A mechanical impact method and device for effectively reducing laser cladding cracks

A technology of laser cladding and mechanical impact, which is applied in the coating process and coating of metal materials, can solve the problems that affect the large-scale application of laser cladding, the formation of cracks in molded parts, and the cladding layer cracks, etc., to achieve the suppression of thermal cracks and the generation and expansion of cold cracks, the increase in strength, and the effect of refining the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

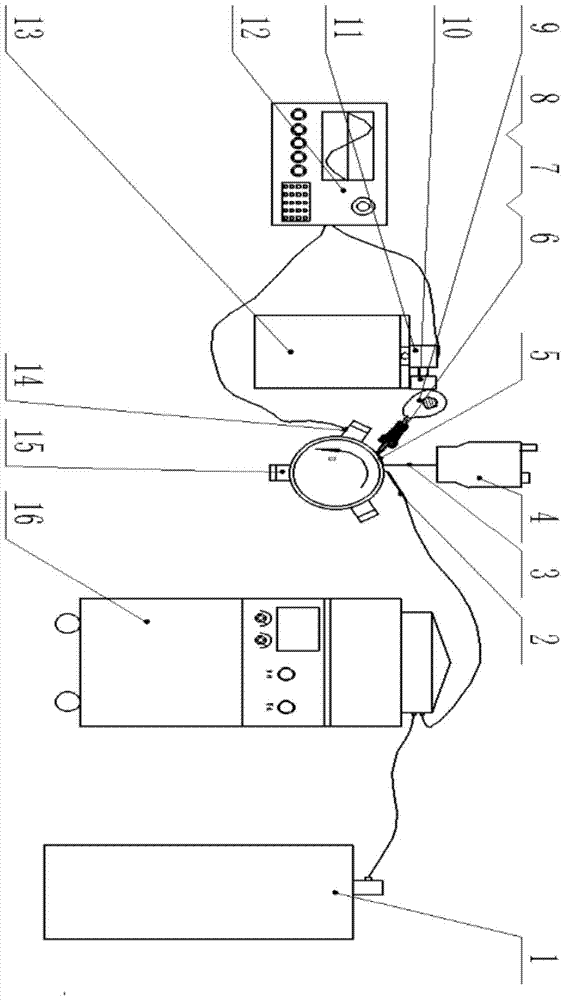

Embodiment 1

[0029] A laser cladding coating of Fe90 self-fluxing alloy powder + TiC powder is performed on a 20CrMnTi steel shaft substrate with a diameter of 20mm, and the self-fluxing alloy alloy powder used is cladding (chemical composition percentage Wt%: 13.6Cr, 1.6 B, Si1.2, Mo0.8, C0.8, Fe balance), add TiC with a mass fraction of 5%, mix well with a three-dimensional mixer, dry it in a dryer, and add it to the powder feeder stand-by. Carry out turning treatment on the surface of the substrate, clean the surface fatigue layer, holes, cracks, etc., clean the surface with acetone or alcohol, and clamp the workpiece with the three-jaw chuck of the CNC bed. Apply mechanical shock to the single pass of the workpiece that has been cladding, and input the relevant parameters in the CNC system. The shaft surface linear speed is 250mm / min, the overlap rate is 40%, the powder feeder speed is 80g / min, and the gas The flow rate is 5l / min, the laser power is 2.5kw, and the spot diameter is 3mm....

Embodiment 2

[0031] The method is the same as in Example 1, except that the mechanical impact frequency is 300 Hz, L1 is 10 mm, and L2 is 15 mm during laser cladding. by Picture 9 It can be seen that the structure is uniform, the arrangement is orderly, the crystal grains are more refined, and the pores basically disappear.

[0032] It can be seen from the above two embodiments that with the aid of mechanical shock, the number of various defects (pores, cracks, etc.) in the cladding layer is suppressed, so that the performance of the cladding layer is improved. The coating can effectively reduce cracks in the cladding layer and improve the structure of the cladding layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com