Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Control heat input" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

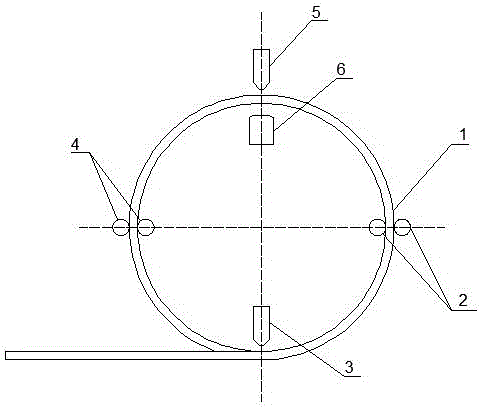

Method for preparing TiAl+Ti2AlNb composite materials by laser melting deposition

ActiveCN110449581ATurn up the plasticityControl the preheating temperatureAdditive manufacturing apparatusTransportation and packagingStress concentrationLaser additive manufacturing

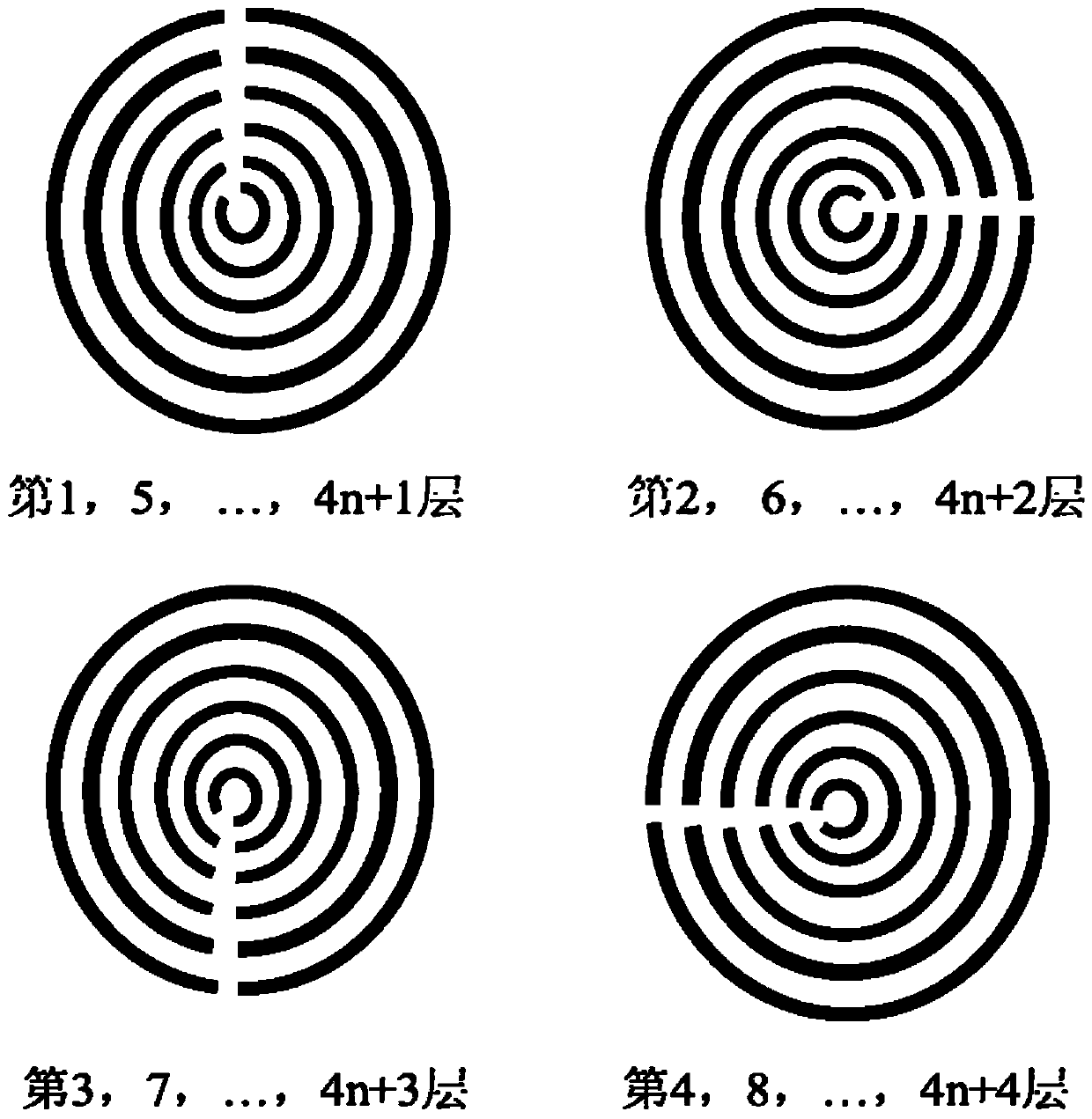

The invention belongs to the technical field of laser added material manufacturing, and relates to a method for preparing TiAl+Ti2AlNb composite materials by laser melting deposition. The laser melting deposition method is adopted to form the TiAl+Ti2AlNb composite materials; and the feeding quantity of Ti2AlNb is adjusted to achieve a pinning effect in composite material structures to improve overall plasticity of the materials. Meanwhile, circular samples are formed, and scanning paths are changed to concentric arcs to prevent the tensile stress of linear scanning paths of rectangular samples; and concentric circle openings on each layer are converted by 60-90 degrees, that is, the positions of scanning initial points on each layer are changed, so that the thermal stress concentration isreduced to prevent cracks. The heat input quantity in the forming process is controlled, and the substrate preheating temperature in the forming process is adjusted to slow down the formed metal solidification speed and cooling speed, so that the stress is released for a longer time.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

