Strong impact flake disrupter

A kind of impact powder loosening machine, strong technology, applied in the direction of grain processing, etc., can solve the problems of low impact strength, increase of ash content, decline in effect, etc., and achieve the effect of improving the flour extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

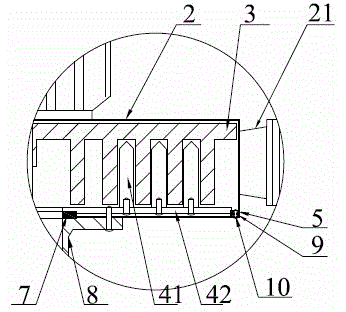

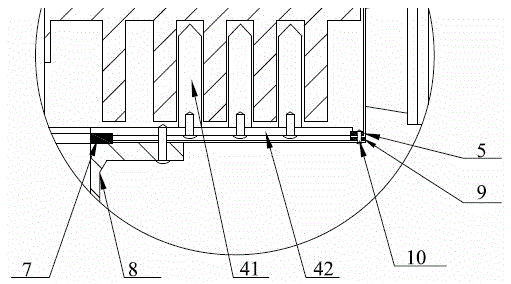

[0020] as attached figure 1 , attached figure 2 , attached image 3 The shown powerful impact powder loosening machine comprises a motor 1, a casing 2, a rotor 3, a stator 4, a feed port 24 and a discharge port 23, and the stator 4 includes a stator plate 42 and a stator pin 41, and the feed port 23 communicates with the feed pipe 8, the housing 2 includes a housing 21 and a cover 22, the motor 1 is installed on the surface of the housing 21, the rotor 3 is connected to the motor shaft through a connecting key, and the stator pin 41 It is a cylindrical pin with a tapered protrusion at one end, and the rotor 3 includes rotor pins 31 distributed on the disk in a circular shape. The rotor pins 31 are several square pins. A sealing ring b7 is provided between the end faces of the housing 21, a sealing ring a5 is provided at the contact position between the housing 21 and the outer edge of the stator plate 42, a sealing ring c9 is provided between the connecting surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com