit is dug, a form frame is arranged, a surface form is installed, a mold cavity is formed between the surface form and the inner wall of the foundation pit, a rebar frame is arranged in the mold cavity, concrete is poured layer by layer, and curing is carried out on a basement protection wall. According to the technical scheme of the technology, the rebar frame is embedded in the concrete, the structure strength and the bearing capacity ofthe basement protection wall are enhanced, through the adoption of the steel surface form, the flatness of the surface of the basement protection wall is improved, by adopting a layer-by-layer pouringconstruction process, air doped in the concrete can sufficiently escape, the concrete is compact in condensation, the concrete engineering quality is improved, cracks can be effectively avoided on the surface of the concrete by flattening the concrete in an initial setting state, sufficient maintenance is conducted on the surface of the poured and formed basement protection wall, and the concreteengineering construction quality is guaranteed.

Owner:张瑨

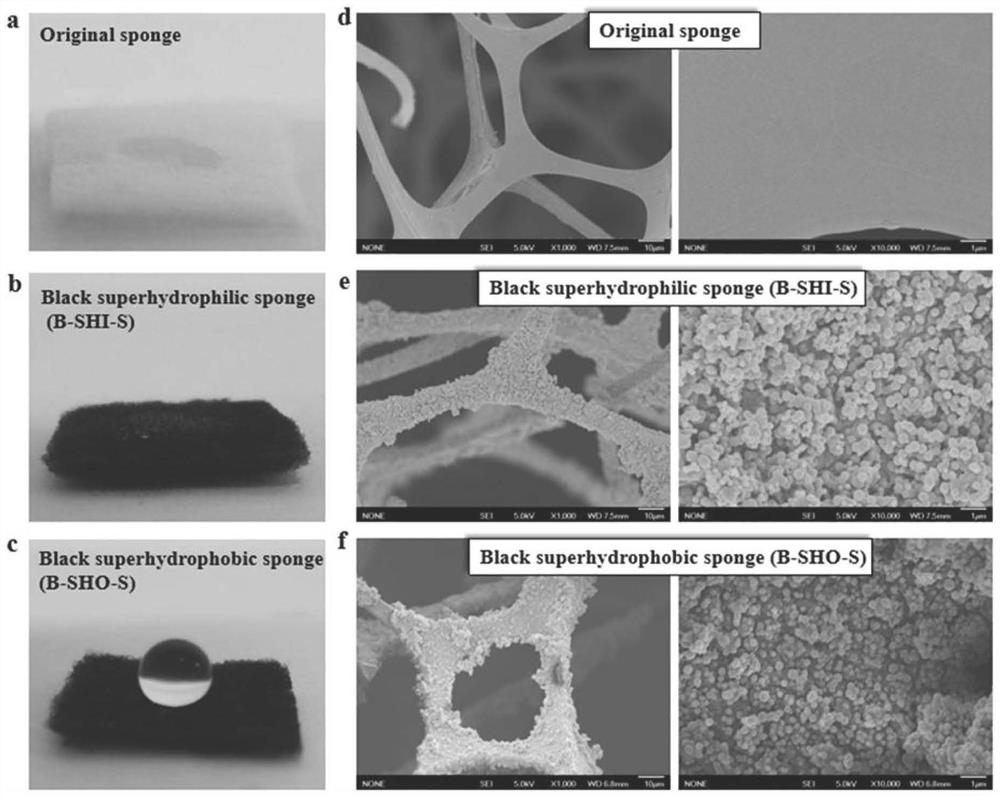

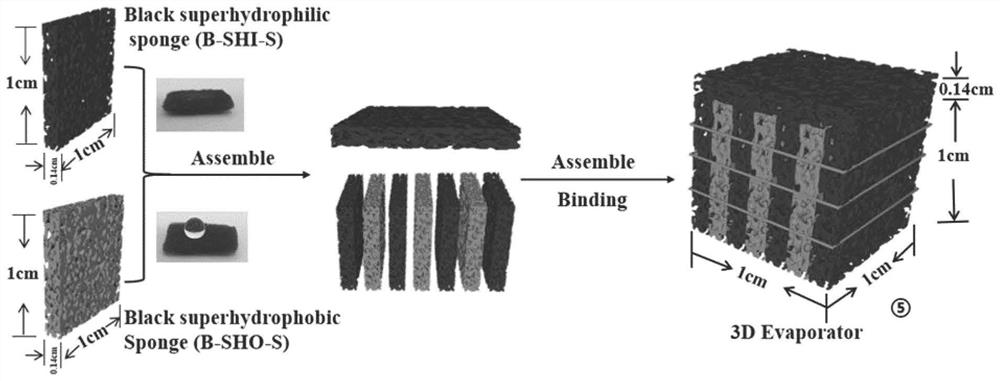

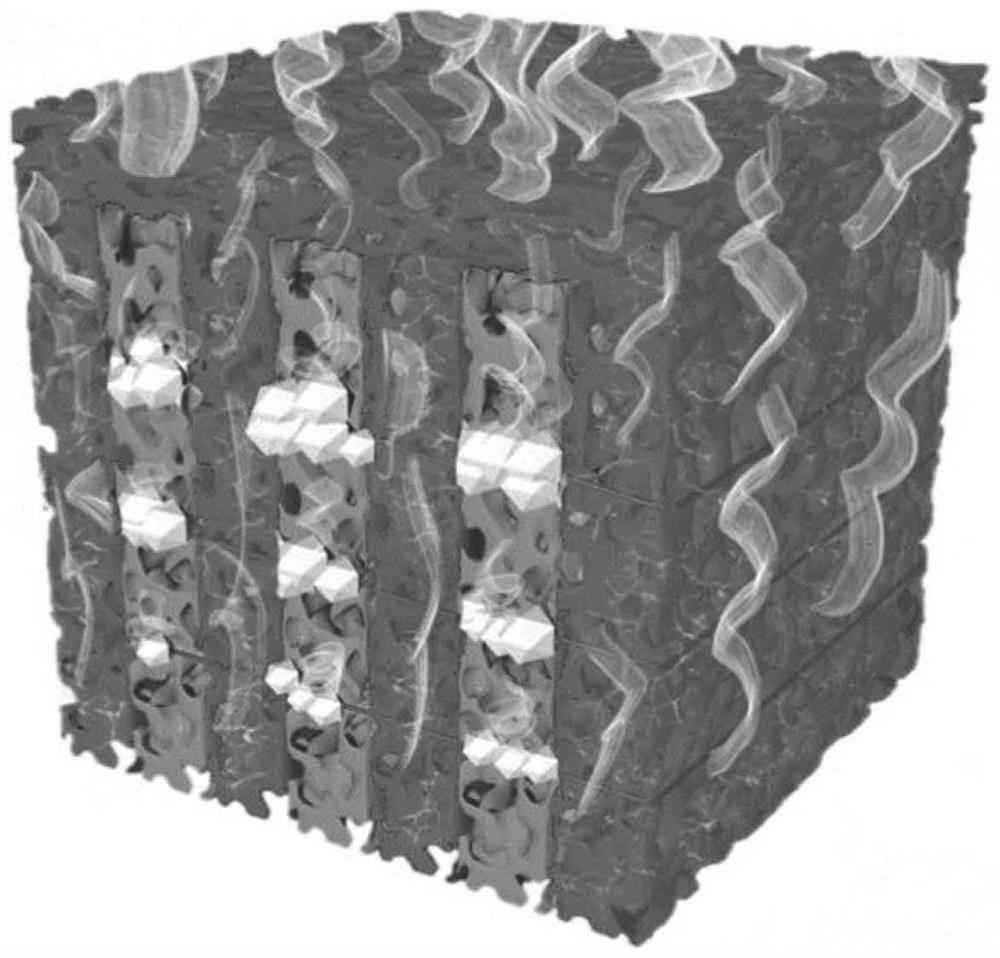

Three-dimensional solar evaporator with directional salt deposition function and used for treating high-concentration saline water and preparation method of three-dimensional solar evaporator

ActiveCN114835183ASolve the problem of low evaporation efficiencySolve pollutionGeneral water supply conservationSeawater treatmentHigh concentrationSaline water