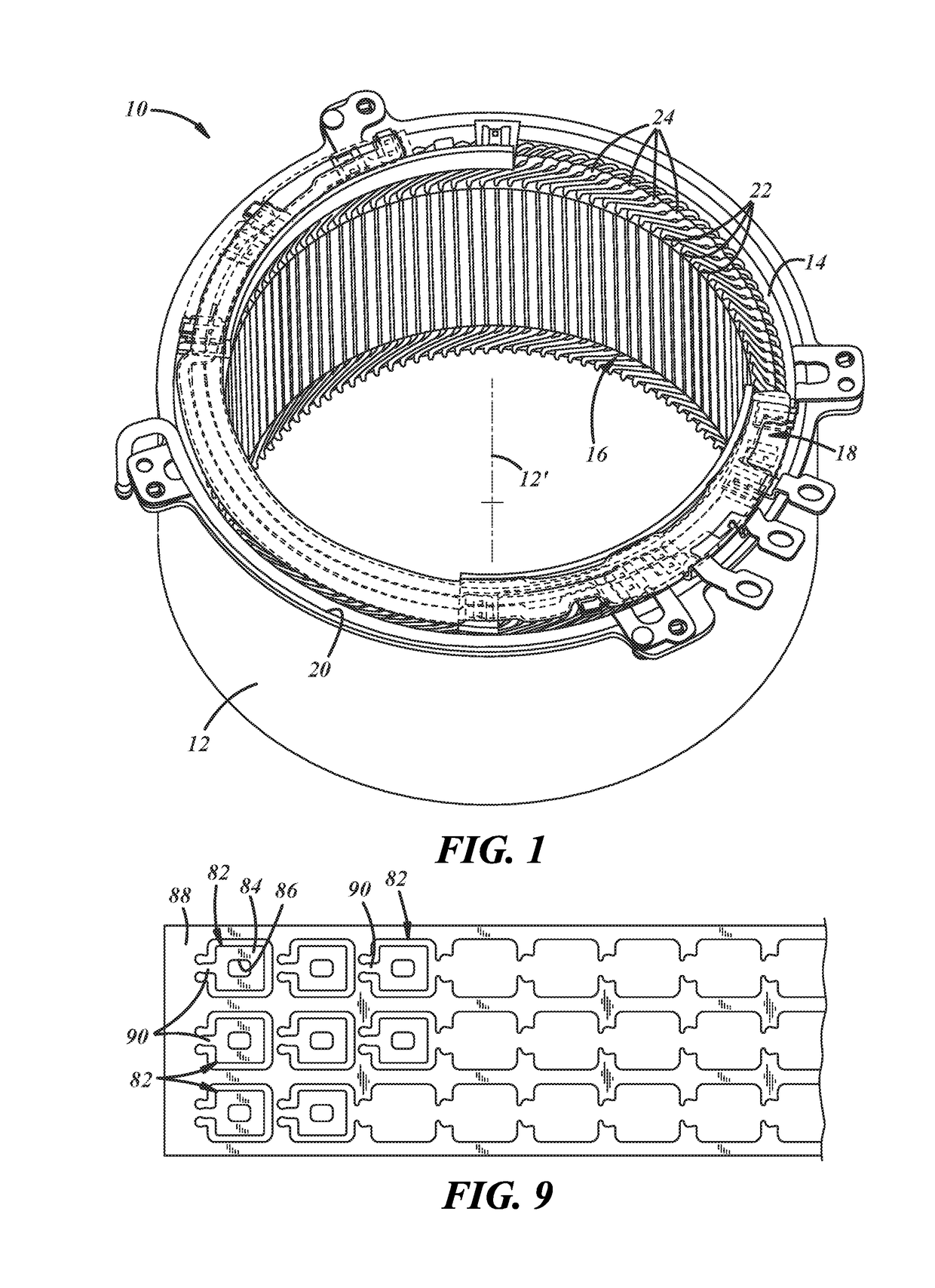

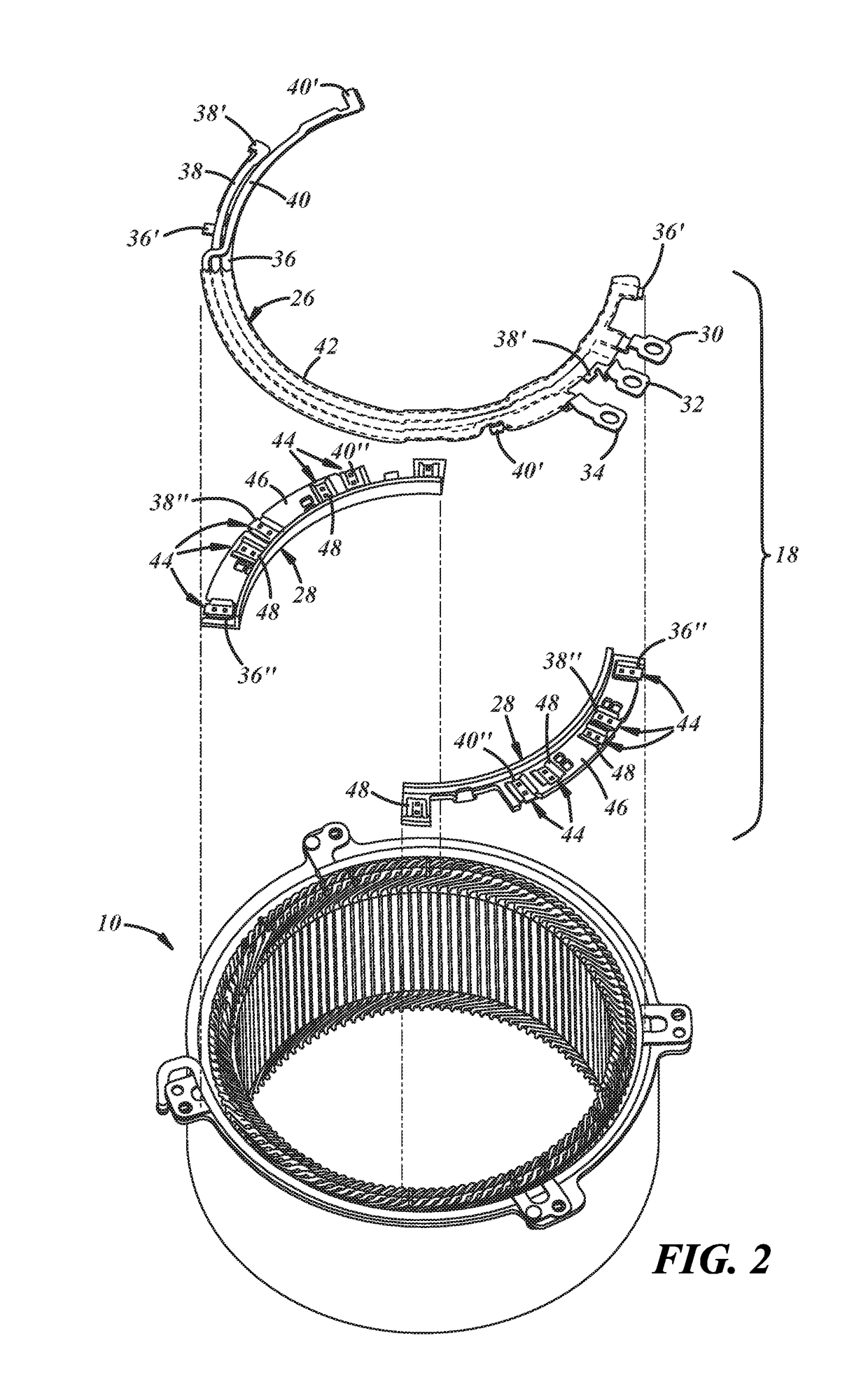

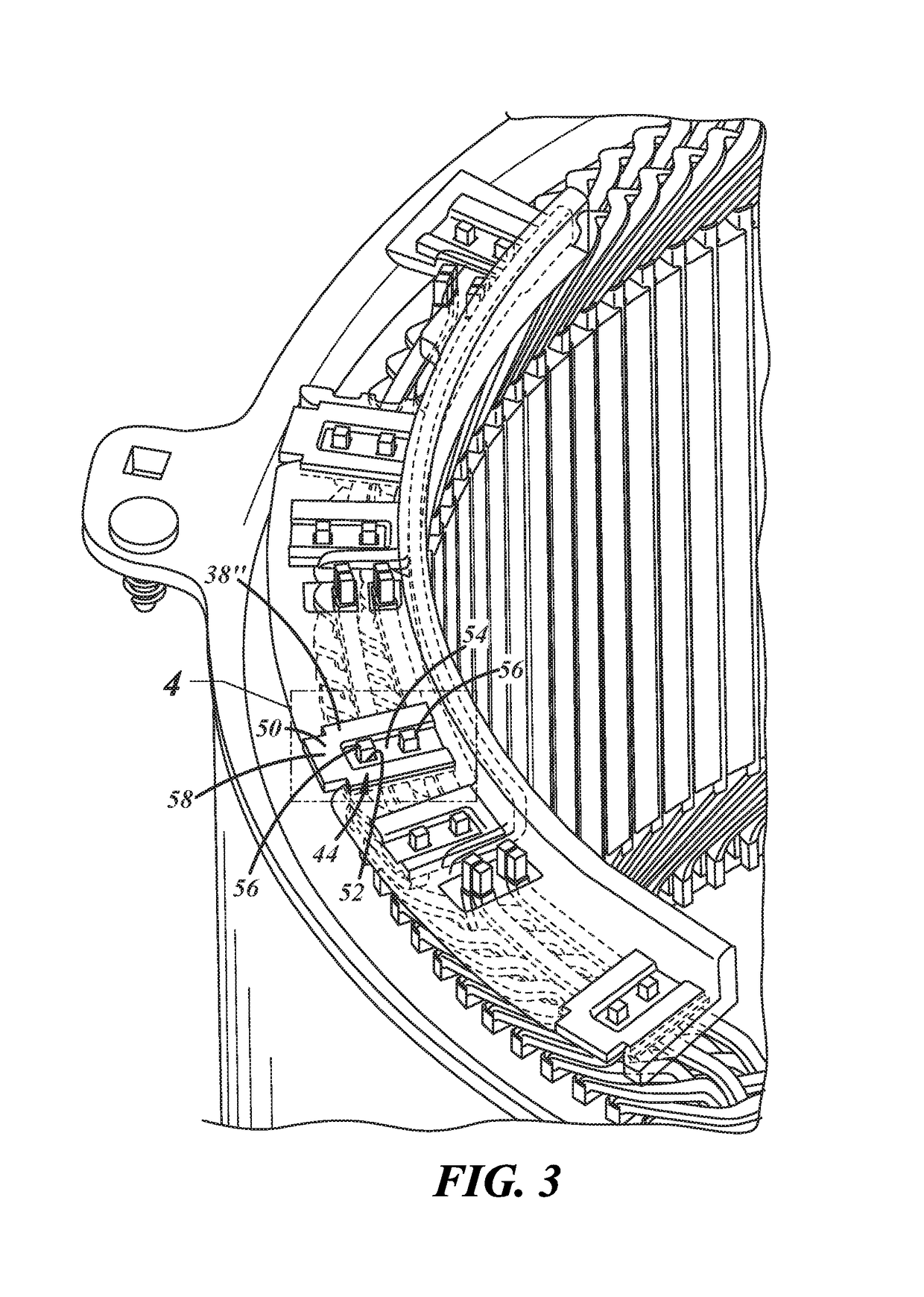

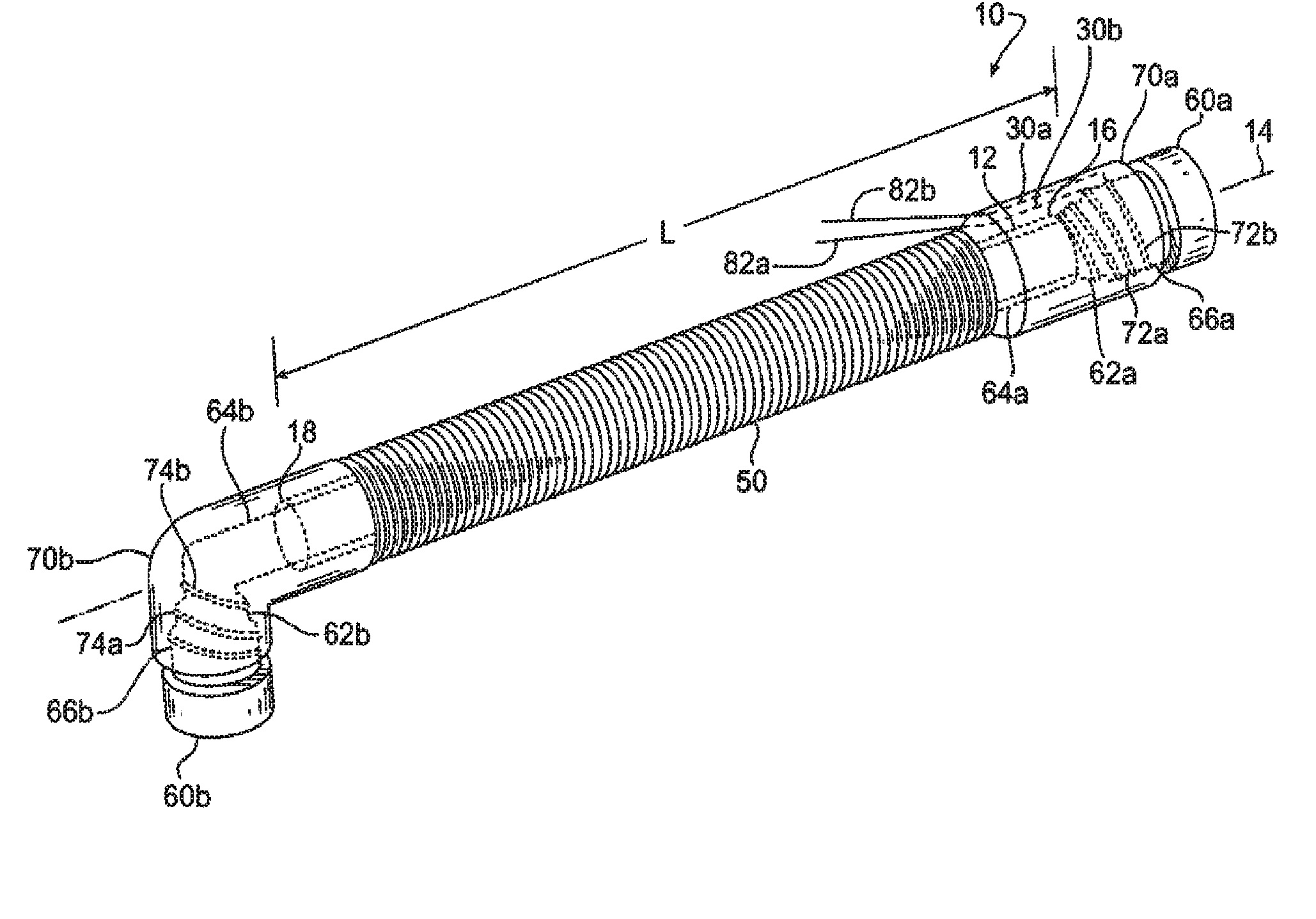

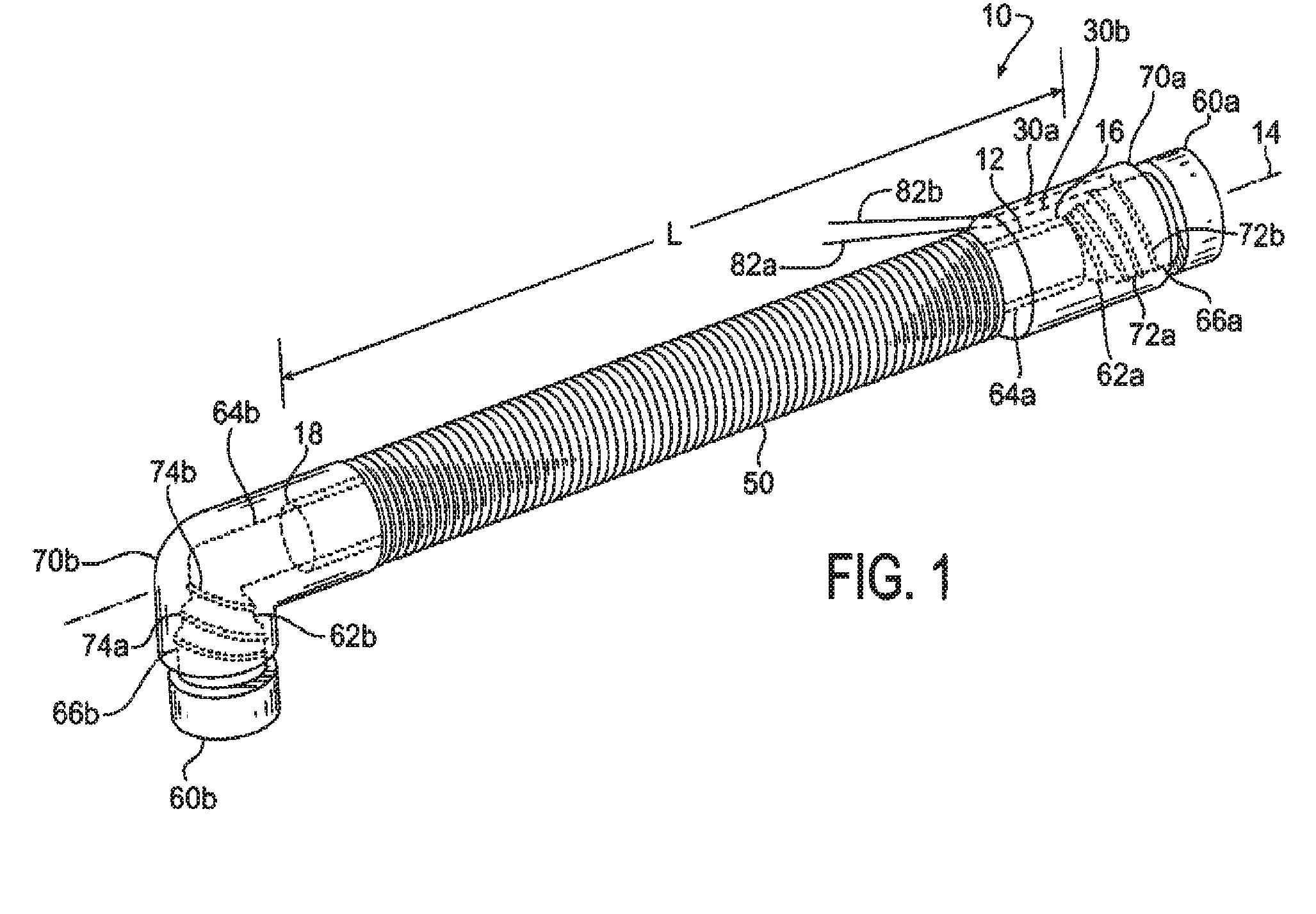

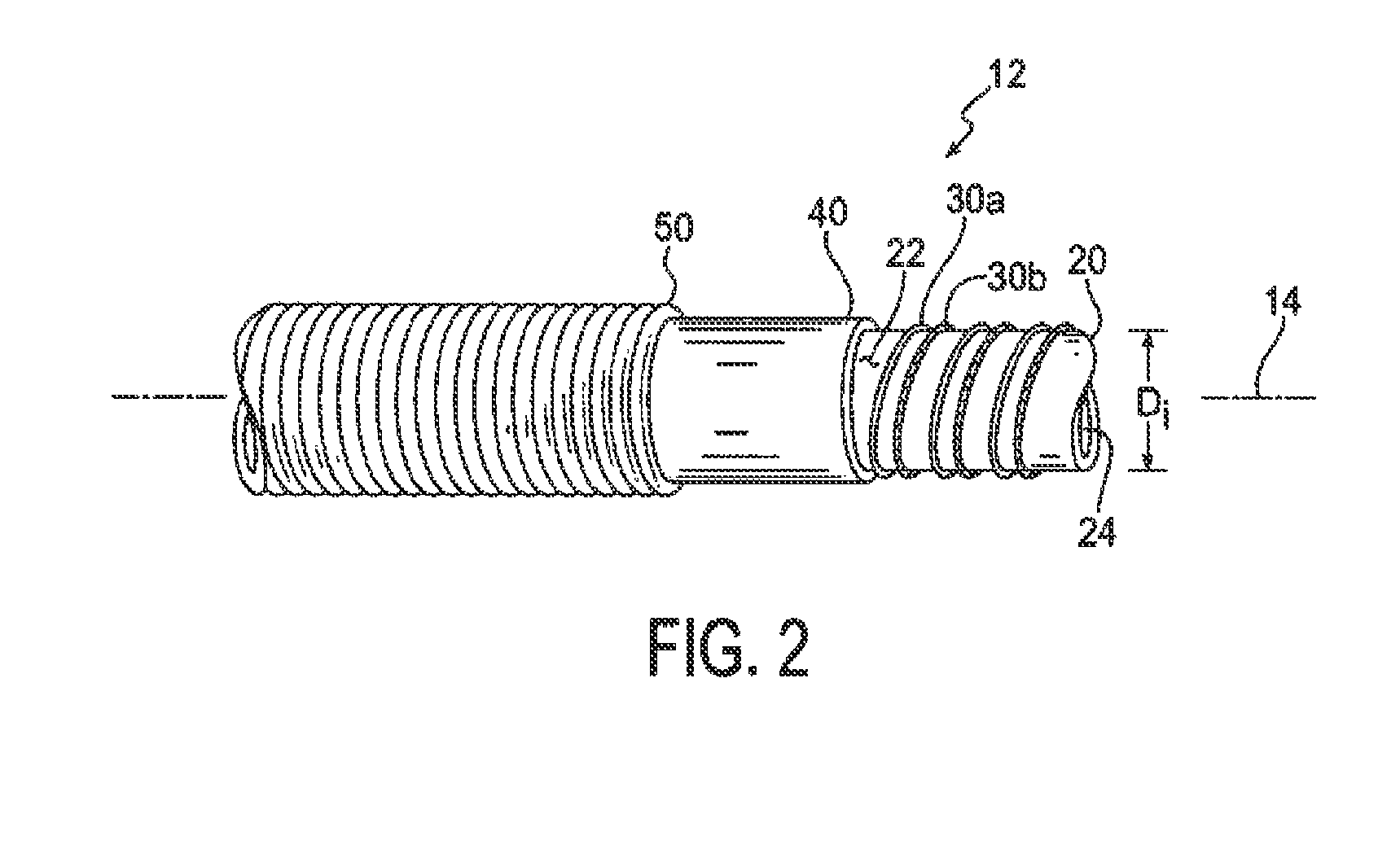

Electrically-heated hose assembly for selective catalytic reduction (SCR) systems

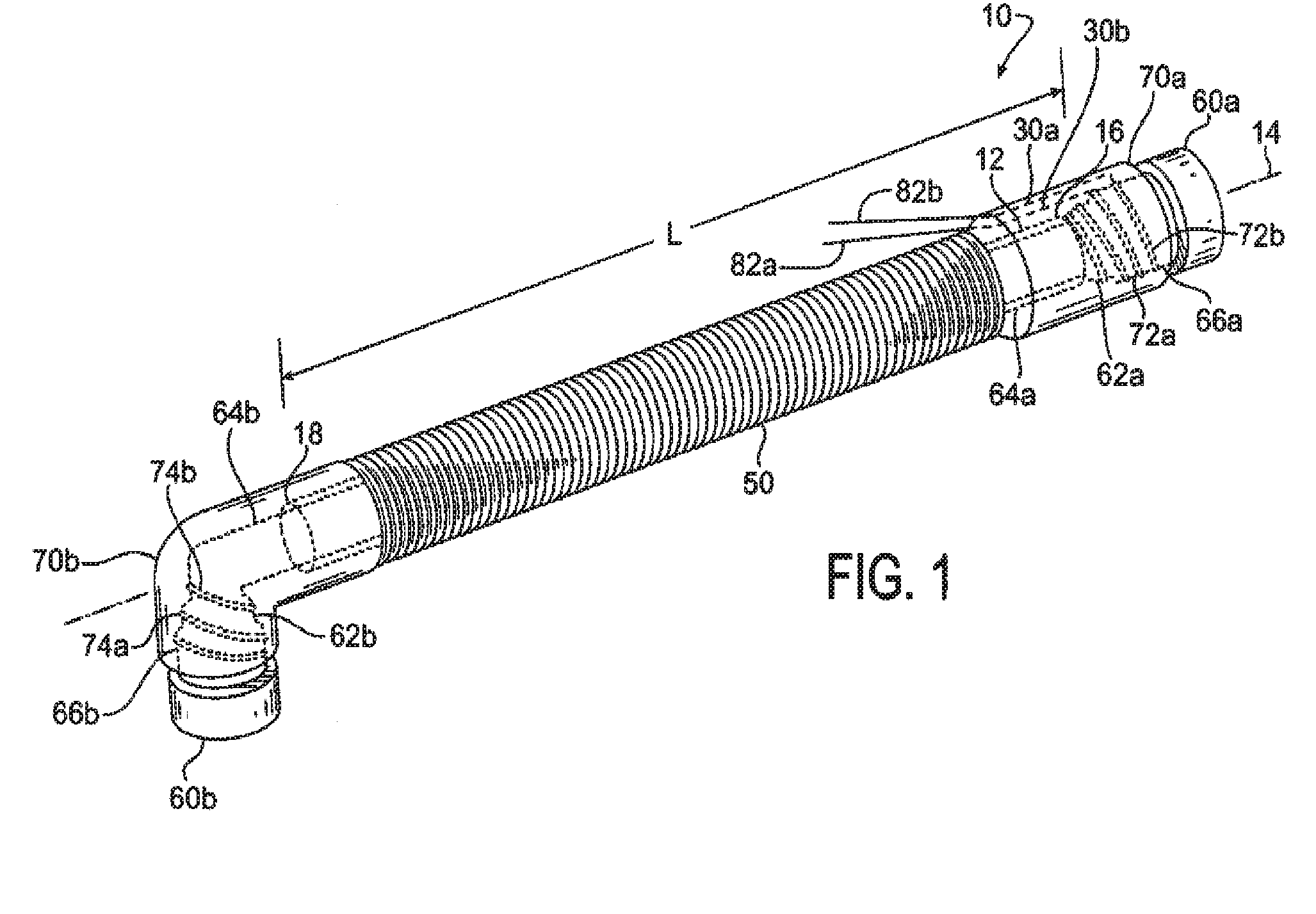

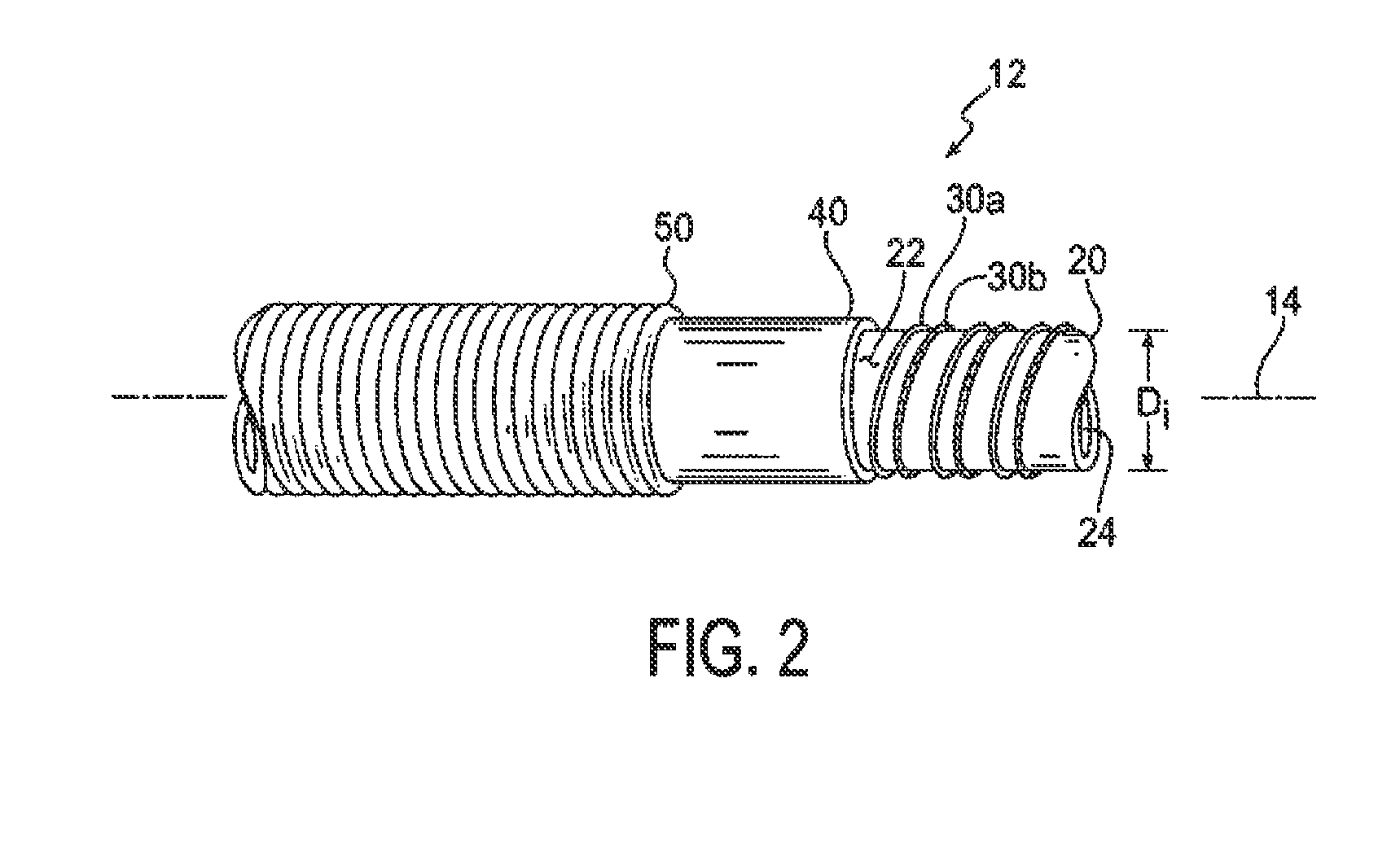

ActiveUS20120234421A1Control heat inputReadily apparentInternal combustion piston enginesExhaust apparatusSpiral woundEngineering

