Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

173results about How to "Less welding spatter" patented technology

Efficacy Topic

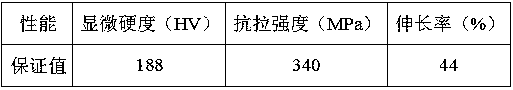

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

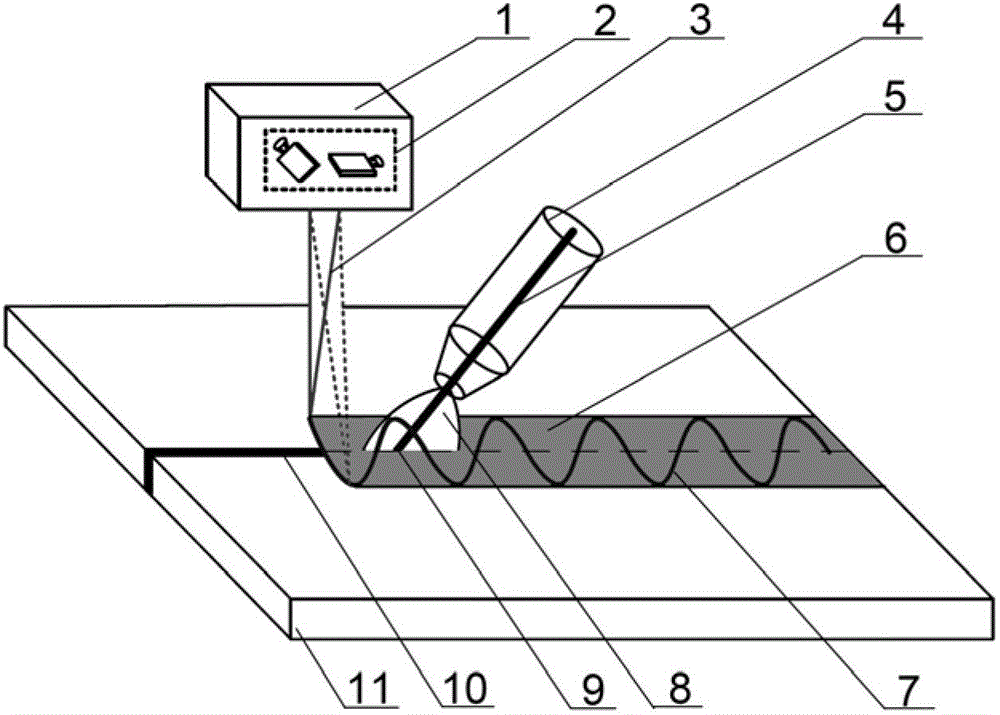

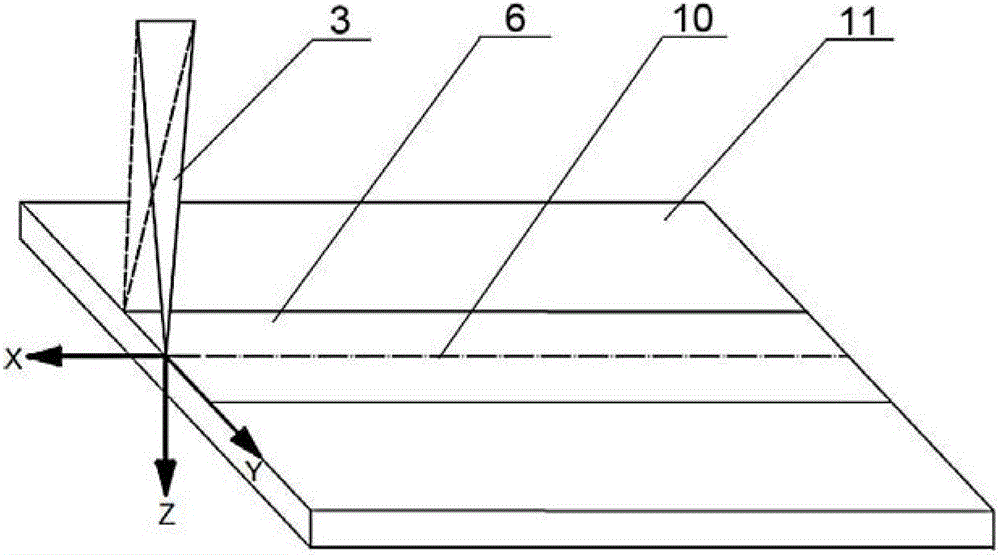

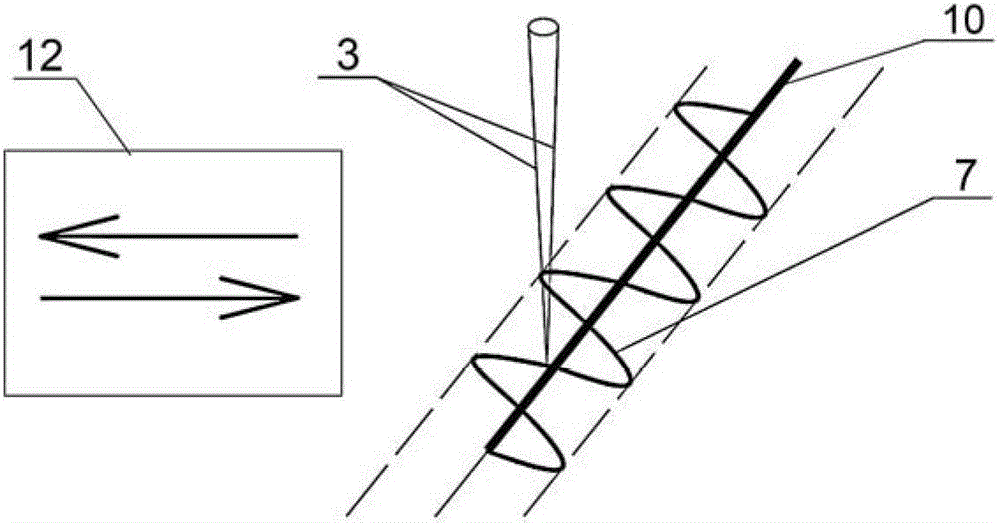

Oscillatory scanning laser beam-electric arc hybrid welding method and system

ActiveCN103056533AImprove featuresImprove welding qualityLaser beam welding apparatusPorosityLaser scanning

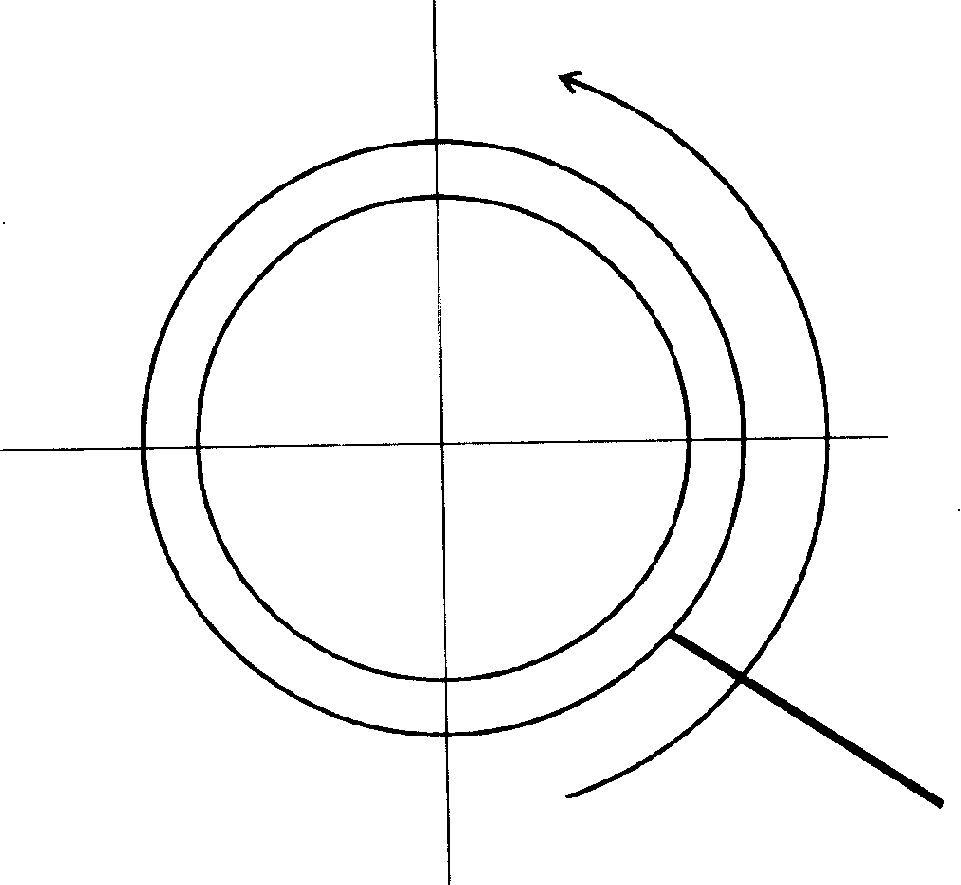

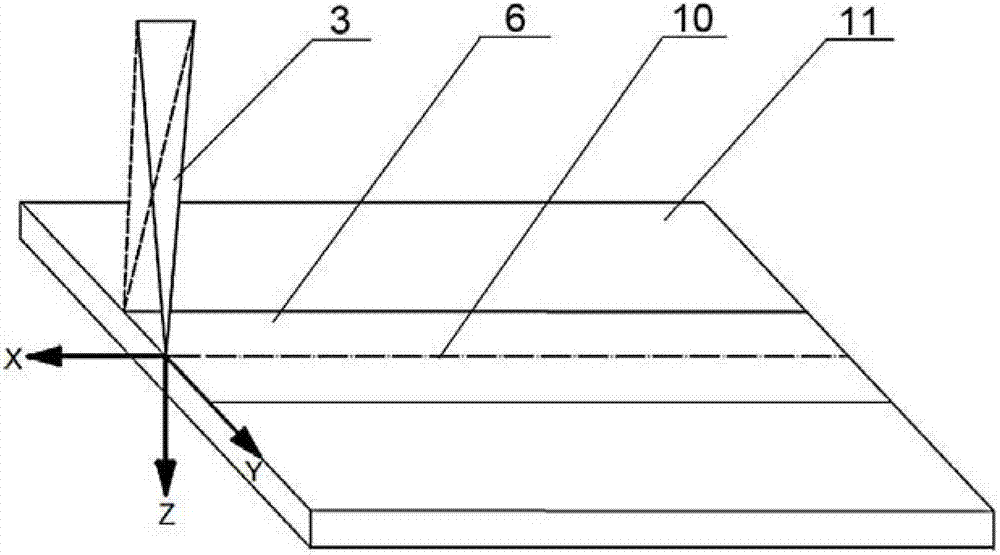

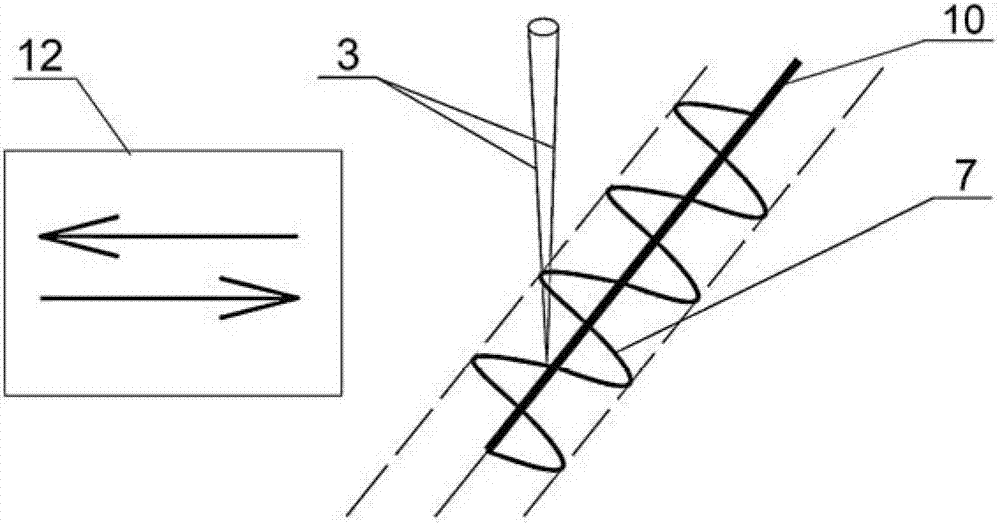

The invention discloses an oscillatory scanning laser beam-electric arc hybrid welding method and system. Laser beams and electric arc move together along an abutted seam in large range space, simultaneously the laser beams surround acting points of the electric arc to perform oscillatory scanning movement in a local small area, and an actual welding track is a curve formed by overlying two types of movements. As for an optimal range of laser beam oscillatory scanning displacement, the range in the direction of an X axis is minus 2mm to 3mm, the range in the direction of an Y axis is minus 5mm to 5mm, the range in the direction of a Z axis is minus 2mm to 2mm, and the oscillation frequency is in a range from 20Hz to 500Hz. According to the method and the system, an enhanced technical effect is achieved by the aid of interaction of a laser beam oscillatory scanning effect and a laser-electric arc synergistic effect, and the welding quality is improved. Compared with existing laser-electric arc hybrid welding and laser scanning welding methods and systems, the method and the system have the advantages that higher weld porosity inhibiting capability is achieved, and the weld strength is improved by 10% to 50%.

