Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

434results about How to "Extended cooldown" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

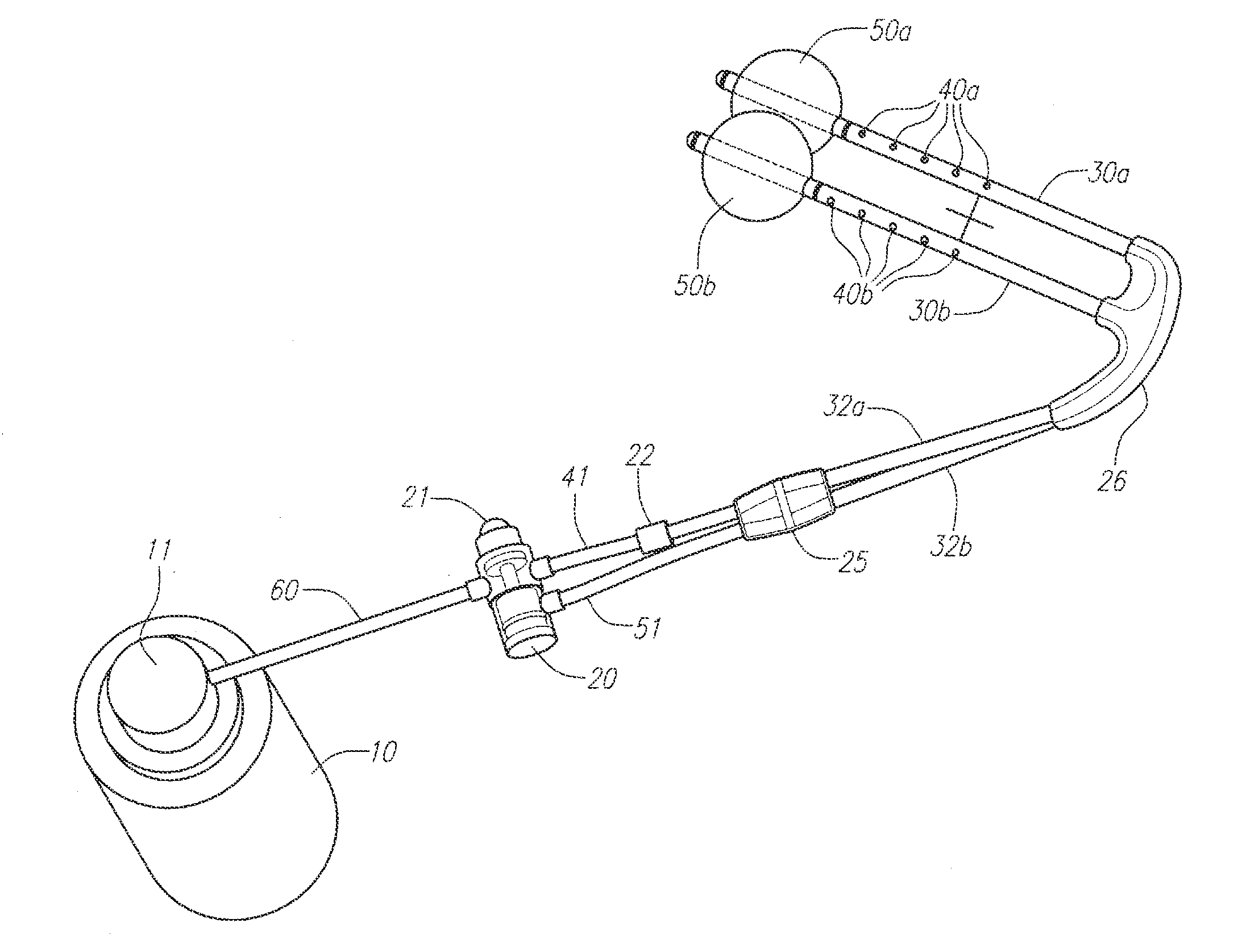

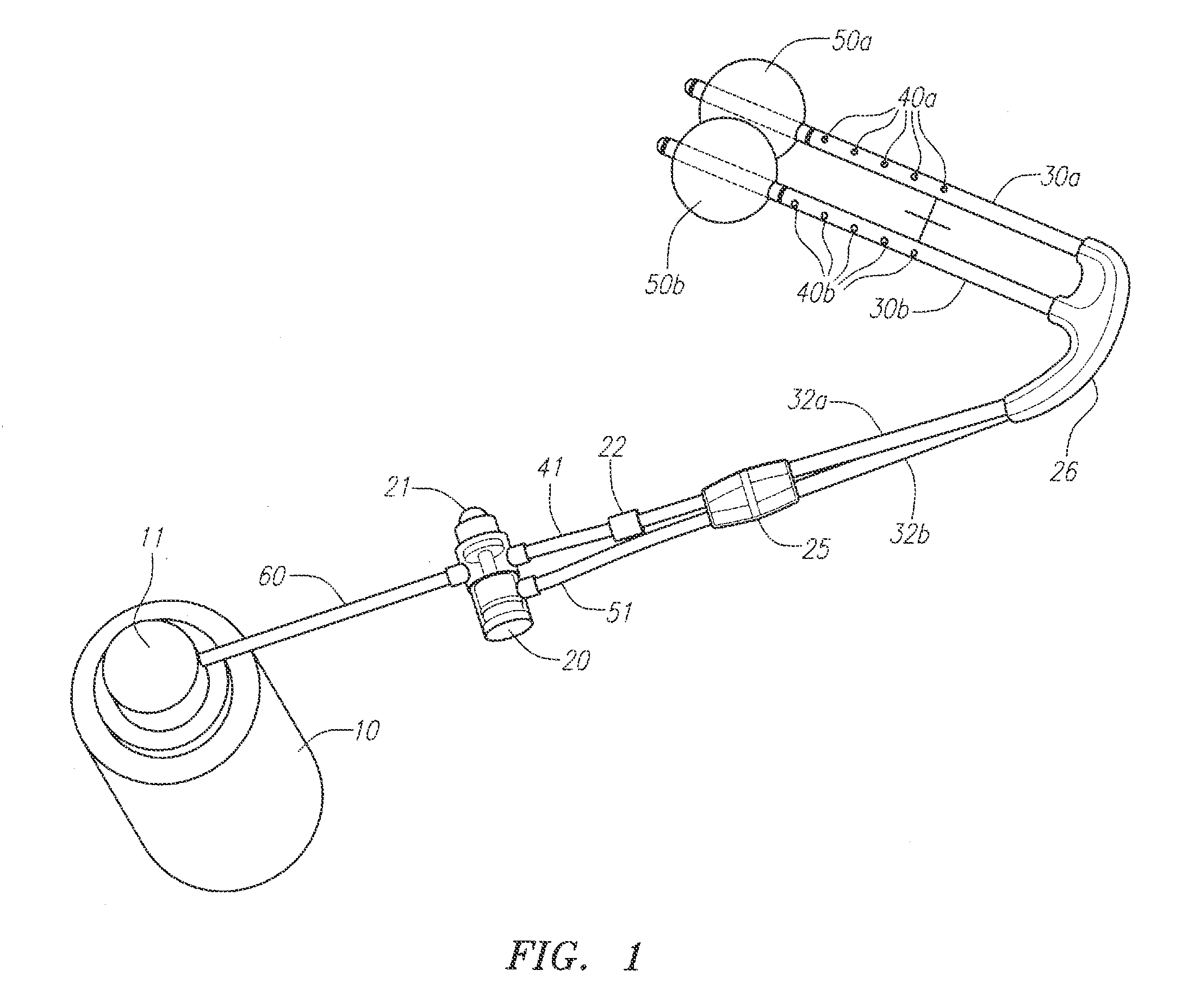

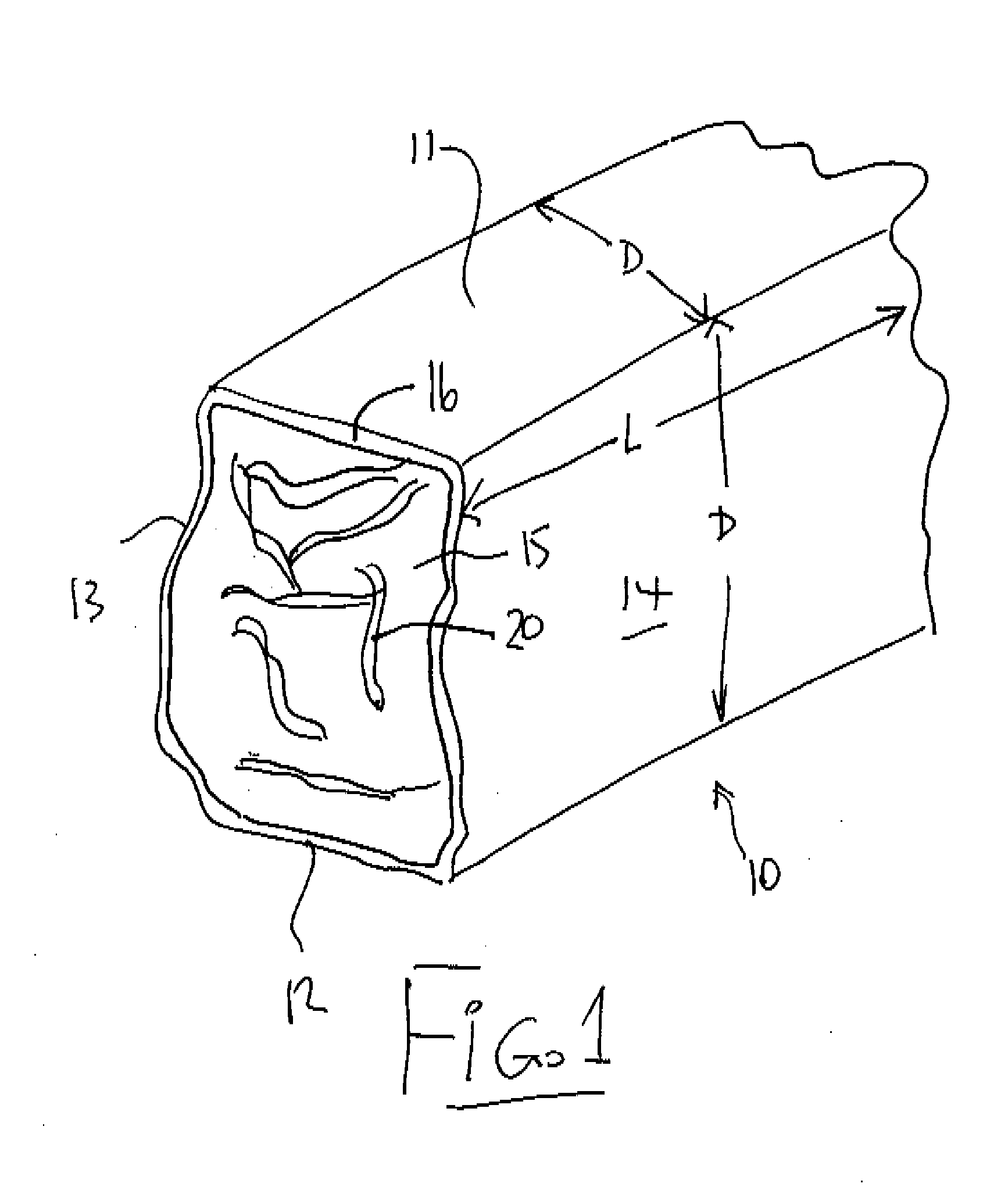

Devices for cooling the nasal cavity

ActiveUS20100324483A1Extended cooldownMinimize neurologic deficitsRespiratorsStentsBoiling pointCheck valve

A cerebral cooling device that uses a pressurized source to deliver a fluid that evaporates in the nasal cavity to provide cooling and has a balloon on the distal end that inflates from some of the pressure from the pressurized source. The device includes a nasal catheter having delivery ports located in the distal region and a balloon on the distal end. The proximal end of the catheter is in fluid communication with a pressurized source of a low boiling point fluid. A manifold located between the pressurized source and the catheter distributes the fluid and pressure from the pressurized source to a first lumen of the catheter to inflate the balloon and to a second lumen of the catheter through the delivery ports to cool the nasal cavity. A check valve in the manifold ensures that the fluid and pressure are first delivered to the balloon.

