Multifunctional vacuum furnace

A vacuum furnace, multi-functional technology, applied in furnaces, muffle furnaces, cooking furnaces, etc., can solve the problems of long heating and holding time, single cooling gas running direction, inconsistent workpiece temperature, etc., to achieve high product performance and heat preservation And the effect of short cooling time and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

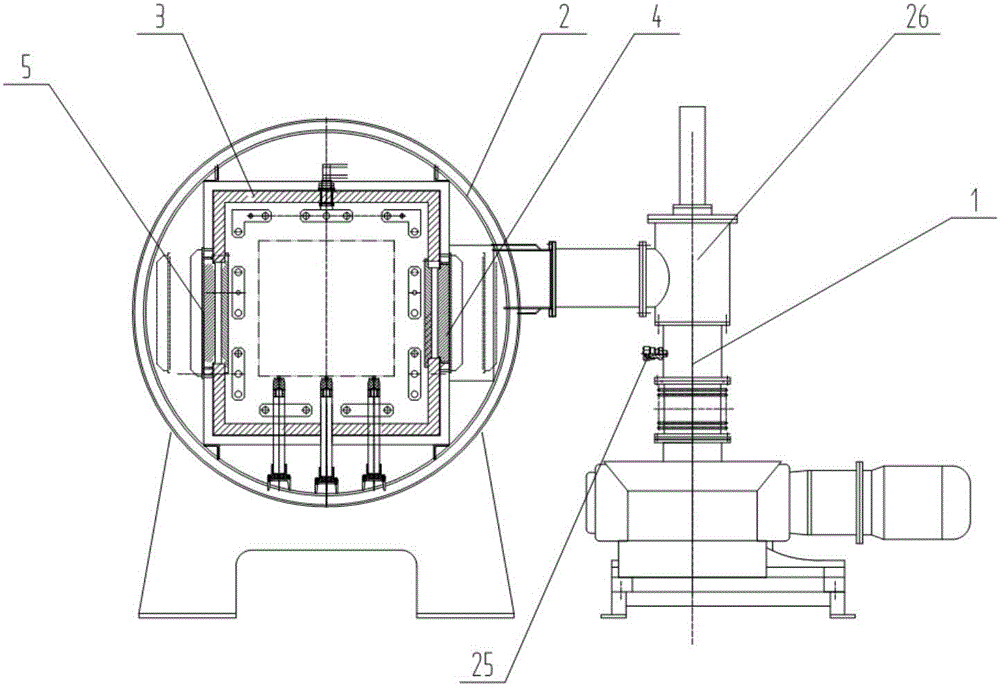

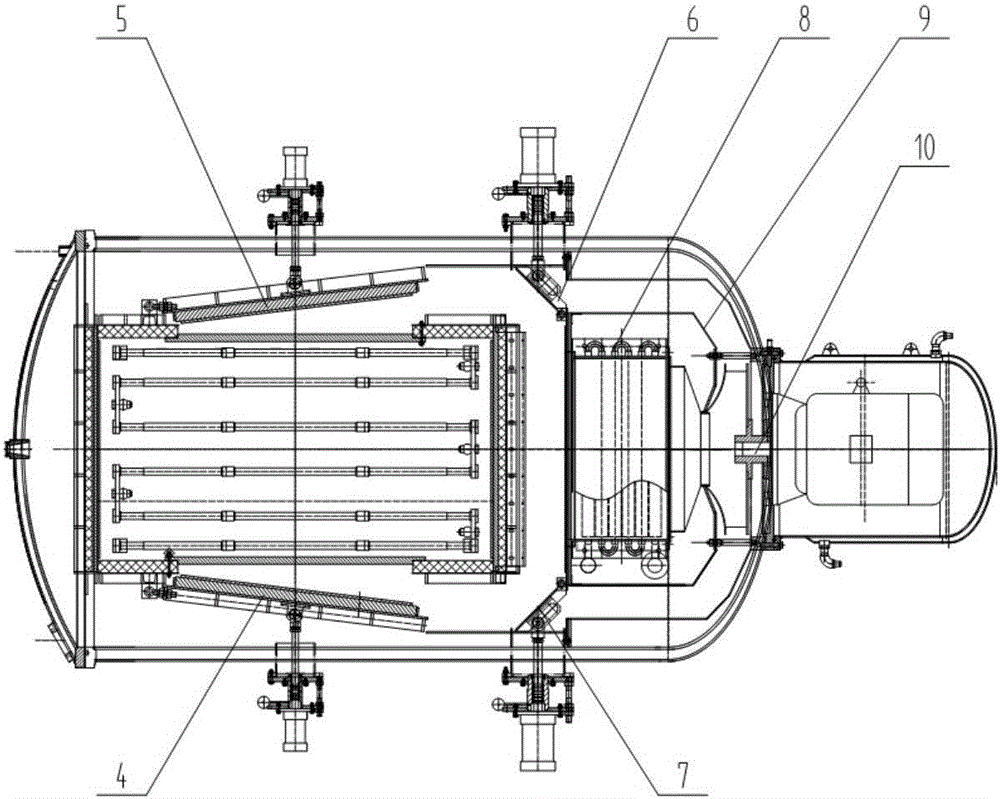

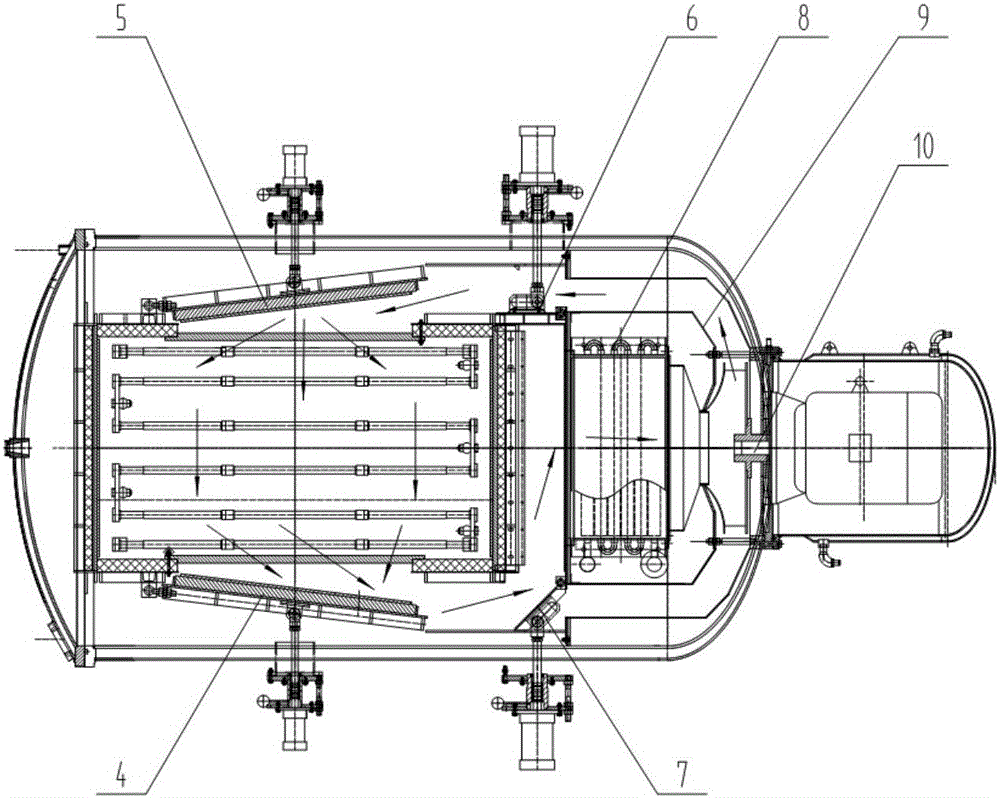

[0018] The multifunctional vacuum furnace of the present invention comprises a furnace shell, a heating chamber, a vacuum system, a cooling system, and a PLC intelligent control system, see figure 1 , 2 , the furnace shell 2 is a cylindrical vacuum-tight container, installed axially parallel to the ground, the front end of the cylinder is a spherical door, and the rear of the furnace shell 2 is a cooling system, including a fan 10, a heat exchanger 8, and an air duct 9. A vacuum system 1 is installed on the outer side of the furnace shell 2 and connected by a valve 26. A square heating chamber 3 is installed axially inside the furnace shell 2. It is characterized in that the vertical walls on both sides of the heating chamber 3 are equipped with a front right damper 4 and a front left damper 5 that move left and right. Front right and front left dampers 4 and 5 frame front vertical sides are connected with heating chamber 3 vertical walls with hinges. Inside the furnace shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com