Basement protection wall concrete pouring construction technology

A construction technology and concrete technology, which is applied in artificial islands, water conservancy projects, underwater structures, etc., can solve the requirements of high bearing capacity and structural strength, which affect the construction quality, bearing strength, and doping of basement parapet walls. problems, to achieve the effect of improving the quality of concrete pouring construction, reducing the emission of water, and ensuring the quality of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

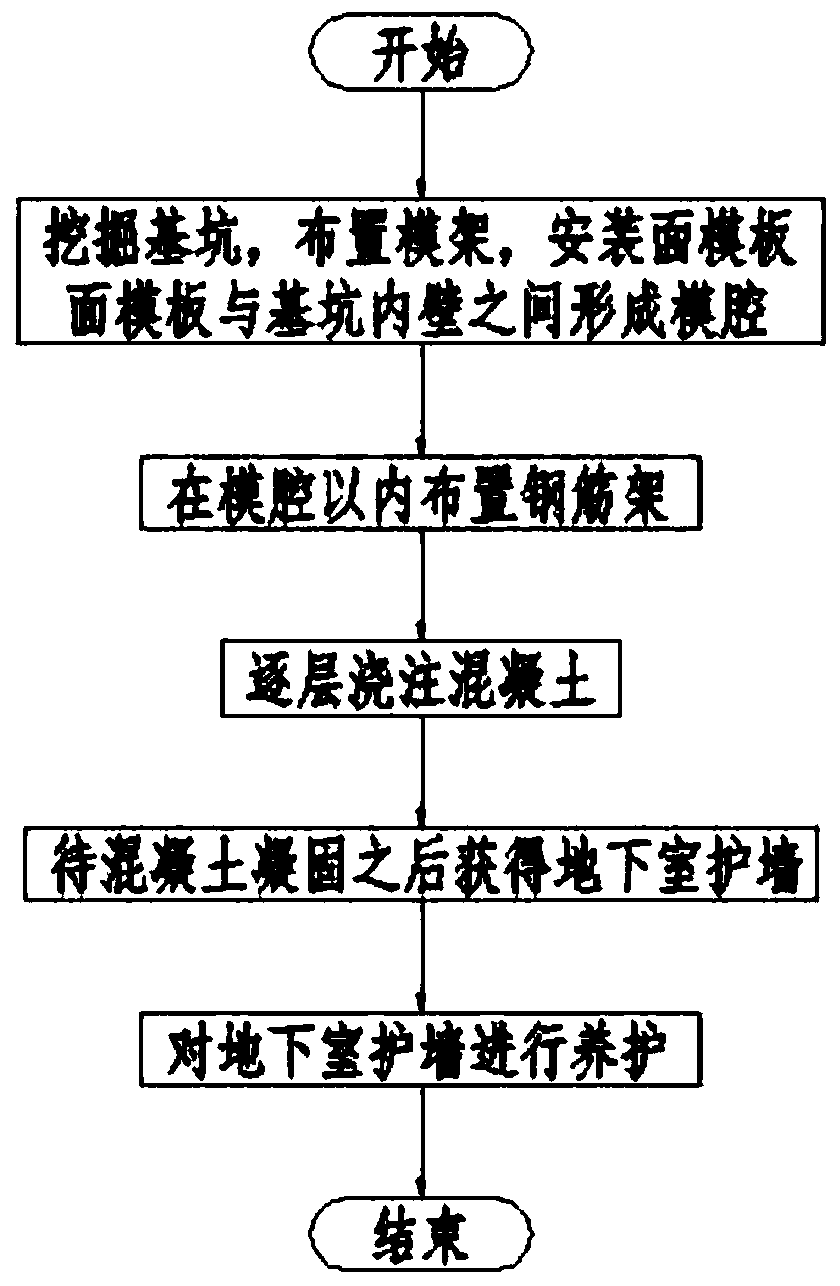

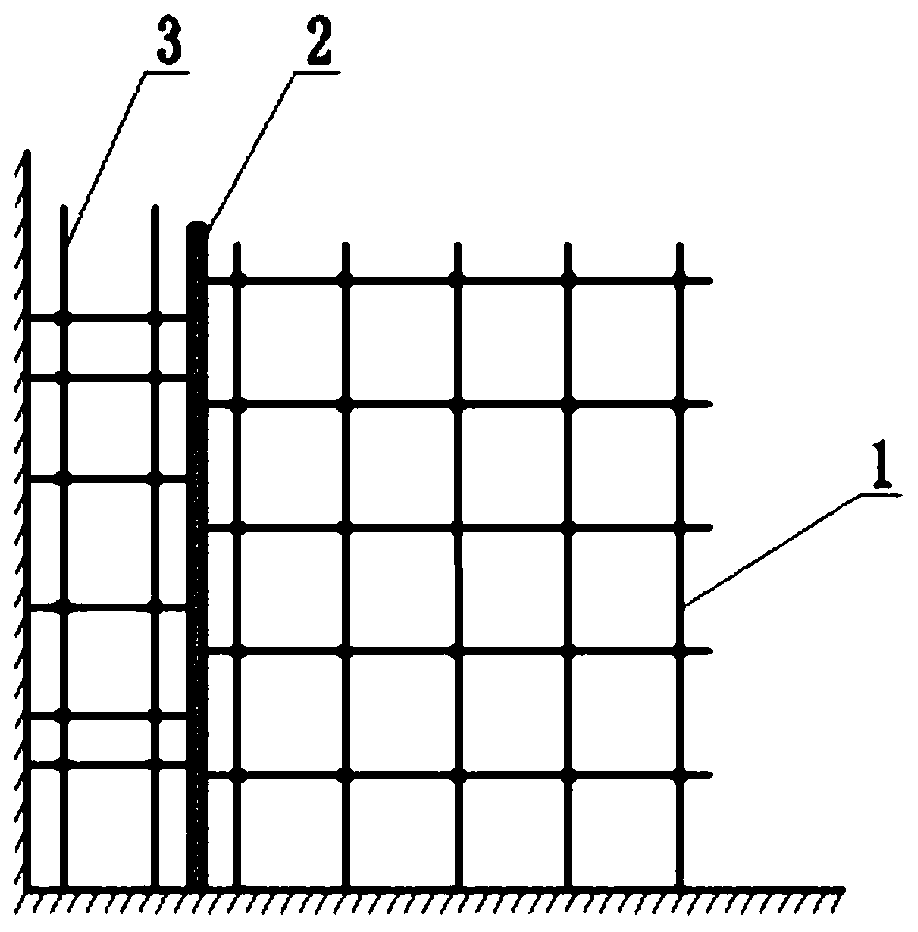

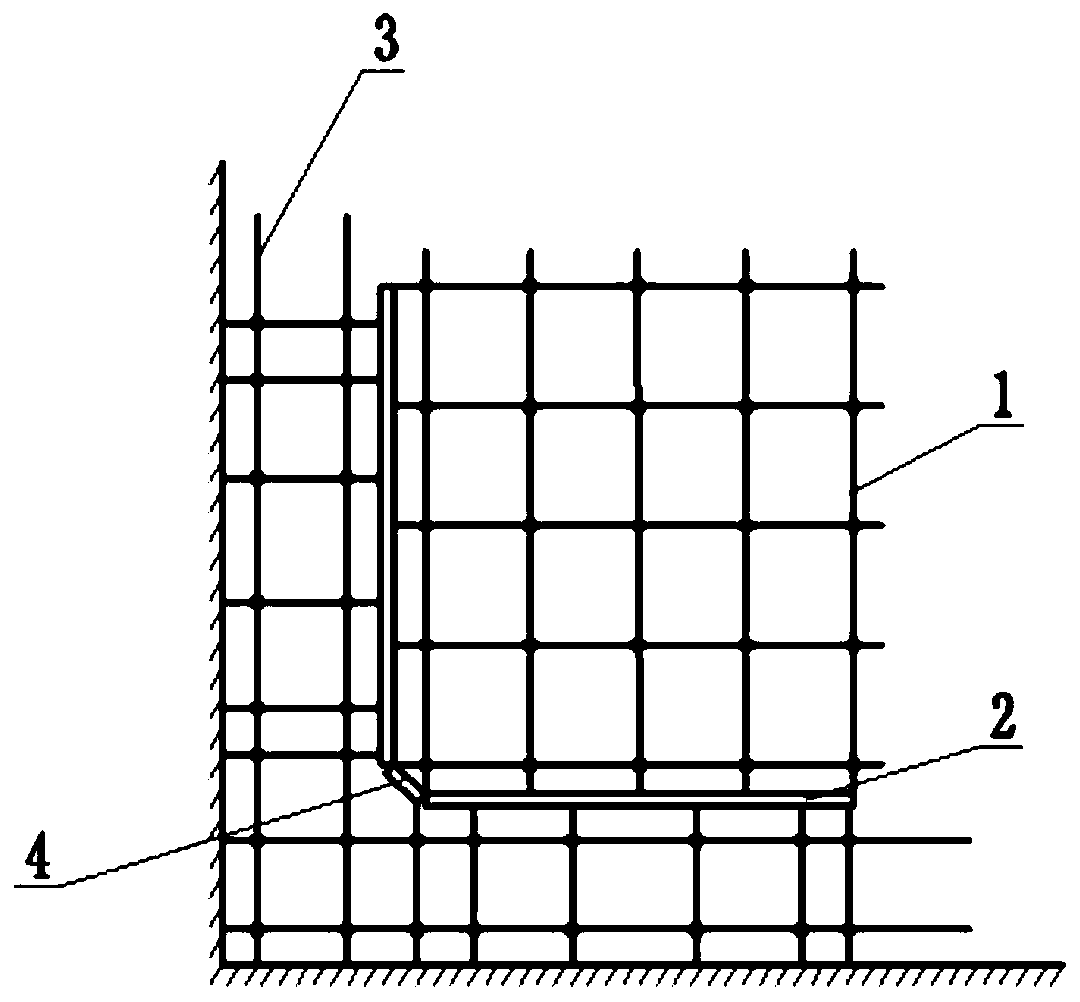

[0025] like figure 1 , figure 2 and image 3 As shown, the invention provides a kind of basement retaining wall concrete pouring construction technology, comprises the following steps:

[0026] Step 1: A foundation pit is excavated on the ground, and formwork 1 is provided. Formwork 1 is placed flat on the bottom of the foundation pit. Surface formwork 2 is installed on the side of formwork 1, and surface formwork 2 is opposite to the inner wall of the foundation pit. The surface formwork 2 and the inner wall of the foundation pit constitute the mold cavity; in addition, the formwork 1 in step 1 is a scaffold constructed by arranging a plurality of steel pipes along the vertical, horizontal and longitudinal directions respectively, and any two adjacent The distance between vertical steel pipes is 600mm to 1100mm, the distance b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com