Owner:BRAINCOOL

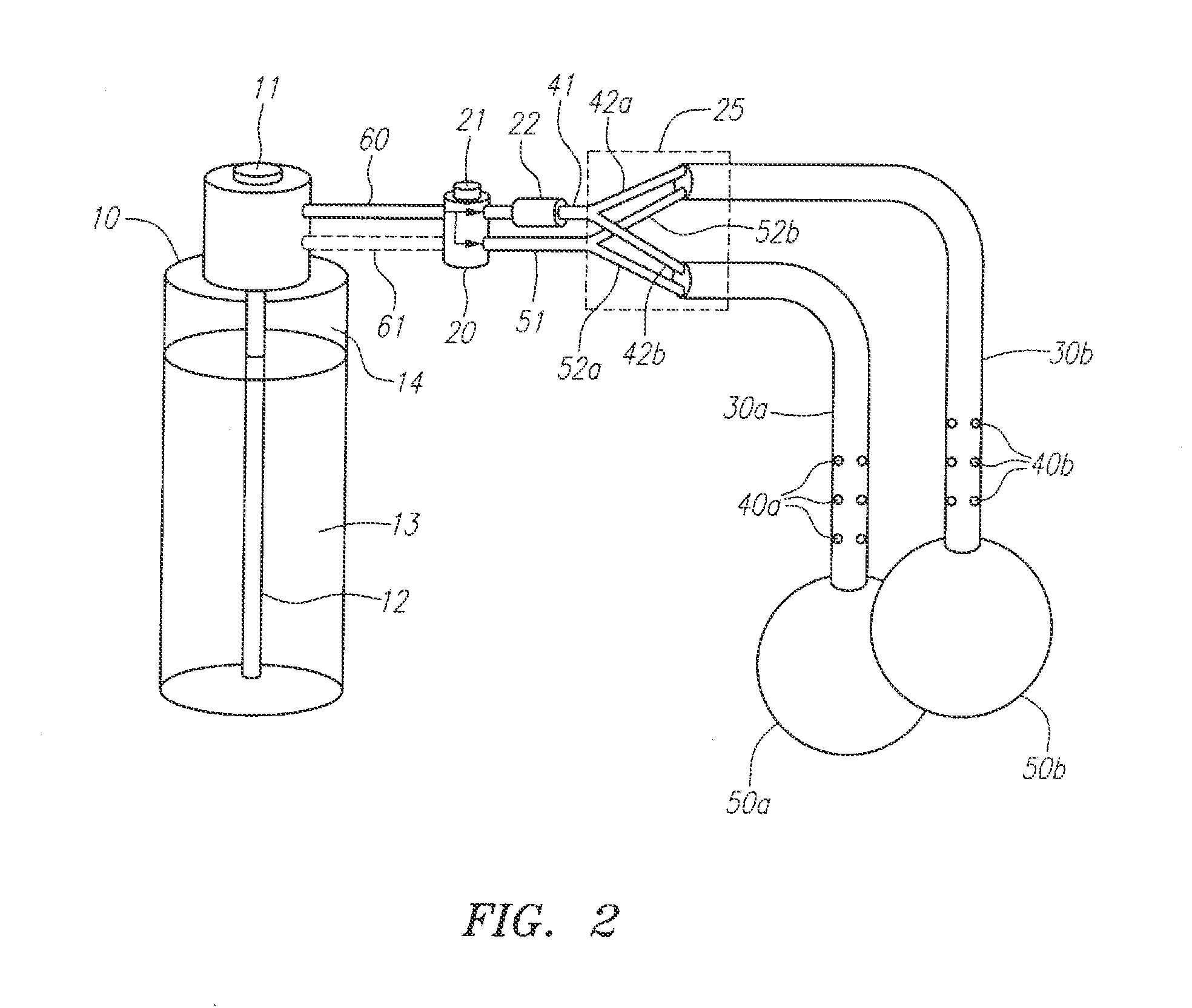

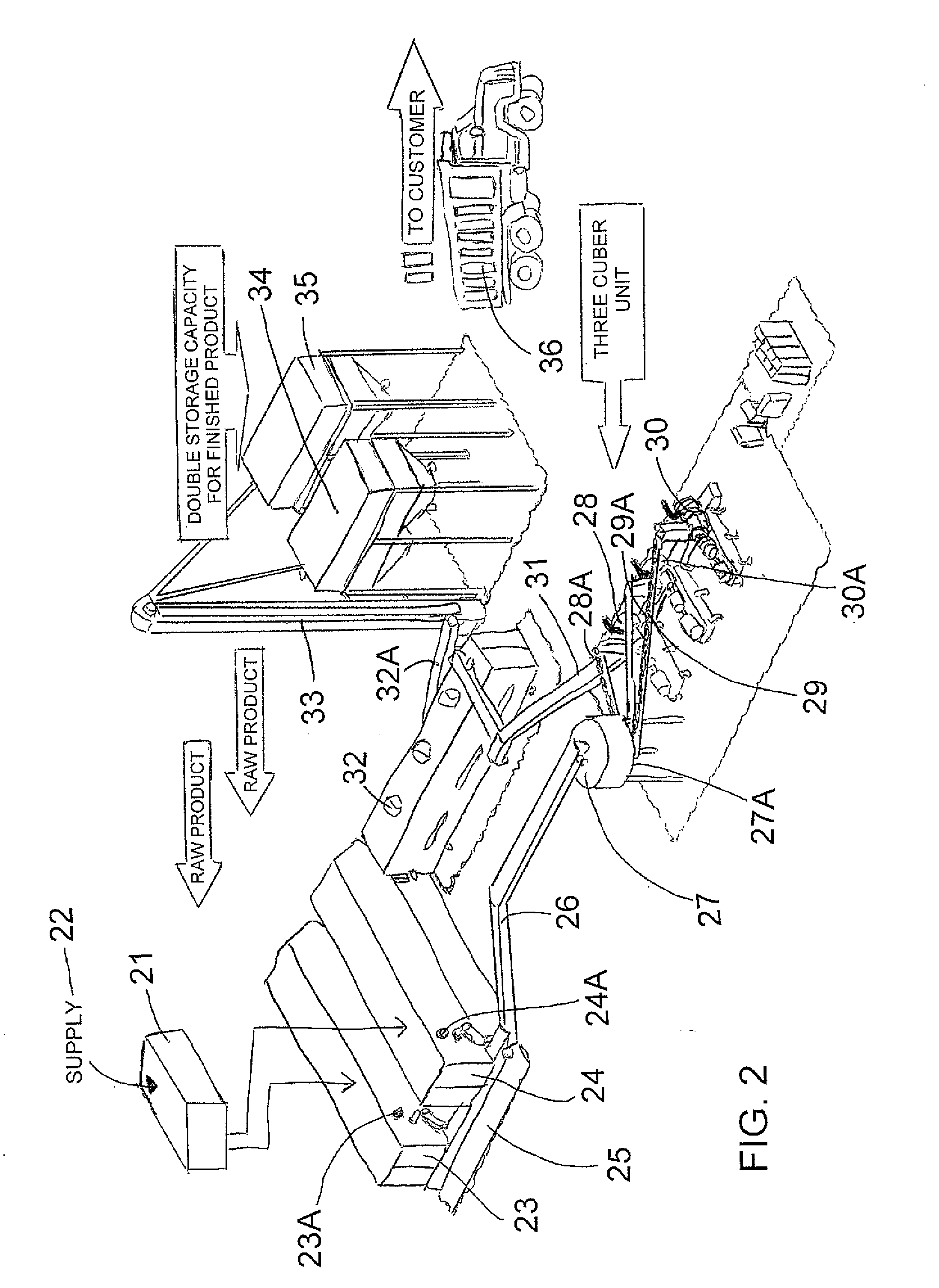

Method for manufacture of plant biomass solid fuel

InactiveUS20090056206A1Enhance cube durability and energy contentHigh qualityBiofuelsSolid fuelsBiomassCellulose

A solid fuel is formed in a cuber to form body pieces formed of materials extruded through a die with a density greater than 35 lbs / cu ft; an energy content greater than 6500 BTU / lb; transverse dimensions less than 1.5 inches; and a length less than 4 inches; from plant biomass material which contains components when extended of greater than 1.0 inch. Primarily the materials are paper or other cellulose product and crop residue such as wheat straw. The cellulose and lignin from these materials act without additional binders as binders and encasing materials. The moisture content is maintained at a target value by mixing selected quantities of the materials without drying. The cubing machine has a feeding system where the space between the inner rotor and outer casing is smaller than 4 inches and the height of the outer flight is less than 1 inch.

Owner:PRAIRIE BIO ENERGY

Special poultry meat fine and deep processing method

InactiveCN101961114AImprove sterilization efficiencyExtend heating timeMeat/fish preservationSlaughtering/stunningDeep processingFood item

The invention relates to a food processing method, in particular to a special poultry meat fine and deep processing method. In the invention, high-technology content special duck meat deep processed new products and special convenient and quick poultry meat green products are developed by using technology for preserving raw material duck meat with edible multifunctional preservation films, ultrasonic rapid penetration salting promoting technology, energy-saving, emission-reducing and environmentally-friendly microwave assisted sterilization technology, vacuum cooling technology, vacuum oil frying technology, infrared roasting technology and the like.

Owner:赵保雷

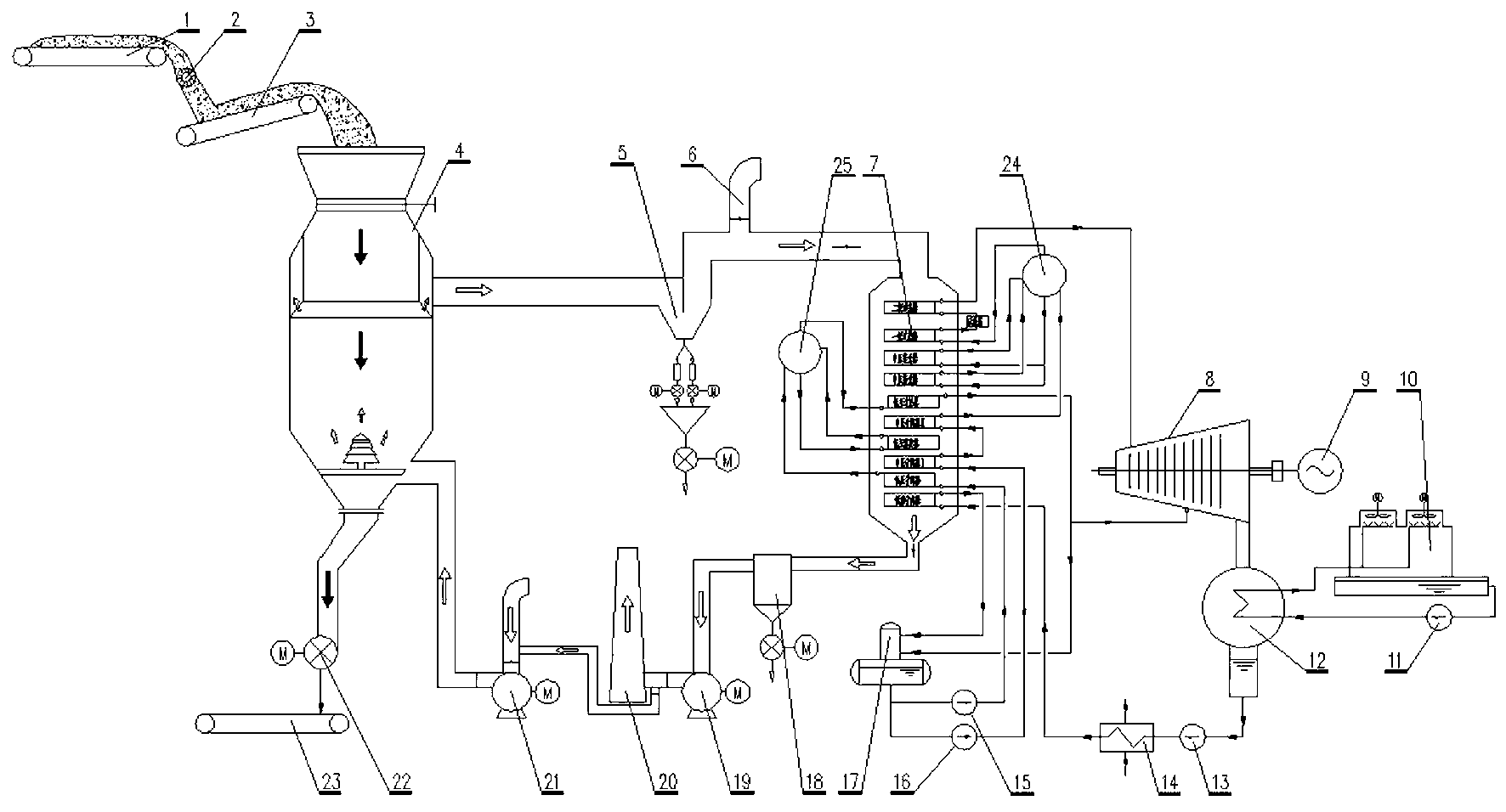

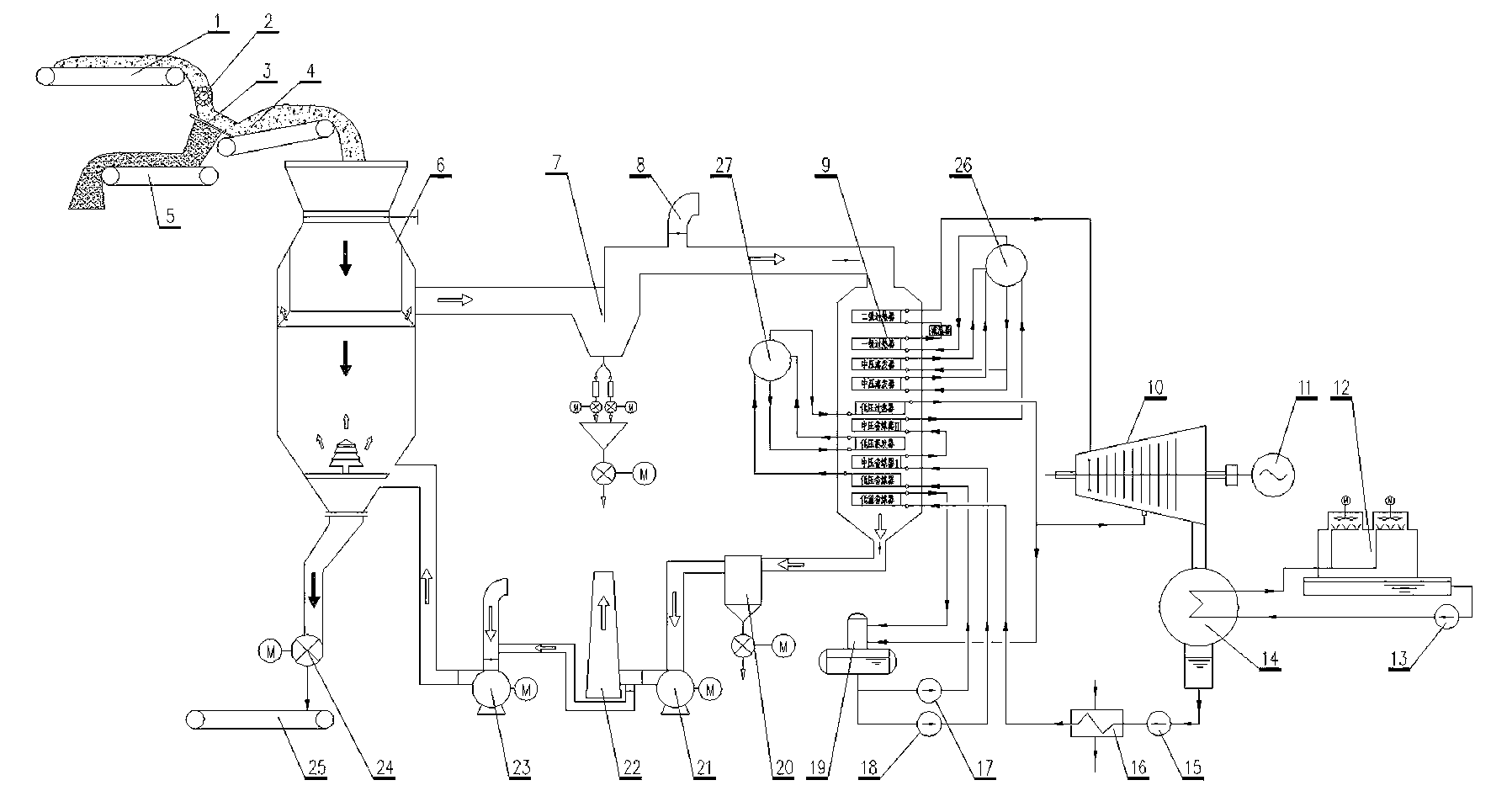

Device and process for generating power through efficient recovery of waste heat of sintered ores

ActiveCN103234362AIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialCogenerationMaterials science

The invention discloses a device and a process for generating power through efficient recovery of waste heat of sintered ores and belongs to the technical field of cogeneration. The device comprises a sintered ore cooling system, a waste heat power generating system and a smoke system, wherein the sintered ore cooling system and the waste heat cycling power generating system are connected through the smoke system to form a loop. The process comprises the steps of 1), cooling of sintered ores; 2) the smoke system; and 3) waste heat power generating. The device and the process for generating power through waste heat have the advantages that discharged waste heat is used fully during cooling of sintered ores, the electric energy production is improved significantly, the power rate of the system is reduced significantly, and the energy-saving effect is significant.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Additional electric arc heating copper backing board pre-heating aluminum alloy and magnesium alloy welding method

InactiveCN101264541AReduce crackingExtended cooldownArc welding apparatusWelding/soldering/cutting articlesButt jointCopper

The invention relates to a welding method, in particular to a welding method in which an electric arc is added to heat a copper padding plate and preheat aluminum alloy and magnesium alloy, aiming to reduce defects of blowholes and cracks at the joint, ensure good forming at the back of the joint, and finally obtain high quality joint which is suitable for aluminum alloy and magnesium alloy. In order to solve the problems that the aluminum alloy and magnesium alloy are liable to generate blowholes and cracks during welding and the forming at the back of the joint is poor, the invention provides the welding method in which the electric arc is added to heat the copper padding plate and preheat aluminum alloy and magnesium alloy. The copper padding plate is adopted when the butt joint is welded using aluminum alloy and magnesium alloy, and the electric arc is added at the back of the copper padding plate. The shape of the copper padding plate varies with the weldment. The method has the advantages of simple and easy practice, convenient operation, and obvious effect for improving the forming at the back of the joint and the quality of the joint.