Owner:武汉飞能达激光技术有限公司

Flux-cored wire for austenitic stainless steel welding

ActiveCN102451961AReduce carbon contentImprove oxidation capacityArc welding apparatusWelding/cutting media/materialsManganeseRutile

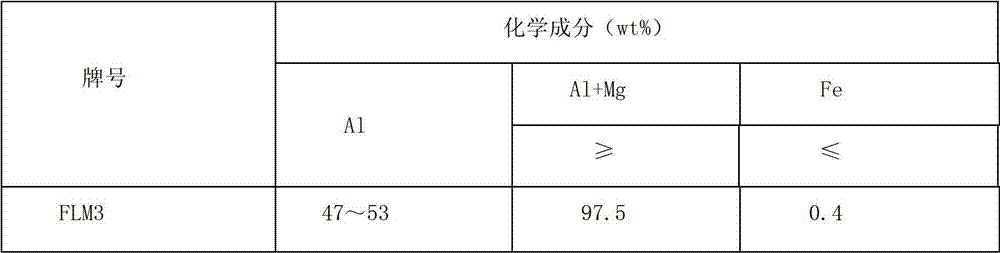

The invention discloses a flux-cored wire for austenitic stainless steel welding. The flux-cored wire consists of a flux core and an external steel belt; the external steel belt is an austenitic stainless steel belt of which the carbon content is less than 0.025 percent; the carbon content of the flux core is not greater than 0.04 percent and carbon accounts for 18.0 to 24.0 percent based on the total weight of the flux-cored wire; the flux core comprises the following components in percentage by weight: 18.5 to 25.0 percent of metal chromium powder, 8.0 to 10.0 percent of metal nickel powder, 2.0 to 5.0 percent of electrolytic manganese metal, 1.0 to 3.0 percent of aluminum magnesium alloy, 28.0 to 35.0 percent of rutile, 3.0 to 5.0 percent of quartz, 2.0 to 5.0 percent of zircon sand, 2.0 to 5.0 percent of feldspar, 1.0 to 2.0 percent of cryolite, 2.0 to 5.0 percent of arc stabilizer and the balance of iron powder; and the arc stabilizer consists of K2O, Na2O and TiO2 in a weight ratio of (6.0-8.0):(8.0-10.0):(68.0-70.0), and the water content is not greater than 400 ppm.

Owner:CHINA JINGYE ENG TECH CO LTD +1

Welding method of duplex stainless steels

InactiveCN102019485ALess welding spatterBeautiful weld shapeArc welding apparatusWelding/cutting media/materialsCarbon dioxideCorrosion

The invention belongs to a welding method of duplex stainless steels, comprising the following steps of backing welding, filling welding and cosmetic welding. 99.99% of argon inert gas shield is used for performing the backing welding of the manual tungsten electrode argon tungsten-arc welding, or gas shield formed by adding 80% of argon and 20% of carbon dioxide gas is used for performing semi-automatic filling and cosmetic welding. The welding method of the duplex stainless steels has the advantages that mechanical properties and corrosion resistance of welding joints can be fully ensured, welding spatters are reduced, and weld shaping is beautiful.

Owner:宋卫国

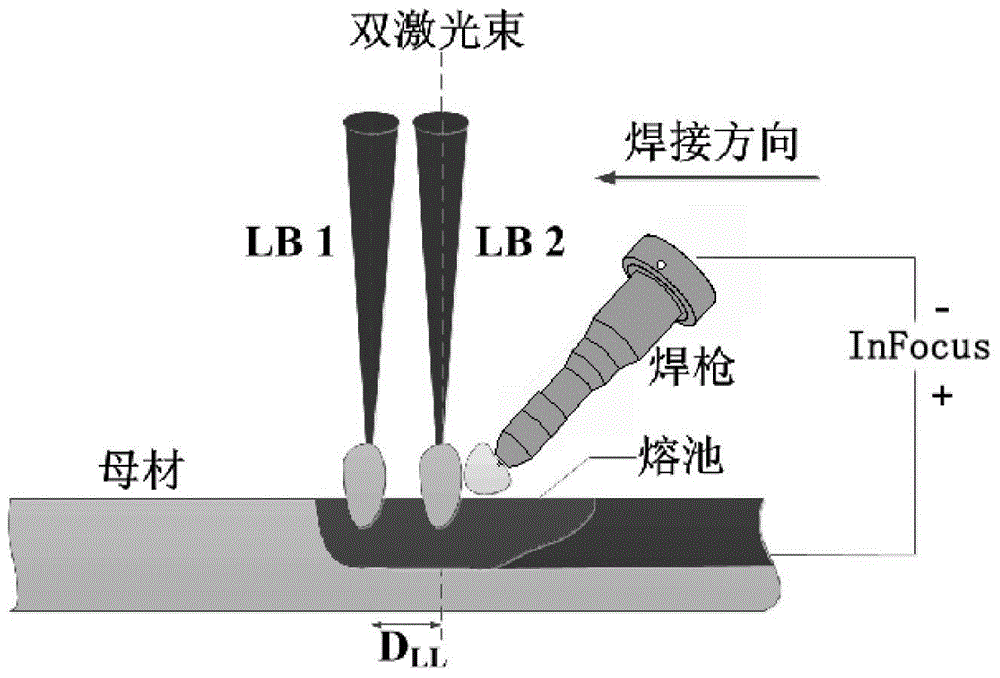

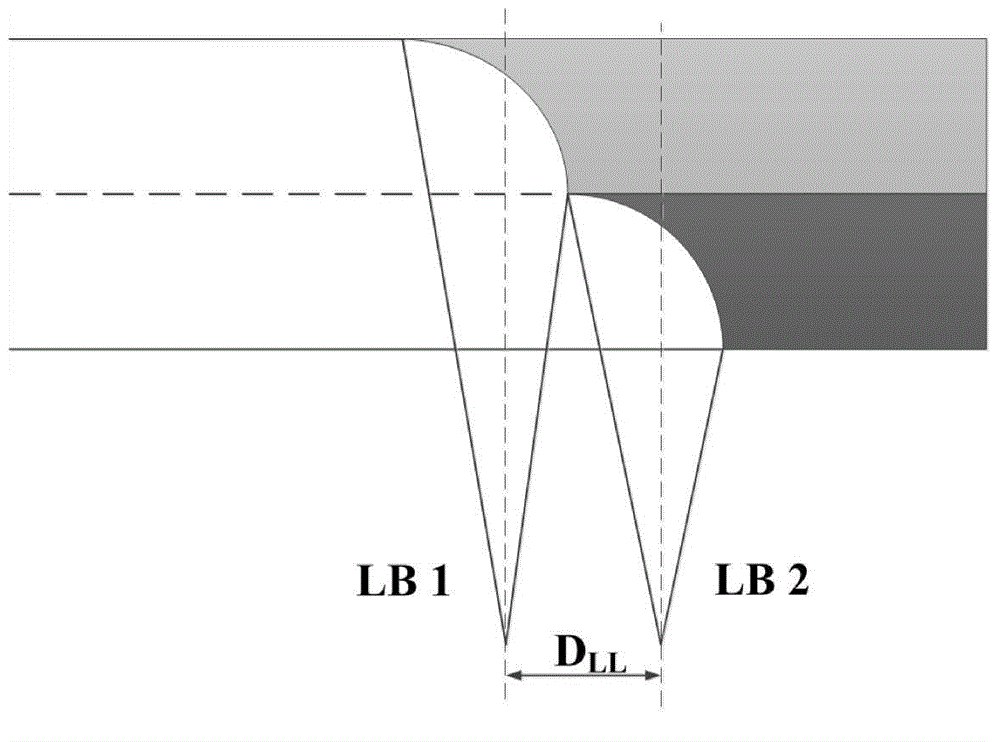

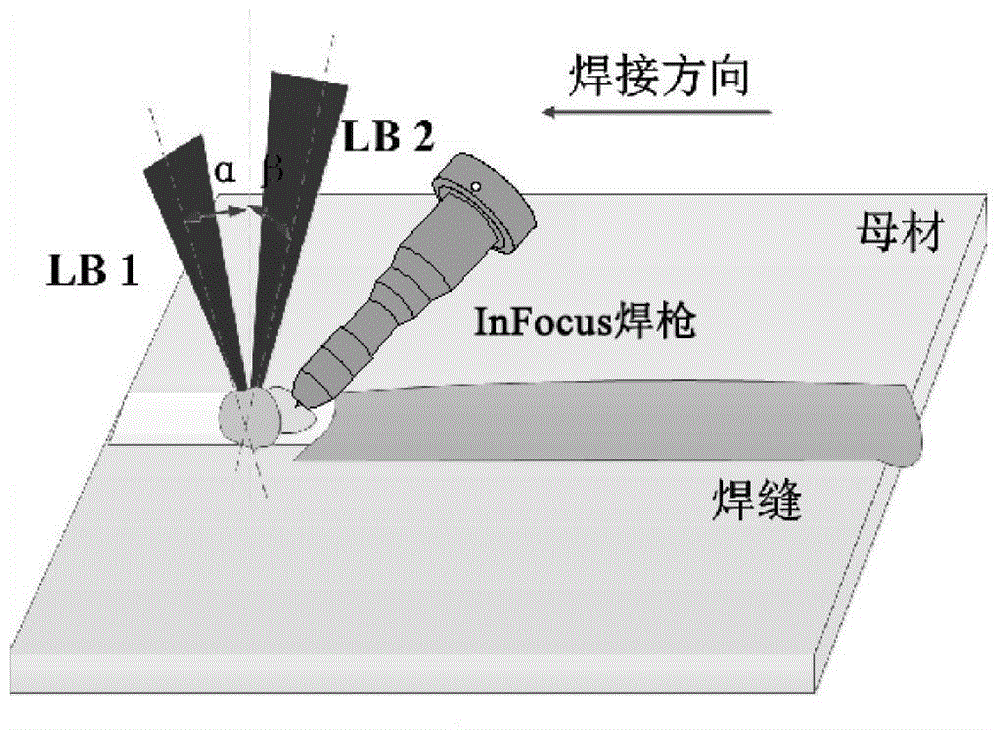

Bifocus laser and InFocus arc hybrid welding method

InactiveCN104985327AImprove energy utilizationIncrease weld penetrationLaser beam welding apparatusElectric arcEngineering

The invention discloses a bifocus laser and InFocus arc hybrid welding method, and relates to a welding method. The method includes the steps that (1) a to-be-welded workpiece is polished or washed; (2) the spot diameter is set to range from 0.1 mm to 0.5 mm, and the defocusing amount ranges from -3 mm to +3 mm; (3) welding parameters are set, wherein the arc current ranges from 50 A to 900 A, an included angle formed between a welding gun and the vertical direction ranges from 25 degrees to 55 degrees, the welding speed ranges from 100 mm / min to 1000 mm / min, the wire feeding speed ranges from 100 mm / min to 600 mm / min, the protection gas is inert gas, and the flow of the protection gas ranges from 15 L / min to 30 L / min; and (4) a switch is started, and laser-InFocus arc welding is carried out. According to bifocus lasers and InFocus, as the InFocus arc fusion depth is larger, and a key hole can be formed through welding, when a medium-thickness plate is welded, the lasers can directly act on the bottom of the key hole generated by the InFocus arc, and the fusion depth is continuously increased.