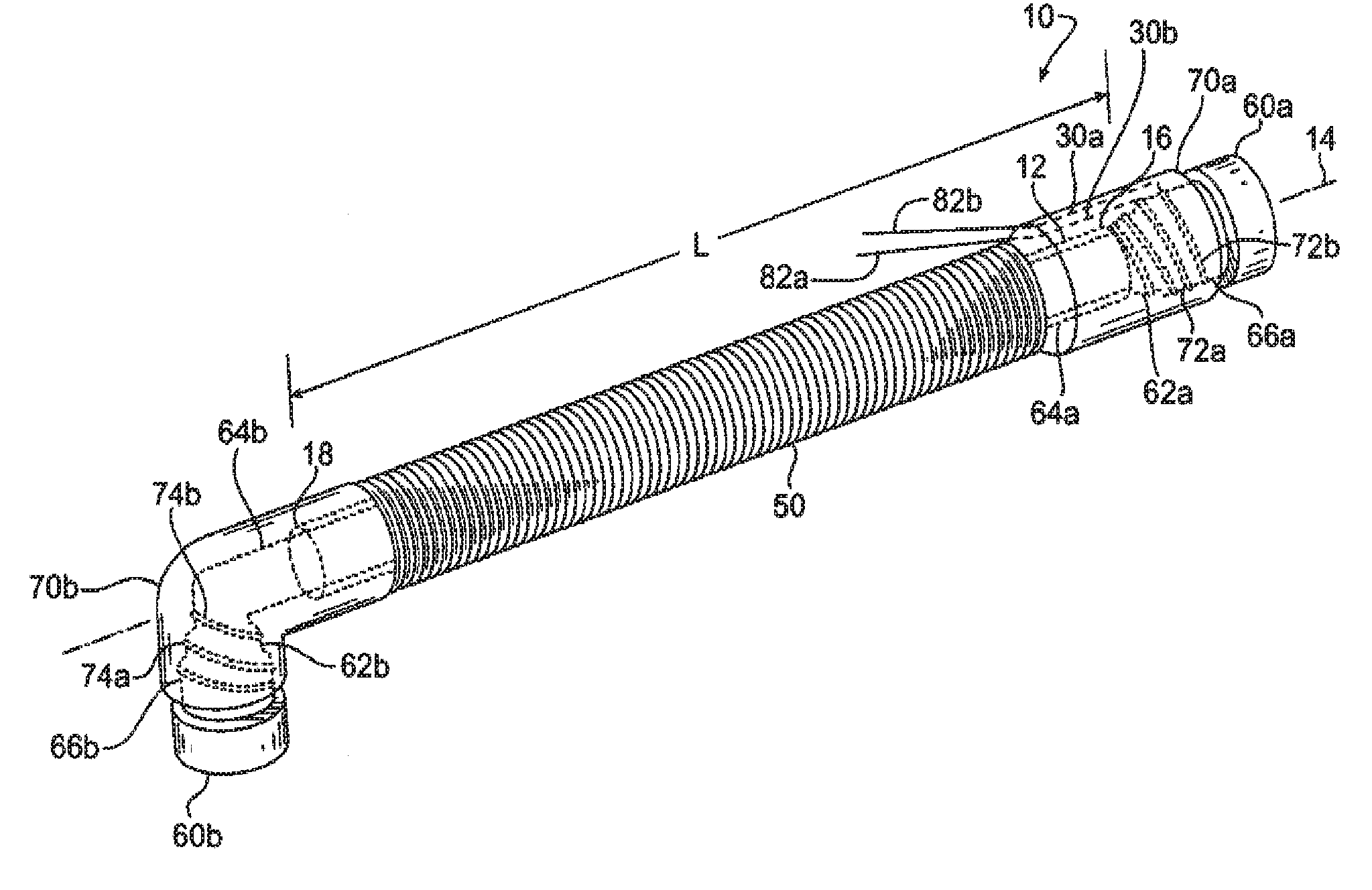

Electrically-heated hose assembly including a hose and a first and a second fitting. The hose is constructed as having a core tube, a pair of spiral wound wires surrounding the core, and a jacket surrounding the core tube. A first end of each of the fittings is within a corresponding end of the hose, with a second end of the fittings extending beyond the hose end. The wires are wound around at least a portion of the second fitting end of a corresponding one of the fittings.

Owner:PARKER INTANGIBLES LLC

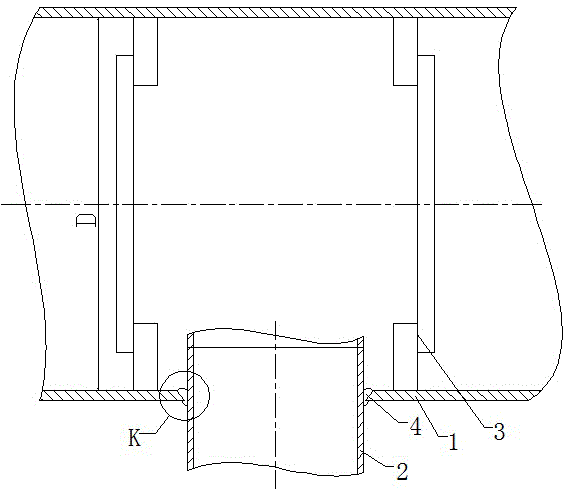

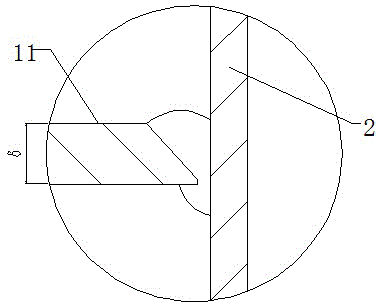

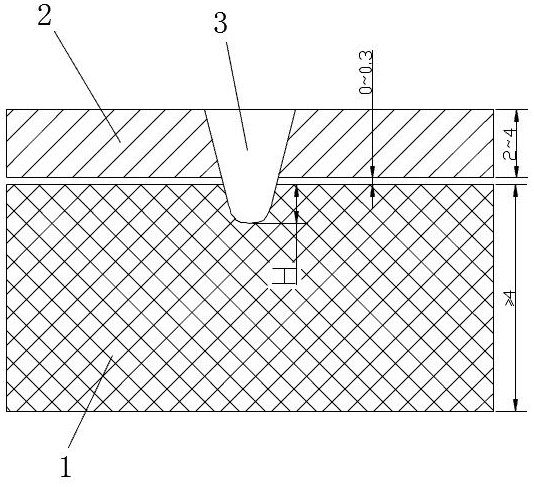

Method for controlling deformation generated when connection pipe is welded to large-diameter thin-wall barrel

ActiveCN104588958ASolve the collapseSolve the problem of cylinder deformationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention relates to the field of thin-wall workpiece welding and discloses a method for controlling deformation generated when a connection pipe is welded to a large-diameter thin-wall barrel. According to the method, the amount of actual deformation is small. When the large-diameter thin-wall barrel is welded to the connection pipe connected with the large-diameter thin-wall barrel, an inner groove is adopted as a connection pipe groove in the barrel, and the two sides of the connection pipe groove in the barrel are provided with inner supports used for supporting the inner wall of the barrel; after the connection pipe is connected with the barrel through spot welding, the position of the connection pipe is adjusted, so that the connection pipe is located below the barrel, a circumferential welding line of the connection pipe is divided into an even number of welding line segments, welding of each welding line layer is completed through two rounds of segmented symmetry welding, welding of a half of each welding line segment in the length direction is completed in each round of segmented symmetry welding, and the next layer is welded after all the welding line segments on the upper layer are welded. The whole welding line is divided into a plurality of regions, a layered and regional welding sequence of the welding line is worked out, and therefore heat input is controlled well, welding deformation is reduced, and the problems that the large-diameter connection pipe droops and the barrel deforms are solved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

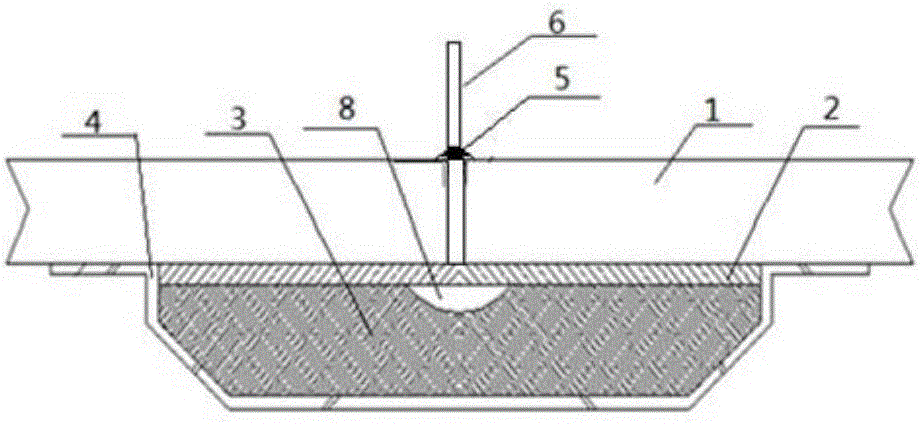

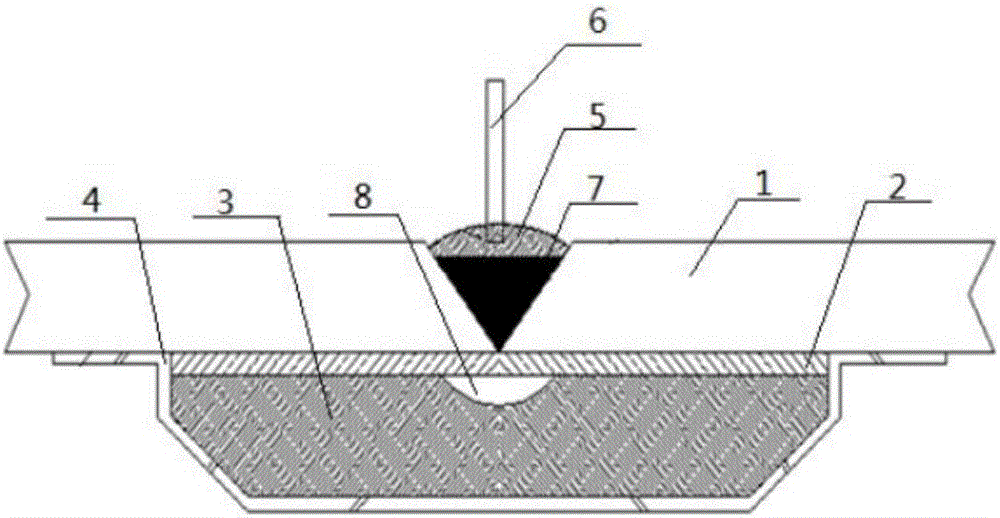

Double-sided forming welding process of FGB process one-sided submerged arc welding

ActiveCN106392274AImprove low temperature impact toughnessImprove welding efficiencyArc welding apparatusWelding/cutting media/materialsPower flowAlloy

The invention discloses a double-sided forming welding process of FGB process one-sided submerged arc welding. The process comprises the steps of: S1, butt-jointing ground two to-be welded steel plates to from a groove; S2, adhering a liner; and S3, when the groove is a V-shaped groove, filling alloy powder and then covering the groove with sintered flux and when the groove is an I-shaped groove, covering the groove with sintered flux, and pulling a welding wire for submerged-arc welding for automatic primary formed welding through a submerged arc welding machine for the I-shaped groove or the V-shaped groove covered by the sintered flux, wherein the welding parameters are as follows: the welding current is 400-1200A, the welding voltage is 25-45V and the welding speed is 10-80cm / min. By improving the composition ratio of raw materials of the sintered flux, the alloy powder and the ceramic liner, different welding modes are adopted due to different thicknesses of the welded steel plates; angular deformation is effectively avoided on the basis of improvement of the welding efficiency, and the process has the beneficial effects of simple field operation and wide application range.