Owner:HARBIN INST OF TECH

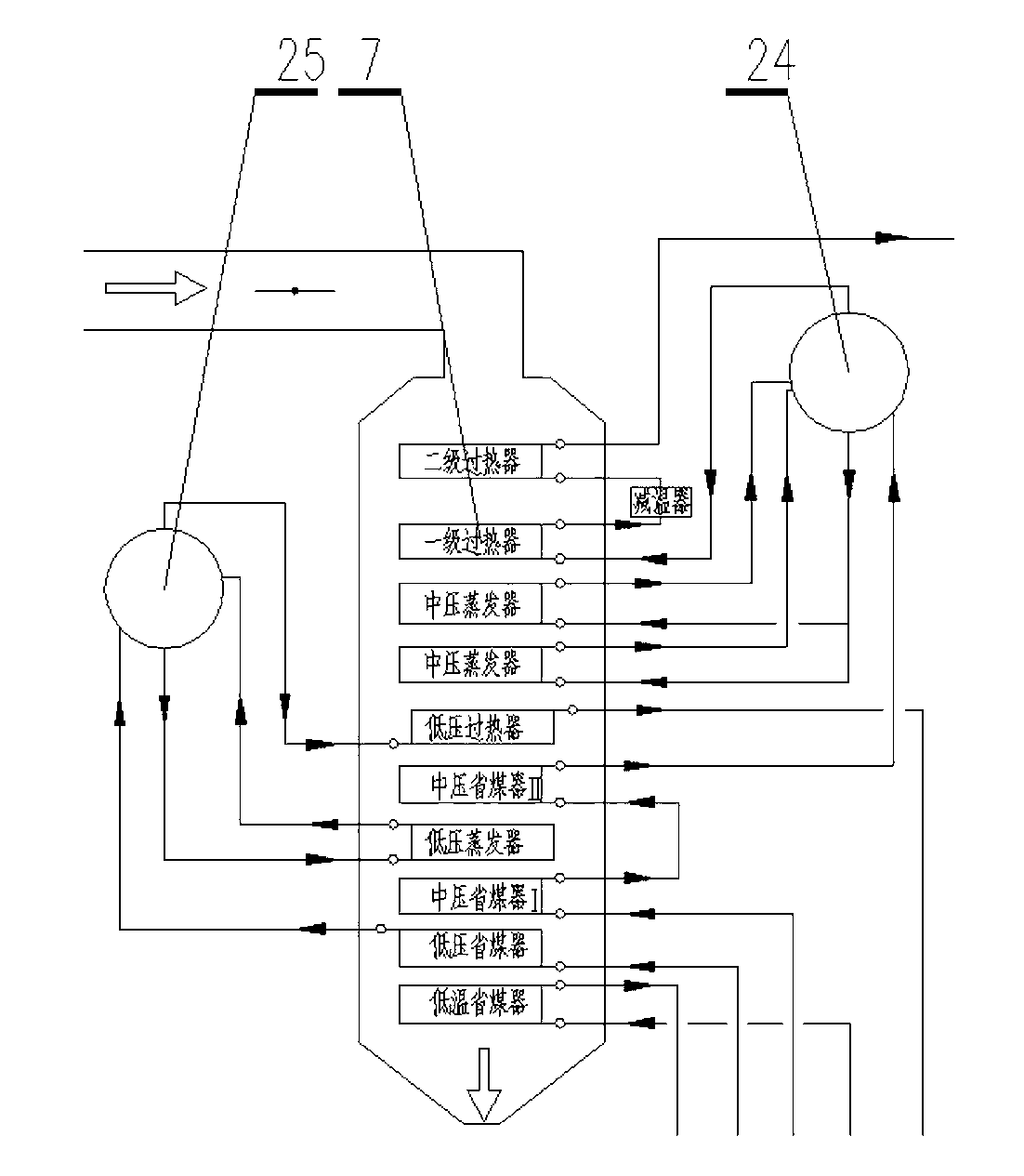

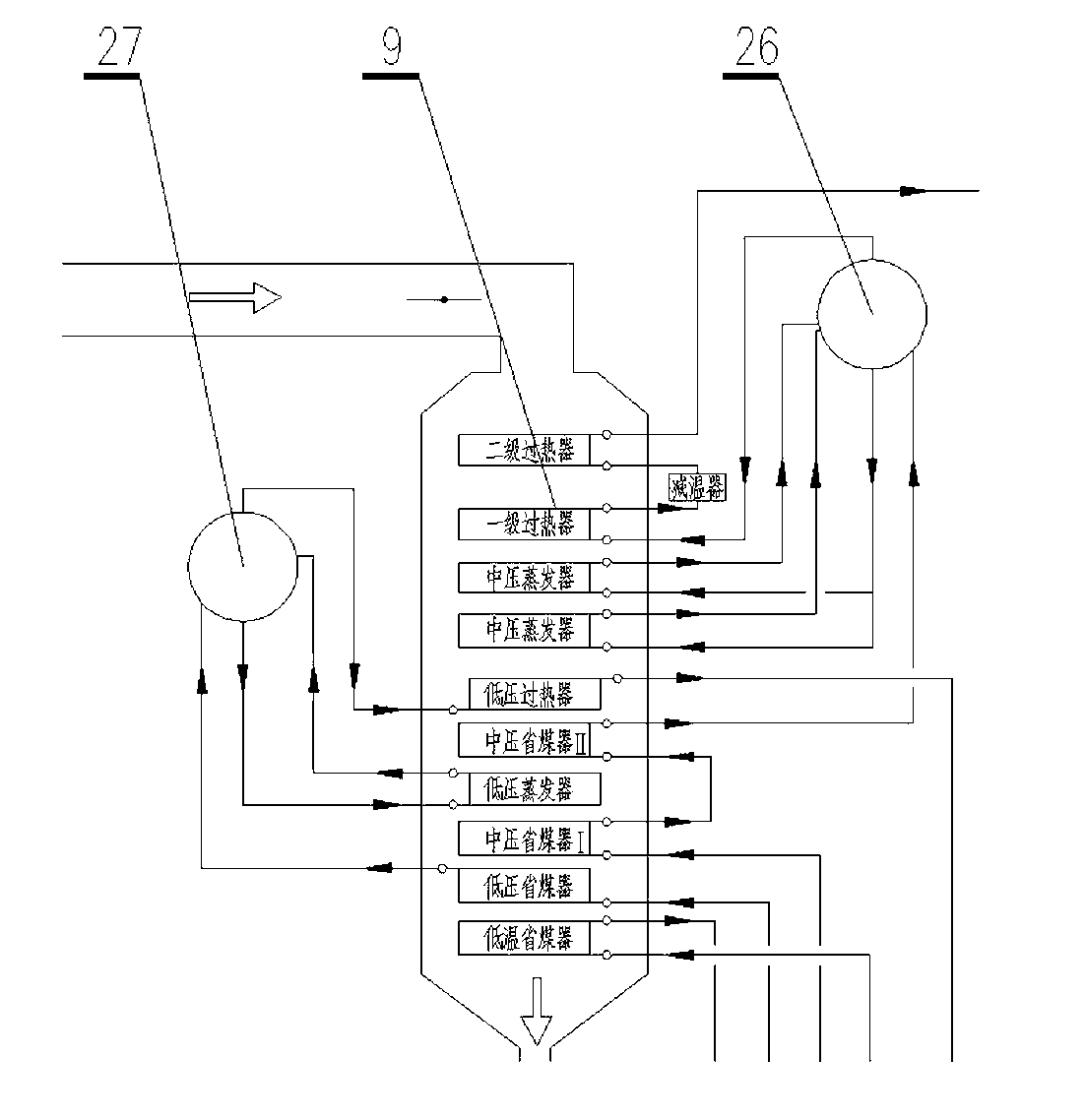

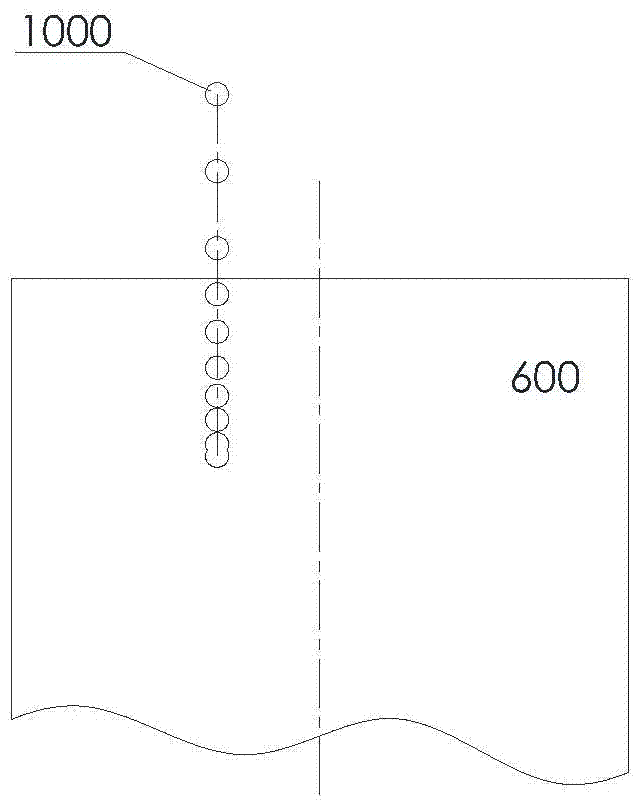

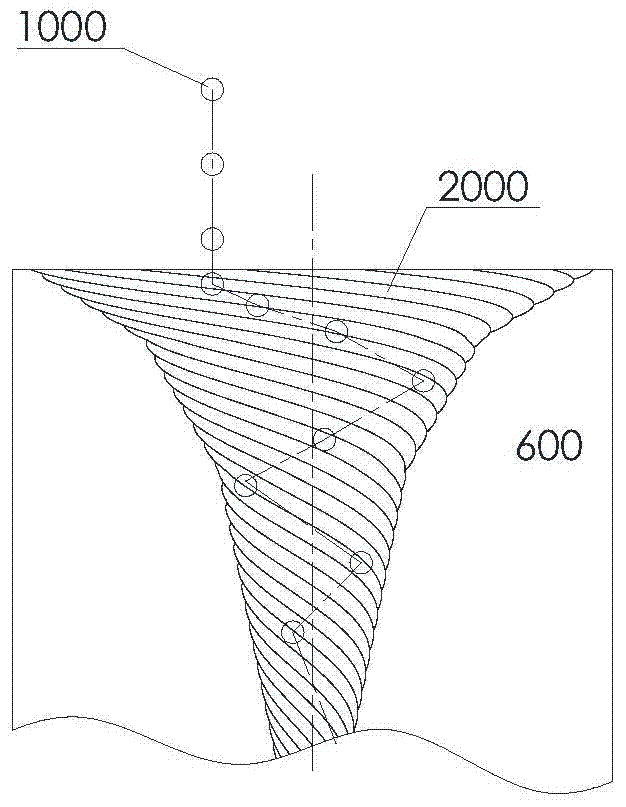

System used for sinter ore cooling and sensible heat efficient recycling

InactiveCN105627755AEfficient recyclingExtended sinter cooldownIncreasing energy efficiencyFurnace typesKilnMaterials science

A system used for sinter ore cooling and sensible heat efficient recycling comprises a stepping sintering machine used for sintering mixed iron ore materials, a vertical cooling kiln used for cooling sinter ore which is sintered and crushed, a feeding mechanism arranged between a discharging opening of the stepping sintering machine and a feed inlet of a material receiving funnel of the vertical cooling kiln, a gravity dust remover, a high-temperature smoke unit, a discharging machine, a belt conveyer and a vertical double-pressure waste heat boiler used for heat exchange, wherein the gravity dust remover and the high-temperature smoke unit are connected with a gas outlet in the upper portion of the vertical cooling kiln, and the discharging machine and the belt conveyer are arranged on a discharging opening of the vertical cooling kiln. A gas outlet of the vertical double-pressure waste heat boiler is connected with a gas inlet of a low-temperature gas unit, a gas outlet of the low-temperature gas unit is connected with a gas inlet in the lower portion of the vertical cooling kiln, and a heat exchange pipe of the vertical double-pressure waste heat boiler is connected with a power generation system. By means of the system, the sinter ore and cooling air can flow reversely in a closed space, cooling time of the sinter ore is prolonged, heat exchange is sufficient, heat efficiency of the system is greatly improved, and efficient recycling of sensible heat of the sinter ore is achieved.