Owner:HARBIN INST OF TECH

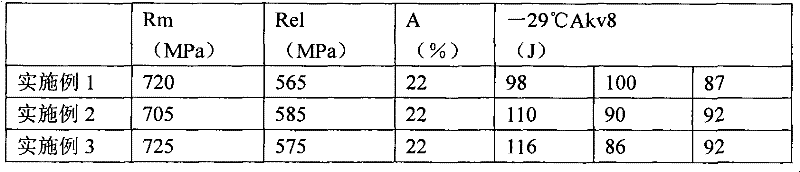

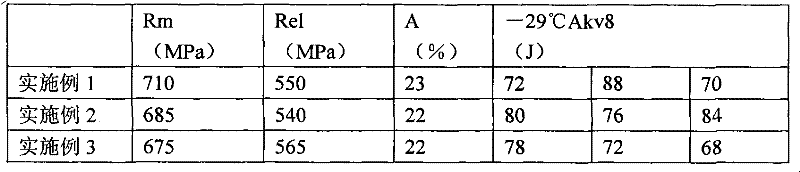

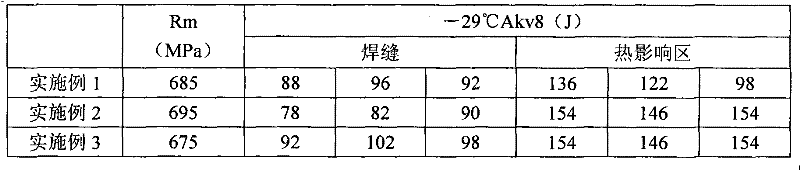

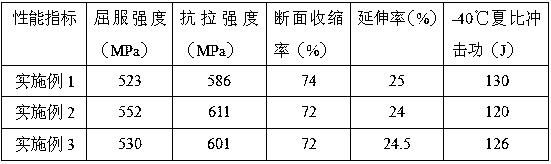

Gas protection solid welding wire for 1000 MPa high-strength steel welding and preparing and welding methods of gas protection solid welding wire

ActiveCN106312372AHigh strengthImprove impact toughnessArc welding apparatusWelding/cutting media/materialsSocial benefitsPower station

The invention discloses a gas protection solid welding wire for 1000 MPa high-strength steel welding and preparing and welding methods of the gas protection solid welding wire. Chemical ingredients of the welding wire include, by weight, 0.07-0.13 part of C, 0.3-0.5 part of Si, 1.8-2.3 parts of Mn, 2.7-3.2 parts of Ni, 0.3-1.2 parts of Cr, 0.4-0.85 part of Mo, 0.01-0.1 part of Ti, 0.01-0.03 part of Al, 0.008 part or below of P, 0.005-0.010 part of S, 0.3 part or below of Cu, 0.01-0.035 part of Nb and the balance Fe. The welding wire can replace an imported welding wire, the construction cost of high-strength steel for large hydropower stations, water pumping and energy storage power stations and the like can be remarkably reduced, and remarkable economic benefits and social benefits are achieved.

