Special welding rod for sulfuric acid dew point corrosion-resistant steel

A technology that corrodes steel and is resistant to sulfuric acid. It is applied in welding medium, welding equipment, welding/welding/cutting items, etc. It can solve problems such as failure to meet expected requirements, high content of diffusible hydrogen, and insufficient corrosion resistance, and achieve low production costs. , high deposition rate and excellent welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

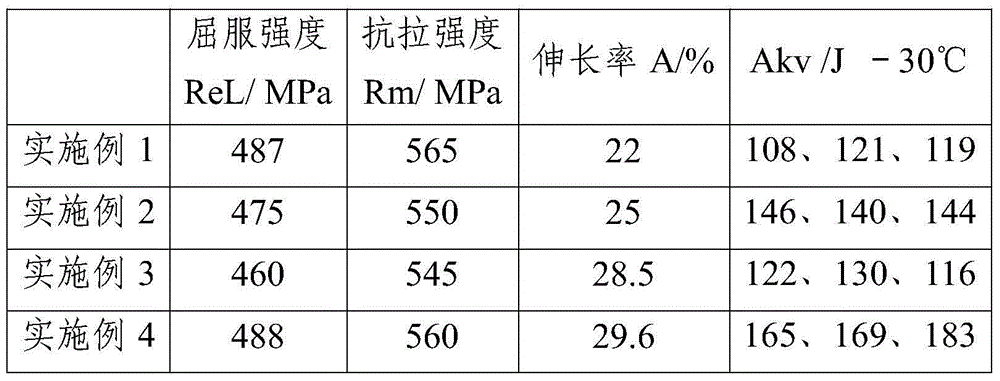

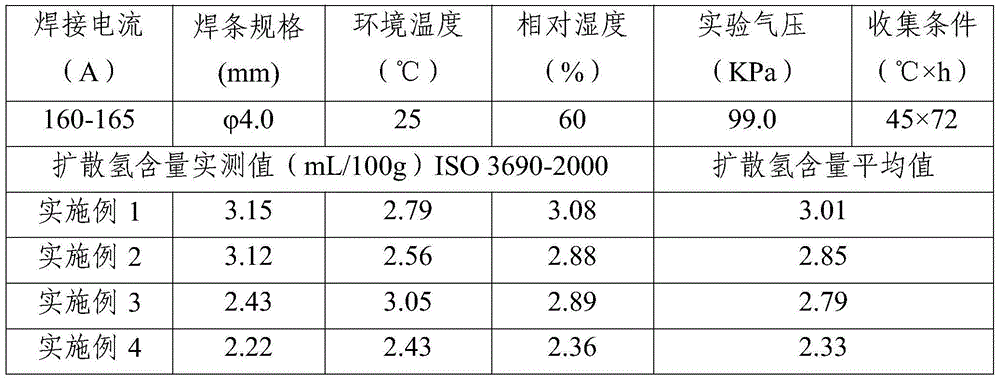

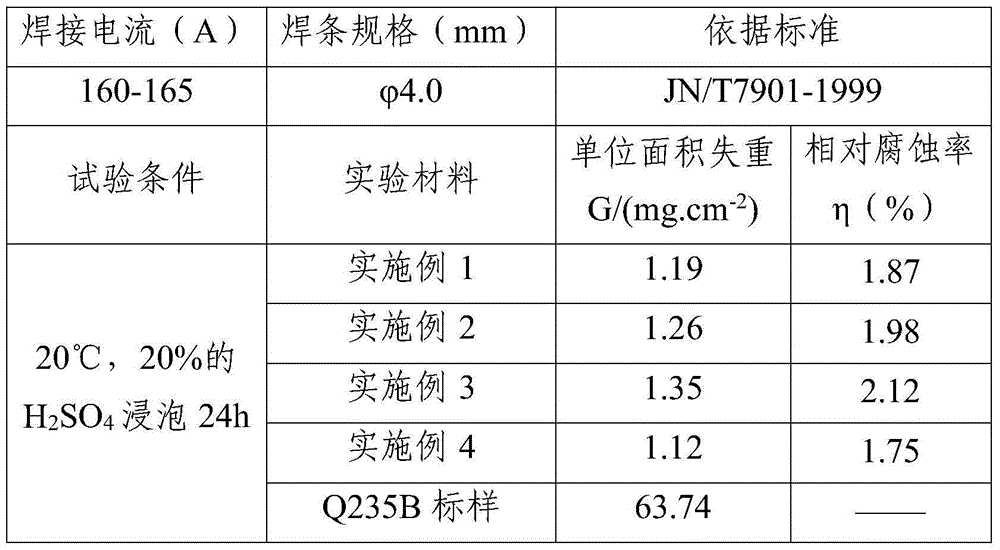

Examples

Embodiment 1

[0034] Sulfuric acid dew point corrosion resistant steel supporting electrode, composed of steel core and coating, the steel core of the electrode is H08GX steel wire, using high-modulus pure sodium water glass as the binder, the coating accounts for about 35-40% of the total weight of the electrode. The skin composition is in weight percentage: CaCO 3 : 33%, CaF 2 : 29%, TiO 2 : 13%, SiO 2 : 5%, Si-Fe: 6%, Mn: 2%, Cr: 2%, Cu: 0.8%, Sb: 0.1%, Na 2 CO 3 : 1%, rare earth oxide: 2%, the rest is iron powder.

Embodiment 2

[0036] Sulfuric acid dew point corrosion resistant steel supporting electrode, consisting of steel core and coating, the steel core of the electrode is H08GX steel wire, using high-modulus pure sodium water glass as the binder, the coating accounts for about 35-40% of the total weight of the electrode. The skin composition is in weight percentage: CaCO 3 : 45%, CaF 2 : 18%, TiO 2 : 8%, SiO 2 : 9%, Si-Fe: 4%, Mn: 4%, Cr: 3.5%, Cu: 1.5%, Sb: 0.3%, Na 2 CO 3 : 1.5%, rare earth oxide: 3%, the rest is iron powder.

Embodiment 3

[0038] The steel supporting electrode for sulfuric acid dew point corrosion is composed of a steel core and a coating. The steel core of the electrode is H08GX steel wire. The high-modulus pure sodium water glass is used as the binder. The coating accounts for about 35-40% of the total weight of the electrode. The skin composition is in weight percentage: CaCO 3 : 40%, CaF 2 : 20%, TiO 2 : 10%, SiO 2 : 8%, Si-Fe: 5%, Mn: 3%, Cr: 2.8%, Cu: 1%, Sb: 0.2%, Na 2 CO 3 : 1%, rare earth oxide: 4%, the rest is iron powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com