Halogenated hydrocarbon-contaminated soil remediation device

A technology for polluted soil and halogenated hydrocarbons, applied in the field of soil remediation, can solve the problems of poor removal effect of halogenated hydrocarbons, low restoration efficiency, poor heating effect, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

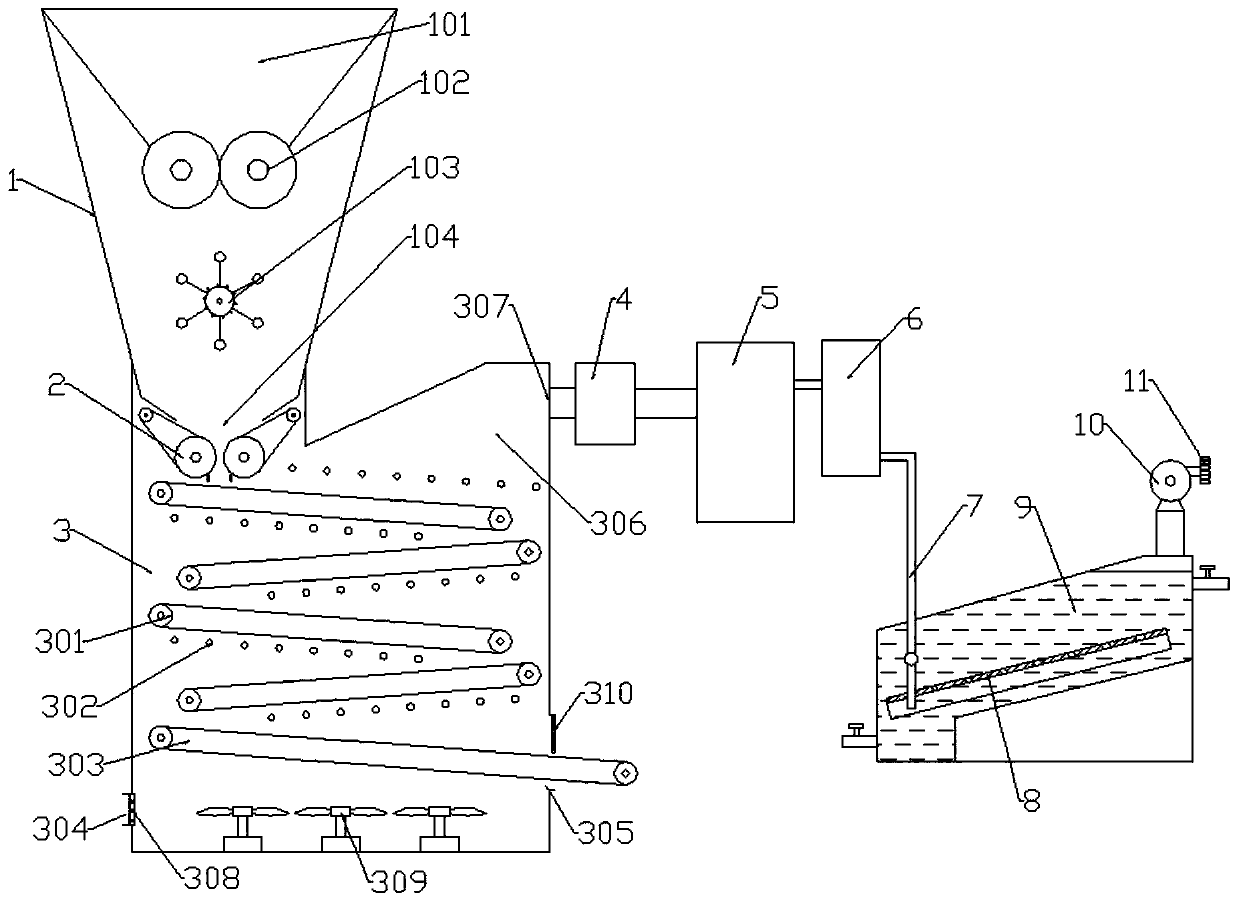

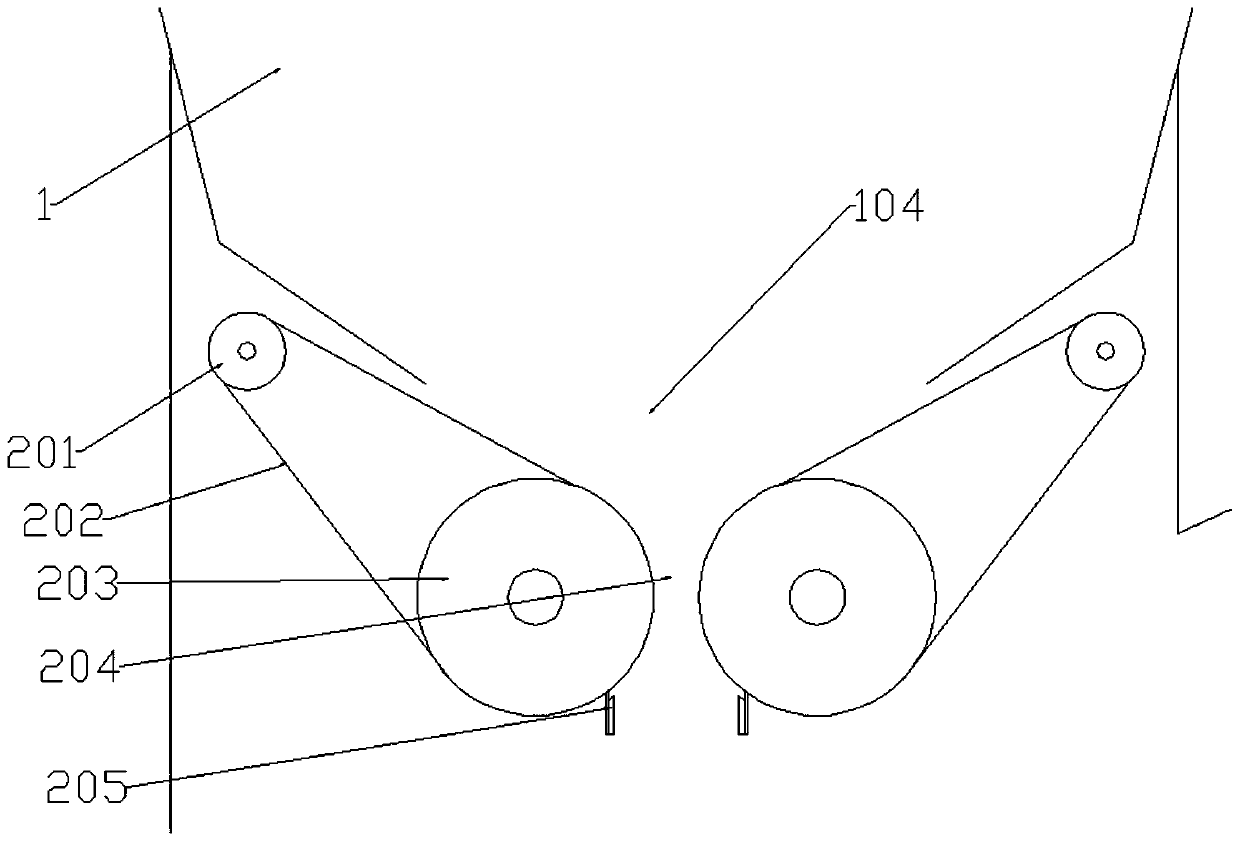

[0022] Referring to the accompanying drawings: a halocarbon-contaminated soil remediation device in this embodiment includes a halocarbon removal box 3, a hopper 1 is provided at the upper left of the halocarbon removal box 3, and a hopper 1 is provided at the top of the hopper 1. A sub-hopper 101, the bottom of the sub-hopper 101 is provided with a pulverizer 102, a soil stirring device 103 is provided below the pulverizer 102, a soil feeding port 104 is provided at the bottom of the hopper 1, and a soil rolling-off device is provided under the soil feeding port 104. Device 2, the inside of the halogenated hydrocarbon removal box 3 is provided with a number of soil conveyor belts 301 alternately "Z" from top to bottom, and the bottom of the halogenated hydrocarbon removal box 3 is provided with a soil discharge conveyor belt 303, the soil discharge conveyor belt 303 below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com