Owner:SICHUAN XIYE NEW MATERIAL

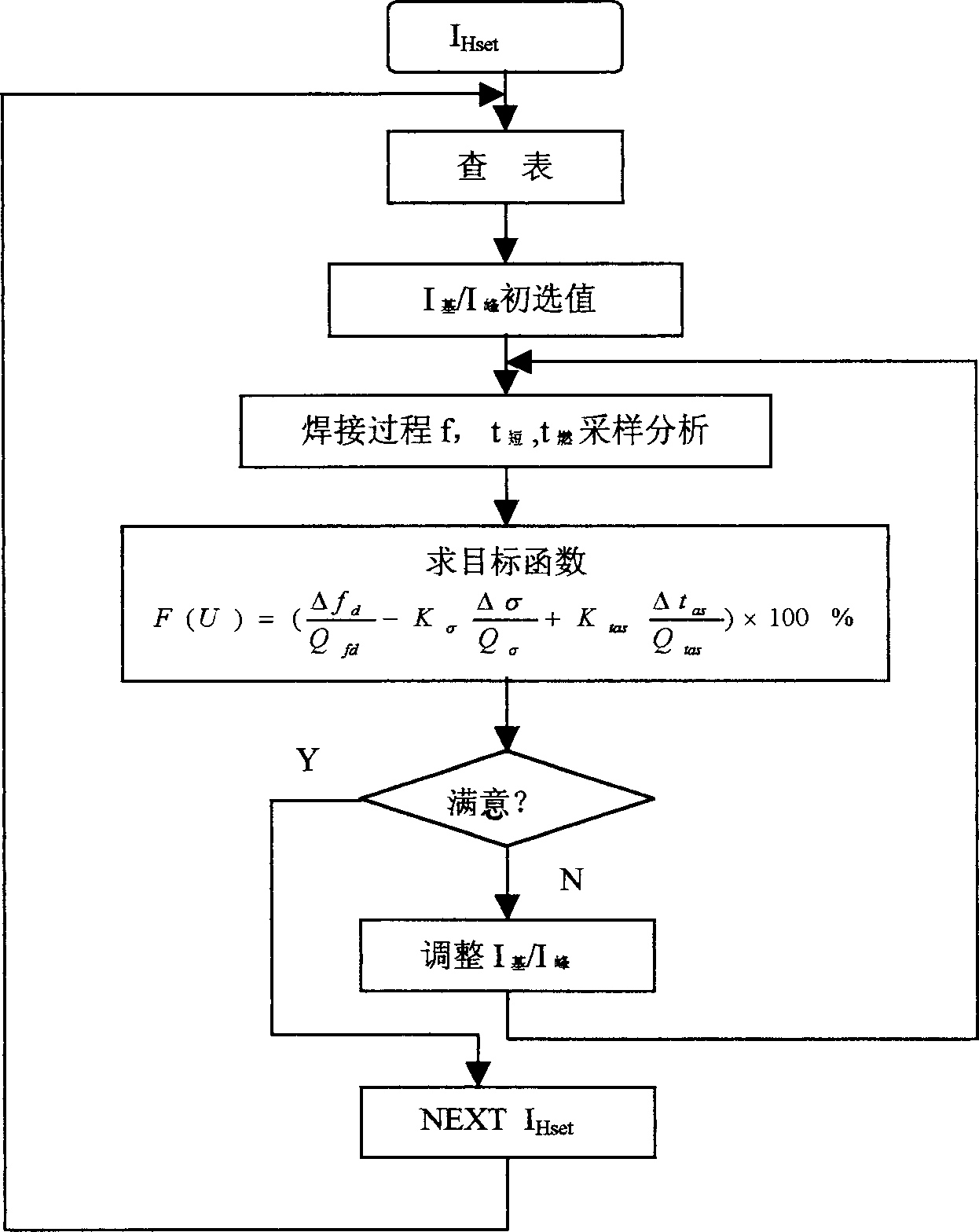

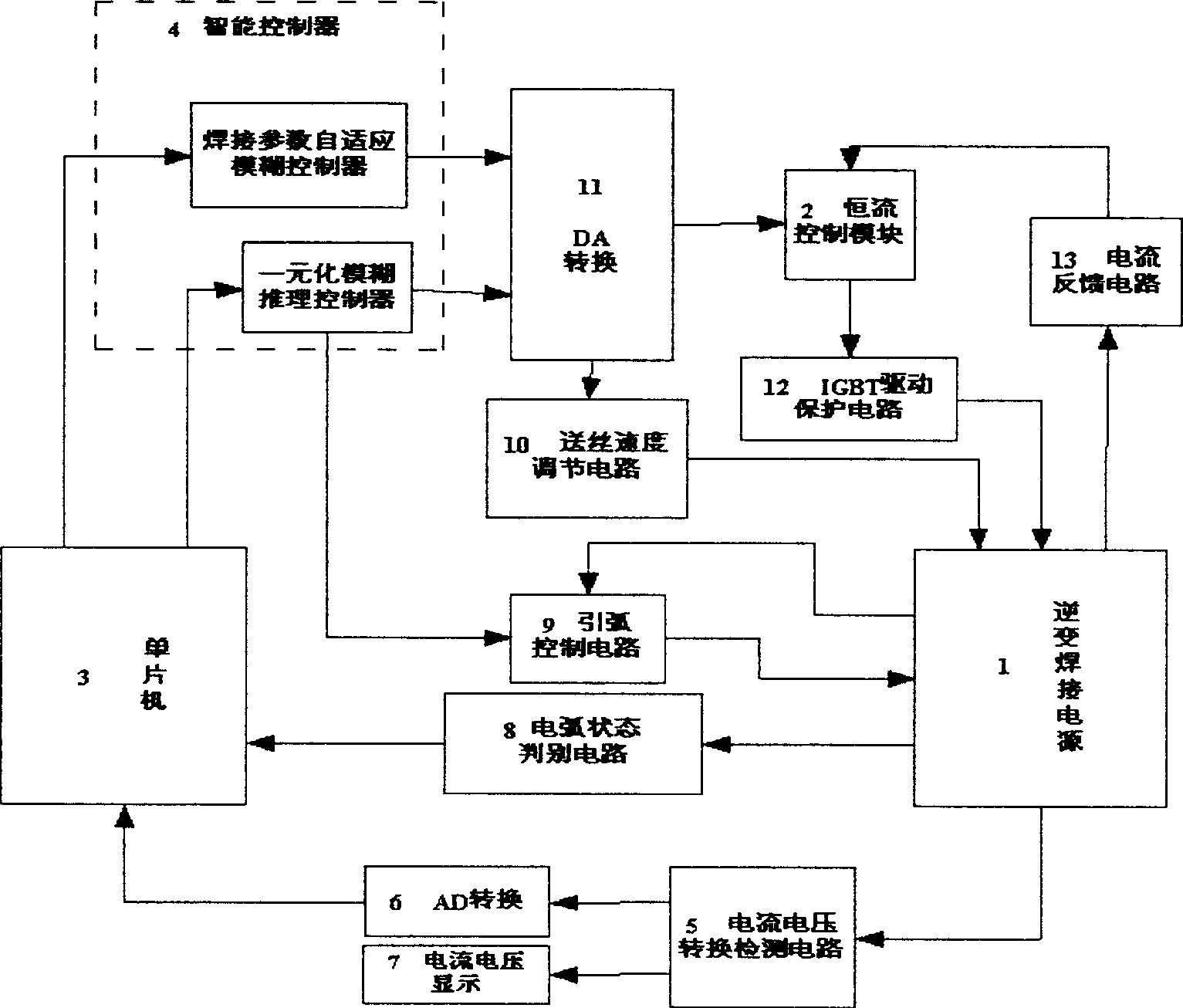

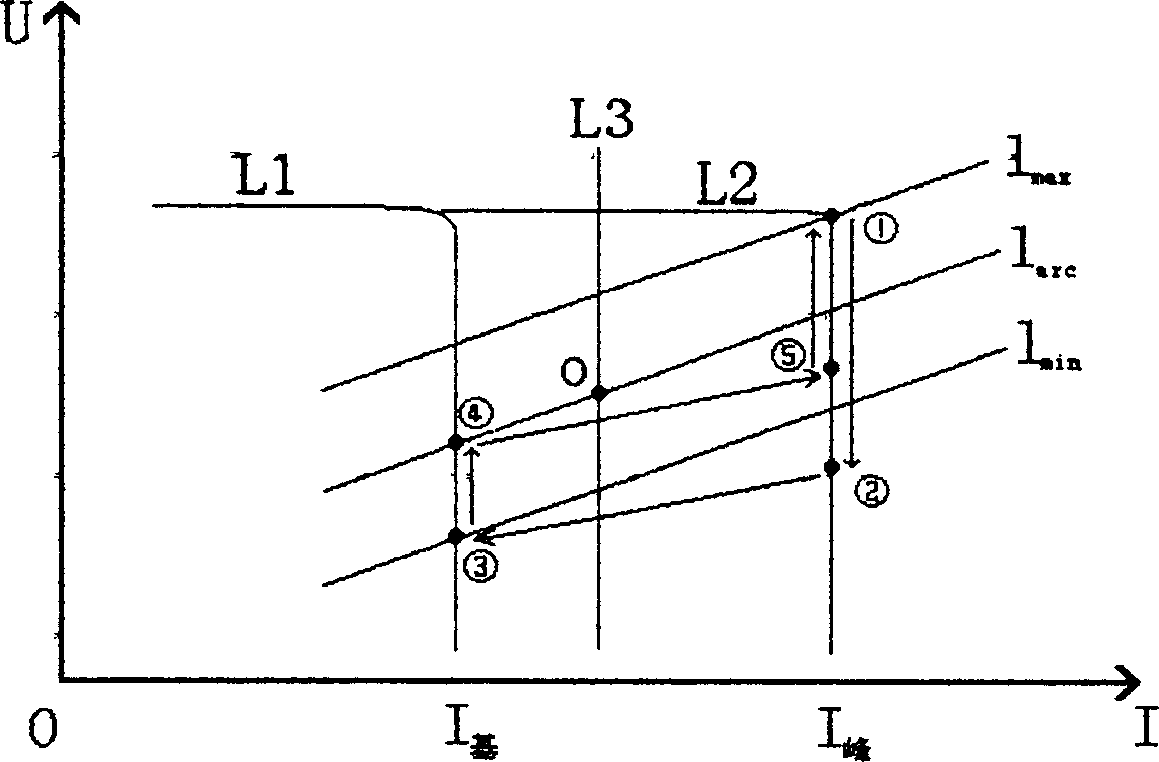

Double constant currents of intelligent inversion soldering machine and self-optimizing control method

InactiveCN1539588AImprove power dynamic performanceImprove dynamic performanceArc welding apparatusFuzzy control systemEngineering

A dual constant current and self-optimizing control method for intelligent inverter welder features that the external characteristics at different stages can be automatically determined according to welding current setting and electric arc state and the dual or multiple constant current is used according to electric arc state for realizing the self-optimized intelligent control to automatically and quickly make the response to arc variation and welding current setting. Its advantages are good shape of welded seam and less splash.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Gas shield welding wire for nuclear power

InactiveCN102528318ALess welding spatterEfficient processWelding/cutting media/materialsSoldering mediaNuclear powerManganese

Owner:ANGANG STEEL CO LTD

High-speed laser welding method for invar film

InactiveCN103862173AReduce the tendency of welding hot crackingFast welding speedWelding/soldering/cutting articlesLaser beam welding apparatusLight beamOptoelectronics

The invention discloses a high-speed laser welding method for invar film, and belongs to the technical field of high-speed laser welding. According to the high-speed laser welding method for the invar film, parallel laser beams of a laser welding machine are divided into first reflection laser beams and second reflection laser beams through a weir type spectroscope, the first reflection laser beams are focused through a focus lens to form a preheating laser beam, the second reflection laser beams are focused through a focus lens to form a welding laser beam, and the preheating laser beam and the welding laser beam carry out preheating and welding on a weld joint of a welding test piece at the same time. According to the high-speed laser welding method for the invar film, welding is carried out in a double-beam laser serial mode, the previous laser beam is used for preheating, the later laser beam is used for carrying out welding, the temperature gradient and welding stress are reduced through control over distribution of weld heat input energy on the weld joint and in the nearby area, and therefore high-speed flawless welding of invar is achieved.

Owner:DALIAN UNIV OF TECH

High-weather-resistance gas protection welding wire with excellent weldability

ActiveCN106216877AImproved arc stabilityLess welding spatterArc welding apparatusWelding/cutting media/materialsWeather resistanceMetallurgy

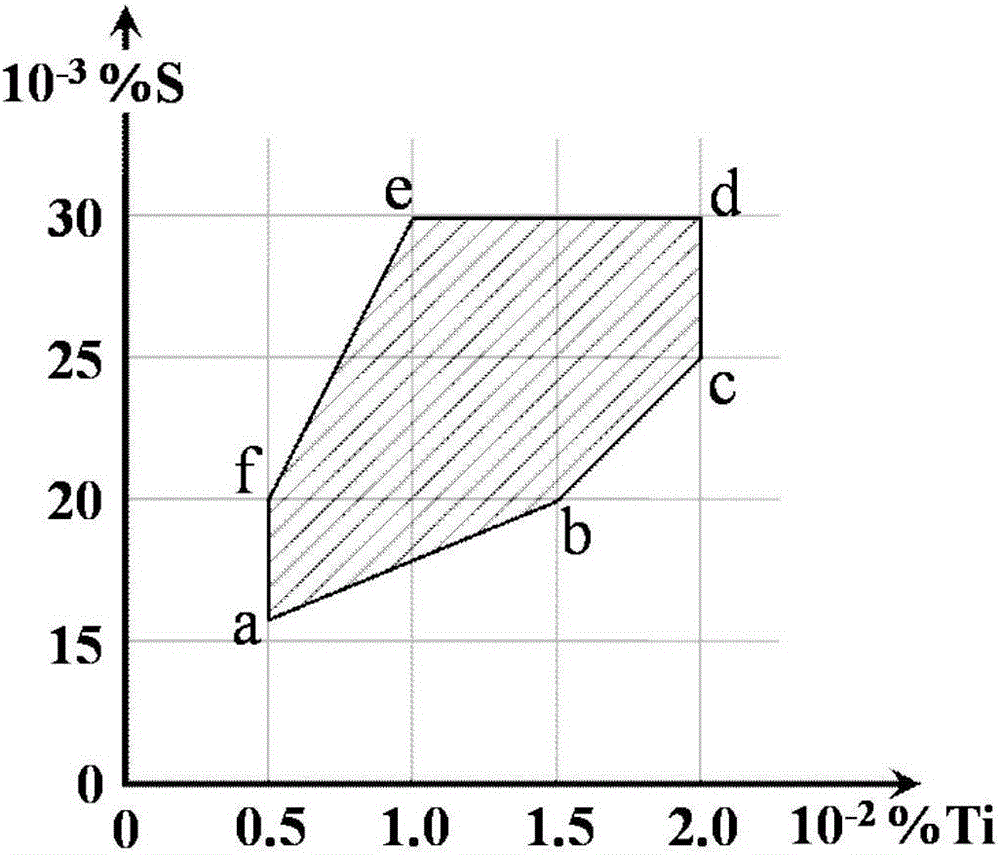

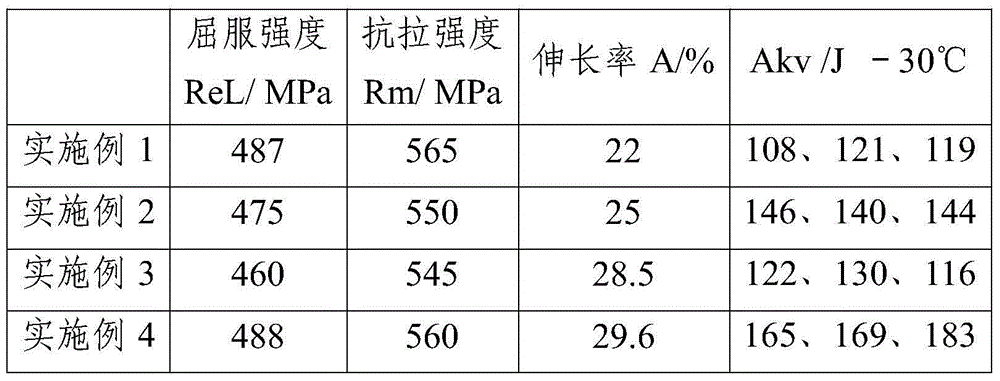

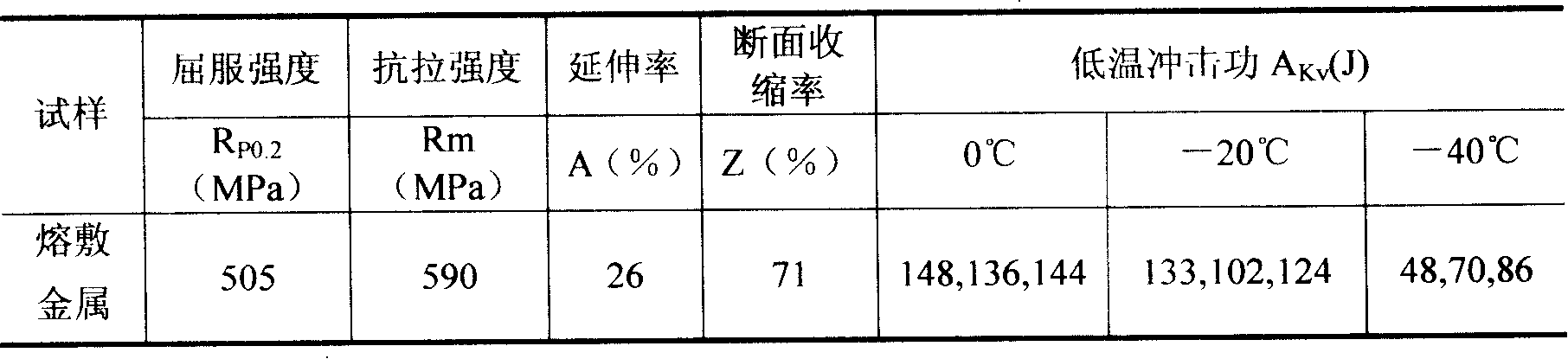

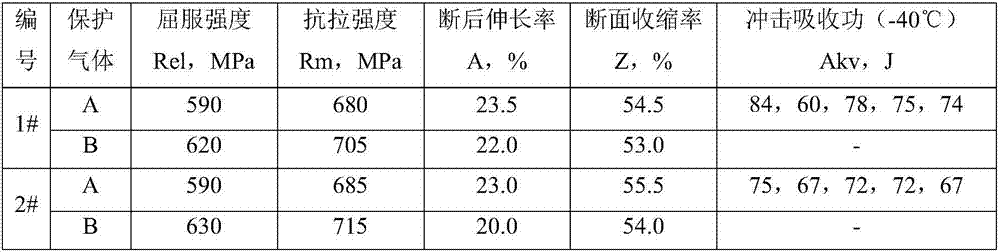

The invention discloses a high-weather-resistance gas protection welding wire with excellent weldability. The high-weather-resistance gas protection welding wire comprises the following components in percentage by mass: C less than 0.02%, 0.75-1.30% of Mn, 0.20-0.40% of Si, P not more than 0.015%, 0.016-0.030% of S, 2.2-4.0% of Ni, 0.80-1.20% of Cr, 0.10-0.30% of Cu, 0.005-0.020% of Ti, and the balance of iron and inevitable impurities; and Ti and S elements are reasonably matched in a stated range. The welding wire is suitable for welding of such steel structures as bridges, building structures and railway trucks with higher atmospheric corrosion resisting requirements. The welding wire adopts 100% of CO2 or Ar+20% of Co2 as protection gas for welding, is excellent in welding line surface and section forming, is excellent in comprehensive performance of welding line metal, reaches the welding line tensile strength of not less than 650 MPa, and reaches -40 DEG C impact power of not less than 100 J.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Electrogas welding gas shield flux-cored wire for large heat input welding

ActiveCN102009287AImprove low temperature toughnessImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaMagnesiumWelding joint

The invention discloses an electrogas welding gas shield flux-cored wire for large heat input welding, belonging to the technical field of high-efficiency high heat input welding. An SPCC (steel plate cold rolled commercial) steel tape with the size of 0.9*14 mm is used for manufacturing the flux-cored wire, the fill rate of powder is controlled to be within a range of 17-23%, and a welding wire with the diameter of phi1.6mm is manufactured. The flux core comprises the following raw materials: 1-3% of potassium or sodium fluoride, 3-6% of SiO2, 1-3% of one or two of rutile and zircon sand, 1-5% of one, two or three of strong deoxidizer magnesium powder, aluminite powder or aluminum and magnesium powder, 2-5% of one, two or three of strong deoxidizer titanium iron powder, silicon zirconiumpowder and zirconium iron powder and the balance iron powder. In addition, according to the intensity requirement of the welded steel plate and the low-temperature mechanical property requirement of a welding joint, in the flux core formula, a proper amount of alloying agent metal powder can be added, such as molybdenum iron powder, nickel powder and the like so as to obtain the alloy ingredient with a proper proportion. The flux-cored wire provided by the invention has the advantages that the flux-cored wire has good welding technology performance, less welding splash, beautiful welding lineshaping and good mechanical property of the welding joint.