Owner:武汉天高熔接股份有限公司

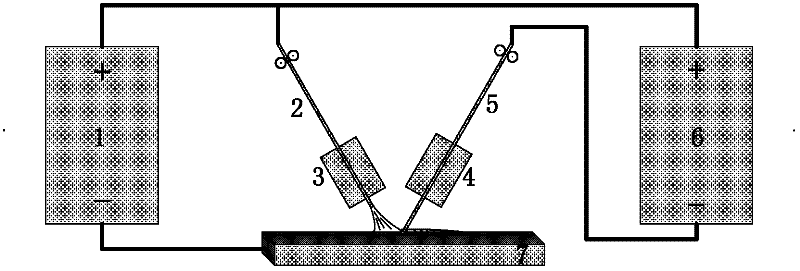

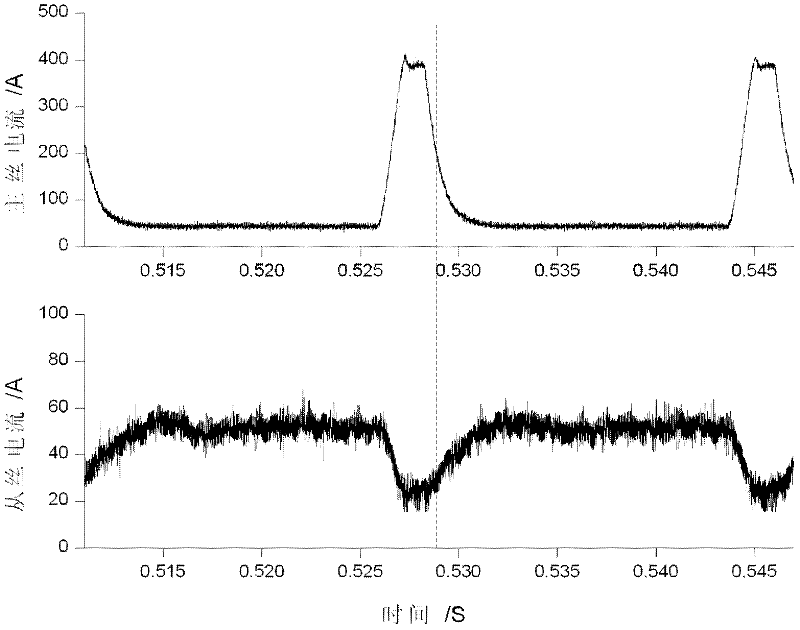

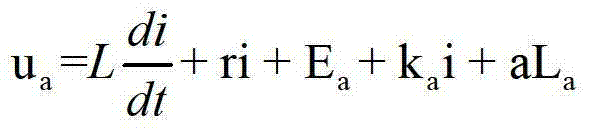

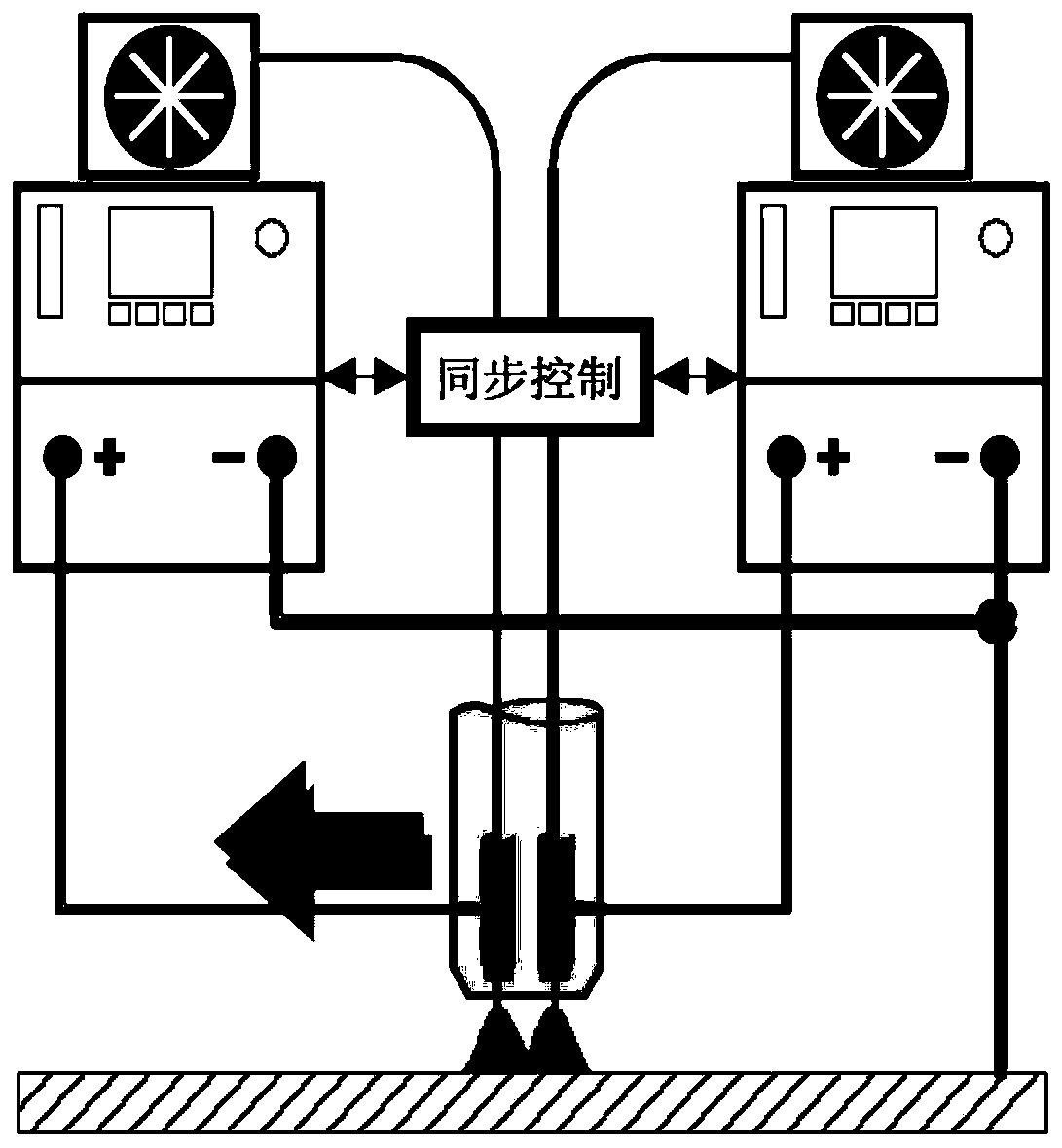

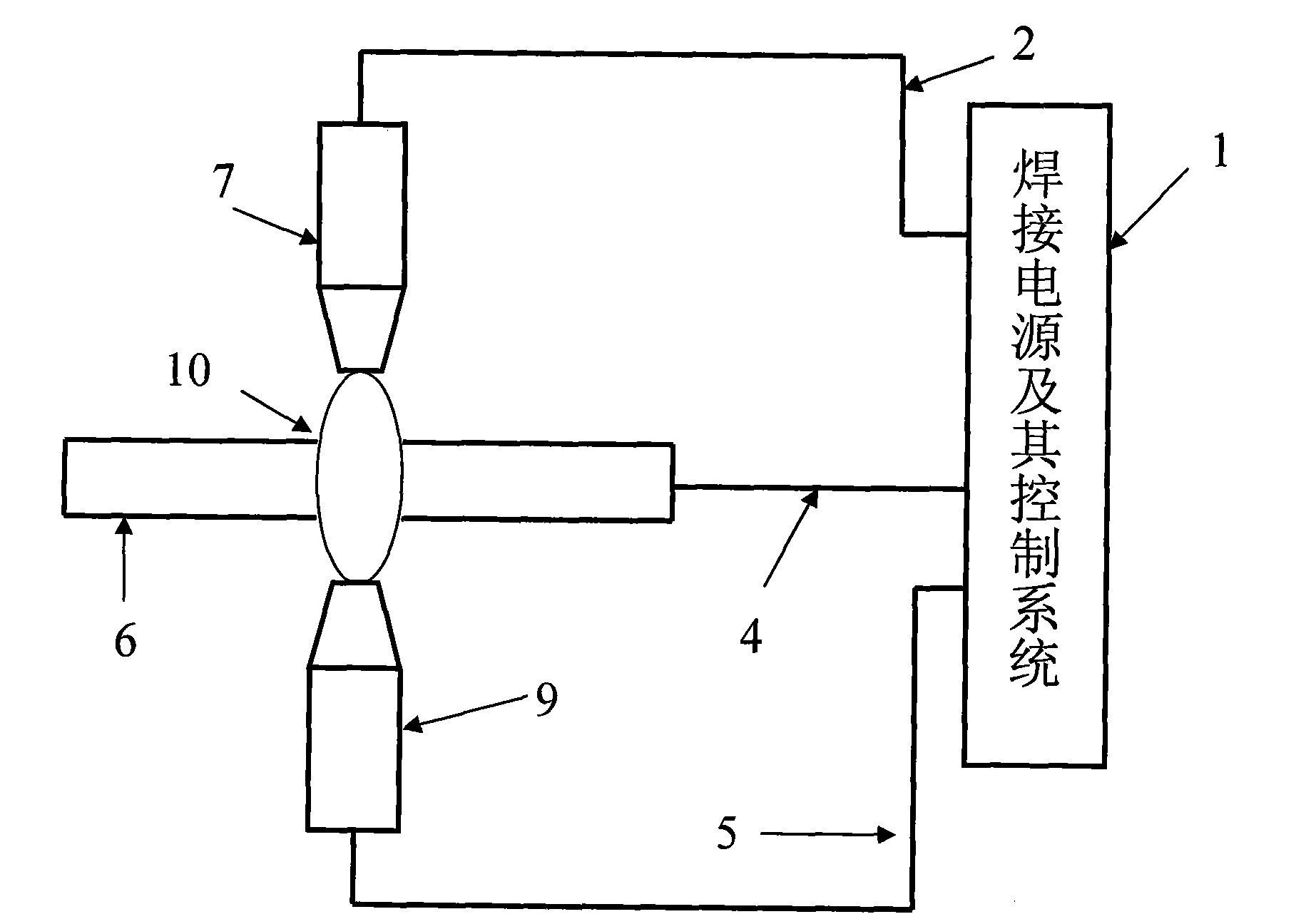

Double consumable electrode and single arc bypass coupled compound welding system and method

The invention discloses a double consumable electrode and single arc bypass coupled compound welding system and a welding method thereof. The compound welding system comprises a first welding machine, a second welding machine, a first welding wire and a second welding wire, wherein anodes of the first and second welding machines are connected with the first welding wire; the first welding wire and a workpiece form an arc; a cathode of the first welding machine is connected with the workpiece; the cathode of the second welding machine is connected with the second welding wire; and the second welding wire and the workpiece do not form the arc. By adopting the technical scheme provided by the invention, the melting efficiency of the welding wires is greatly promoted, high-efficient welding is realized, a stable welding process is realized, the heat input quantity of base metal is controlled, the possibility of occurring a welding defect is reduced, and the compound welding system is beneficial to acquiring excellent welding quality.

Owner:TIANJIN UNIV

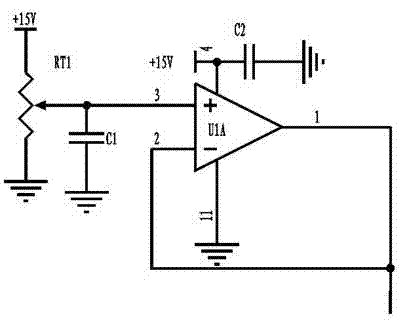

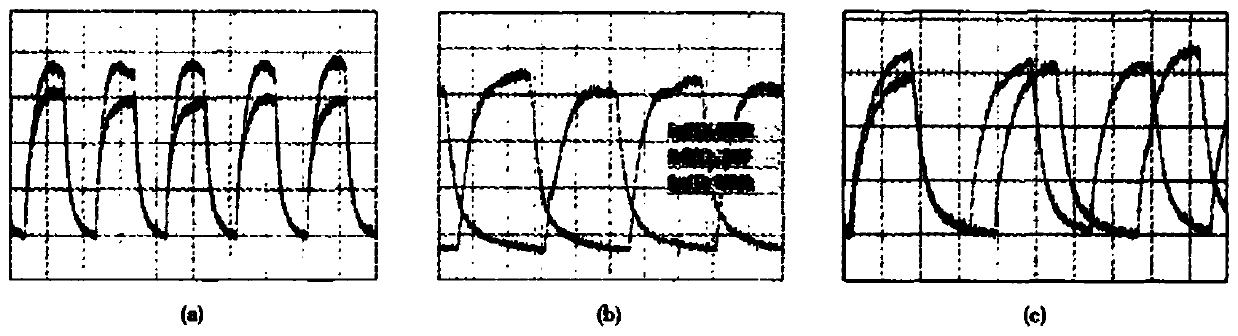

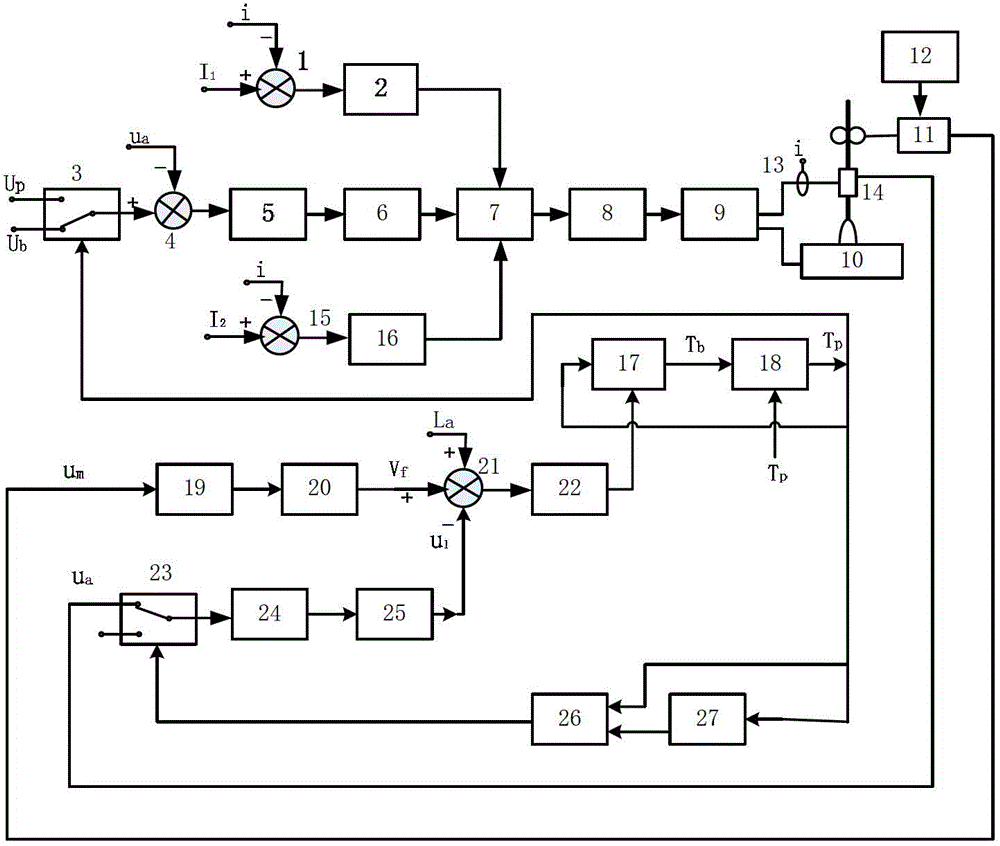

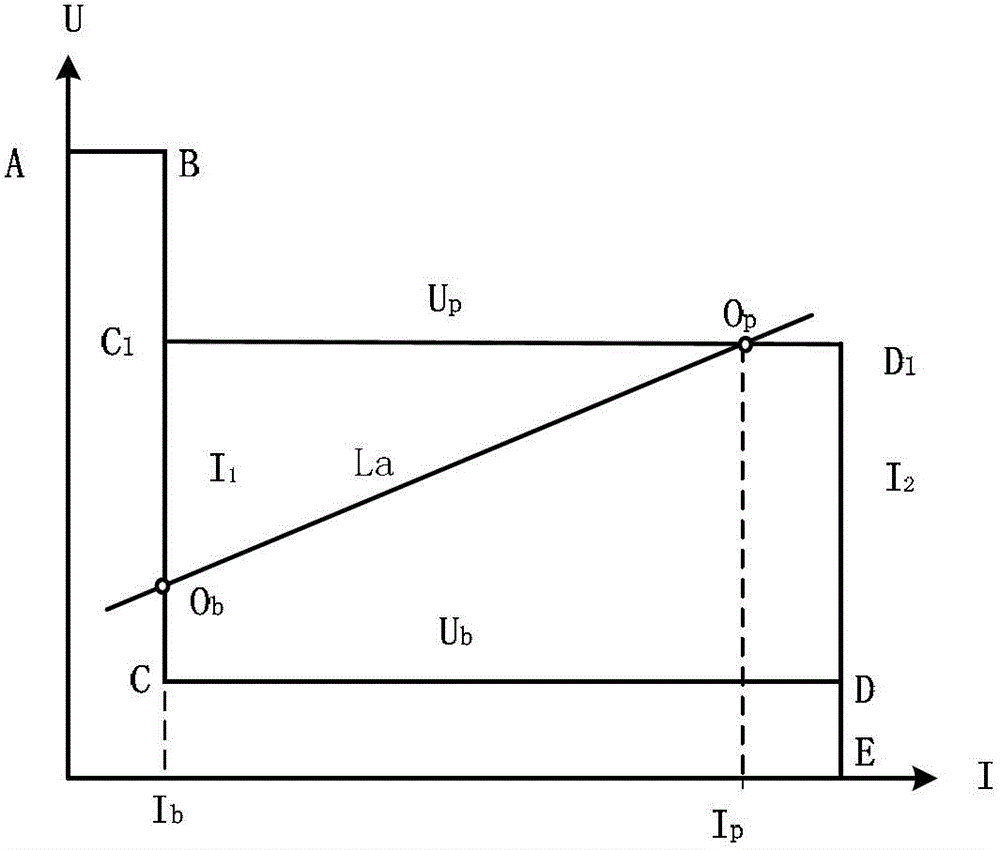

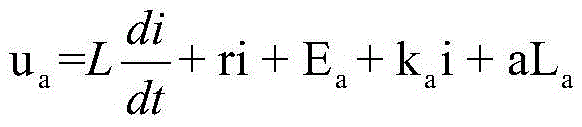

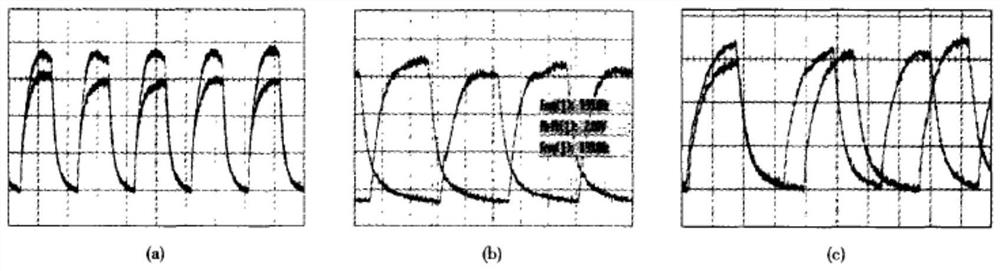

Control method and system for pulse MIG (Metal-Inert Gas) welding electric arc

ActiveCN103203530AThe arc length is constantConstant pulse widthArc welding apparatusNegative feedbackLoop closing

The invention discloses a control method and system for a pulse MIG (Metal-Inert Gas) welding electric arc. The method and the system disclosed by the invention has the advantages that the pilot-arc width or the pulse frequency of the pulse MIG electric arc is commonly controlled in a loop-opened feed-forward control mode of a welding-wire feeding speed signal and a loop-closed negative-feedback control mode of an electric arc length signal so as to maintain dynamic balance of the feeding speed and the fusion speed of welding wires and maintain constant electric arc length of the system and a constant jet transient mode of molten drops when welding current adjustment (by adjusting the wire-feeding speed), wire-feeding speed disturbance or arc length disturbance occurs. In addition, the invention also discloses a new process which adopts the method and the system and is used for controlling the fusion depth and the forming of welding seams by adopting a pulsating feeding mode for welding.