Owner:天津天丰钢铁股份有限公司 +2

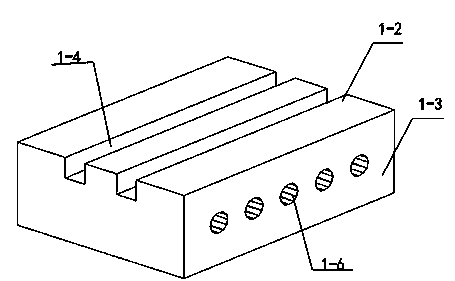

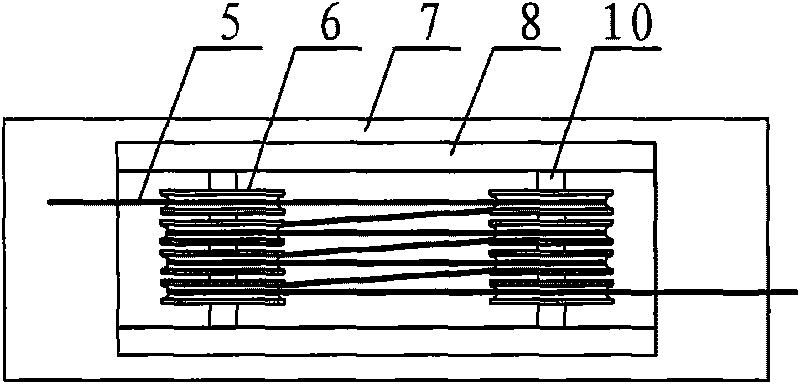

Solid state heat sink device used for friction stir welding and welding method of solid state heat sink device

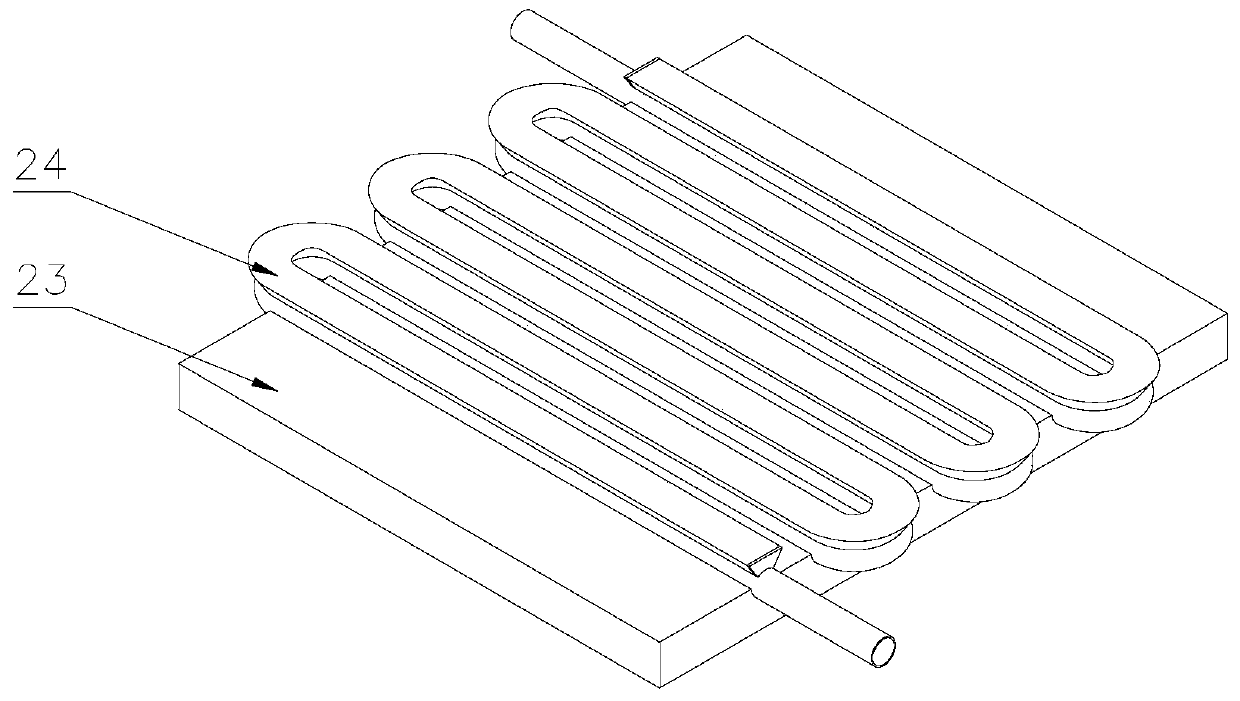

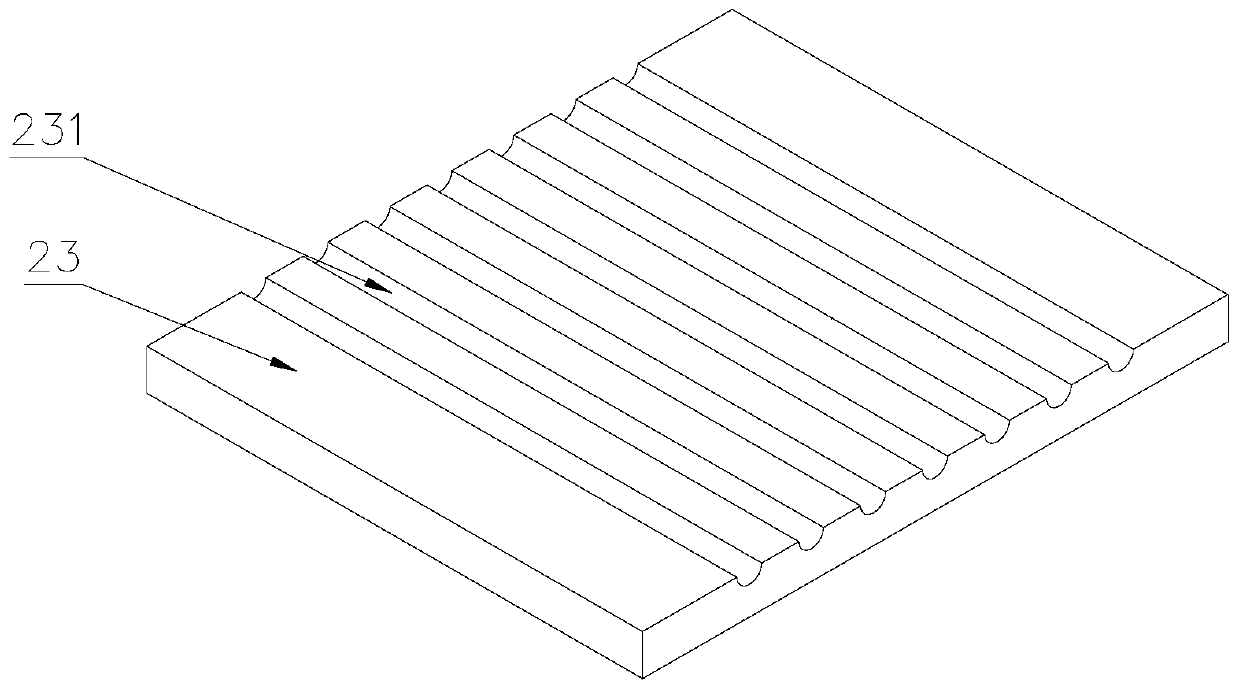

InactiveCN103639588AImprove performanceReduce unevennessWelding/cutting auxillary devicesAuxillary welding devicesWater channelEngineering

The invention discloses a solid state heat sink device used for friction stir welding and a welding method of the solid state heat sink device. The solid state heat sink device comprises a solid state heat sink, a push rod connected with the solid state heat sink and a cooling water pipe, wherein the solid state heat sink comprises an upper bottom face, a lower bottom face and a side face, heat dissipation through grooves are formed in the lower bottom face, cooling water channels are formed in the side face, the cooling water channels are connected with the cooling water pipe, and an installation hole used for installation of the push rod is formed in the upper bottom face of the solid state heat sink. The solid state heat sink device synchronously moves in the welding direction along with a friction stir welding device, and the lower bottom face makes full contact with the surface of a weldment so that heat conduction can be achieved, heat dissipation and cooling can be conducted on a weld joint which is still at a high temperature, and the peak temperature of the weld joint can be effectively lowered. Meanwhile, cooling water is injected into the water channels formed inside the heat sink to conduct forced heat dissipation and cooling. According to the solid state heat sink device and the welding method, the weld joint can be prevented from being overheated, weld joint crystalline grains are refined, the well-formed formation is improved, residual stress and strain of a welded joint can be eliminated or reduced, and the aims of improving the quality of the weld joint and improving the comprehensive performance of the joint are achieved.

Owner:JIANGSU UNIV OF SCI & TECH

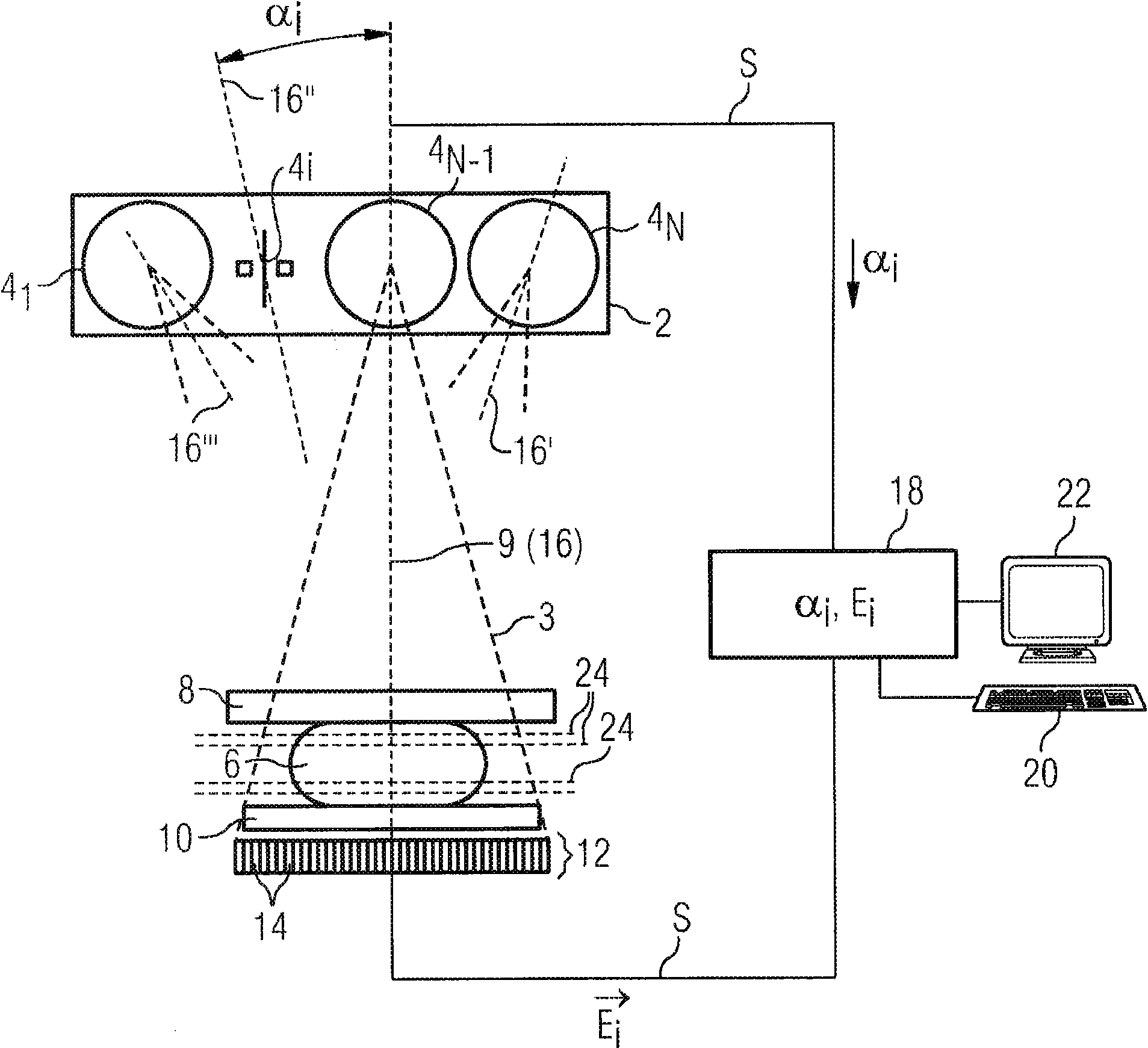

Method and device for producing a tomosynthetic 3d x-ray image

InactiveCN101641589AQuality improvementLarge doseTomographyX-ray tube cold cathodesProjection image3d image

In a method and device for producing a tomosynthetic 3D x-ray image, a number of 2D projection images of an examination subject are acquired using a fixed x-ray source. The x-ray source has multiple,individually controllable emitters that respectively emit a single x-ray dose from various different directions. The tomosynthetic 3D image is reconstructed from the individual 2D projection images, and at least one 2D projection image is composed of multiple individual images.

Owner:SIEMENS AG

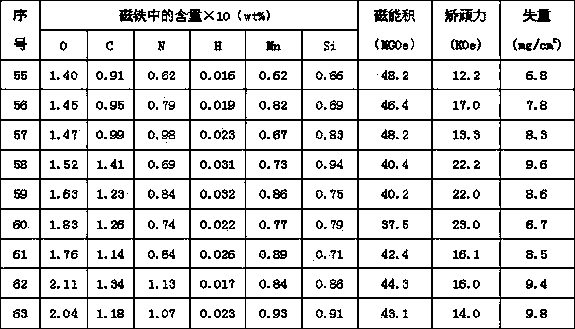

Manufacturing method for rare earth permanent magnet alloy, neodymium iron boron rare earth permanent magnet and manufacturing method

ActiveCN104249137AGood grain consistencyFine grain boundary phaseInductances/transformers/magnets manufactureMagnetic materialsTundishOxide

The invention discloses a manufacturing method for double-roll cooled rare earth permanent magnet rapidly hardened alloy. The manufacturing method comprises the following steps of heating, fusing and refining neodymium iron boron raw materials into fused alloy liquid under a vacuum or protection condition; pouring the alloy liquid to the outer edge of a first water-cooled rotating roll through a gap of a tundish to form an alloy plate; rotating the alloy plate along with the first rotating roll; separating the alloy plate from the first rotating roll so that the alloy plate drops to the outer edge of a second water-cooled rotating roll; rotating the alloy plate along with the second rotating roll; and separating the alloy plate from the second rotating roll so that the alloy plate drops to form a double-surface-cooled alloy plate. The neodymium iron boron permanent magnet which is made of the alloy has R2T14Q main phases and grain boundary phases, wherein R is selected from elements of Pr, Nd, Dy, La, Ce, Gd, Tb and Ho; T is selected from elements of Fe, Co, Al and Mn; Q is selected from elements of B, N and C; the main phases are isolated from one another by the grain boundary phases; and oxides and nitrides of Pr and Nd are distributed in the grain boundary phases.