Owner:SHOUGANG CORPORATION

Special welding rod for sulfuric acid dew point corrosion-resistant steel

ActiveCN104907738ALess welding spatterBeautiful shapeWelding/cutting media/materialsWelding/soldering/cutting articlesCorrosion resistantDew point

The invention discloses a special welding rod for sulfuric acid dew point corrosion-resistant steel. The welding rod comprises a steel core and a coating. The coating comprises, by weight, 33-45% of CaCO3, 18-29% of CaF2, 8-13% of TiO2, 5-9% of SiO2, 4-6% of Si-Fe, 2-4% of Mn, 2-3.5 % of Cr, 0.8-1.5% of Cu, 0.1-0.3% of Sb, 1-1.5% of Na2CO3, 2-4% of rare earth oxide, and the balance iron powder. The welding bar is little in welding splashing, attractive in shape, easy to deslag, high in deposition rate and good in welding performance, and corrosion resistance, deposited metal chemical components and deposited metal mechanical property of the welding bar can meet the welding requirements of the sulfuric acid dew point corrosion-resistant steel. Materials are convenient to purchase, production cost is low, the application range is wide, and use is convenient.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Carbon dioxide gas shielded welding flux-cored wire

InactiveCN102764941ADeposition speed is fastImprove work efficiencyWelding/cutting media/materialsSoldering mediaIron powderHardness

The invention discloses a carbon dioxide gas shielded welding flux-cored wire, which is characterized in that the flux-cored powder of the wire is mixed by the following components in percentage by weight: 10-30% of rutile, 10-30% of silicomanganese, 15-40% of iron powder, 2-15% of nickel powder, 2-25% of chromium metal, 1-5% of aluminium magnesium alloy, 2-10% of ferromolybdenum and 2-10% of ferrovanadium. The carbon dioxide gas shielded welding flux-cored wire disclosed by the invention has the advantages that the hardness and the non-deforming performance of a hot mill guide plate, a hot-forging die, a valve and the like are still can be kept even if the hot mill guide plate, the hot-forging die, the valve and the like work under the high-temperature impact load for a long time.

Owner:NINGBO LONGXING WELDING CUTTING TECH STOCK

Welding method of high-performance weather-proof bridge steel for extremely cold area

ActiveCN108057940AReduce workloadPreventing Weld LeakageArc welding apparatusWelding/cutting media/materialsChemical compositionEngineering

The invention discloses a welding method for bridge steel. The welding method is aimed at specific chemical components, the applicable technical condition and different plate thicknesses of the Q420qFNH high-performance weather-proof bridge steel for the extremely cold area. The welding process problem of the weather-proof steel is solved. Abut-joint or T-type angular joint is adopted in the welding joint manner, according to the welding method, submerged-arc welding and solid welding wire rich-argon gas protection welding are adopted, according to the different plate thicknesses, the before-welding preheating temperature is determined, according to different welding methods and different welding positions, welding process parameters are determined. The joint manner and the thickness specification of a bridge structure are comprehensively considered, the technical scheme is simple, convenient, and high in adaptation, the implementing effect meets the technical requirement of existing bridge steel and bridge structure building related standard, and the method can be actually applied to welding of a Q420qFNH weather-proof steel bridge.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD +1

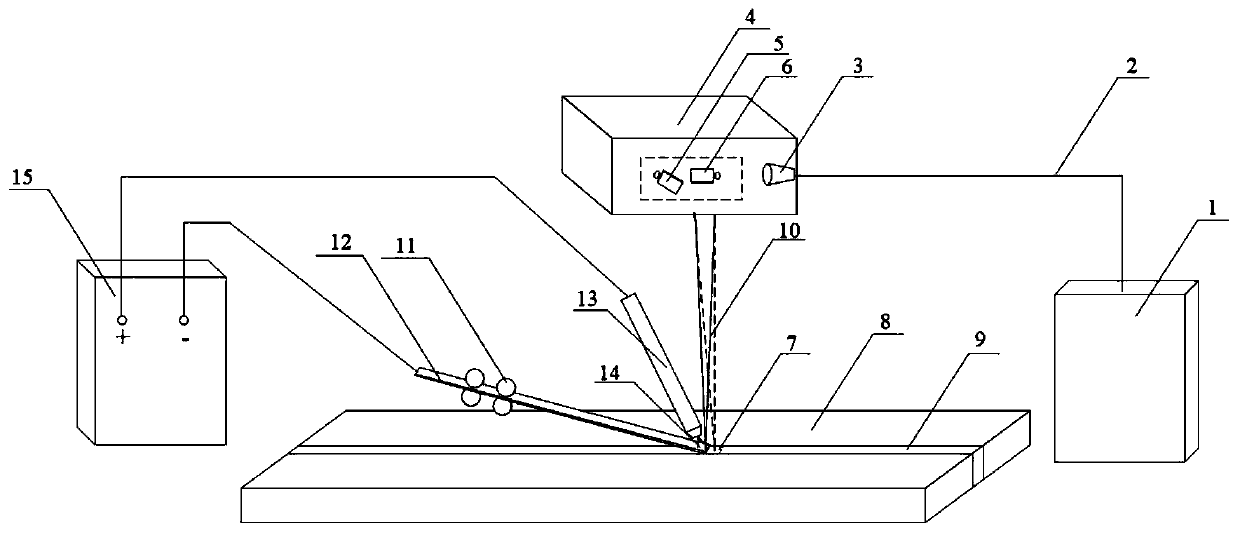

Device applying pulsed TIG electric arc for assisting MIG welding and welding method achieved by adopting device