Owner:广州焊王电气科技有限公司

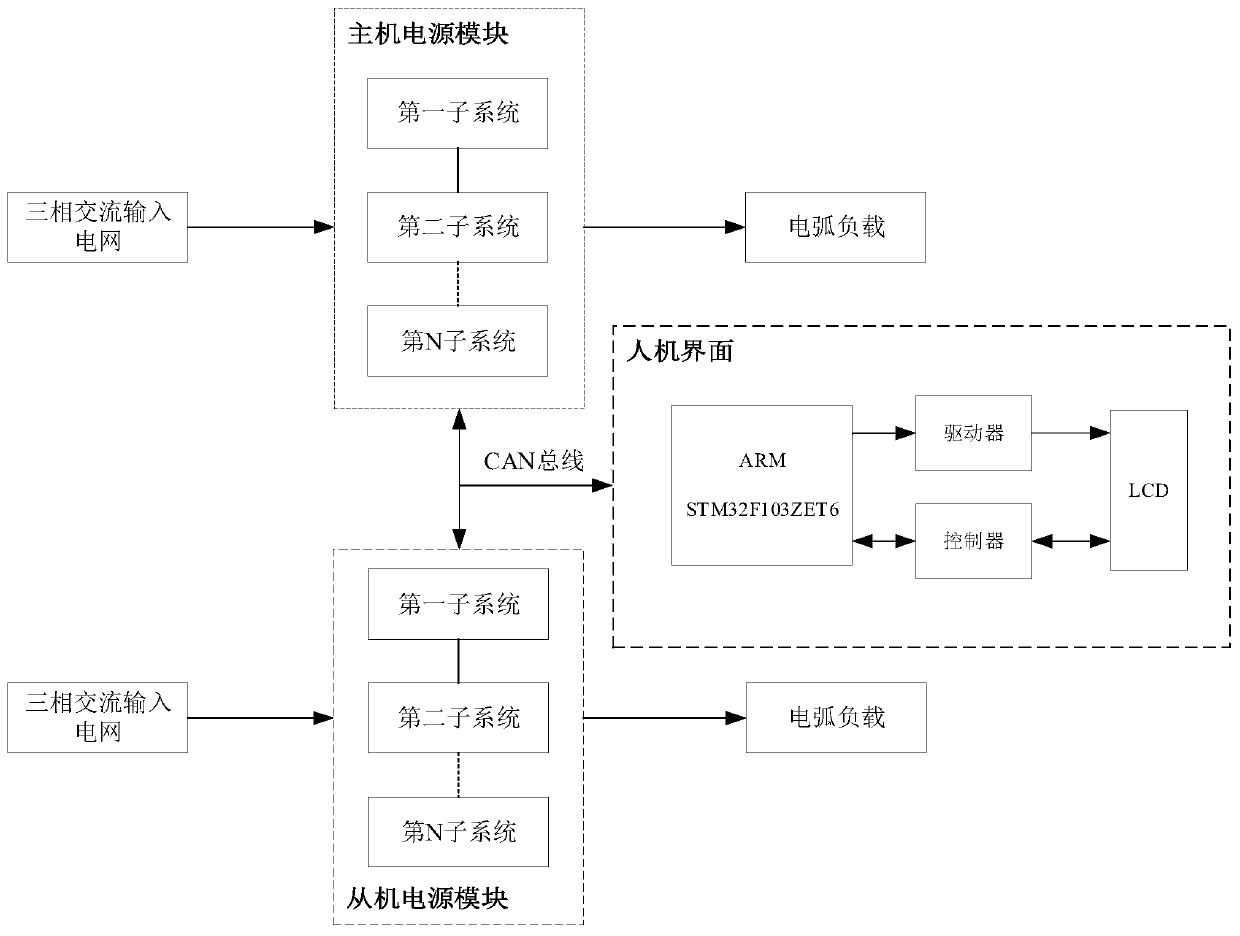

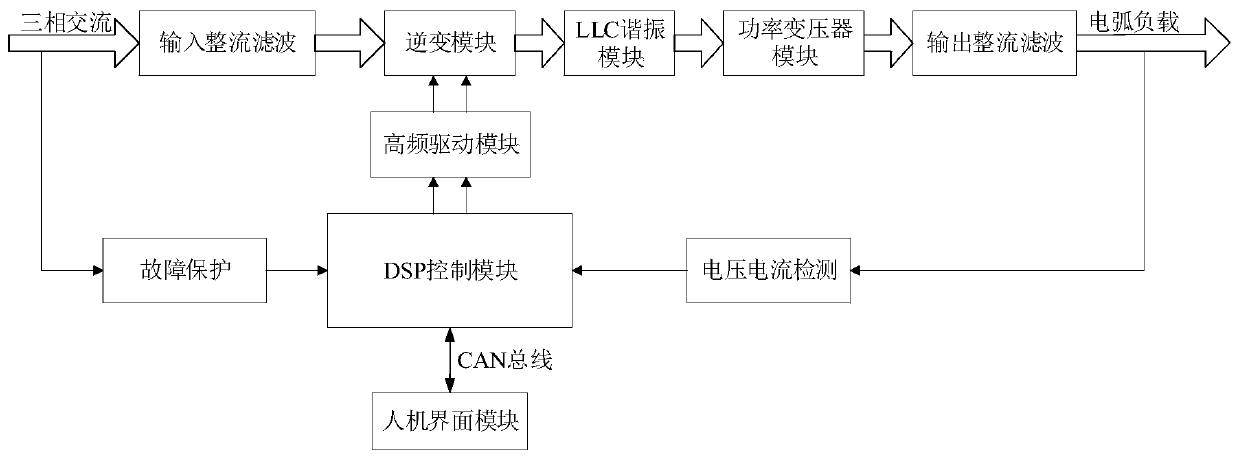

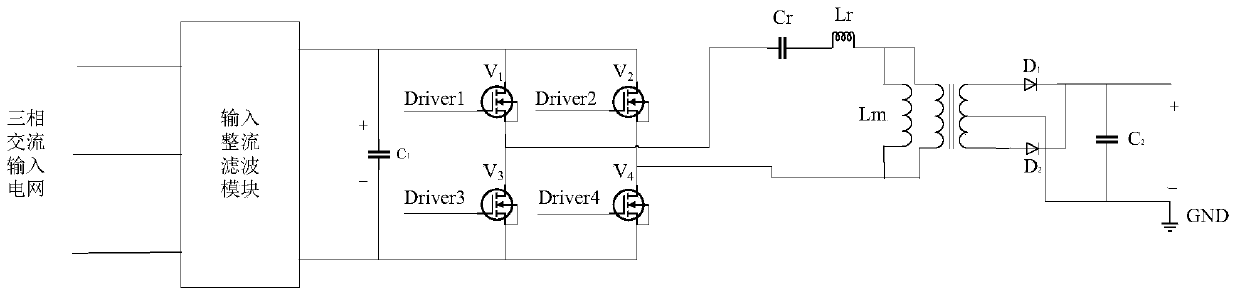

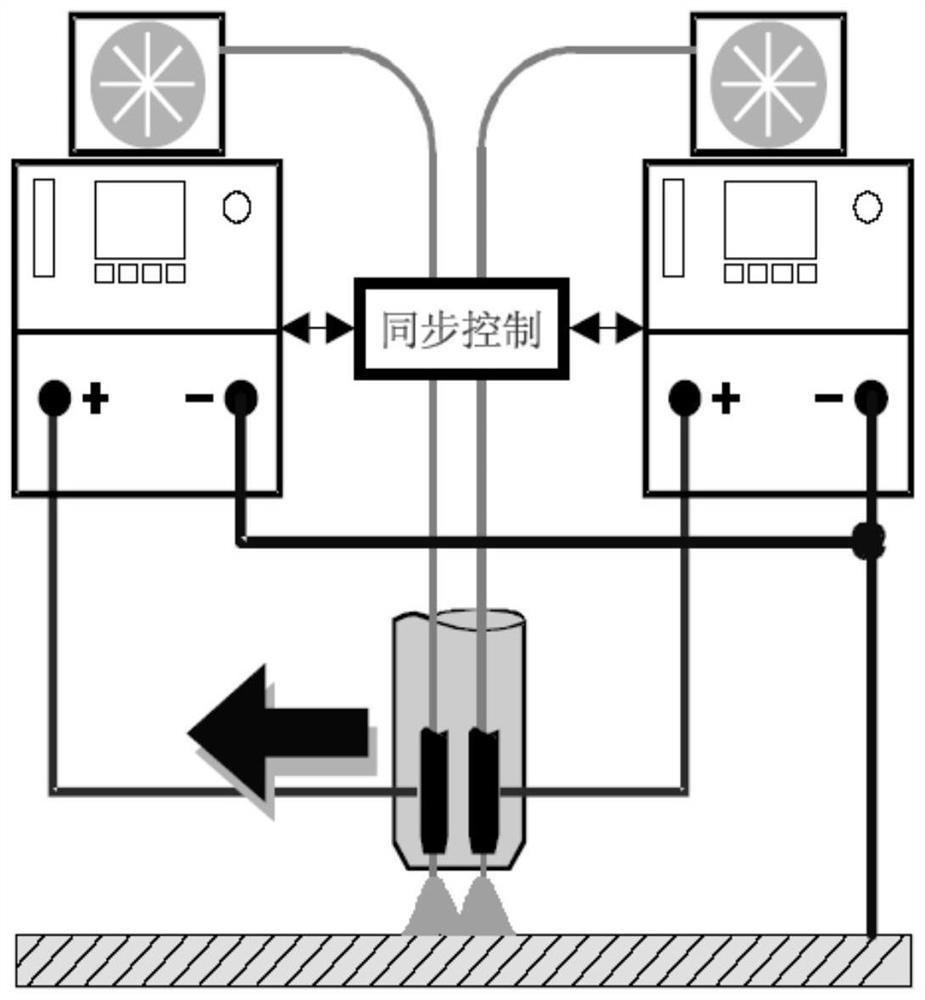

Double-wire pulse MIG welding power supply system based on LLC and control method

PendingCN110421237AEasy to moveSimple structureArc welding apparatusHuman–machine interfaceWelding power supply

The invention discloses a double-wire pulse MIG welding power supply system based on LLC and a control method. The system comprises a three-phase alternating current input power grid, a host power supply module, a slave power supply module, a human-computer interface module and an arc load; the arc load comprises a host arc load and a slave arc load; the main power supply module is connected to the three-phase alternating current input power grid and the host arc load; the slave power supply module is connected to the three-phase alternating current input power grid and the slave arc load; andthe human-computer interface module is connected to the host power supply module and the slave power supply module, and the host power supply module and the slave power supply module are same in structure and are formed by N subsystems in parallel. The control method is the double-wire pulse phase control comprising synchronous phase, alternating phase and independent phase. According to the system, the advantages of being high in cladding efficiency of double-wire pulse MIG welding and high in electric energy conversion efficiency of a LLC resonant converter are combined, so that any switching of the output of three-phase pulse waveform is realized.

Owner:SOUTH CHINA UNIV OF TECH

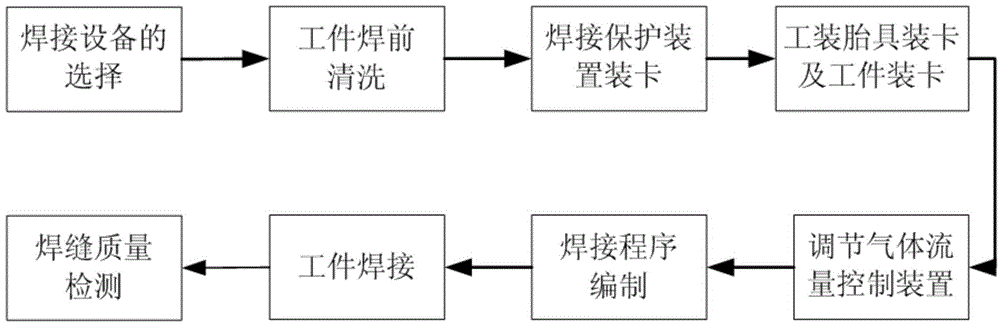

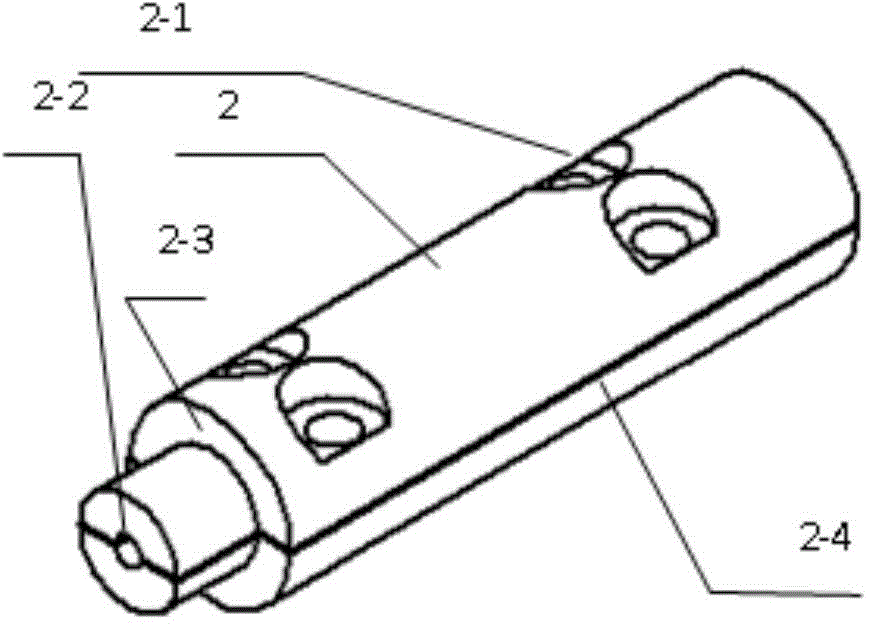

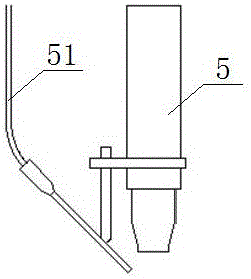

Installing and clamping tool and method for conducting capillary tube welding through installing and clamping tool

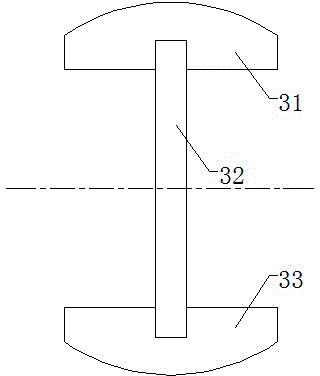

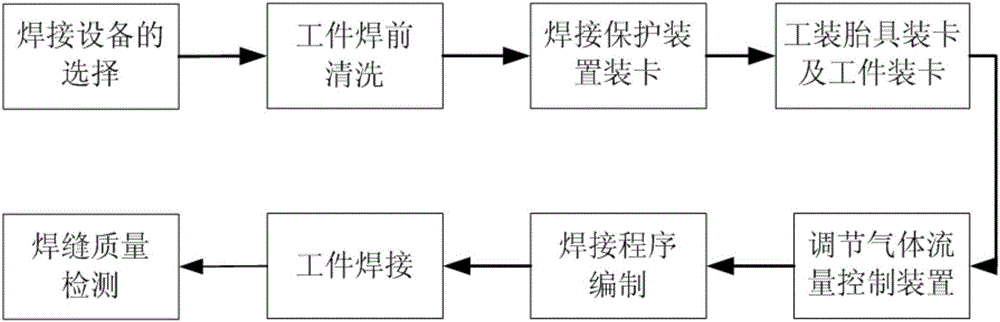

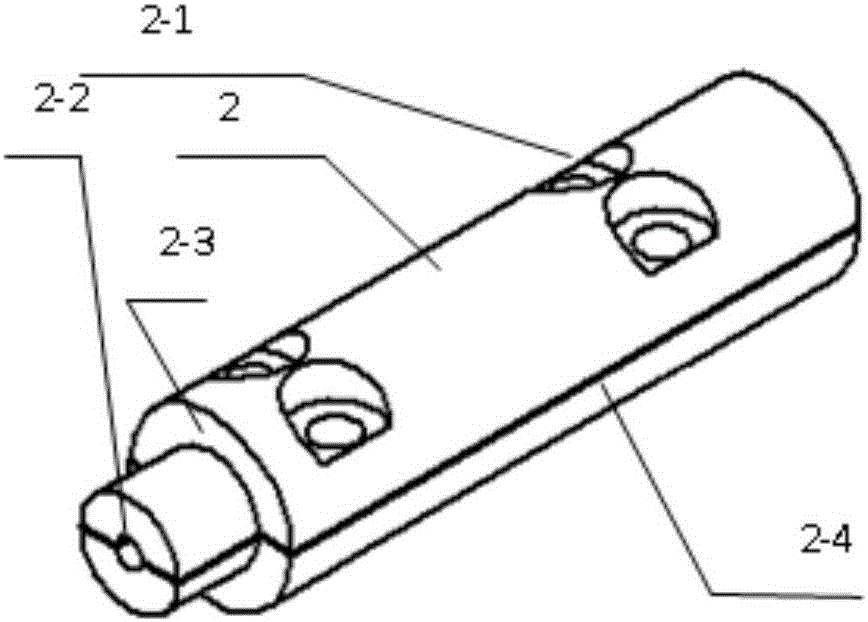

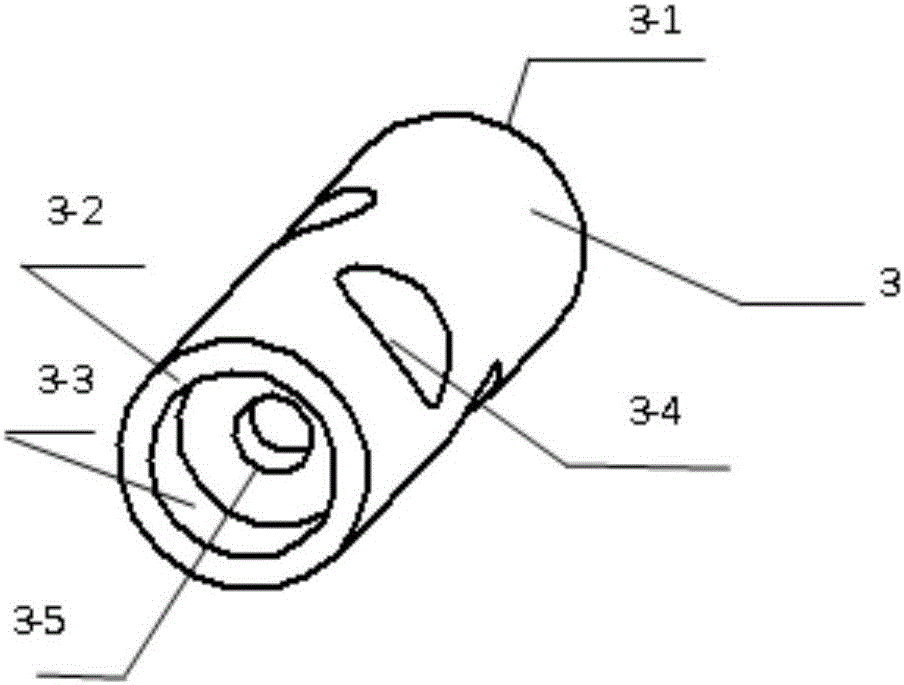

ActiveCN104972213ALow costGood welding operation environmentPipeline systemsMetal working apparatusEngineeringTungsten