The invention discloses a three-dimensional solar evaporator with a directional salt deposition function and used for treating high-concentration brine and a preparation method of the three-dimensional solar evaporator, and belongs to the field of seawater desalination. According to the solar evaporator, porous sponge is subjected to black super-hydrophilic and black super-hydrophobic modification. And then the three-dimensional Janus structures are vertically stacked at intervals to form a plurality of three-dimensional Janus structures, so that the problems of small evaporation area, insufficient gas overflow hole channels and low evaporation efficiency caused by large energy loss of a common three-dimensional solar evaporator are solved. In addition, the solar evaporator solves the problem that when a common evaporator treats high-concentration saline water, salt is deposited on the evaporation face of the common evaporator, so that the evaporation rate is greatly reduced, and even the evaporator loses efficacy. The solar evaporator has the advantages of being high in evaporation efficiency, capable of treating high-concentration saline water, economical, environmentally friendly and the like.

Owner:NANCHANG UNIV

Steel mould trolley tunnel concrete lining construction method

PendingCN112253169AReduce disturbancePrevent water seepageUnderground chambersTunnel liningWater seepageTunnel wall

The invention provides a steel mould trolley tunnel concrete lining construction method. The steel mould trolley tunnel concrete lining construction method comprises the following steps that underground earthwork is successively excavated in a target region in a segmented mode to form a plurality of linear tunnel sections and a plurality of bent tunnel sections, all the linear tunnel sections andthe bent tunnel sections finally communicate in sequence according to the excavation sequence to form a spillway tunnel, and meanwhile, a steel mould trolley is used for conducting segmented successive lining in the extending direction of the spillway tunnel, linear tunnel walls are formed on the linear tunnel sections in a lining mode, bent tunnel walls are formed on bent tunnel sections in a lining mode, all the linear tunnel walls and the bent tunnel walls are finally connected in sequence according to the lining sequence to form a tunnel body protecting wall, the length of the linear tunnel walls is smaller than 8 m, and the length of the bent tunnel walls is smaller than 4 m. By adopting the technical scheme, disturbance to surrounding rock of the spillway tunnel is reduced through the methods of segmented excavation, segmented lining and layered concrete pouring, the excavated surrounding rock is reinforced in time, water seepage is effectively prevented, and the safety of constructors is guaranteed.