Owner:SHENYANG GENERAL MAGNETIC

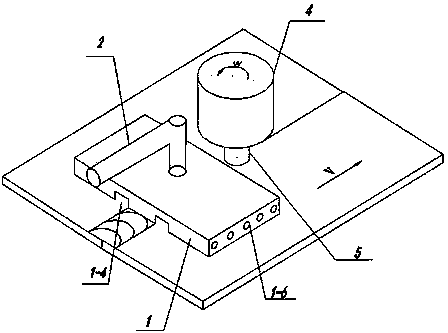

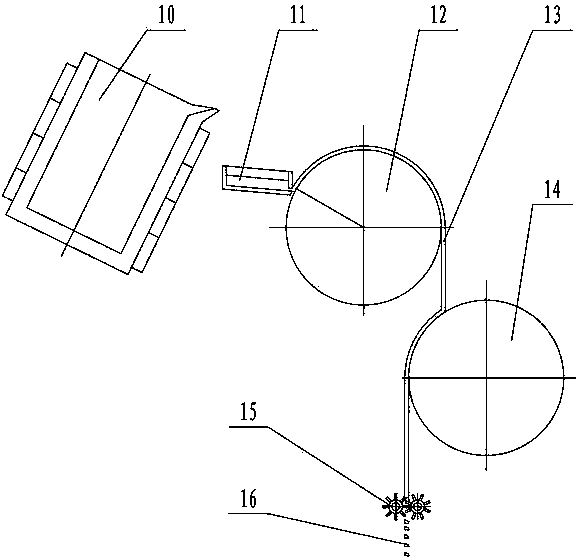

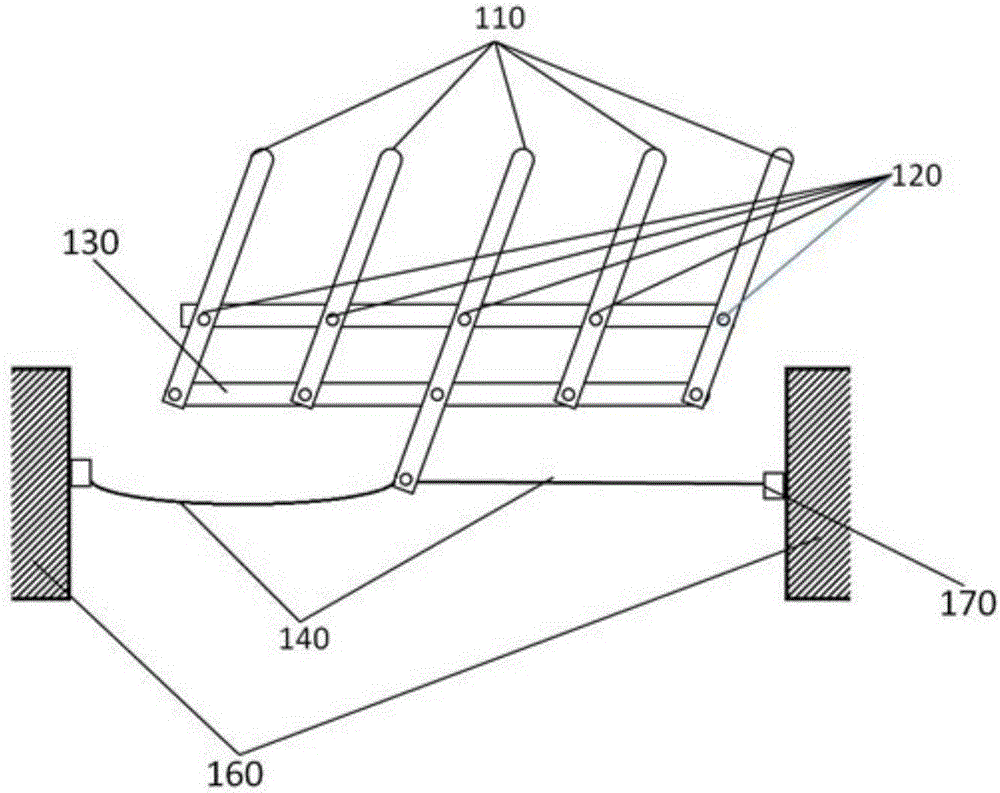

Device for soaking oil on steel rope surface

InactiveCN101701427AAvoid pollutionExtended cooldownRope making machinesReduction driveBlock and tackle

The invention relates to steel rope maintaining equipment, in particular to a device for soaking oil on the steel rope surface. The device comprises a grease heating groove, an electrical heating device, a steel rope release frame and a steel rope traction device, wherein the electrical heating device and the steel rope release frame are installed in the grease heating groove. The device for soaking oil on the steel rope surface is characterized in that a pulley block is installed behind the grease heating groove, and an oil receiving disk is arranged under the pulley block; and the steel rope traction device is driven to rotate by a motor and a speed reducer. Because the pulley block is additionally arranged behind the grease heating groove, and the oil receiving disk is arranged under the pulley block, thereby enabling the cooling time of a steel rope soaked with the oil to be prolonged by the pulley block; meanwhile, the dropping grease of the steel rope in the cooling process falls into the oil receiving disk, on one hand, a plurality of grease are recovered, on the other hand, the problem of pollution of the grease to the environment is solved.

Owner:中电建宁夏工程有限公司

Sectioned laser cladding remanufacturing method with preheating and heat treatment for complex parts

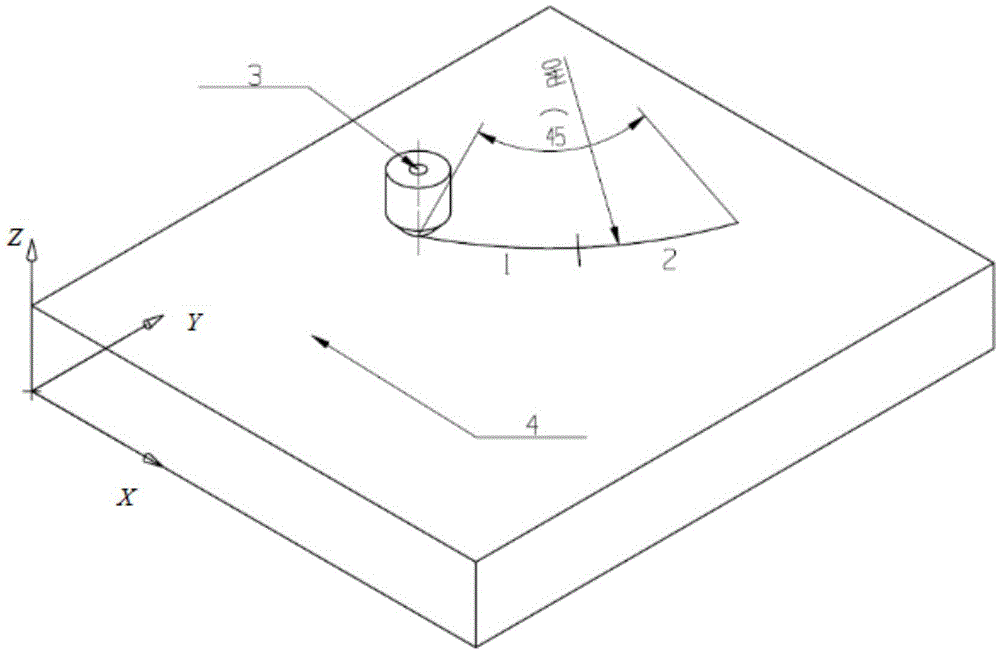

InactiveCN105624669AIncrease temperatureExtended cooldownMetallic material coating processesSurface stressPath length

The invention belongs to the field of laser cladding remanufacturing, and provides a sectioned laser cladding remanufacturing method with preheating and heat treatment for complex parts. According to the invention, on the basis of a single-track and single-layer laser cladding experiment, laser cladding parameters are determined with reference to the track shape of laser cladding and the complexity of workpieces; the laser powers of preheating treatment and aftertreatment are selected according to the laser cladding parameters, the lead time of the laser preheating and the lag time of the heat treatment are determined according to requirements on the surface stress and the surface hardness of the parts, the path length of each laser cladding is determined according to the lead time and the lag time, and the preheating, the laser cladding and the heat treatment are successively carried out on each section. The method is capable of effectively reducing the generation of laser cladding cracks relative to common laser cladding, and is capable of processing a curve path and high in adaptability compared with three-beam preheating and heat treatment laser cladding.

Owner:DALIAN UNIV OF TECH

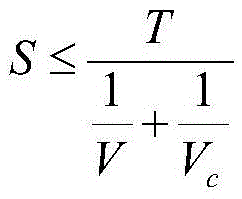

Vehicle-mounted air condition air sweeping device driven by electric control shape memory alloy

InactiveCN105946515AReduce volumeNo electromagnetic interferenceAir-treating devicesVehicle heating/cooling devicesMicrocontrollerMicrocomputer

The invention discloses a vehicle-mounted air condition air sweeping device driven by an electric control shape memory alloy. The vehicle-mounted air condition air sweeping device is composed of a drive part, a control part, a transmission part and an execution mechanism. The drive part adopts the shape memory alloy as a drive element, the shape memory alloy shrinks when electrified to be heated and is lengthened when cooled, and output of displacement and force of a driver is achieved. The control part is composed of a sensor, a single-chip microcomputer and a manual control key, the current on a shape memory alloy wire is controlled, and therefore the temperature of the shape memory alloy wire is controlled. The transmission part is mainly composed of a clutch device or a reset device. The execution mechanism is vehicle-mounted air conditioner air sweeping blades. The vehicle-mounted air condition air sweeping device has the beneficial effects of being small in size, simple in structure, convenient to install, easy to achieve, free of electromagnetic interference, good in periodical control effect and the like.

Owner:JILIN UNIV

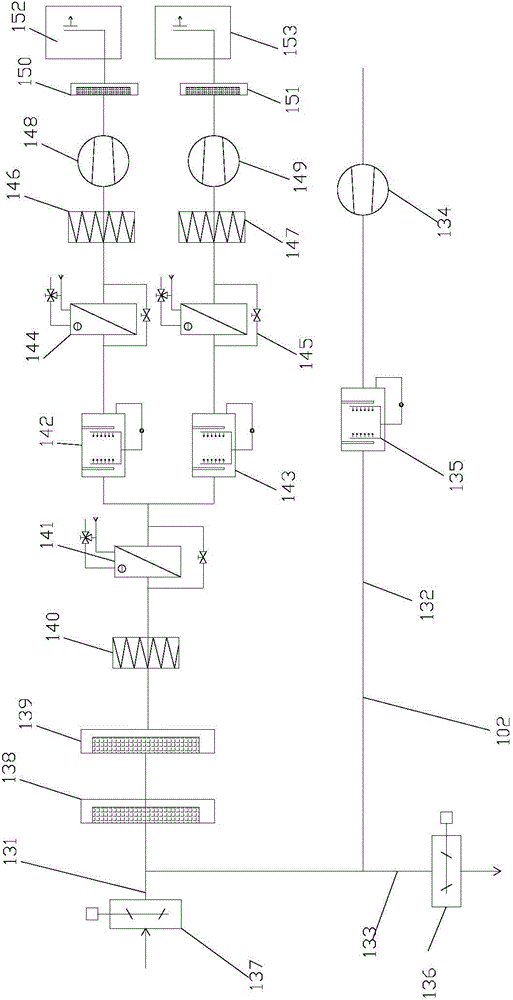

Device with griddle and process for generating power by efficiently recycling sinter waste heat

ActiveCN103234364AIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialProcess engineeringUtilization rate

A device with a griddle and a process for generating power by efficiently recycling sinter waste heat relate to the technical field of waste heat power generation. The device comprises a sinter cooling system, a waste heat power generation system and a smoke system. The sinter cooling system and the waste heat circulation power generation system are connected through the smoke system to form a loop. The process includes 1) sinter cooling, 2) the smoke system and 3) waste heat power generation. The device and the technological process for waste heat power generation have the advantages of completely utilizing waste heat discharged in the sinter cooling process, obviously increasing power generation quantity, obviously reducing system self power utilization rate and being remarkable in energy-saving effect.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

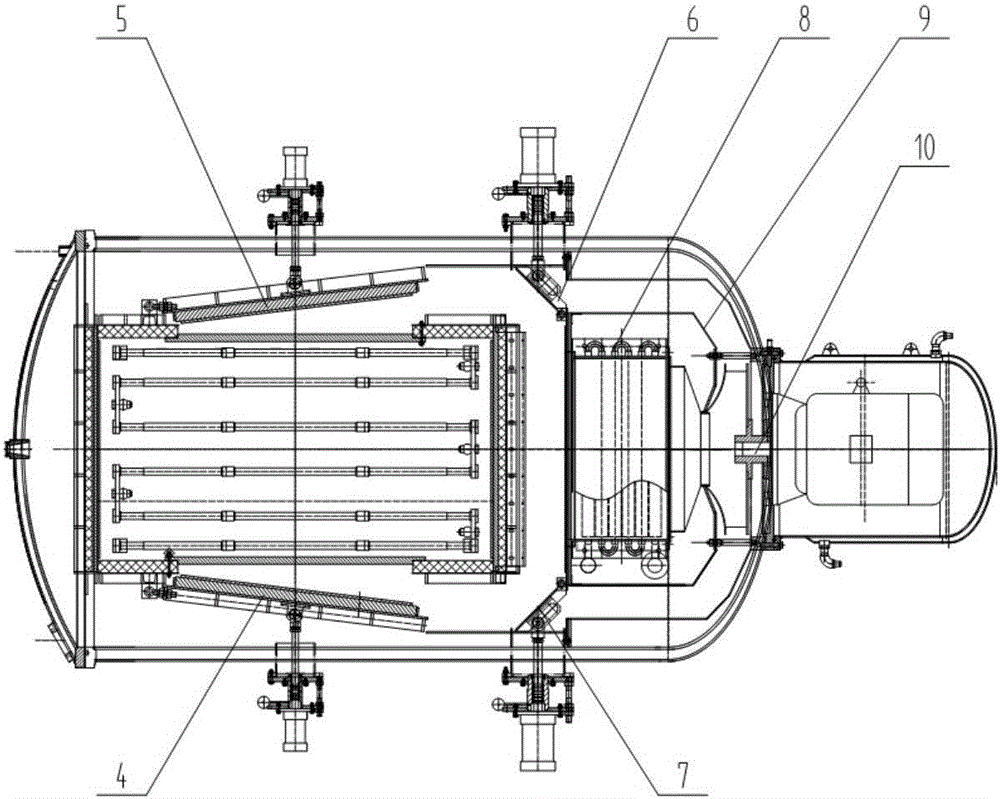

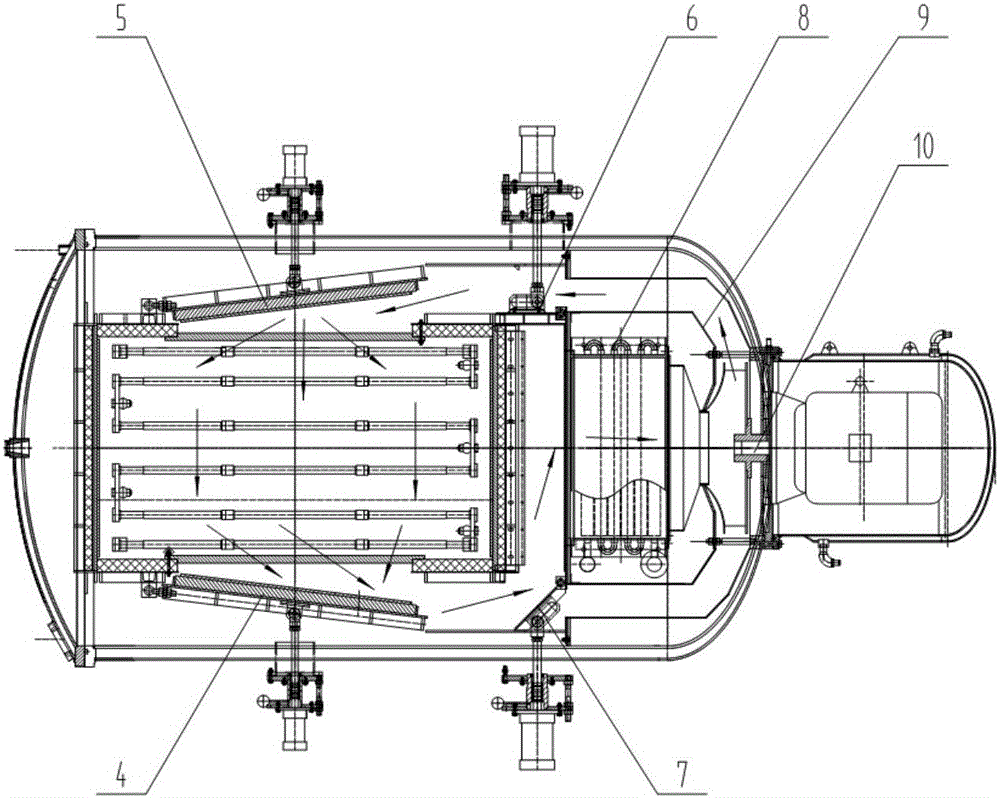

Multifunctional vacuum furnace

InactiveCN106500503AAvoid energy lossHeating evenlyMuffle furnacesRetort furnacesVacuum furnaceReverse mode