The invention provides an installing and clamping tool and a method for conducting capillary tube welding through the installing and clamping tool. The installing and clamping tool is used for accurately installing and clamping a capillary tube. The method for conducting capillary tube welding through the installing and clamping tool includes the steps of selecting of argon tungsten-arc welding equipment, workpiece pre-welding washing, installing and clamping of a welding protective device, installing and clamping of a tool mold, installing and clamping of a workpiece, adjusting of a gas flow control device, programming of a welding procedure, workpiece welding, weld joint quality detecting and the like. In addition, in order to achieve welding, high-quality welding of the capillary tube is achieved through the gas flow control device and the welding protective device in the welding process, and wide application prospects are achieved in the field of capillary tube welding.

Owner:BEIJING INST OF CONTROL ENG

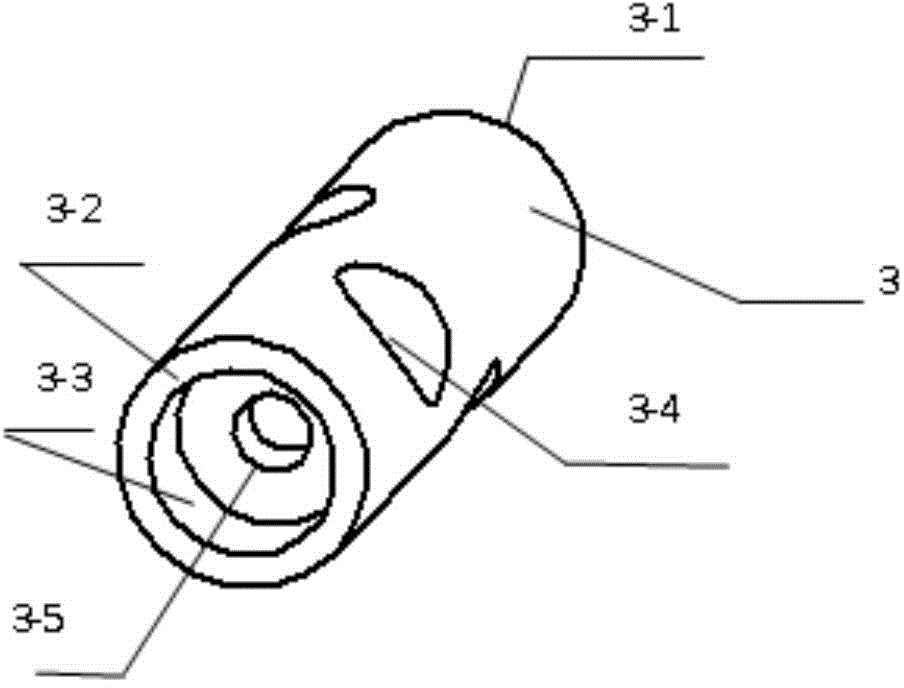

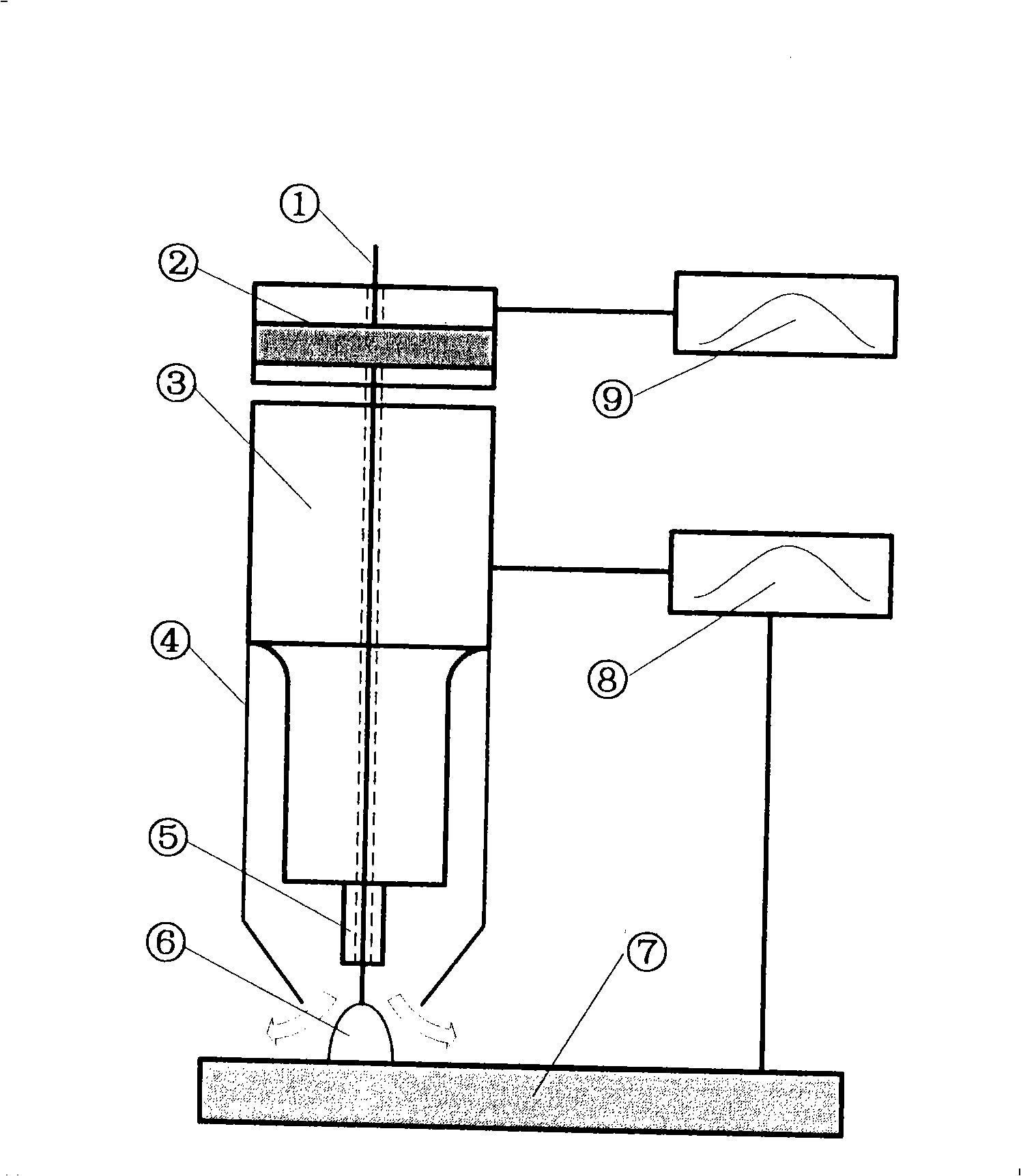

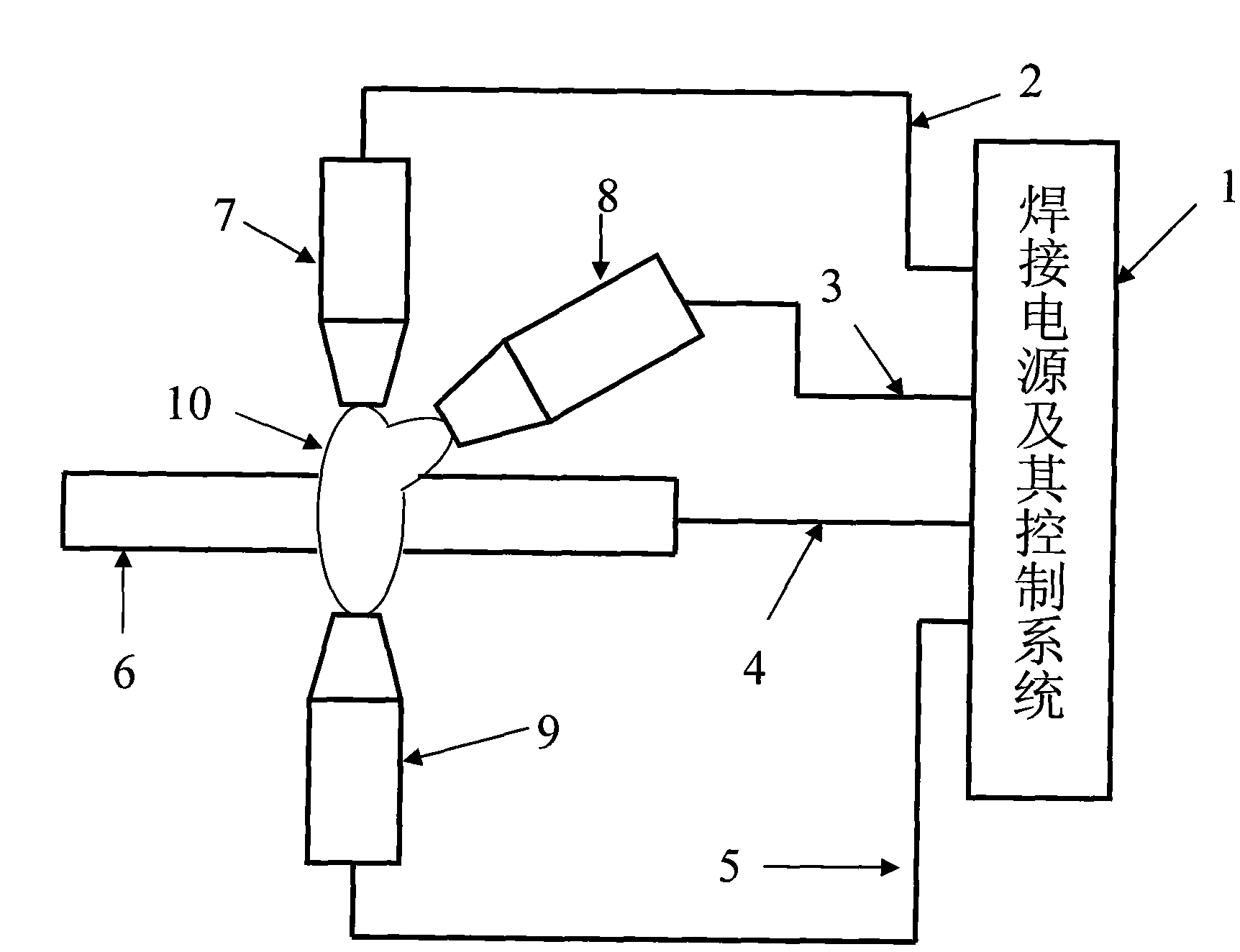

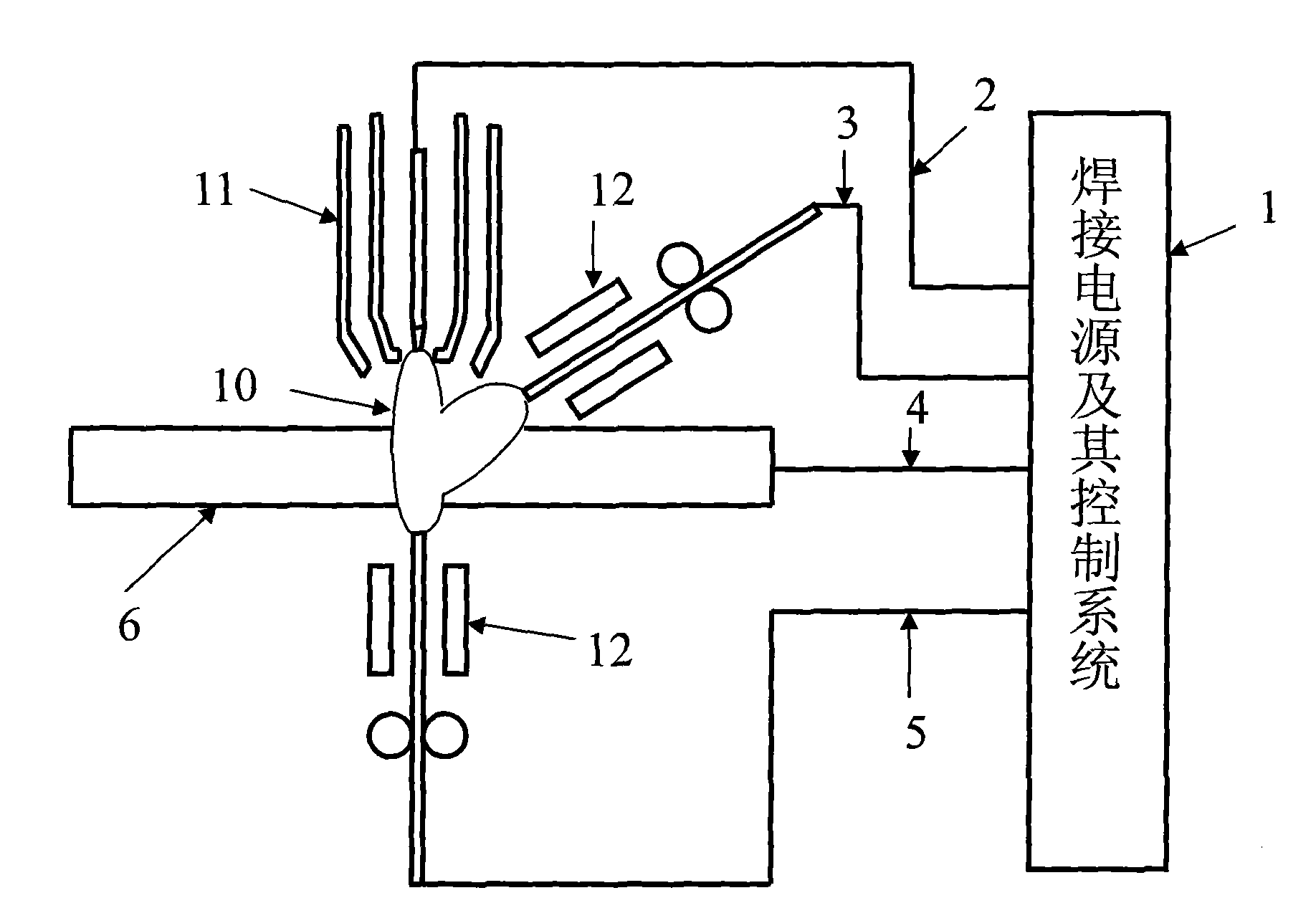

Electric arc welding method and device using additional acoustic pressure mode

InactiveCN101269437AWeld firmlyIncrease weld penetrationWelding accessoriesAcoustic energyEngineering

The invention relates to an arc welding method adopting an external sound pressure mode and a device, and the arc welding method aims to provide a gas shielded welding device of a complex method which can realize stable process, high welding formation quality and greatly improved welding efficiency. The device consists of an acoustic energy transducer (2), an acoustic amplitude-change rod (3), a protective gas injecting nozzle (4), a welding electrode clamp (5), an acoustic generation source (9) and a welding source (8). Under the non-melt electrode mode, the arc welding method has the advantages of stable welding process, improved weld penetration of a single-pass weld and high welding formation quality, as well as realization of high effective welding under the common non-melt electrode welding environment. When being used under the melt electrode mode, the arc welding method has the advantages of greatly improved welding efficiency, effective control of welding heat input quantity, changed weld penetration due to the changed acoustic frequency, the protective gas injecting nozzle, the welding height and other parameters, and effective control of solidification and crystalline state of the molten metal.