Owner:SINOHYDRO BUREAU 9

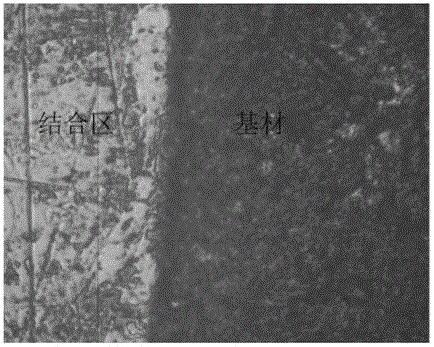

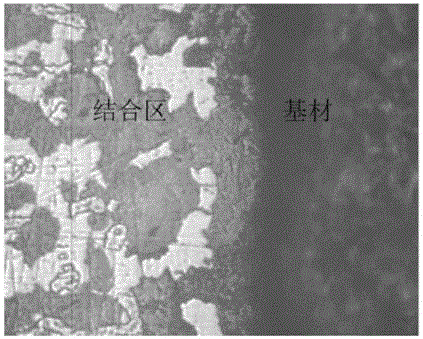

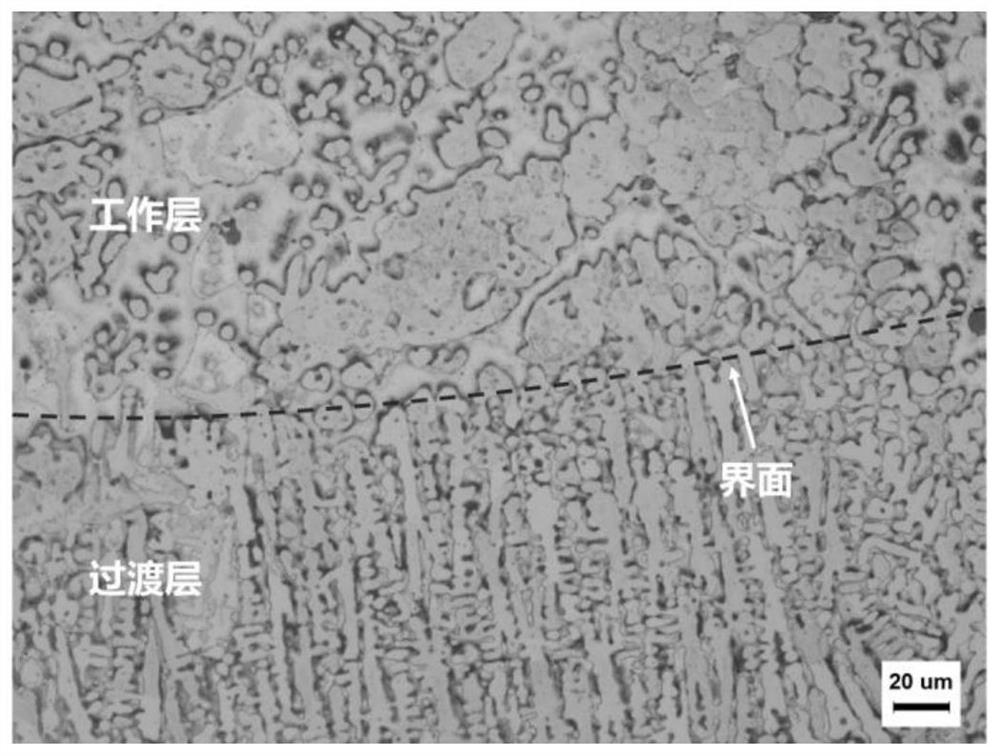

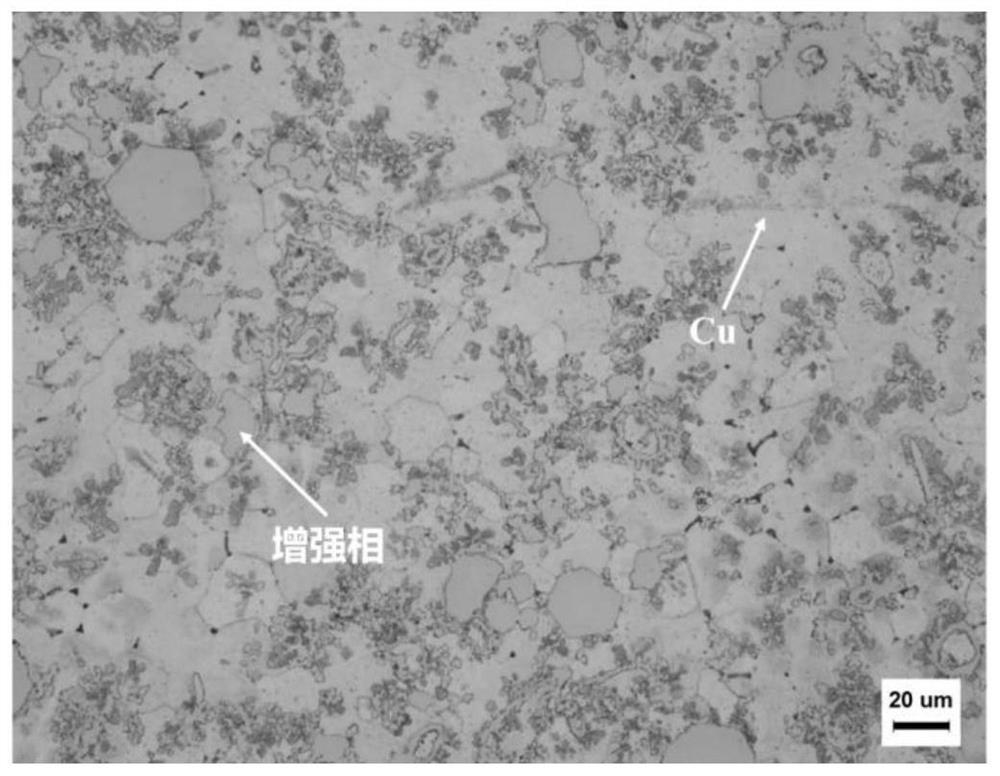

Multi-element transition metal carbide hybrid reinforced copper-based surfacing layer and preparation method thereof