Disclosed is a multifunctional vacuum furnace. The multifunctional vacuum furnace is characterized in that the front portion of the body of a heating chamber is provided with a movable front left air door and a movable front right air door, a rear left reversing air door and a rear right reversing air door are symmetrically installed at the air flue end outside the heating chamber, air door air cylinders are installed outside a furnace shell, and air cylinder piston rods penetrate through the furnace shell to be connected with air door pin shafts through sealing structures. The multifunctional vacuum furnace has the advantages that in the heating process, the front left air door and the front right air door are closed, no air through hole is formed, energy loss in the heating process is avoided, energy is saved, and it is ensured that heating is more uniform; and in the cooling process, the opening degree of the front left air door and that of the front right air door are large, meanwhile, the rear left air door and the rear right air door can achieve reversing, in other words, airflow alternately flows in a reversing mode inside the heating chamber, outside the heating chamber, on the left of the heating chamber and on the right of the heating chamber, reversing time can be set, accordingly, workpieces are uniformly cooled, the cooling speed is increased, and the furnace discharge time is shortened. The problem that production efficiency is affected is solved, energy consumption is lowered to minimum, product performance is higher, and production efficiency is improved.

Owner:SHENYANG HENGJIN VACUUM TECH

Substrate processing method and substrate processing apparatus

ActiveUS20120186275A1Reduce the temperatureIncrease ratingsLighting and heating apparatusSemiconductor/solid-state device manufacturingEngineeringSubstrate surface

A cooling gas discharge nozzle 7 is arranged above an initial position P(Rin) distant from a rotation center P(0) of a substrate W toward the outer edge of the substrate W and supplies a cooling gas to the initial position P(0) of the rotating substrate W to solidify DIW adhering to an initial region including the initial position P(Rin) and the rotation center P(0). Following formation of an initial solidified region FR0, a range to be solidified is spread toward the outer edge of the substrate W and all the DIW (liquid to be solidified) adhering to a substrate surface Wf is solidified to entirely freeze a liquid film LF.

Owner:DAINIPPON SCREEN MTG CO LTD

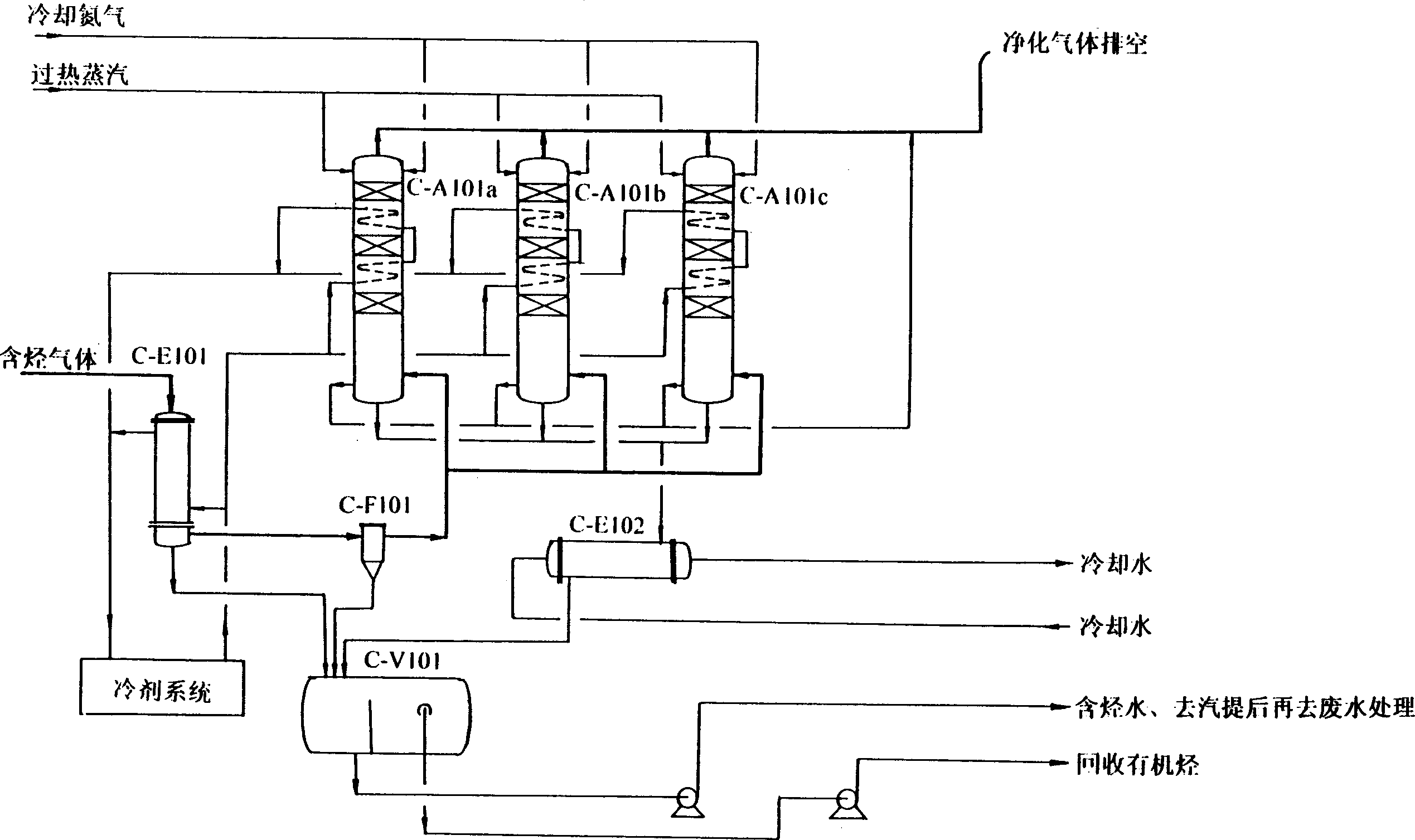

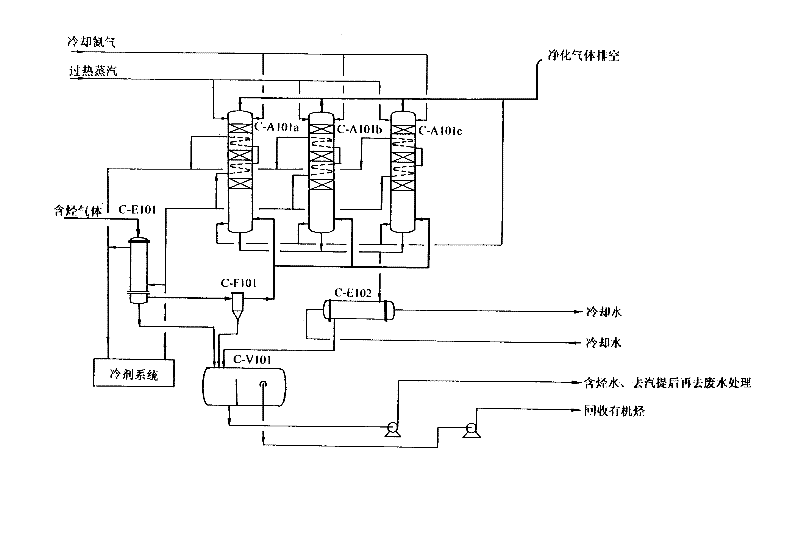

Adsorption technique

InactiveCN1539544AIncrease the adsorption rateImprove adsorption capacityDispersed particle separationHeat regenerationChemistry

An adsorption technology features that its system is composed of more than one adsorption tower and condenser. All the adsorption towers are parallelly connected to gas-material pipeline and each adsorption tower has a built-in cooler. Said adsorption technology includes condensing part of raw organic hydrocarbon, oil-water separation, flowing rest of organic hydrocarbon in adsorption tower, multi-layer adsorbing, cooling for optimal adsorption, switching to next adsorption tower while thermal regeneration for this adsorption tower, and introducing cooling gas to bed and cooling medium to cooler.

