Compound damping steel plate making process and apparatus

A composite damping and manufacturing method technology, applied in the field of steel plate manufacturing, can solve the problems of high energy consumption, achieve the effects of improving composite performance, saving heating energy consumption, and reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

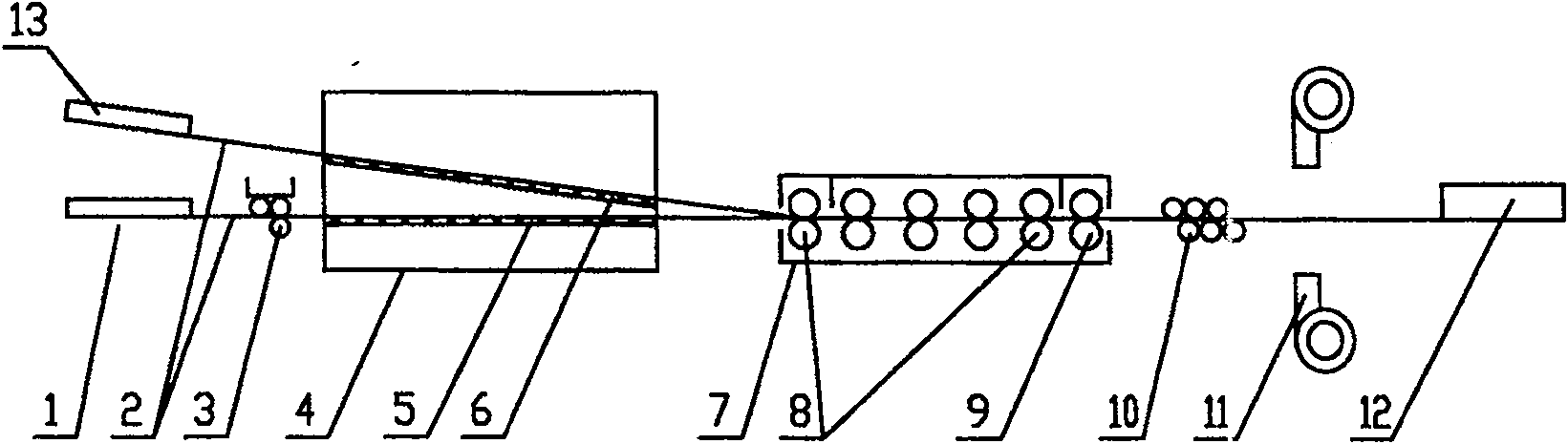

[0016] A steel plate 1 enters the glue coating machine 3 from the conveyor belt 2, and after being coated with a layer of polymer damping resin glue by the glue coating machine 3, it enters the lower drying tunnel 5 of the heating furnace 4 for heating, so that the solvent in the resin is volatilized and the resin is mainly used. agent activation. At the same time, another steel plate 13 is input from the conveyor belt 2 into the upper drying tunnel 6 of the heating furnace 4 for preheating, the lower drying tunnel 5 and the upper drying tunnel 6 respectively heat the steel plates 1 and 13 for 1 to 3 minutes, and the The steel plates are sent out of the heating furnace 4 at the same time, automatically aligned and laminated by the mechanical control of the prior art, and the steel plates 1 and 13 are hot-compressed and laminated sequentially through five pairs of thermal lamination rollers 8, and the damping resin layer between the steel plates 1 and 13 is simultaneously Heati...

Embodiment 2

[0018] The processing steps of this embodiment are the same as those of Embodiment 1. The main materials and process conditions of this embodiment are: steel plates 1 and 13 are cold-rolled steel plates with a thickness of 1 mm; The film thickness is 65 μm; the temperature of the heating furnace 4 is 200°C, and the heating is for 2 minutes; among the five pairs of hot composite rolls, the surface temperature of the first pair of rolls is 300°C, and the surface temperatures of the second to fifth pair of rolls are respectively 450°C, The time for the steel plate to pass through the first to fifth pairs of pressure rolls is 18 seconds respectively; the surface temperature of the sixth pair of cold composite rolls is 80°C, the time for the steel plate to pass through the pair of pressure rolls is 20 seconds, and each pair of rolls adopts conventional linear pressure. The peel strength value of the prepared composite damping steel plate is 80N / cm, the tensile shear strength is 15M...

Embodiment 3

[0020] The processing steps of this embodiment are also the same as that of Embodiment 1. The main materials and process conditions are: steel plates 1 and 13 are cold-rolled steel plates with a thickness of 1mm; the damping resin is the same as that in Example 1 or Example 2; , the surface temperature of the first pair of rolls is 180°C, the surface temperature of the second to fifth pair of rolls is 250°C, and the time for the steel plate to pass through the first to fifth pair of rolls is 30 seconds respectively; the surface temperature of the sixth pair of cold composite rolls The temperature is 50°C, the time for the steel plate to pass through the pair of rollers is 20 seconds, and each pair of rollers adopts conventional linear pressure. The peel strength value of the prepared composite damping steel plate is 40N / cm, the tensile shear strength value is 6.5MPa, and the vibration damping characteristic η value is 0.20.

[0021] In the method of the present invention and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com