ActiveCN114393342AHigh surface hardnessImprove surface wear resistanceArc welding apparatusWelding/cutting media/materialsTransition metal carbidesCarbide

The invention discloses a multi-element transition metal carbide hybrid reinforced copper-based surfacing layer. The multi-element transition metal carbide hybrid reinforced copper-based surfacing layer comprises a Cu-Ni-W-Nb transition layer and 2-3 WC + NbC hybrid reinforced copper-based working layers which are arranged in sequence, a raw material used by the Cu-Ni-W-Nb transition layer is a transition layer flux-cored wire; and a raw material used by the WC + NbC hybrid reinforced copper-based working layer is a working layer flux-cored wire. Wherein the WC + NbC reinforcement phase in the working layer is generated by in-situ reaction of alloy elements. According to the surfacing layer, the surface hardness can be improved while good interface bonding is guaranteed, and the wear resistance is enhanced. The invention further discloses a preparation method of the multi-element transition metal carbide hybrid reinforced copper-based surfacing layer.

Owner:XIAN UNIV OF TECH

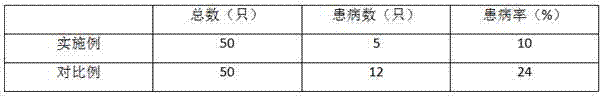

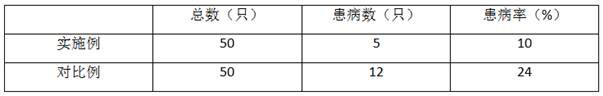

Chinese herbal bath lotion with pig immune improving function and preparation method of Chinese herbal bath lotion

ActiveCN107260864AHas the effect of sterilizing and repelling insectsTreatment of Toxic Heat DysenteryAnthropod material medical ingredientsPharmaceutical delivery mechanismAbsinthiumAdditive ingredient

The invention discloses a Chinese herbal bath lotion with a pig immune improving function. The Chinese herbal bath lotion is prepared by mixing of honeysuckle, liquorice, gallnut, cortex phellodendri, fructus kochiae, pericarpium granati, saponin, potassium alum and bitter artemisia. In addition, the invention further discloses a preparation method of the Chinese herbal bath lotion. The preparation method includes the steps of S1), preparation of raw materials; S2), frying; S3), cold storage; S5), preparation. Immune of the pigs bathed with the Chinese herbal bath lotion can be improved obviously, morbidity of the pigs is reduced, medicinal ingredients of Chinese herbs, absorbed by the pigs are through the skin, and good effect is achieved.

Owner:XISHUI COUNTY GELIN ECOLOGICAL AGRI TECH

A kind of Chinese herbal medicine bath liquid for increasing pig immunity and its preparation method

ActiveCN107260864BHas the effect of sterilizing and repelling insectsTreatment of Toxic Heat DysenteryAnthropod material medical ingredientsPharmaceutical delivery mechanismOfficinalImmunity

This patent discloses a Chinese herbal medicine bath liquid for enhancing the immunity of pigs. The Chinese herbal medicine bath liquid is made by mixing honeysuckle, licorice, gallnut, cortex cork, Kochia chinensis, pomegranate peel, saponins, alum and Artemisia annua. The patent also discloses a method for making the Chinese herbal medicine bath liquid, which includes the following steps: S1, preparation of raw materials; S2, frying; S3, refrigeration; S4, boiling; S5: preparation. Adopting the Chinese herbal medicine bath liquid of the present application to bathe pigs can significantly improve the immunity of pigs and reduce their morbidity, and the medicinal ingredients of Chinese herbal medicines absorbed by pigs are absorbed through the skin, so the effect is better.

Owner:XISHUI COUNTY GELIN ECOLOGICAL AGRI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com