Owner:SHANGHAI SUPEZET ENG TECH CO LTD

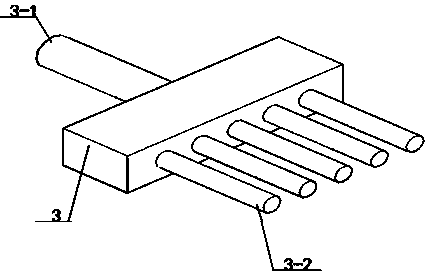

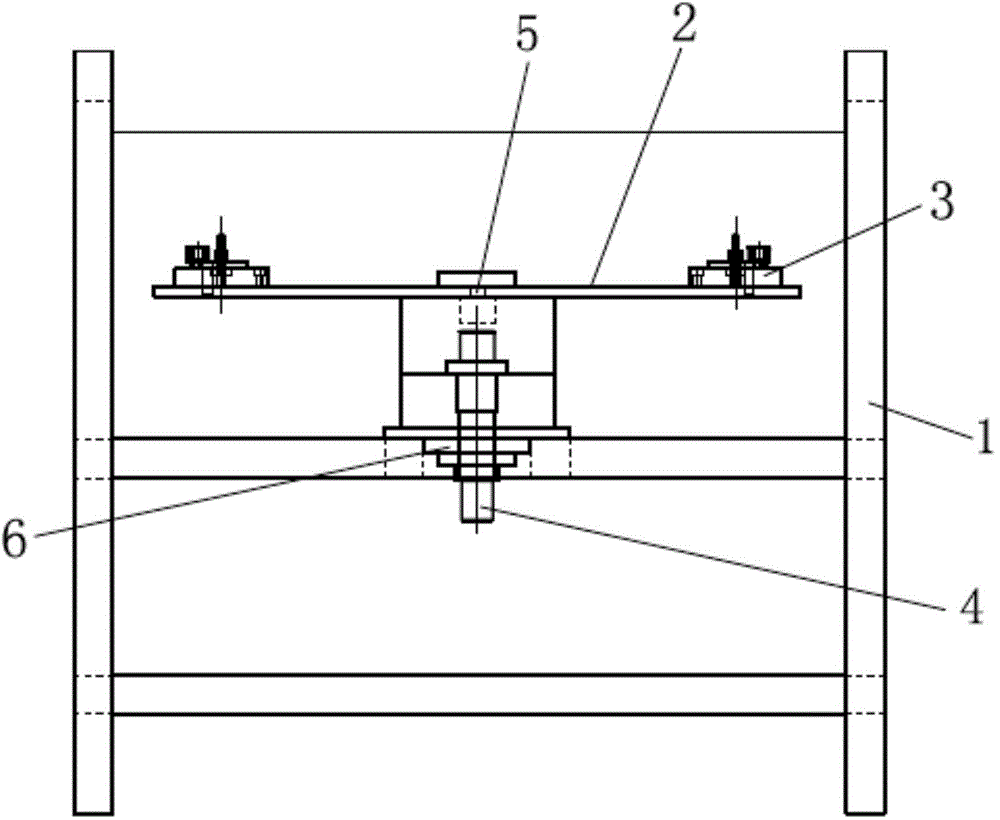

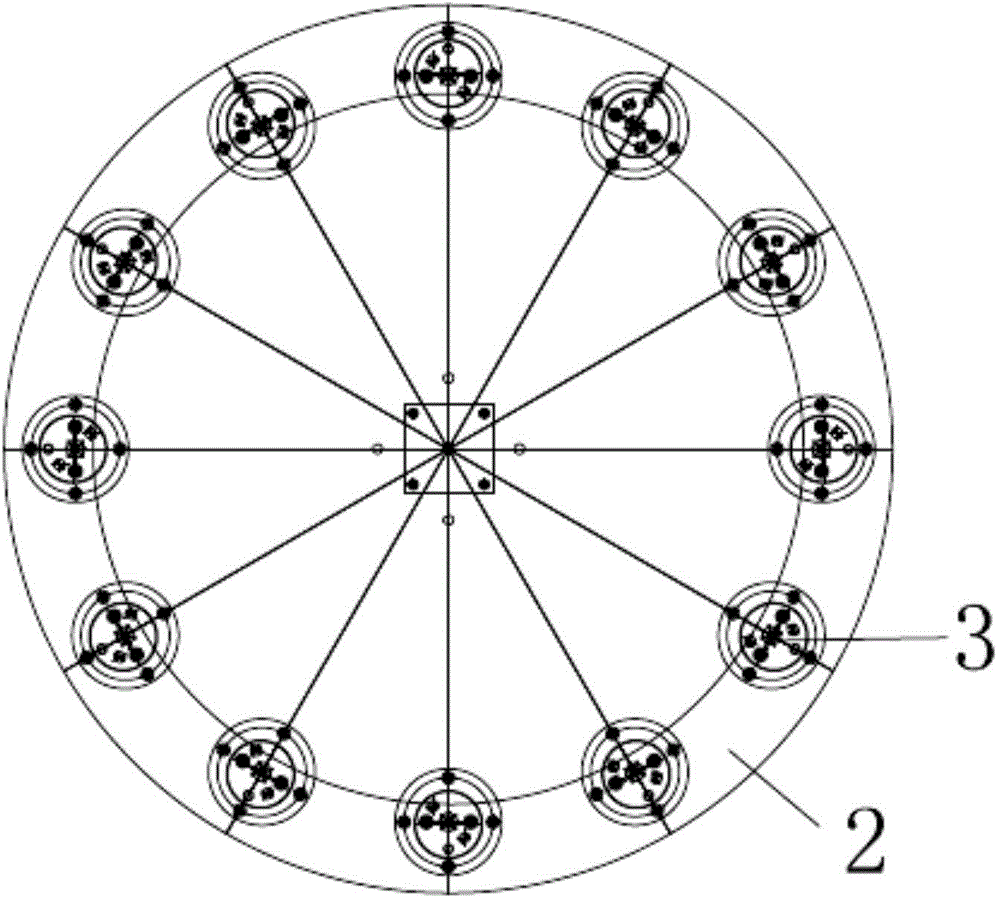

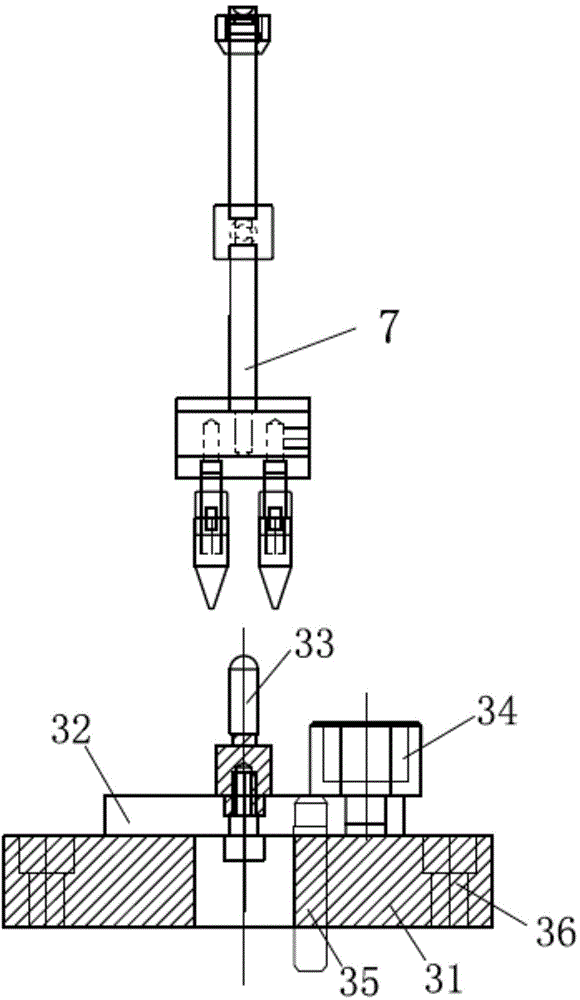

Exhaust pipe welding set of compressor upper shell

InactiveCN104690390ALittle variabilityReduce dependenceHeating appliancesWelding/cutting media/materialsEngineeringExhaust pipe

The invention discloses an exhaust pipe welding set of a compressor upper shell. The exhaust pipe welding set comprises a supporting bracket (1) and a rotating disc which is rotatably connected with the bracket (1), wherein a plurality of welding clamps (3) which are used for fixing the compressor upper shell (8) and an exhaust pipe (9) are uniformly distributed in the circumferential direction of the rotating disc (2); the lower end of the exhaust pipe (9) is sleeved by a welding ring (10); a welding gun (7) which is used for welding is arranged on the side edge of the bracket (1); and the welding device further comprises a controller which is used for controlling the rotating disc (2) and the welding gun (7) to be matched to start and stop intermittently. When the welding device is used for welding, the operation is convenient and orderly, the welding performance is stable the changeability is small, the undesirable phenomenon of weldment leakage is reduced, the welding quality of the weldment is greatly enhanced and relatively strong practicability is achieved.

Owner:WUHU DECHUANG ELECTRIC

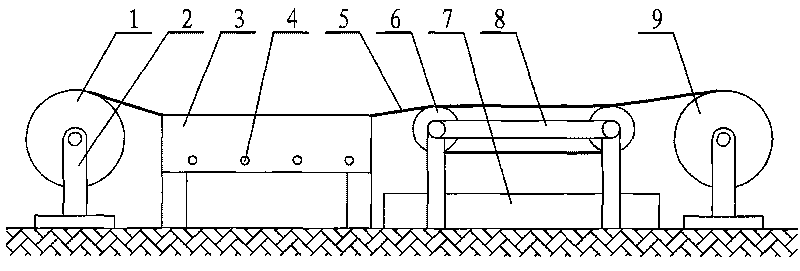

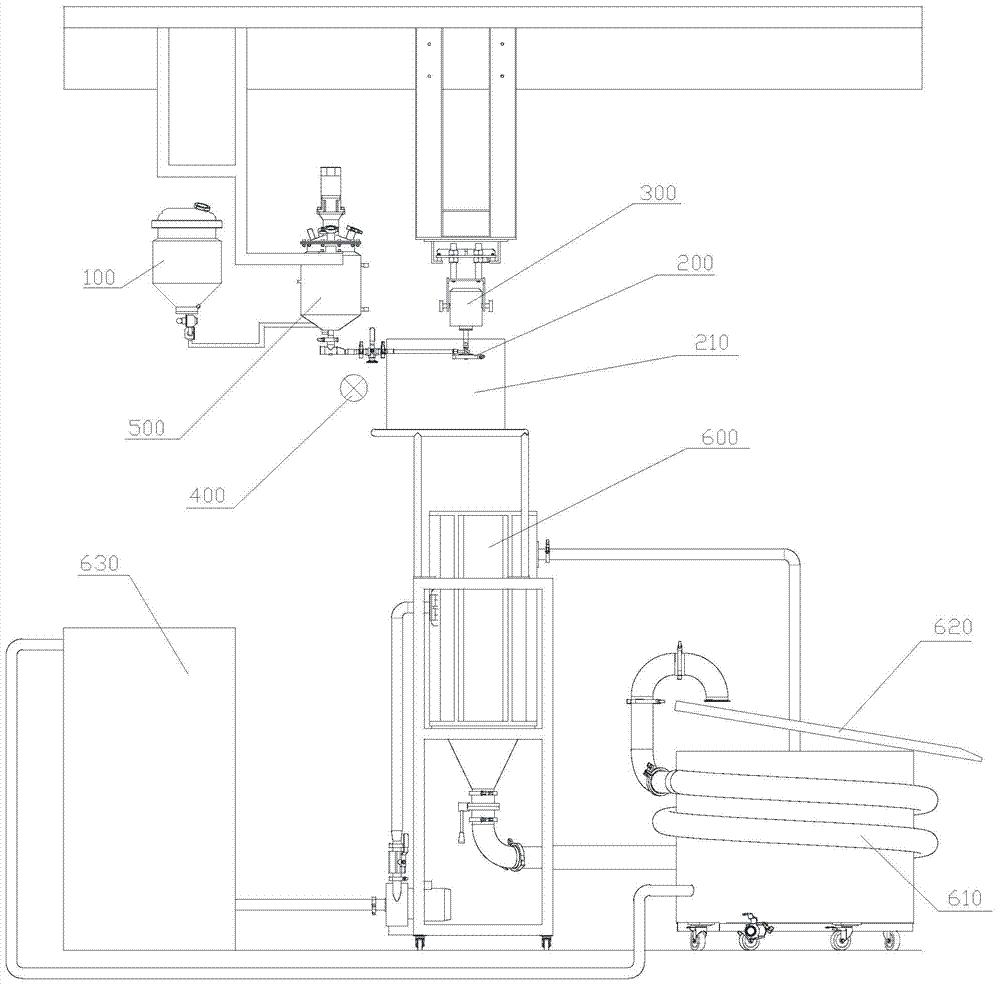

Liquid cooling dropping pill production line

InactiveCN104274327AReduce impactSmooth feedingPharmaceutical product form changeMelting tankEngineering

The invention provides a liquid cooling dropping pill production line, which comprises a dropping pill system, a liquid cooling circulation system and a control system, wherein the dropping pill system comprises a material melting tank and a dropper connected with the material melting tank, a vibration device is arranged between the material melting tank and the dropper, an on-line monitoring device is arranged on the dropper, the on-line monitoring device comprises a pulse signal emitting mechanism, the emitting frequency of the pulse signal emitting mechanism is identical to the vibration frequency of the vibration device, and the control system controls and regulates dropping parameters according to the monitoring results of the on-line monitoring device. The liquid cooling dropping pill production line has the advantages that the high-frequency cutting dropping is combined, the dropping pill quality is detected in real time on line and is controlled and regulated, the yield is improved, and the drilling pill diameter range is expanded; a plurality of tangential inlets are formed inside the tank wall of a cooling tank, and the impact force caused by cooling liquid surface on liquid drips when the liquid drips enter the cooling tank can be effectively reduced; the swarming and the pulse can be effectively eliminated, so the material conveying of a dropping pill machine is stable; the dropping pill cooling time is increased through regulating the length-to-diameter ratio of a discharging pipeline, the quality is ensured, and meanwhile, the energy consumption is reduced.

Owner:TIANJIN TASLY PHARMA CO LTD

Furnace type efficient recovery system for flue gas waste heat of cooled sinter

InactiveCN103234363AImprove qualityImprove waste heat utilization efficiencyIncreasing energy efficiencyWaste heat treatmentProcess engineeringFlue gas

A furnace type efficient recovery system for flue gas waste heat of cooled sinter comprises an air blower, a cooling furnace, a primary dust remover, an emergency blow-off valve, a waste heat boiler, a secondary dust remover, a draft fan and a chimney. An outlet of the air blower is communicated with a cooling air inlet on the lower portion of the cooling furnace. A flue gas outlet on the upper portion of the cooling furnace is communicated with the primary dust remover, the waste heat boiler, the secondary dust remover, the draft fan and the chimney through pipelines successively. The emergency blow-off valve is arranged on a pipeline between the primary dust remover and the waste heat boiler. A connection pipeline is arranged between the draft fan and the air blower. The furnace type efficient recovery system for flue gas waste heat of cooled sinter has the advantages that the sinter quality is improved, the sinter return rate is reduced, flue gas parameters are stable, the system own power consumption rate is reduced, and the energy-saving effect is apparent.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

selective laser melting(SLM) 3D printer

PendingCN108687347AFast scanningFast cooling and solidificationAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingEngineering

The invention discloses a selective laser melting (SLM) 3D printer. The SLM 3D printer comprises an air protection tank and a computer arranged on the outer wall of the air protection tank; the air protection tank is internally provided with a powder laying forming workbench; two groups of X-axis movement mechanisms are arranged above the powder laying forming workbench; the two groups of X-axis movement mechanisms are connected with a Y-axis movement mechanism; a powder feeding cylinder, a powder laying forming cylinder and a powder recycle cylinder are sequentially arranged on the powder laying forming workbench in an inserting mode; the powder laying forming cylinder is internally provided with a printing substrate plate; a Z-direction movement mechanism used for driving the printing substrate plate to move in the Z direction in the powder laying forming cylinder is arranged on one side of the printing substrate plate; and each group of X-axis movement mechanism is provided with a laser cladding device used for performing selective laser melting on the printing substrate plate and a laser thermal treatment device used for improving metal structure and mechanical properties. TheSLM 3D printer has the beneficial effects that cracks produced in the process of metal solidification are prevented, yield rate is further improved, and meanwhile 3D printing speed is improved to be suitable for mass production.

Owner:JILIN UNIV

Heat-treatment cooling process for train wheel

ActiveCN110055394AImprove mechanical propertiesEasy to useFurnace typesHeat treatment furnacesThree stageHardness

The invention discloses a heat-treatment cooling process for a train wheel, and belongs to the technical field of heat-treatment cooling for train wheels. The heat-treatment cooling process for the train wheel comprises the steps that first, the whole wheel is heated to be completely austenitized; second, the wheel is transferred onto a quenching table and is made to rotate, a gas-mist two-phase flow with the pressure being increased step by step is sprayed onto a wheel tread; and third, the whole wheel is placed into a tempering furnace for heat preservation and is finally taken out to be air-cooled, wherein the gas-mist two-phase flow with the pressure being increased step by step is sprayed onto the wheel tread sequentially through three stages, the rotation speeds V1, V2 and V3 of thewheel, the water pressures P1, P2 and P3 and the quenching times T1, T2 and T3 in the three stages are controlled, and the numbers of started nozzles which are distributed at equal intervals in the circumferential direction of the wheels in the three stages are respectively M, 2M and 3M. By adoption of the heat-treatment cooling process for the train wheel, the capacity to cool the interior of a rim can be improved, the cooling speed is kept balanced and consistent from the wheel tread to the deep interior of the rim, the structure of the whole cross section of the rim is optimized, and accordingly, the radial hardness gradient of the rim is greatly reduced, and the mechanical property and usability of the wheel are greatly improved.

Owner:MAANSHAN IRON & STEEL CO LTD

Lubricating grease blending kettle

PendingCN107774224AImprove liquidityAvoid blind spotsRotating receptacle mixersTransportation and packagingSpiral bladeFan blade

The invention provides a lubricating grease blending kettle. The lubricating grease blending kettle comprises a tank body of the blending kettle, wherein the tank body of the blending kettle is arranged on a support base and comprises a kettle body and a jacket; a stirring mechanism and a stirring motor are arranged at the top part of the kettle body; the stirring mechanism comprises a stirring shaft and spiral blades, and a circle of spiral scraping strips is arranged at the exterior of each spiral blade; the jacket comprises an inner jacket and an outer jacket, a heating wire is arranged inthe inner jacket, the outer jacket is provided with a cooling water inlet and a cooling water outlet, a flow guide plate is arranged in an inner cavity of the outer jacket, and a rotary motor is arranged at the bottom part of the jacket. The lubricating grease blending kettle has the beneficial effects that by arranging the spiral scraping strips at the outer side of each spiral blade on the stirring shaft, the lubricating grease which is attached to the inner wall of the kettle body can be driven, so that the integral fluidity is improved, and the dead corner at the inner wall of the kettle body is prevented; the rotary motor is used for driving the kettle body to rotate, the lubricating grease at the bottom part are stirred by fan blades, the dead corner at the bottom part of the kettlebody is prevented, and the stirring and blending effect is better.

Owner:天津市津冠润滑脂有限公司

Apparatus and method of producing dope

InactiveUS20060118980A1Improve cooling efficiencyImproved in kneading functionDough homogenizationFrozen sweetsSolubilityOptical property

A stock solution is prepared by mixing and swelling TAC as a solute in a solvent, and is fed into an extrusion machine. The extrusion machine is cooled by a cooling medium, and is provided with twin-shaft screws. The screws are a compressing type where thread pitches of a helical flight decrease toward downstream. The screws are in mesh with each other and rotated in the same direction. Through the extrusion machine, the solute is dissolved in the solvent to form a dope. The dope is further cooled in a cooler to promote the solubility of the dope. Thereafter, the dope is heated by a heater to raise the fluidity. From the obtained dope, TAC film with excellent optical properties may be formed by a solution casting method.

