Dual-MAG heat source dual-filament submerged arc build-up welding method

A submerged arc surfacing and thin wire technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of high labor intensity of welders, difficult control of process parameters, waste of repair costs, etc., and reduce the repair rate of weld seams. , Avoid the influence of welder skills and reduce the effect of flux loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

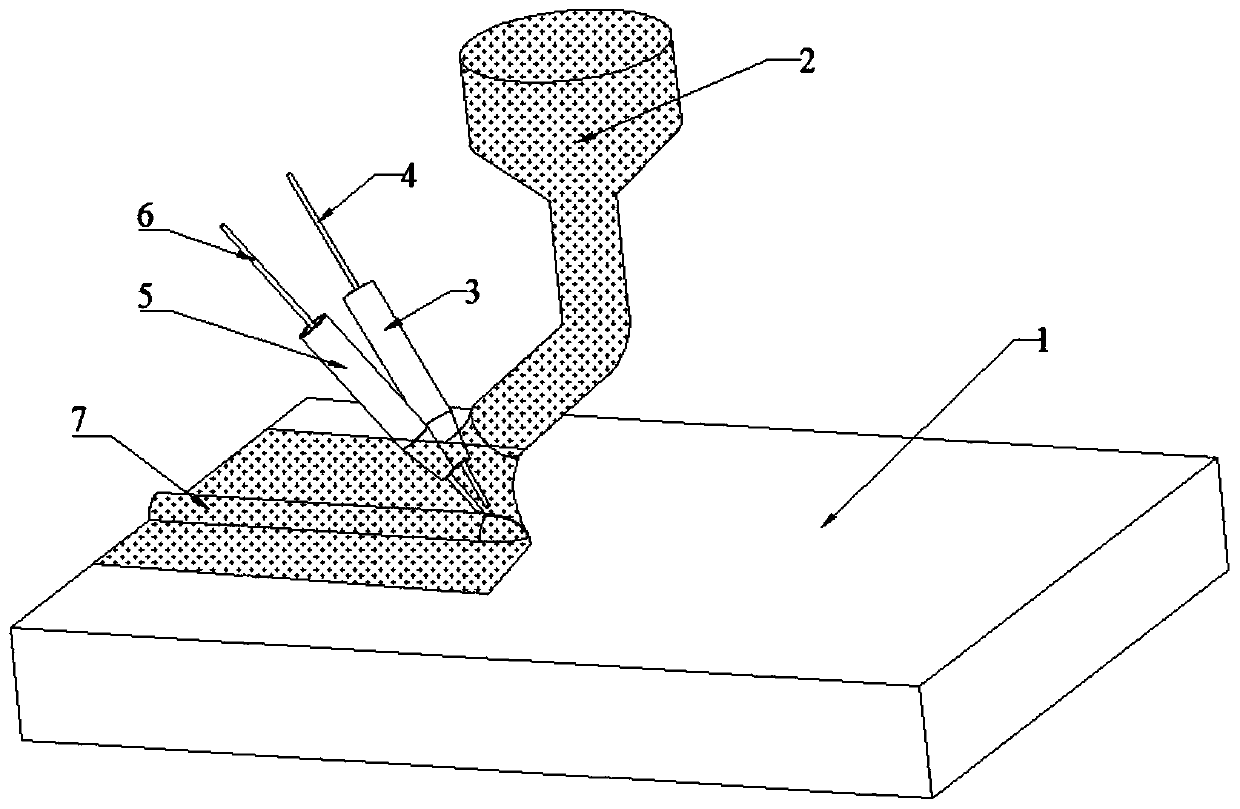

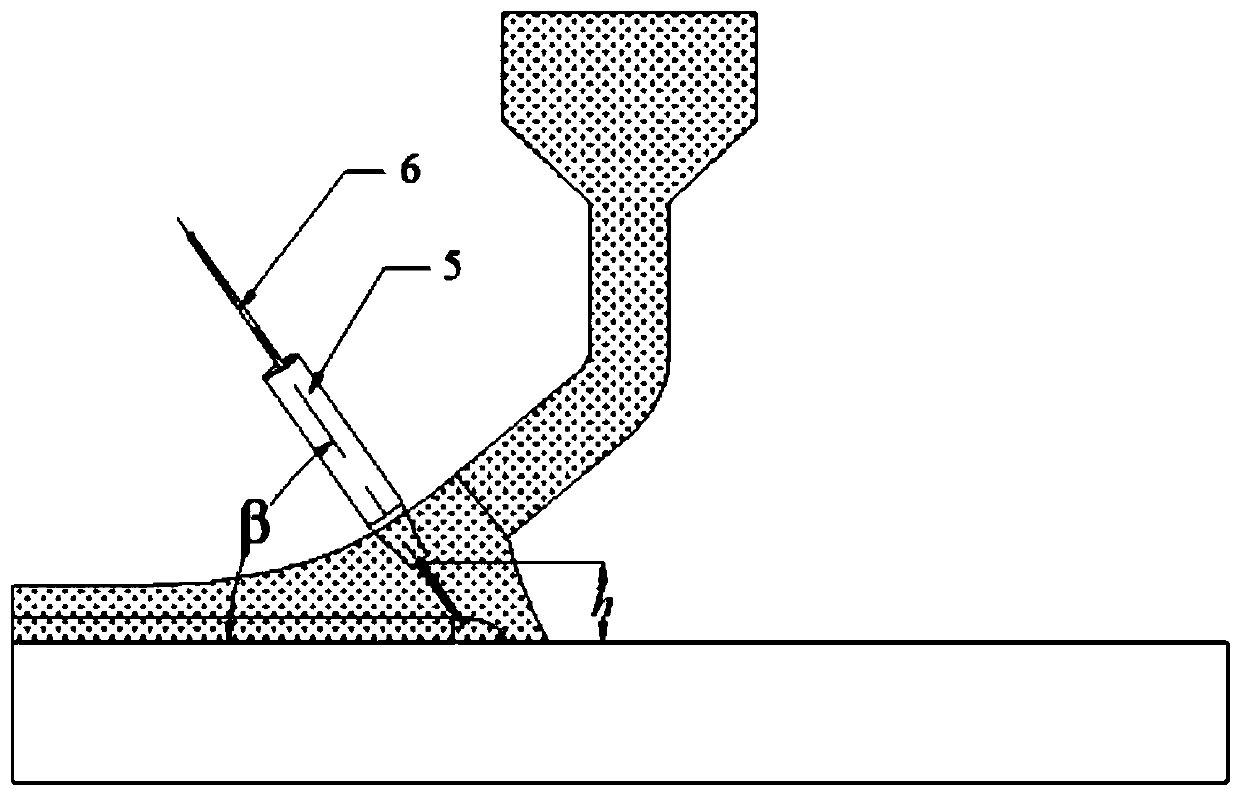

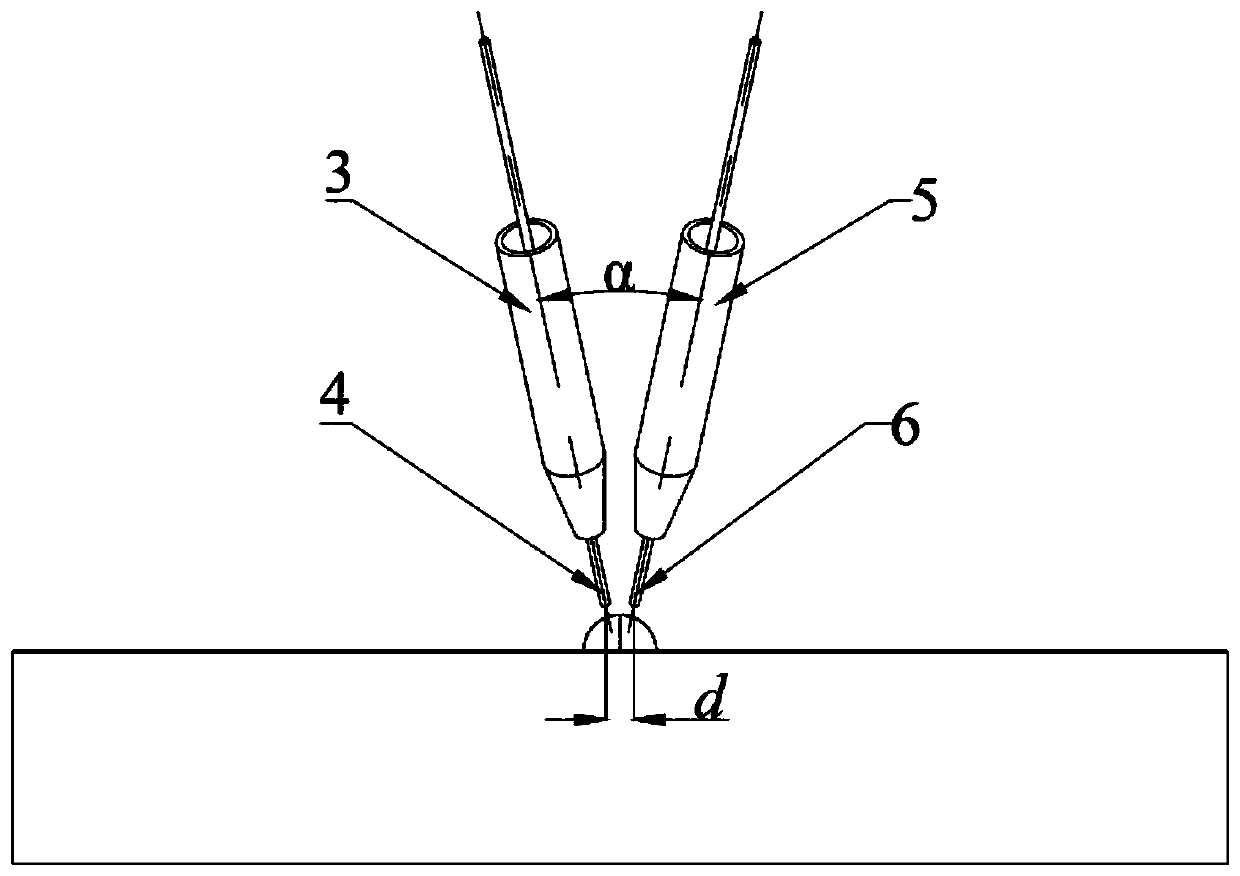

[0021] The invention provides a double MAG heat source double filament submerged arc surfacing welding method. Technical scheme of the present invention is:

[0022] 1) Cleaning before welding: Grinding to remove oxides on the surface of the workpiece 1 to be welded, exposing the metallic luster, and the workpiece 1 to be welded does not need to be preheated;

[0023] 2) Welding material preparation: the first welding wire 4 and the second welding wire 6 are aluminum bronze welding wires with a diameter of 1.2mm and the model is AWS ERCuAl-A2, and the protective flux 2 is the melting flux of the model HJ260, and the particle size of the flux is 8 mesh to 25 At present, the drying temperature before welding is 350°C, the drying time is 2 hours, and no protective gas is needed;

[0024] 3) Welding machine preparation: Two MAG welding machines of the OTC brand CPVM500 type of welding power source are used, and the two power sources are DC reversed;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com