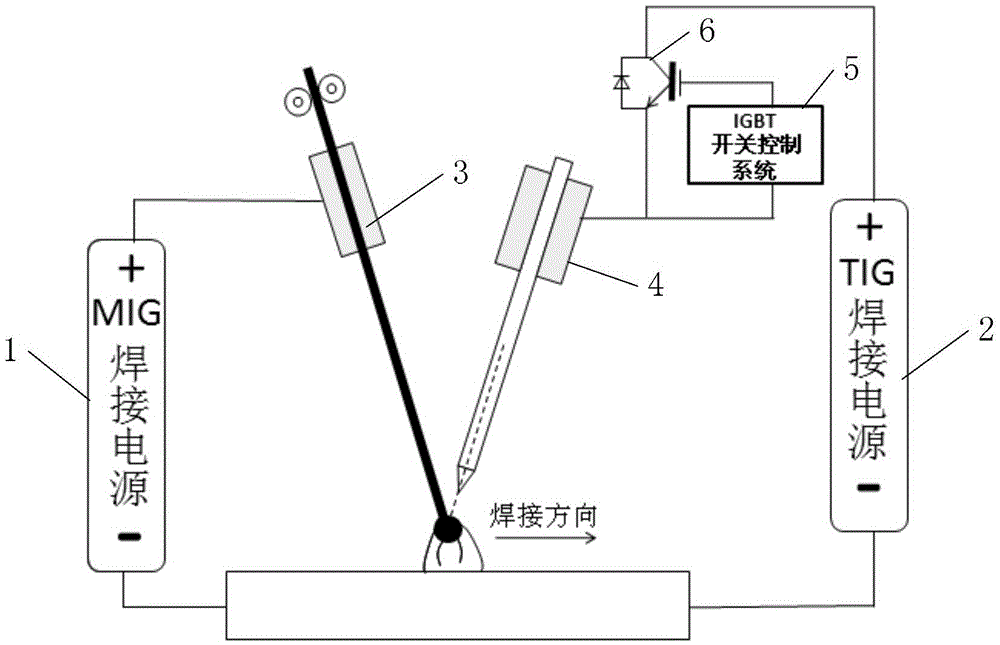

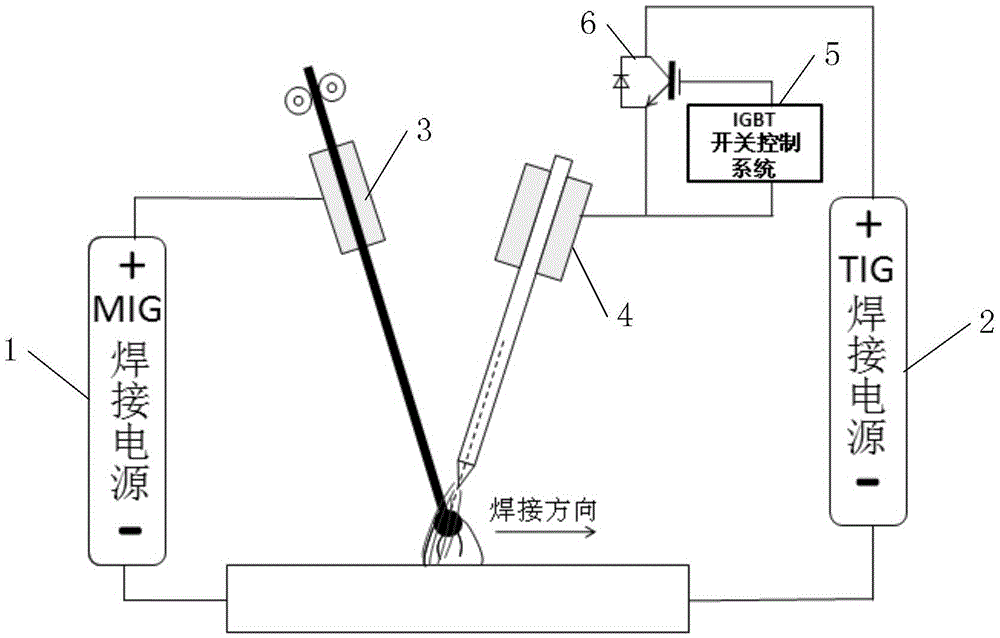

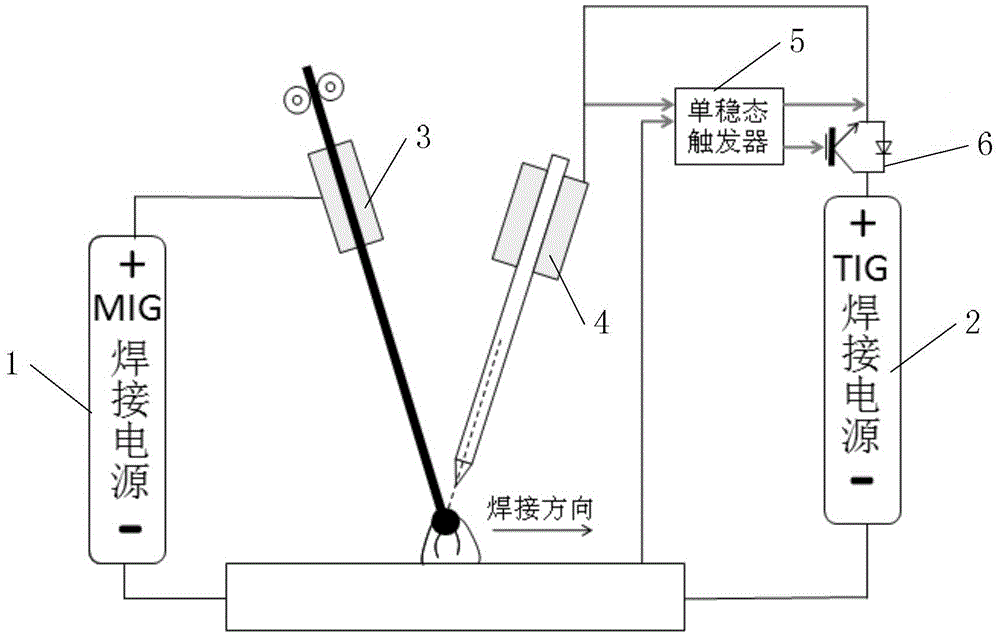

The invention discloses a device applying pulsed TIG electric arc for assisting MIG welding and a welding method achieved by adopting the device and belongs to the technical field of welding. The problem that low-current short circuiting transfer and globular transfer of MIG welding are poor in stability in the prior art is solved. The positive electrode output end of an MIG welding power source is connected with a consumable electrode holder of an MIG welding gun. The negative electrode output end of the MIG welding power source is connected with one end of a to-be-welded workpiece. The negative electrode output end of a TIG welding power source is connected with the other end of the to-be-welded workpiece. The positive electrode output end of the TIG welding power source is connected with the positive electrode input end of an IGBT switch. The negative electrode input end of the IGBT switch is simultaneously connected with a tungsten electrode holder of a TIG welding gun and the electrical signal input end of an IGBT switch control system. The control signal output end of the IGBT switch control system is connected with the control end of the IGBT switch. The device is mainly used for welding the to-be-welded workpiece.

Owner:HARBIN INST OF TECH

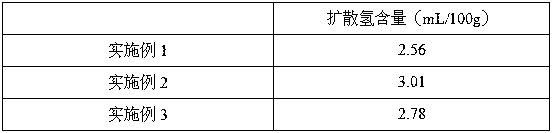

High-toughness titanium alkaline type seamless flux-cored wire suitable for full-position welding

ActiveCN108406159ASimple processImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaCrack resistanceSlag

The invention discloses a high-toughness titanium alkaline type seamless flux-cored wire suitable for all-position welding. The flux-cored wire is composed of a low-carbon steel strip at the peripheryand flux core powder inside; and the flux core powder comprises the following components, by weight percentage: 30-40% of rutile, 1-2% of aluminum oxide, 2-4% of dehydrated feldspar, 1-3% of quartz,1-3% of zircon sand, 1-2% of rare earth oxide, 1-2% of silicon powder, 0.2-0.4% of ferroboron, 6-8% of nickel powder, 8-15% of metal manganese, 4-9% of magnesium powder and the balance iron powder andinevitable impurities. According to the flux-cored wire, a titanium alkaline slag system is adopted, the proportion of alloy elements is optimized, the content of mineral powder is adjusted, and under the protection of CO2 gas, horizontal, transverse and vertical position welding can be realized; the mechanical property is stable, the impact power at 40 DEG C below zero reaches 100J, the crack resistance is good, diffusible hydrogen is low, the moisture resistance is strong, the seawater corrosion resistance is good, and the anti-cracking ability is good.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Self-shielded flux-cored wire for non-magnetic steel 20Mn23Al and preparing method of wire

InactiveCN107322181AHigh tensile strengthImprove corrosion resistanceWelding/cutting media/materialsSoldering mediaFerrosiliconShielding gas

The invention discloses a s elf-shielded flux-cored wire for non-magnetic steel 20Mn23Al. The wire comprises a flux core and a skin; the flux core is composed of 18 to 28% of chromium powder, 2 to 8% of nickel powder, 1.5 to 3.5% of molybdenum powder, 2.5 to 10% of manganese powder, 0.5 to 1.5% of ferrosilicon powder, 2 to 8% of aluminum and magnesium, 0.5 to 1.5% of ferrocolumbium, 0.5 to 1% of ferrotitanium, 10 to 17% of barium fluoride, 5 to 15% of magnesium oxide, 1 to 5% of aluminum oxide, 0.5 to 1.5% of cerium oxide, 1 to 3.5% of quartz sand, 18 to 26% of rutile, 2 to 8% of zircon sand, 1 to 3% of lithium carbonate, 0.5 to 3% of calcium carbonate and 0.5 to 5% of iron oxide powder. The wire is used for 20Mn23Al welding, protection gas does not need to be added, a welding joint with higher tensile strength and corrosion resistance can be obtained, the welding wire is simple in preparing method, and large-scale batched production is facilitated.

Owner:XIAN UNIV OF TECH

Method for preparing low hydrogen type downwards electrode

InactiveCN101168219AArc blowing force is largeAdjust physical and chemical properties of slagWelding/cutting media/materialsSoldering mediaMelting tankGram

The invention discloses a process for preparing hydrogen-controlled downwards electrodes. Steel wires H08E are used as a welding core, and explosive cartridge weight is 35-50% of the welding electrode weight. The percentage by weight of the invention is that CaCO3 is 25-38%, TiO2 is 10-20%, CaF2 is 12-20%, SiO2 is 5-10%, and Al2O3 is 3-6%. 8-15% ferrous alloy and 10-18% pure metal powder are added to meet the demand of the deposited metal rigidity and low-temperature flexibility. The electrodes have outstanding downward technology operational property, the welding positions, including flat, vertical and backstroke and the like, keep a metallic molten pool to be clean, and molten slag can not drip. The tensile strength of the weld metal is equal or more than 550 MPa, the ballistic work under the low-temperature of below 20 DEC G is more than 100 J, and the diffusible hydrogen content is less than 5 ml per 100 grams. The invention is adaptable for the welding of X42-X65 of API standard or other tube steel with equal rigidity grade, and is also suitable for the integral-position welding of pressure containers, ships, engineering machinery or other important structures, and the like.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

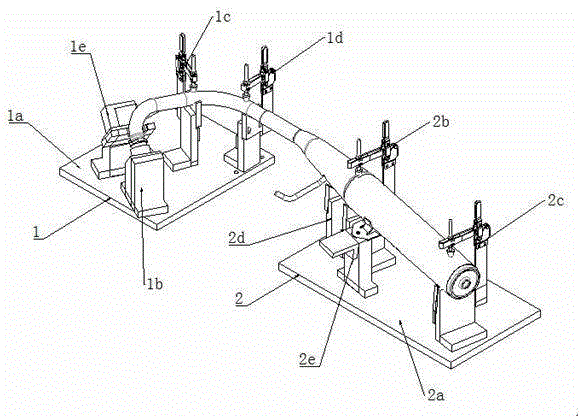

Double-gun welding device and machining method

InactiveCN105127659APrevent deviationImprove consistencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention discloses a double-gun welding device and a machining method, and belongs to the field of automobile mufflers. The method includes the steps that chamfering is conducted on pipes needing to be welded first; then the pipes are fixed to special clamps; afterwards, welded joints between the pipes are welded through two welding guns at the same time; the clamps are rotated while welding is conducted, so that circumferential welding of the pipes is achieved. The device comprises a welding machine and the clamps. The clamps comprise the first clamp and the second clamp. The first clamp comprises a clamp body and a plurality of clamping jaws fixed to the clamp body. The second clamp comprises a clamp body and a plurality of clamping jaws fixed to the clamp body. The device further comprises clamp rotating devices. The welding guns of the welding machine are located between the first clamp and the second clamp. By the adoption of the method and structure, circumferential welding can be conducted on multiple points between multiple sections of an automobile muffler pipeline at the same time, manual spot welding fixation is needless, labor cost is reduced, the machining procedure is simplified, manual operation is reduced, machining precision is improved, product quality is improved and production efficiency is improved obviously.

Owner:CHONGQING JINLUN MACHINERY MFG CO LTD

Solid welding wire for gas-shielded electric-arc welding of high-strength steel

InactiveCN107009047AImprove mechanical propertiesImprove impact toughnessWelding/cutting media/materialsSoldering mediaProcess windowMechanical property

The invention discloses a solid welding wire for gas-shielded electric-arc welding of high-strength steel, and belongs to the technical field of welding materials. The solid welding wire consists of the following chemical components in percentage by mass: 0.06-0.15% of C, 0.60-1.00% of Si, 1.50-2.00% of Mn, less than or equal to 0.025% of P, less than or equal to 0.020% of S, 0.10-0.60% of Ni, 0.40-0.80% of Cr, less than or equal to 0.25% of Cu, 0.02-0.10% of V, 0.08-0.25% of Ti, 0.002-0.008% of B, less than or equal to 0.0070% of O, less than or equal to 0.0070% of N, and the balance iron and inevitable impurities. The solid welding wire has mechanical property superior to that of a base material, is excellent in welding operation property, is suitable for a relatively wide operation process window, is mature and efficient in industrial production route, and is low in processing manufacturing cost.

Owner:SHOUGANG CORPORATION

Stainless steel flux cored wire protected by CO2 gas

InactiveCN103495816AProportionally largeSmall footprintWelding/cutting media/materialsSoldering mediaIron powderManganese

The invention discloses a stainless steel flux cored wire protected by CO2 gas. The stainless steel flux cored wire protected by CO2 gas is characterized in that flux cored powder and a steel belt wrapping the flux cored powder are included, and the flux cored powder of the flux cored wire comprises, by weight, 15-35% of rutile, 12-25% of silicon manganese alloy, 12-30% of iron powder, 5-16% of nickel powder, 3-10% of aluminium magnesium alloy, 10-25% of micro-carbon ferro chrome, 5-15% of ferro-molybdenum and 5-15% of ferrovanadium. The stainless steel flux cored wire protected by CO2 gas has the advantages of being suitable for welding on small-specification ultrathin stainless steel devices and containers.

Owner:NINGBO LONGXING WELDING CUTTING TECH STOCK

TC4 titanium alloy solid welding wire for large-thickness ultra-narrow-gap laser wire filling welding and preparation method thereof

ActiveCN112872654AWill not affect subsequent weldingDoes not affect welding qualityWelding/cutting media/materialsSoldering mediaPlastic packagingIngot

The invention discloses a TC4 titanium alloy solid welding wire for large-thickness ultra-narrow-gap laser wire filling welding and a preparation method thereof. The invention belongs to the technical field of welding materials. The invention provides the TC4 titanium alloy solid welding wire for large-thickness ultra-narrow-gap laser wire filling welding and the preparation method thereof. The solid welding wire is prepared from chemical components in percentage by mass as follows: 5.0%-7.0% of Al, 4.0%-6.0% of V, 1.5%-2.5% of Mo, 0.2%-0.5% of Cr, 0.5%-1.5% of Zr and the balance of Ti. The method comprises the following steps: weighing raw materials according to the chemical components of the welding wire, mixing the raw materials, pressing into an electrode block, welding into a consumable electrode, carrying out primary smelting to obtain a primary cast ingot, carrying out secondary smelting to obtain a titanium alloy cast ingot, turning a skin, cutting a dead head, forging into a square billet, rolling, drawing, straightening and polishing to obtain a wire material, carrying out vacuum annealing, carrying out drawing diameter reduction, stress relief annealing and cleaning in a vacuum tube type annealing furnace, winding on a wire reel, and vacuum plastic packaging to obtain the large-thickness ultra-narrow-gap TC4 titanium alloy solid welding wire for laser wire filling welding.