Owner:FUJIFILM HLDG CORP +1

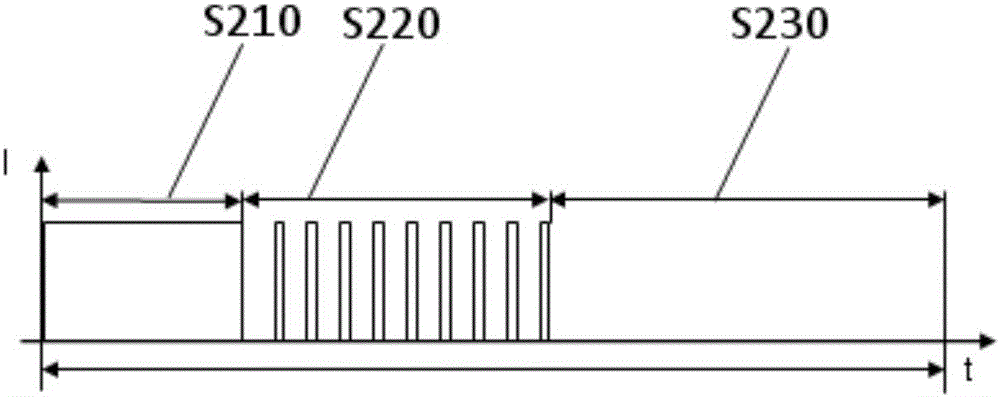

Hydraulic oil temperature control system and engineering machinery

InactiveCN103912540AExtend cycle timeExtended cooldownFluid-pressure actuator componentsControl systemFuel tank

The invention provides a hydraulic oil temperature control system and engineering machinery. The hydraulic oil temperature control system comprises a pump, a main oil tank, an oil return circuit, a radiator, an auxiliary oil tank, a reverse valve, a temperature sensor and a controller. When the hydraulic oil temperature in the main oil tank is higher than a preset value, the controller controls the reverse valve to cut off the oil circuit between the radiator and the main oil tank and communicates with another oil circuit between the radiator and the auxiliary oil tank; when the hydraulic oil temperature in the main oil tank is lower than the preset value, the controller controls the reverse valve to cut off the oil circuit between the radiator and the auxiliary oil tank and communicates with the oil circuit between the radiator and the main oil tank. By the arrangement, the auxiliary oil tank can be selectively connected or disconnected according to the hydraulic oil temperature in the main oil tank, so that the hydraulic oil temperature can be sustained within the best temperature range, leakage of hydraulic oil can be further reduced, and operation efficiency of the hydraulic system can be improved while the service life of the same can be prolonged.

Owner:SANY HEAVY MACHINERY

Preparation method of tungsten powder used for high-density alloy

ActiveCN109261980ALarge specific surface areaAvoid high temperature and violent volatilizationHigh densityAmmonium paratungstate

The invention belongs to the technical field of powder metallurgy, and specifically relates to a preparation method of tungsten powder used for high-density alloy. The method specifically includes thefollowing steps that high-specific-surface-area tungsten oxide preparation, boat loading, reduction, cooling and sieving. The high-specific-surface-area tungsten oxide is prepared through ammonium paratungstate, hydrogen serves as a reducing agent, the high-specific-surface-area tungsten oxide can be reduced tungsten powder at high temperature more than 800 DEG C, the reduced tungsten powder is cooled in multi-stage mode, and finally, the tungsten powder is subjected to ultrasonic sieving to obtain near-spherical tungsten powder, wherein grain growth is complete, the tungsten powder is full,the activity is low, the dispersion property is good and the tungsten powder has particle morphology.

Owner:ZIGONG CEMENTED CARBIDE CORP

Multifunctional temperature self-regulating film and face mask and eye mask manufactured therefrom

InactiveUS20170231884A1Reduce peak heating temperature temperatureReduce cooling temperatureCosmetic preparationsToilet preparationsFacial skinThermal insulation

The present invention discloses a multifunctional temperature self-regulating multilayer film, from outside to inside comprising at least: a carrier layer (1) loaded with functional material, and a thermal-insulation layer (2) directly contacted with the skin (4); wherein the carrier layer (1) loaded with functional material has a sealed cavity sealed with a flexible water-impermeable material, the sealed cavity is at least loaded with a refrigerating or heat-generating chemical material (11); wherein thermal-insulation layer (2) is made of a material having waterproof and thermal-insulation properties. The present multilayer film can be manufactured into a face mask or eye mask for use on facial skin.

Owner:HANDY TECH ZHUHAI LTD

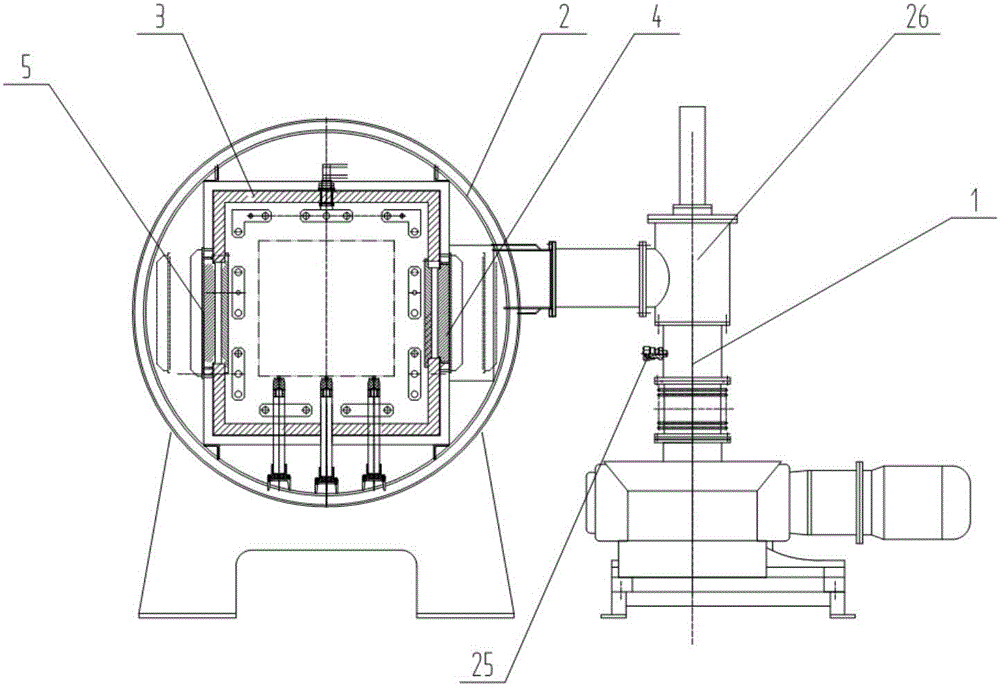

Vacuum melting and rapid hardening equipment with collecting tank and manufacturing methods of permanent magnetic alloy and permanent magnet

ActiveCN104226941AImprove consistencyGood grain consistencyInductances/transformers/magnets manufactureMechanical crushingRare earth

The invention discloses vacuum melting and rapid hardening equipment with a collecting tank. The vacuum melting and rapid hardening equipment comprises a melting crucible, a tundish, a first rotary roller, a crushing device and the collecting tank, wherein the melting crucible, the tundish and the first rotary roller are arranged in a vacuum shell; a rotary mechanical crushing device is arranged below the first rotary roller; a valve is arranged below the mechanical crushing device; one end of the valve is connected with the vacuum shell, and the other end of the valve is connected with the collecting tank; the collecting tank is provided with a cooling device; one of water, a cold medium, argon gas and nitrogen gas is taken as a cooling medium. The invention further discloses methods for producing a neodymium-iron-boron rare-earth permanent magnetic alloy and a rare-earth permanent magnet by adopting the equipment.

Owner:沈阳中北真空技术有限公司

Production method of polyamide-6 fiber

ActiveCN104805513AImprove performanceAvoid uneven coolingArtificial thread manufacturing machinesMelt spinning methodsFiberPolyamide

The invention discloses a production method of polyamide-6 fiber. The production method comprises the following steps: a, adding polyamide-6 chips to a screw extruder, and carrying out melted extrusion; b, spinning; c, carrying out cooling forming on silk bundles by using cross air blow by using a cross air blow spinning cooling device and oiling the cooled silk bundles, wherein the cross air blow to the silk bundles in the cross air blow spinning cooling device is divided into an upper layer and a lower layer which are independent of each other, wherein the upper layer of cross air blow is obliquely blown out upwards, and the lower layer of cross air blow is taken as a main body and horizontally blown out from a cross air blow cylinder; d, carrying out pre-interlacing, drafting, interlacing and winding; e, carrying out inspection package. According to the production method disclosed by the invention, the cross air blow is adopted to substitute for side air blow, so that a melt is uniformly cooled in each direction; the phenomenon that the inner layers and the outer layers of the silk bundles cannot be uniformly cooled is effectively avoided, and the unevenness rate of the silk bundles is reduced, so that the molding quality of the silk bundles is greatly improved; the polyamide-6 fiber prepared by the production method disclosed by the invention is excellent in various performances and has favorable market competitiveness.

Owner:光山县群力化纤有限公司

Liquid-cooled single cabinet data center

PendingCN110278690AImprove stabilityGuaranteed uptimeCooling/ventilation/heating modificationsData centerWarm water

The invention discloses a liquid-cooled single cabinet data center. A heat exchanger is installed at that bottom end inside the cabinet. A separating plate is arranged inside shell. A coolant is arranged on the upper side of the separating plate and circulating water is arranged on the lower side of the separating plate. The lower side of the separating plate is provided with a cold water inlet pipe. The other side of the lower part of the separating plate is provided with a warm water outlet pipe. One side of the water outlet pipe of a circulating water pump is connected with a cold water outlet pipe. One side of the cold water outlet pipe is connected with a water distribution pipe which is provided with multiple water inlet branch pipes. Multiple cold plates are arranged inside the cabinet. A cooling coil pipe is arranged in an installing groove. One end of the cooling coil pipe is connected with the water inlet branch pipes. A water collecting pipe is arranged on the server side. One end of the water collecting pipe is connected with the warm water inlet pipe. Multiple return water branch pipes are arranged on the water collecting pipe. The other end of the cooling coil pipe is connected with the return water branch pipes. The heat exchanger is arranged at the bottom of the cabinet, and the coolant flows into the cooling coil pipe of the upper part of the cold plate through the water distribution pipe and the water inlet branch pipes in turn to cool and dissipate heat for the server so as to improve the stability of the server operation.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

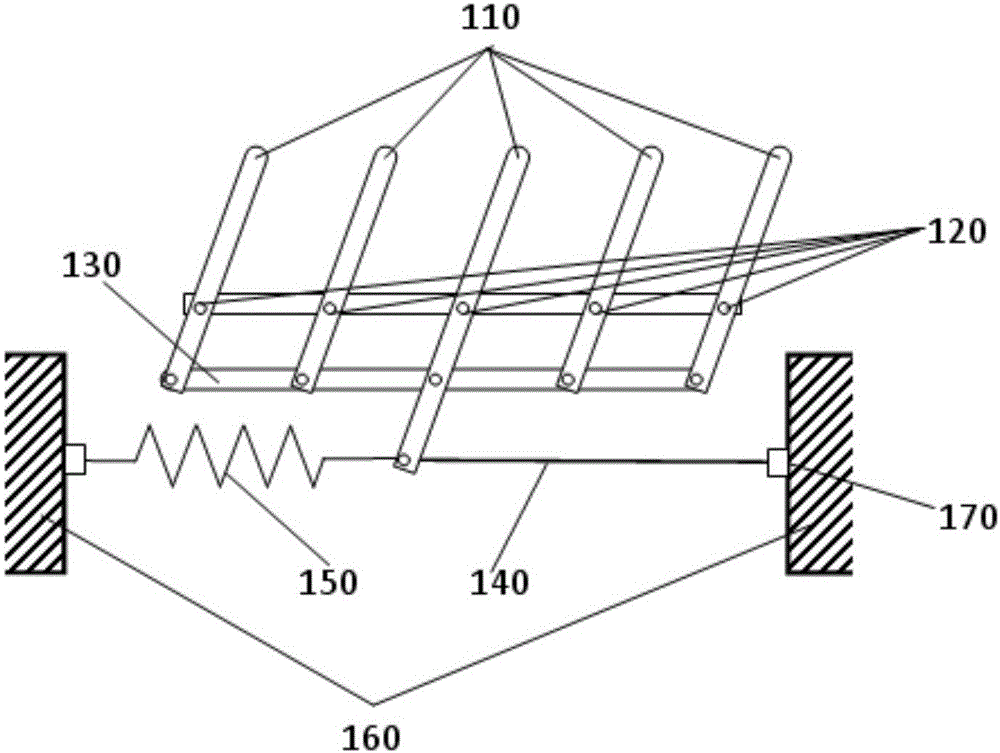

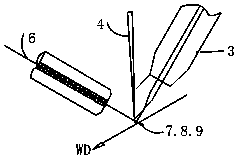

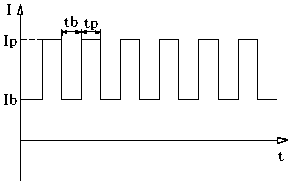

Scanning galvanometer laser-high frequency pulse TIG composite welding method

PendingCN110814552AExtended cooldownIncrease the area of actionLaser beam welding apparatusWelding accessoriesGalvanometerWeld seam

The invention provides a scanning galvanometer laser-high frequency pulse TIG composite welding method. A steel plate to be welded is made into a welding groove, and assembling and cleaning are carried out. A first workpiece to be welded is in butt joint with a second workpiece to be welded. The first workpiece to be welded and the second workpiece to be welded are thick steel plates. A welding seam to be welded with the selected width and length is formed between the two workpieces to be welded. A welding wire is used, laser beams generated by a scanning galvanometer laser-high frequency pulse TIG composite welding gun and a TIG welding gun are used for travelling welding for the welding seam in the direction from one end to the other end, and a mode of a straight-line swing, a circular swing or a "8-shaped" swing is adopted in the welding process. According to the scanning galvanometer laser-high frequency pulse TIG composite welding method, scanning galvanometer laser-high frequencypulse TIG composite welding is adopted, the probability of pore generation can be reduced, the welding seam property is improved, the welding seam heat input is reduced, and the welding deformation is reduced. The scanning galvanometer laser-high frequency pulse TIG composite welding method is suitable to be used as a method of swing laser-high frequency pulse TIG composite welding for members ofthick wall high-strength steel, stainless steel and the like.

Owner:中国船舶集团渤海造船有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com