TC4 titanium alloy solid welding wire for large-thickness ultra-narrow-gap laser wire filling welding and preparation method thereof

A solid welding wire and laser wire filling technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of narrow welding heat affected zone, achieve sufficient solid solution process, increase β phase stability, and prolong solid solution. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

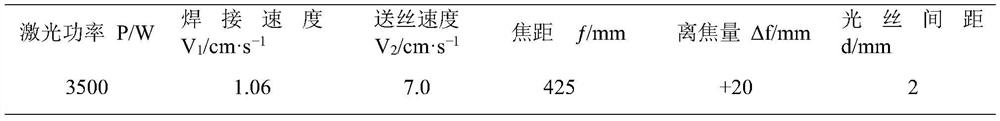

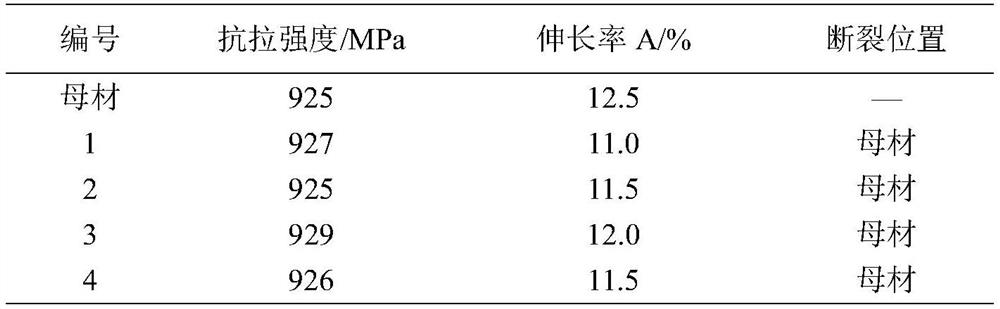

Embodiment 1

[0039] Embodiment 1: The chemical composition and mass percentage of a TC4 titanium alloy solid welding wire for laser welding with large thickness and ultra-narrow gap are Al: 5.5%, V: 4.5%, Mo: 1.5%, Cr: 0.3%, Zr: 1.0%, the balance is Ti, wherein the chemical composition and mass percentage of impurities are Fe: 0.02%, C: 0.02%, O: 0.05%, N: 0.01%, H: 0.001%.

[0040] The method for preparing a kind of large-thickness ultra-narrow gap laser wire-filling welding with TC4 titanium alloy solid welding wire described in Example 1 is carried out according to the following steps:

[0041] Step 1: Weigh titanium sponge, aluminum-molybdenum alloy powder, zirconium sponge, chromium powder and vanadium powder according to the chemical composition of the welding wire as raw materials, mix them and put them into a mold and press them into an electrode block with a gas press;

[0042] Step 2: welding the electrode block prepared in step 1 into a consumable electrode by laser self-fusion ...

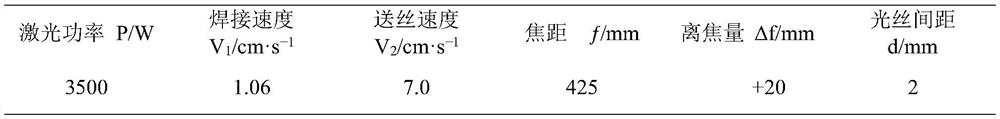

Embodiment 2

[0054] Embodiment 2: The chemical composition and mass percentage of a TC4 titanium alloy solid welding wire for laser welding with large thickness and ultra-narrow gap are Al: 5.8%, V: 5.5%, Mo: 1.85%, Cr: 0.3%, Zr: 0.8%, the balance is Ti, and the chemical composition and mass percentage of impurities are Fe: 0.01%, C: 0.01%, O: 0.03%, N: 0.01%, H: 0.001%.

[0055] The method for preparing a kind of TC4 titanium alloy solid welding wire with large thickness and ultra-narrow gap laser wire filler described in Example 2 is carried out according to the following steps:

[0056] Step 1: Weigh titanium sponge, aluminum-molybdenum alloy powder, zirconium sponge, chromium powder and vanadium powder according to the chemical composition of the welding wire as raw materials, mix them and put them into a mold and press them into an electrode block with a gas press;

[0057] Step 2: welding the electrode block prepared in step 1 into a consumable electrode by laser self-fusion welding;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com