High low temperature toughness carbon steel covered electrode

A high-toughness, carbon steel technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems affecting the low temperature toughness of the electrode, increase the moisture absorption performance of the electrode, low temperature brittle failure, etc., and achieve outstanding economic benefits. and social benefits, beautiful molding, and the effect of improving low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0016] The ferromanganese powder described in Example 2 is medium-carbon ferromanganese powder with a carbon content of 1.2%; the described carbonate powder is magnesium carbonate powder.

Embodiment 3

[0017] The ferromanganese powder described in embodiment 3 is medium carbon ferromanganese powder, and carbon content is 1.0%; Described carbonate powder is calcium carbonate powder, magnesium carbonate powder, barium carbonate powder, and the weight ratio of the three is 3 :2:5.

Embodiment 1

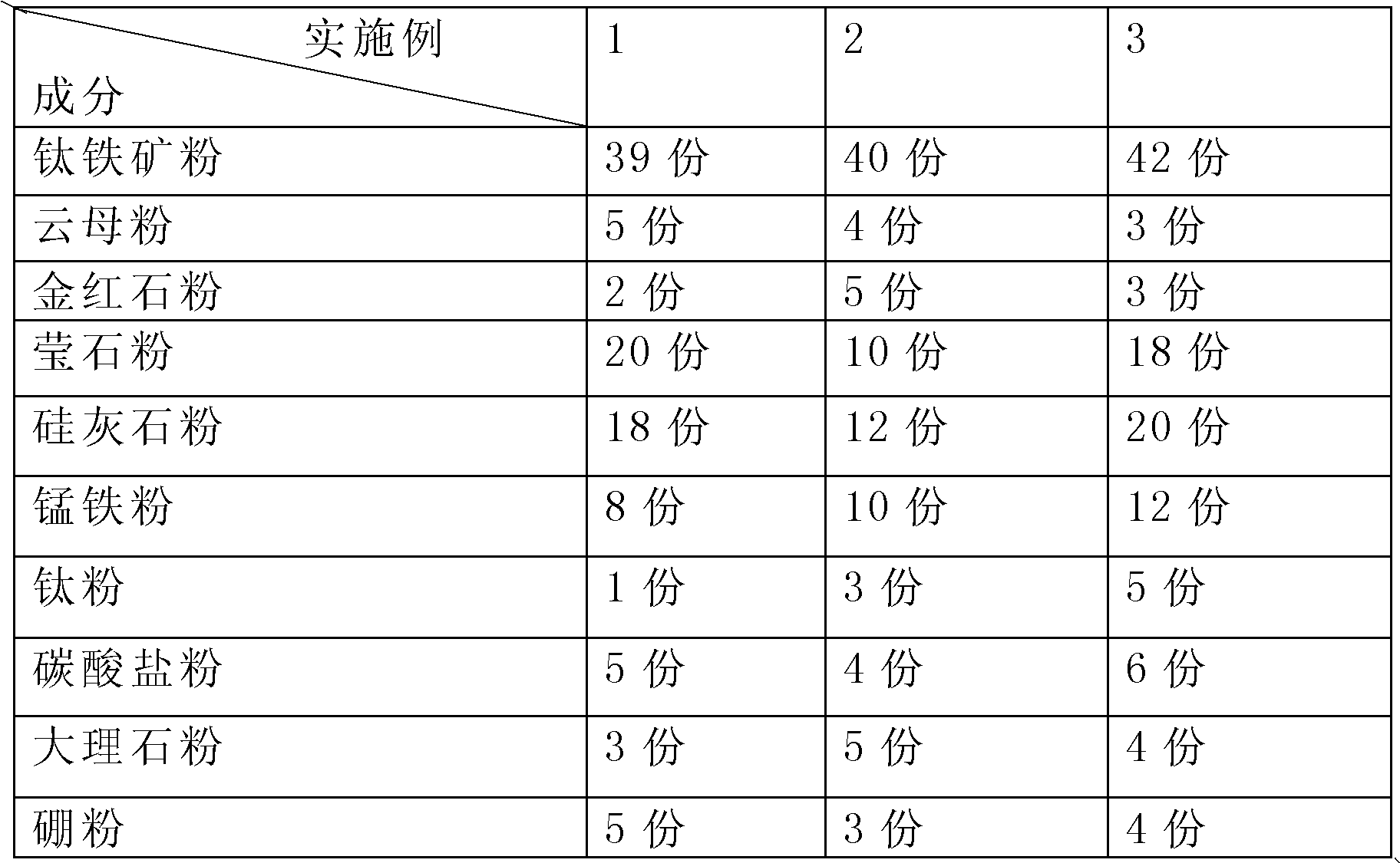

[0019] According to the composition ratio of the carbon steel electrode coating in Example 1 in Table 1, the drug is added to the mixer as required, and then mixed with water glass adhesive to mix evenly, and then added to the electrode press coating machine for coating. After the carbon steel welding core is put into the dryer, it is dried and shaped, and finally inspected and packaged to make carbon steel welding rods of various specifications.

[0020] Example 2

[0021] According to the composition ratio of the carbon steel electrode coating in Example 2 in Table 1, the other processes are the same as in Example 1, and will not be repeated.

[0022] Example 3

[0023] According to the composition ratio of the carbon steel electrode coating composition in Example 3 in Table 1, other processes are the same as in Example 1, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com