Welding method for Q345qDNH weather-resisting steel for bridge

A welding method and technology of weathering steel, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., to achieve the effect of strong practicability, strong applicability and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0045] The chemical composition of the bridge Q345qDNH weathering steel involved in the present invention is listed in Table 1, and the mechanical properties are listed in Table 2.

[0046]

[0047]

[0048] According to different plate thicknesses B of Q345qDNH weathering steel used in bridges, the present invention determines the preheating temperature before welding as follows: when the plate thickness B≤20mm, no preheating is required before welding; Heat at 20-60°C; when the plate thickness B is 30-70mm, preheat at 65-110°C before welding.

[0049] The welding input energy of the present invention: the control range of the welding input energy of the welding heat-affected zone -20°C Charpy impact energy KV2 ≥ 47J is: ≤ 50kJ / cm.

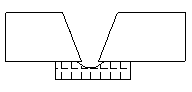

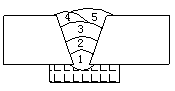

[0050] The present invention aims at the different plate thicknesses B of Q345qDNH weathering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com