Owner:HARBIN WELDING INST LTD

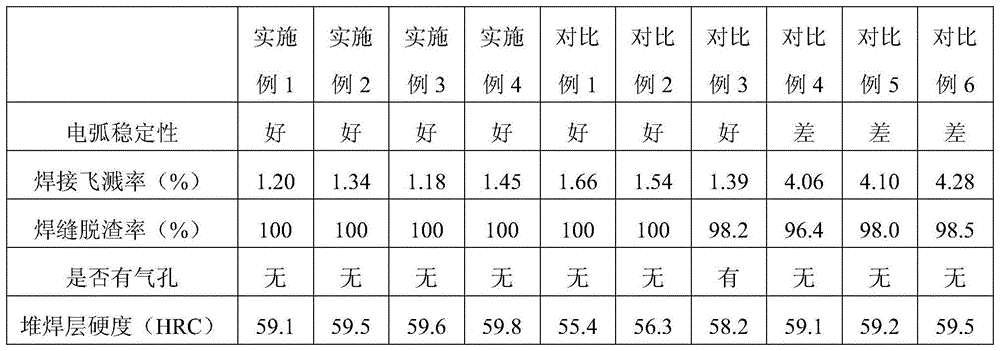

Anti-crack wear-resistant overlaying welding flux-cored wire and preparing method of anti-crack wear-resistant overlaying welding flux-cored wire

InactiveCN104209662AImprove hardenabilityHigh hardnessWelding/cutting media/materialsSoldering mediaCrazingWear resistant

The invention discloses an anti-crack wear-resistant overlaying welding flux-cored wire, which consists of a scarfskin and a flux core, wherein the flux core consists of the following ingredients in percentage by mass: 40 to 50 percent of Cr, 3 to 10 percent of Ni, 5 to 10 percent of Mn, 5 to 10 percent of Si, 4 to 10 percent of CaF2, 5 to 10 percent of Li2CO3, 10 to 15 percent of Al / Mg alloy and the balance Fe. The invention also discloses a preparing method of the anti-crack wear-resistant overlaying welding flux-cored wire. According to the method, flux-cored ingredients are uniformly mixed and are then dried, next, the dried flux-cored ingredients are added into a U-shaped groove rolled by an H08A steel band, then, roller compaction and closed straightening are carried out, finally, the straight pulling is carried out, and the anti-crack wear-resistant overlaying welding flux-cored wire is obtained after the packaging. The anti-crack wear-resistant overlaying welding flux-cored wire has the advantages that the hardness and the wearing resistance are ensured, meanwhile, the occurrence of overlaying welding layer cracks is avoided, an overlaying welding layer has certain toughness, better welding manufacturability is realized, welding spattering is little, and the deposition rate is high; the anti-crack wear-resistant overlaying welding flux-cored wire is suitable for automatic welding equipment, the production efficiency is higher, in addition, the preparing method is simple, and the operation is convenient.

Owner:XIAN UNIV OF TECH

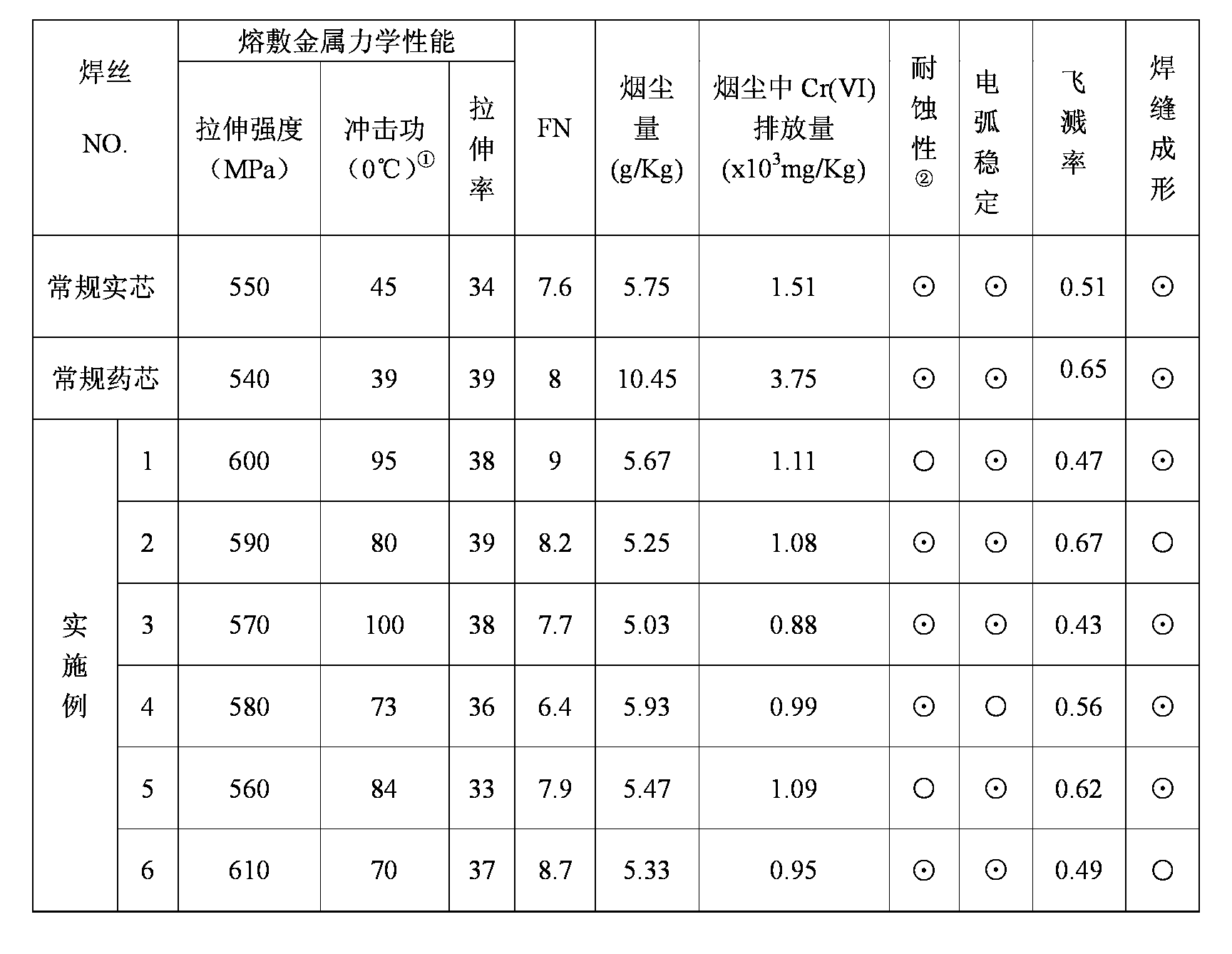

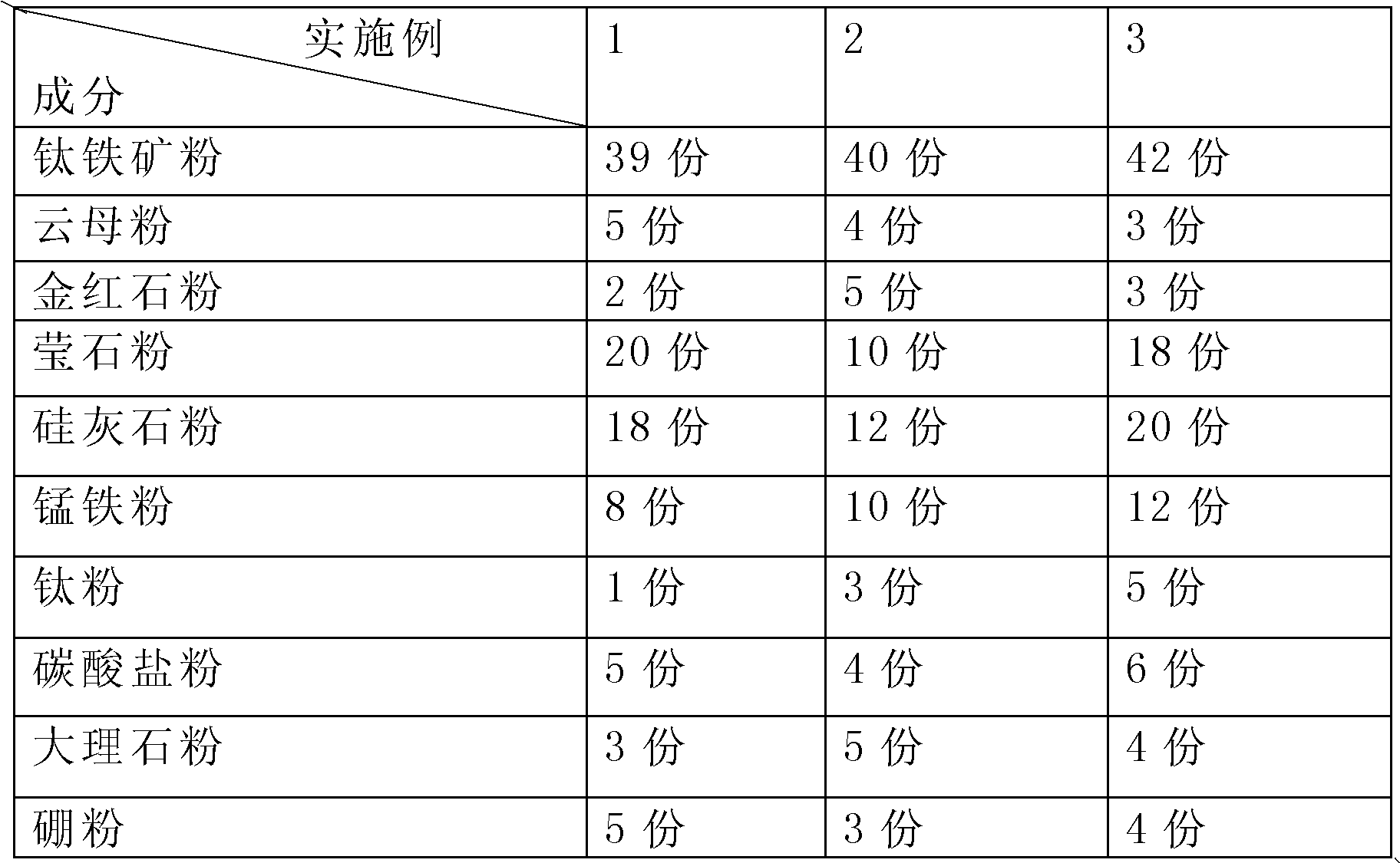

Chromium oxide green 308 austenitic stainless steel metal core welding stick and preparation method thereof

ActiveCN103008914ALow costEmission reductionArc welding apparatusWelding/cutting media/materialsManganeseFilling rate

The invention relates to a chromium oxide green 308 austenitic stainless steel metal core welding stick and a preparation method thereof, and the welding stick and the preparation method thereof belong to the technical field of welding materials. The chemical components of the powder of a metal core are as follows: 0.03 weight percent to 0.065 weight percent of carbon (C), 52 weight percent to 58 weight percent of chromium (Cr), 26 weight percent to 30 weight percent of nickle (Ni), 4 weight percent to 6 weight percent of manganese (Mn), 0.66 weight percent to 1.5 weight percent of silicon (Si), 0.5 weight percent to 1 weight percent of titanium (Ti), 0.5 weight percent to 1 weight percent of zinc (Zn), 0.5 weight percent to 1 weight percent of zirconium (Zr), less than 0.03 weight percent of phosphorus (P), less than 0.03 weight percent of sulfur (S) the rest of ferrum (Fe). The filling rate is 26 percent to 38 percent. According to the chromium oxide green 308 austenitic stainless steel metal core welding stick and the preparation method thereof, under the condition of a little smaller amount of welding dust, the emission of toxic Cr (VI) can be reduced by 30 percent to 40 percent compared with the solid welding stick of the same type, and by 35 percent to 45 percent compared with a stainless steel flux-cored welding stick. Due to the adoption of the low-carbon steel strip, the cost of the welding stick can be greatly reduced, the welding stick has stable welding arc and little splash, a formed welding seam is attractive, and the comprehensive properties of deposited metal are excellent.