Owner:HARBIN INST OF TECH

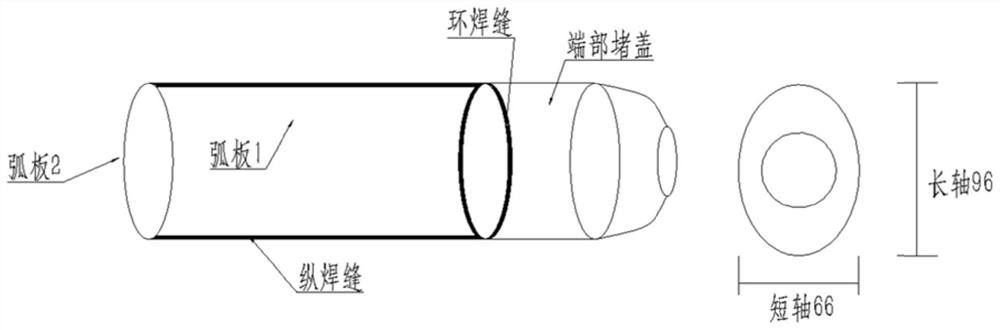

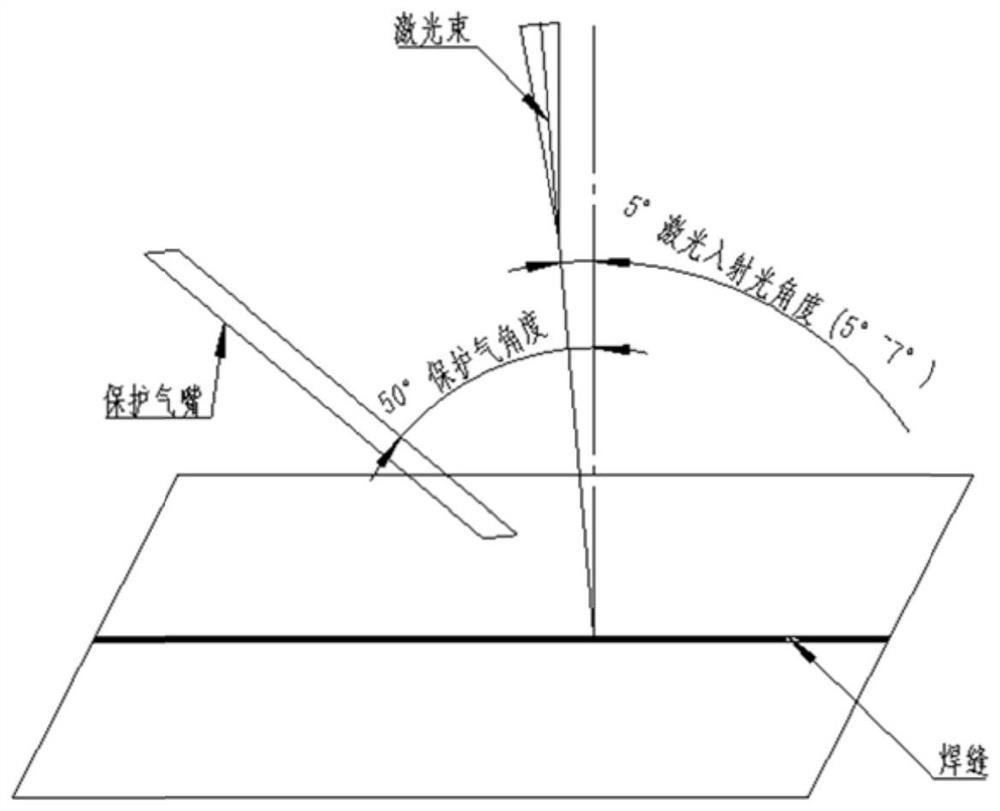

Laser pulse welding method for thin-wall aluminum alloy butt joint

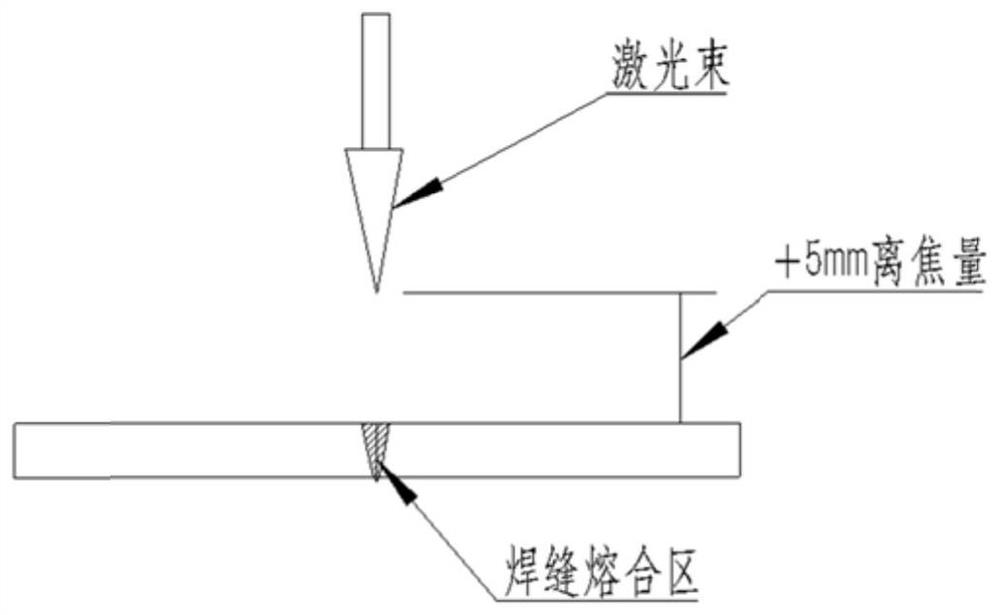

PendingCN112719587APenetration fluctuates littleControl heat inputLaser beam welding apparatusButt weldingShielding gas

The invention provides a laser pulse welding method for a thin-wall aluminum alloy butt joint. The laser pulse welding method includes the steps that step 1, 5A06 aluminum alloy parts are subjected to acid pickling and oil stain removal; step 2, to-be-welded parts of the parts which are processed to reach the size precision is cleaned; step 3, the to-be-welded parts are assembled together in a butt joint mode through a positioning clamp, and the to-be-welded parts are clamped to a rotating device of a laser welding machine; step 4, a cavity is filled with back protection gas, and gas protection is conducted on the back face of a weld joint; step 5, a laser angle and a shielding gas direction and flow are adjusted, laser pulse welding process parameters are set, and a weld joint track is determined for laser welding; and step 6, after a tool is disassembled, the forming quality of the front and back surfaces of the weld joint is checked, and a surface oxide layer of the weld joint is polished. According to the laser pulse welding method for the thin-wall aluminum alloy butt joint, the butt welding of the thin-wall aluminum alloy can be achieved under appropriate technological parameters, a large heat affected zone and air holes generated during laser welding are avoided, the strength of the obtained butt welding joint is high, and the cavity has good pressure resistance.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Arc welding/brazing process for low-heat input copper joining

InactiveUS20160218603A1Reduce heat damageControl heat inputWindingsArc welding apparatusPower flowElectrical polarity

An arc welding / brazing process is disclosed that is useful to join together a first copper piece and a second copper piece without damaging more heat-sensitive materials that may be located nearby is disclosed. The arc welding / brazing process includes using a non-consumable electrode wire, which electrically communicates with a weld control in a straight polarity orientation, to strike an arc across a gap established between a leading tip end of the electrode wire and the first copper piece. The current that flows through the arc when the arc is established heats the first copper piece such that the first copper piece becomes joined to a second copper piece. The joint between the first copper piece and the second copper piece may be an autogenous weld joint or a braze joint.

Owner:GM GLOBAL TECH OPERATIONS LLC

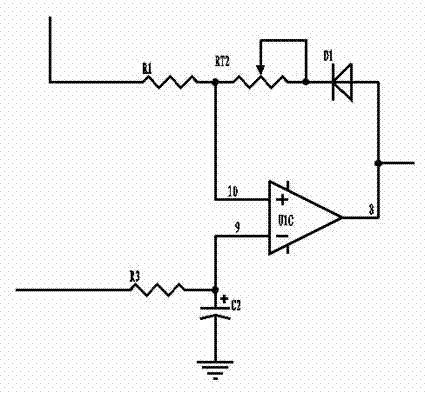

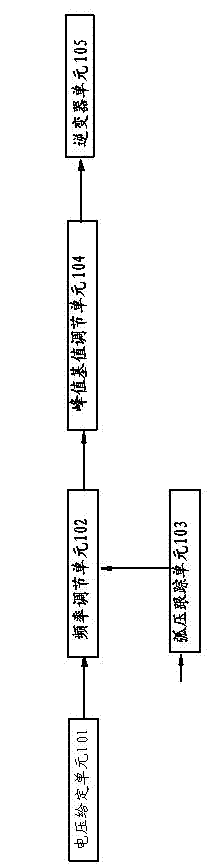

Arc voltage track pulse submerged-arc welding control method, control circuit and welding machine

ActiveCN102773588AEliminate poor fusionImprove weld qualityArc welding apparatusSubmerged arc weldingPower inverter

The invention relates to an arc voltage track pulse submerged-arc welding control method, a control circuit and a welding machine. The arc voltage track pulse submerged-arc welding control method is as follows: a voltage is output by adopting an arc-pressing track mode, and the pulse current is controlled according to the change of the arc voltage. The control circuit comprises a voltage giving unit, a frequency adjusting unit, an arc voltage tracking unit, a peak basic value adjusting unit and an inverter unit, wherein the voltage giving unit and the arc voltage tracking unit are respectively connected with the frequency adjusting unit which is connected with the peak basic value adjusting unit and the inverted unit in sequence. According to the invention, the heat input quantity can be controlled effectively, the common defects of incomplete fusion of the root and the like during the welding of a first welding seam can be effectively, the welding quality and the welding efficiency are improved, furthermore, the control circuit is simple, the implementation cost is low, the manufacturing process is simple, and the performance is stable.

Owner:SHENZHEN RILAND IND

Welding and repairing method of heat-resisting steel casting

InactiveCN108856945AReduce carbon increase on siteImprove welding pass rateWelding/cutting auxillary devicesAuxillary welding devicesMartensiteSteel casting

The invention belongs to the technical field of heat-resisting steel welding, particularly relates to a repairing method of a high-chromium martensite heat-resisting steel casting, and provides a welding and repairing method of a novel heat-resisting steel casting. The method comprises the main steps of defect treatment before welding, welding preheating, welding, heating after welding, and heat treatment after welding. By the adoption of the welding and repairing method, generation of weld cracks is reduced, the yield of welding and repairing is increased, the number of times of welding is reduced, and the repairing cost is reduced substantially.

Owner:KOCEL STEEL

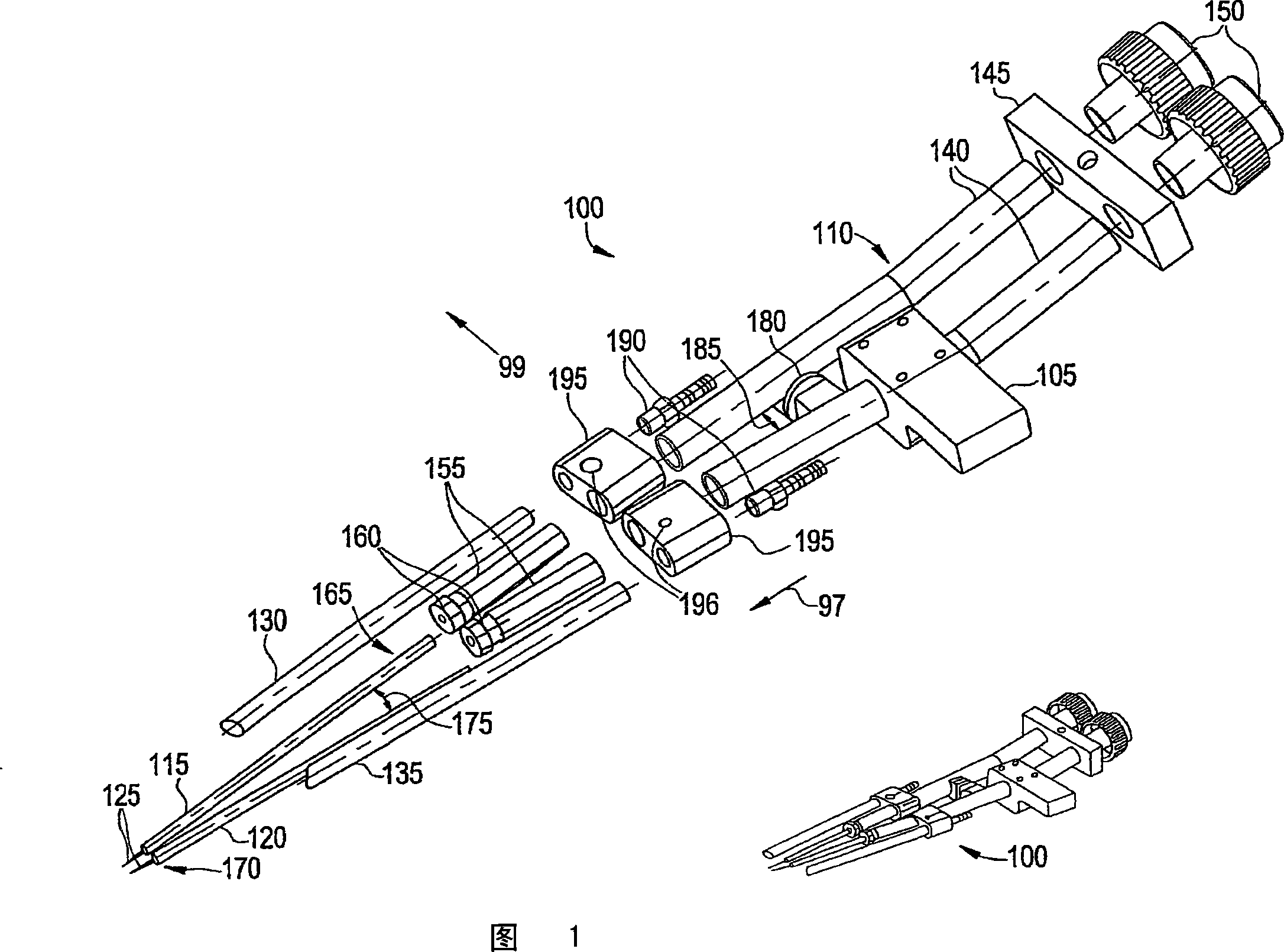

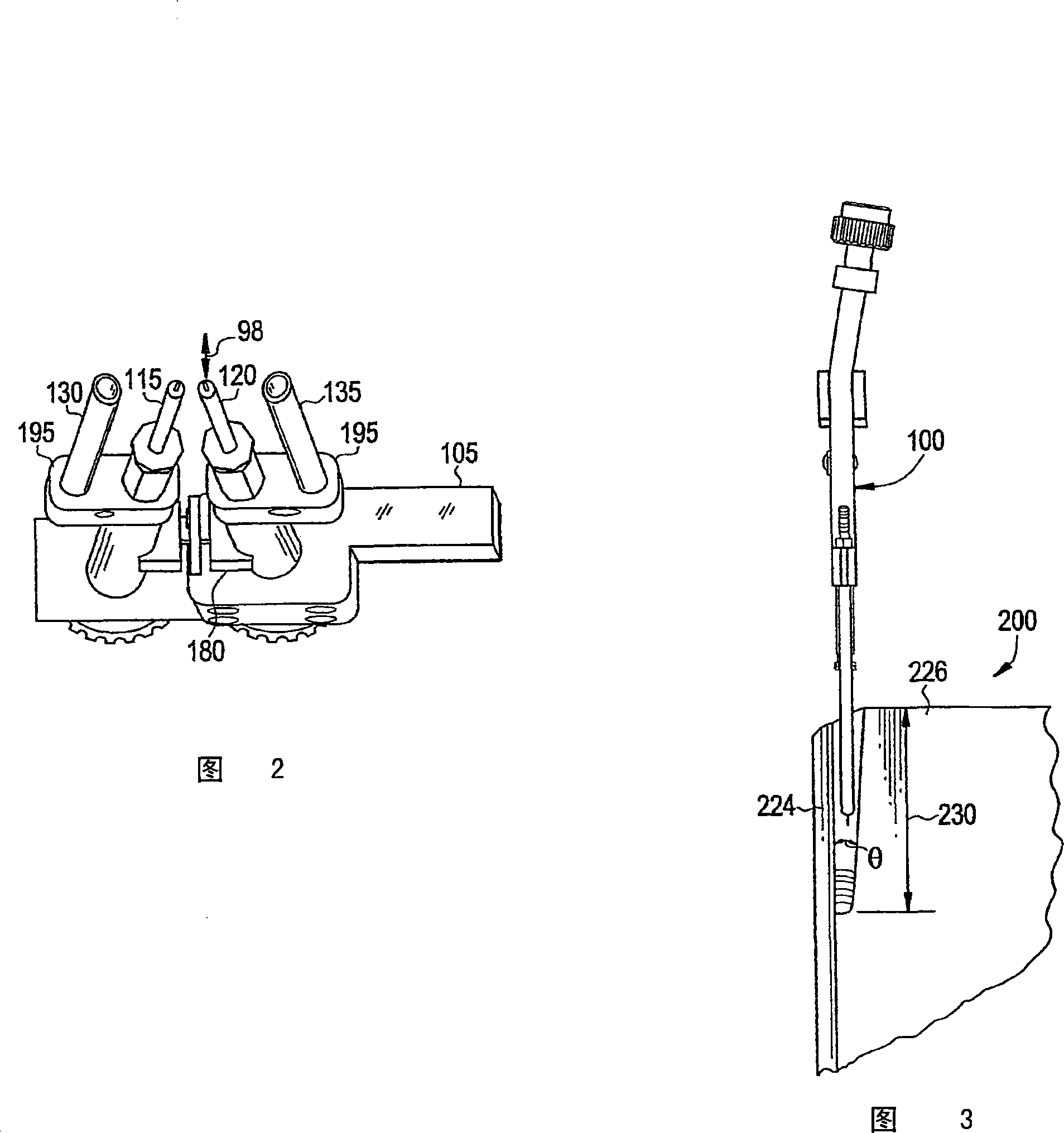

Apparatus for and method of deep groove welding for increasing welding speed

InactiveCN101219500AIncrease deposition rateReduced deformabilityElectrode accessoriesWelding accessoriesEngineeringGas supply

The present invention relates to equipment and methods for deep groove welding. Disclosed is a welding device. The welding device includes a welding torch body (110) having at least one core (140), a plurality of contact tips (115) (120) extending in a direction from the at least one core (140), and (115)(120) a plurality of gas supply tubes (130)(135) arranged, the plurality of gas supply tubes (130)(135) extending in a direction substantially similar to the plurality of contact tips (115)(120).