Owner:科威尔焊接(江苏)有限公司

Sintered flux for nickel base strip electrode electro-slag welding

ActiveCN104708231AReduce burning lossImprove the transition coefficientWelding/cutting media/materialsSoldering mediaFerroniobiumSlag

The invention relates to sintered flux for nickel strip electrode electro-slag welding. The sintered flux for the nickel strip electrode electro-slag welding is characterized in that the intered flux is prepared from dry powder components and binder water glass; the dry powder components comprise, by mass, 45-75% of CaF2, 15-35% of Al2O3, 1-5% of SiO2, 1-5% of CaO, 1-5% of MgO, 1-10% of sodium fluoroaluminate, 1-5% of rare earth fluoride and 1-5% of ferroniobium alloy powder; the ratio of potassium to sodium of the binder water glass is 1 to 1, the molar ratio is 2.2-3.5, the baume degree at room temperature is 38-50, and the dosage is 15-25% of the weight of the dry powder. The sintered flux can be used through being matched with various nickel base welding strip such as EQNiCrMo-3 and EQNiCr-3, when strip electrode electro-slag surfacing is conducted through matching with the nickel base welding strip, stable electro-slag process and welding technological property can be maintained at the quick welding condition of 250 mm / min, the quality of formation of surfacing layers is good, defects do not exist in lap joint, and various indexes of the surfacing layers can meet usage requirements of users.

Owner:BEIJING JINWEI WELDING MATERIAL +1

High low temperature toughness carbon steel covered electrode

InactiveCN101947704ALess welding spatterBeautiful shapeWelding/cutting media/materialsSoldering mediaDeposition rateMetal

The invention provides a high low temperature toughness carbon steel covered electrode, belonging to the technical field of metal welding tool. The invention solves the problem that the low temperature toughness of the existing electrode is low. The high low temperature toughness carbon steel covered electrode of the invention comprises a core wire and a coating which is extruded and pressed on the core wire; wherein the coating is composed of the following components by parts by weight: 39-45 parts of reduced ilmenite powder, 3-6 parts of mica powder, 1-6 parts of rutile powder, 10-23 parts of fluorite powder, 4-27 parts of wollastonite powder, 6-16 parts of ferro manganese powder, 0-5 parts of titanium powder, 4-6 parts of carbonate powder, 2-6 parts of marble powder and 3-5 parts of boron powder, and the powders containing the components are mixed to be uniform, so as to obtain the coating of the electrode. The invention has less welding spatter, beautiful moulding, easy slag detaching, high deposition rate and good welding performance; especially low temperature toughness is improved, and low temperature brittleness is prevented from being destroyed; and production cost is low, application range is wide, and use is convenient.

Owner:台州海翔焊接材料有限公司 +1

900MPa high-strength loop chain pulse flash butt welding process

ActiveCN109676227AFlat surfaceMeet the use requirementsResistance welding apparatusButt weldingPulse pressure

The invention relates to a 900MPa high-strength loop chain pulse flash butt welding process. The 900MPa high-strength loop chain pulse flash butt welding process comprises the steps that a 900MPa loopchain bar is sequentially subjected to ring weaving, surface treatment and preheating treatment after being subjected to annealing treatment; pulse flash butt welding, upsetting and pressure maintaining are performed on the preheated loop chain bar; pre-stretching and quenching-tempering heat treatment are carried out on the welded loop chain bar. Pulse current is superposed on average welding current to achieve the pulse in the pulse flash butt welding process, and meanwhile pulse pressure is applied. By the adoption of the 900MPa-level high-strength loop chain flash welding process, a flashbutt welding head which is flat in surface, free of welding cracks and inclusions and capable of meeting the using requirement can be obtained under the conditions of low splashing and high efficiency.

Owner:SHANDONG JINHENGLI CONTROL CO LTD

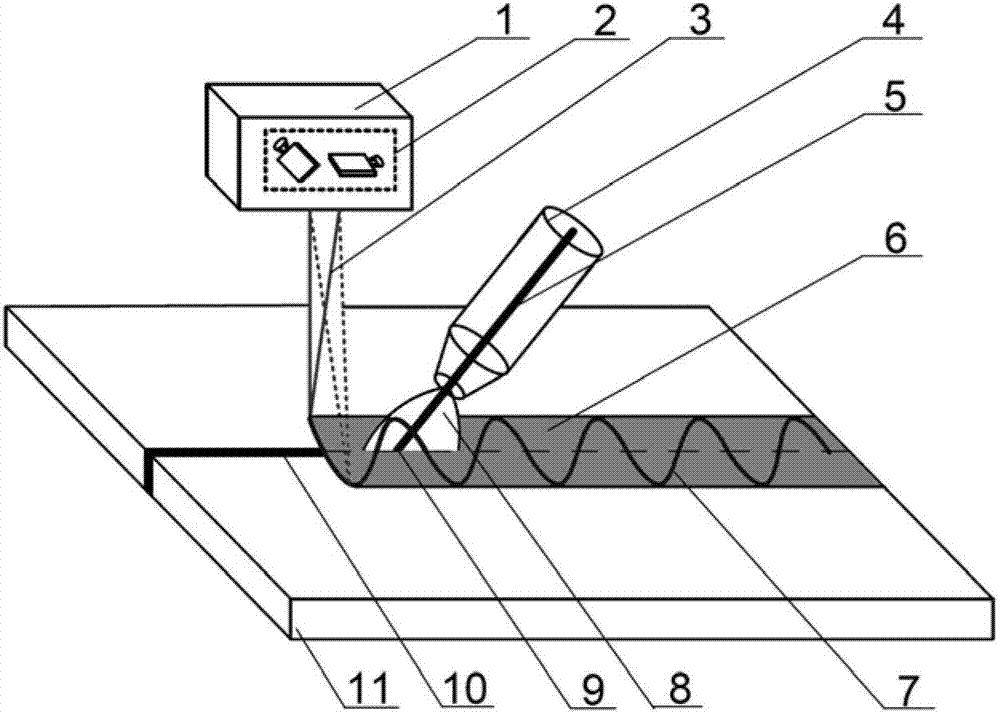

Laser scanning-TIG composite melting strip welding method

InactiveCN110102898AImprove toleranceReduce assembly accuracyLaser beam welding apparatusCouplingLaser scanning

The invention discloses a laser scanning-TIG composite melting strip welding method. The laser scanning-TIG composite melting strip welding method comprises the following steps: during welding, a strip-shaped welding wire with a rectangular section is used; a strip conveying mechanism conveys the strip-shaped welding wire into the space above a gap of a workpiece to be welded; the width directionof the strip-shaped welding wire forms a certain angle with a welding direction; one end of a TIG welding gun is connected with a positive pole of an output end of a power supply; the strip-shaped welding wire is connected with a negative pole of the output end of the power supply; a laser beam scans in the welding direction; one half of a scanning area is located in the strip-shaped welding wire,and the other half is located in a molten pool; and a laser scanning path has different manners according to different materials and welding requirements. According to the laser scanning-TIG composite melting strip welding method, the mutual coupling action of laser and an electric arc is improved; the stirring action of laser on the molten pool is improved; the shortage of driving flow in the molten pool by virtue of surface tension purely is made up; the solidification time of the molten pool is prolonged; and the temperature gradients of molten drops and the molten pool and the impact of the molten drops on the molten pool are reduced, so that the escape of bubbles is benefited, and the formation of crystallization cracks is suppressed.

Owner:BEIJING UNIV OF TECH

Self-protection type flux-cored wire for welding of G520 stainless steel and 25Cr2Ni4MoV alloy steel and preparation method of self-protection type flux-cored wire

InactiveCN108356447ALess welding spatterBeautiful weld shapeWelding/cutting media/materialsSoldering mediaMetallurgyFerrosilicon

The invention discloses a self-protection type flux-cored wire for welding of G520 stainless steel and 25Cr2Ni4MoV alloy steel. The self-protection type flux-cored wire comprises a flux core and a welding scale. The flux core comprises the following components of, by mass, 1%-4% of ferrosilicon powder, 3%-5% of manganese powder, 15%-20% of chromium powder, 12%-16% of nickel powder, 7%-9% of copperpowder, 2%-5% of ferrocolumbium powder, 8%-13% of rutile powder, 13%-15% of fluorite powder, 6%-10% of zircon sand powder, 4%-8% of lithium carbonate powder, 3%-5% of ferric oxide powder, 3%-5% of alumina powder, 4%-5% of magnesium oxide powder, and the balance iron powder, and the sum of the mass percentages of all the above components is 100%. Compared with a stainless steel welding rod and a solid welding wire, the prepared flux-cored wire flux-cored wire has the advantages of little welding spattering, attractive weld joint forming and good welding process performance and can be used fora continuous wire feeding automatic welder, a preparation method is simple, operation is convenient, and the preparation method can be used for mass production.

Owner:XIAN UNIV OF TECH

Oscillatory scanning laser beam-electric arc hybrid welding method and system

ActiveCN103056533BImprove featuresImprove welding qualityLaser beam welding apparatusPorosityLaser scanning

The invention discloses an oscillatory scanning laser beam-electric arc hybrid welding method and system. Laser beams and electric arc move together along an abutted seam in large range space, simultaneously the laser beams surround acting points of the electric arc to perform oscillatory scanning movement in a local small area, and an actual welding track is a curve formed by overlying two types of movements. As for an optimal range of laser beam oscillatory scanning displacement, the range in the direction of an X axis is minus 2mm to 3mm, the range in the direction of an Y axis is minus 5mm to 5mm, the range in the direction of a Z axis is minus 2mm to 2mm, and the oscillation frequency is in a range from 20Hz to 500Hz. According to the method and the system, an enhanced technical effect is achieved by the aid of interaction of a laser beam oscillatory scanning effect and a laser-electric arc synergistic effect, and the welding quality is improved. Compared with existing laser-electric arc hybrid welding and laser scanning welding methods and systems, the method and the system have the advantages that higher weld porosity inhibiting capability is achieved, and the weld strength is improved by 10% to 50%.

Owner:武汉飞能达激光技术有限公司

Chromium-titanium-strengthened high-carbon high-alloy-steel wear-resistant surfacing flux-cored wire and preparing method thereof

ActiveCN106271197AReduce hardening tendencyReduces tendency to flakeWelding/cutting media/materialsSoldering mediaWear resistantManganese

The invention discloses a chromium-titanium-strengthened high-carbon high-alloy-steel wear-resistant surfacing flux-cored wire. The chromium-titanium-strengthened high-carbon high-alloy-steel wear-resistant surfacing flux-cored wire is prepared from an external carbon steel belt and chemical powder wrapped by the external carbon steel belt; the weight of the chemical powder accounts for 38.0% to 42.0% of the total weight of the welding wire, and the chemical powder is prepared from 20.0%-25.0% of high carbon chromium iron, 38.0%-45.0% of ferrotitanium, 1.2%-1.6% of metal manganese powder, 2.0%-2.2% of metal molybdenum powder, 3.5%-4.0% of graphite, 2.5%-5.0% of silicon calcium alloy, 2.0%-3.0% of zirconium quartz sand, 8.0%-10.0% of fluorite, 0.1%-0.2 % of boron carbide and the balance iron powder. A preparing method includes the steps that the U-shaped external carbon steel belt is made, the chemical powder is added into the U-shaped groove, five-pass continuous drawing reducing is carried out after an opening is sealed, and the flux-cored wire is obtained. The chromium-titanium-strengthened high-carbon high-alloy-steel wear-resistant surfacing flux-cored wire is suitable for surfacing composite manufacturing and on-line repairing of a grinding roller and a grinding disc, and the service life of the grinding roller and the service life of the grinding disc can be remarkably prolonged.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com