Owner:GENERAL ELECTRIC CO

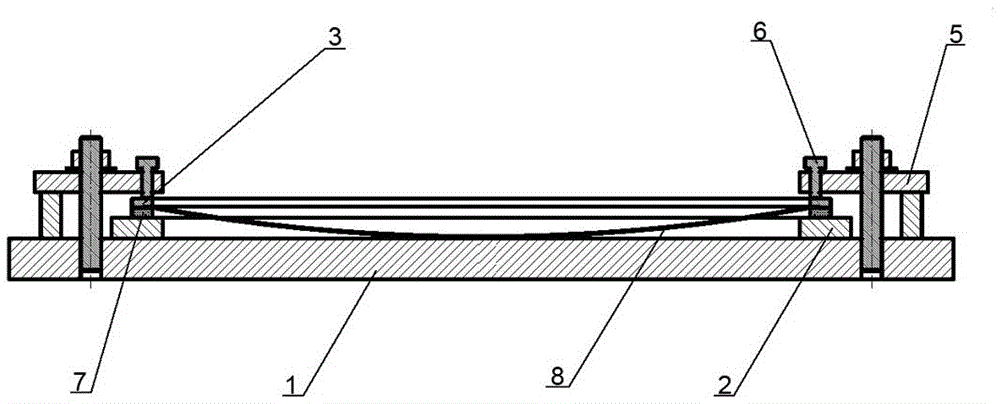

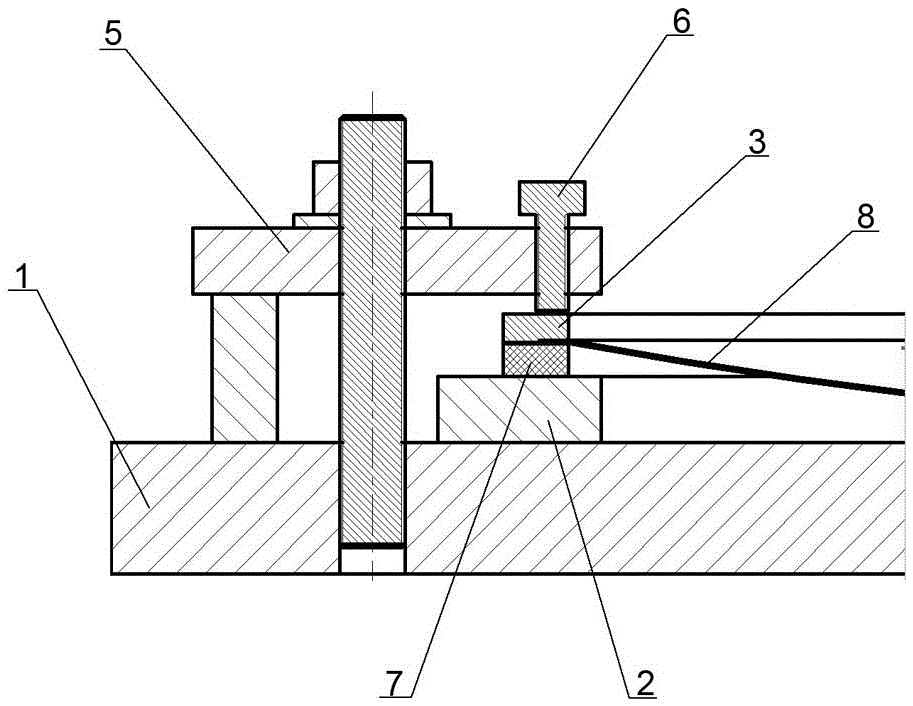

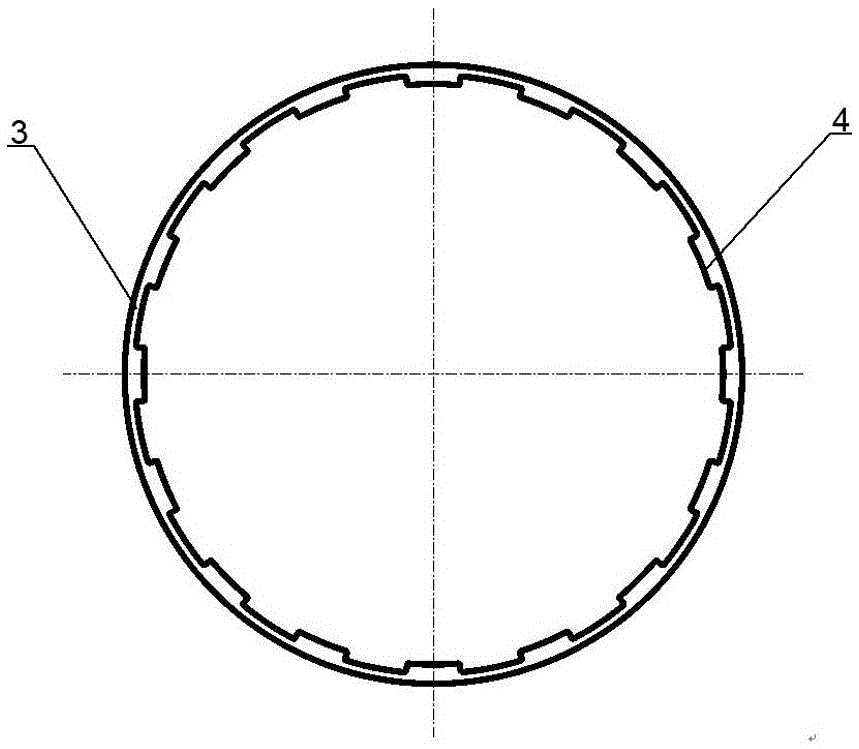

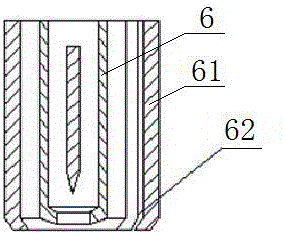

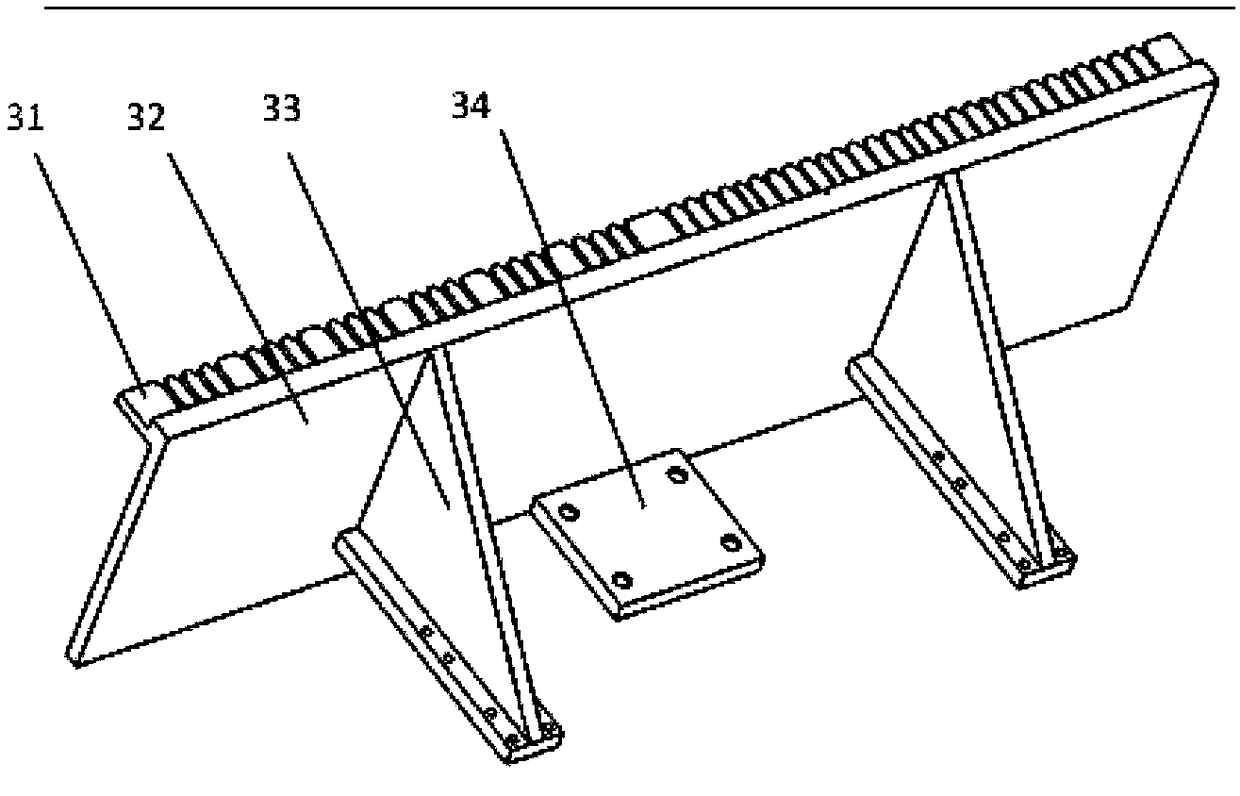

Titanium alloy mounting ring and molybdenum grid welding tool and electron beam welding technology

InactiveCN106541236AHigh strengthLow heat inputWelding/cutting auxillary devicesAuxillary welding devicesAviationTitanium alloy

The invention relates to a titanium alloy mounting ring and molybdenum grid welding tool and an electron beam welding technology. The welding tool comprises a base, an annular base plate, an upper pressing ring and a plurality of pressing sleeves. The annular base plate is fixed to the upper end face of the base. A plurality of pressing blocks used for clamping a molybdenum grid are distributed in the inner circumferential face of the upper pressing ring at intervals. The pressing sleeves which are the same as the pressing blocks in number and correspond to the pressing blocks in position are distributed in the portion, along the circumference of the upper pressing ring, of the base, and comprise brackets and pressing bolts. The brackets are fixedly arranged on the base, and the head ends of the pressing bolts can penetrate through screw holes in the brackets and tightly jack the pressing blocks correspondingly. According to the titanium alloy mounting ring and molybdenum grid welding tool and the electron beam welding technology, a titanium alloy mounting ring and the molybdenum grid are welded through the electron beam welding technique with concentrated energy density and small heat input, the connecting quality and size precision between the mounting ring and the molybdenum grid can be ensured, the bonding strength between the mounting ring and the molybdenum grid is improved, the service lives of the mounting ring and the molybdenum grid can be obviously prolonged, and the weight of a whole aviation component can be obviously reduced.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP +1

Arc welding/brazing process for low-heat input copper joining

InactiveUS10213878B2Reduce heat damageControl heat inputWindingsArc welding apparatusElectrical polarityHeat sensitive

Owner:GM GLOBAL TECH OPERATIONS LLC

Flat-overhead position hybrid welding technique and device for aluminum alloy spiral pipe

ActiveCN106001862AImprove automated welding efficiencyReduce distortionElectrode holder supportersWelding/soldering/cutting articlesThin slabThin sheet

The invention provides a flat-overhead position hybrid welding technique and device for an aluminum alloy spiral pipe and belongs to the technical field of automatic welding. A spiral pipe blank rolling device, two pairs of rotating rollers, a first TIG welding gun, a second TIG welding gun and a plasma welding gun are arranged on a machine frame of the device. Under the positioning of the two pairs of rotating rollers, an aluminum alloy sheet is rolled into a spiral pipe blank with the required diameter according to a certain thread line through the spiral pipe blank rolling device firstly, and then fixed-length point fixing of the spiral pipe is conducted through the first TIG welding gun; then welding in an internal overhead welding position by the plasma welding gun and welding in a flat welding position of the spiral pipe by the second TIG welding gun are conducted synchronously; and plasma welding and second TIG welding are conducted synchronously through pulses, the plasma welding gun sprays cold argon gas to cool weld joints when the pulses are ended, cooling is conducted while welding is conducted, and finally automatic welding of the aluminum alloy spiral pipe is achieved. By the adoption of the flat-overhead position hybrid welding technique and device for the aluminum alloy spiral pipe, the welding efficiency of the aluminum alloy spiral pipe is improved easily, welding deformation of the spiral pipe is reduced, and the quality of a welded product is guaranteed.

Owner:JIANGSU JINXIN ELECTRIC CO LTD

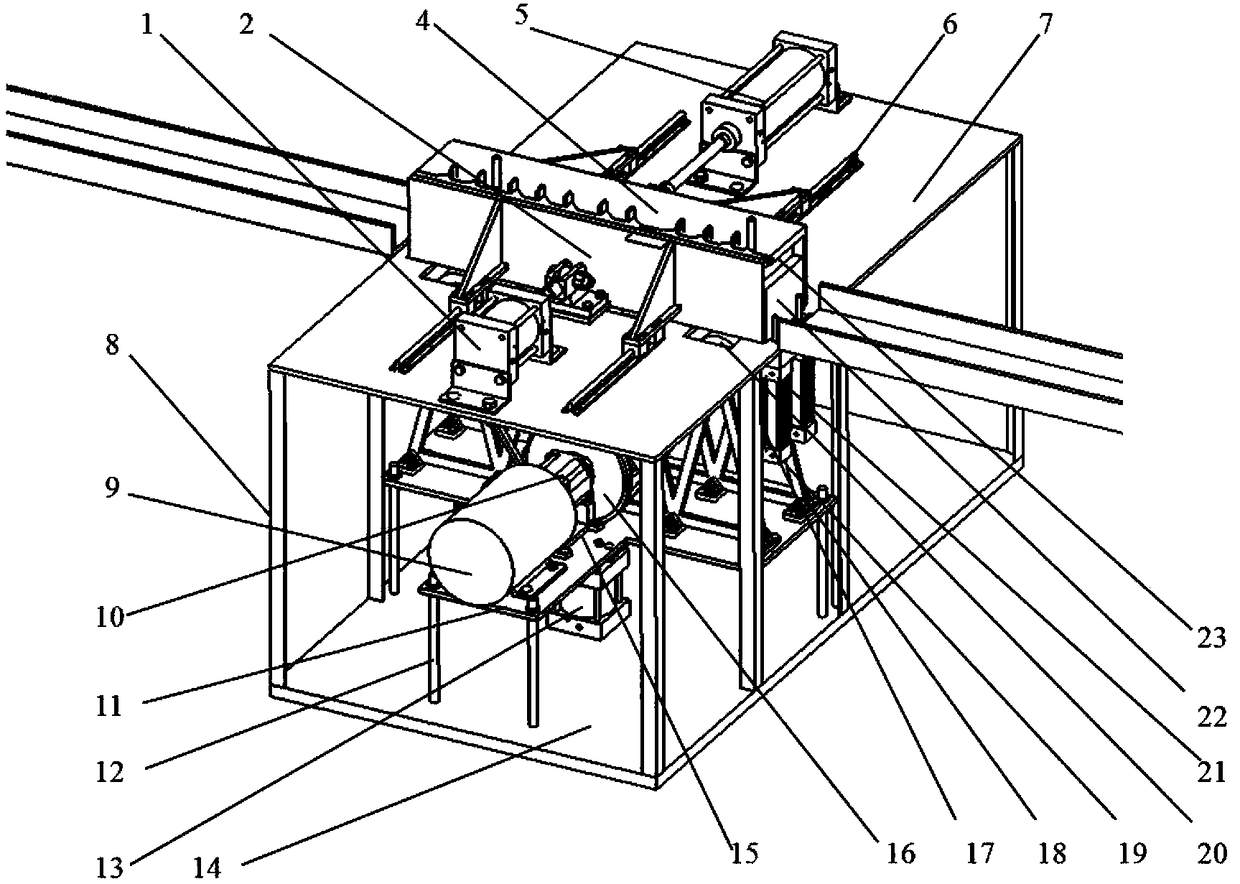

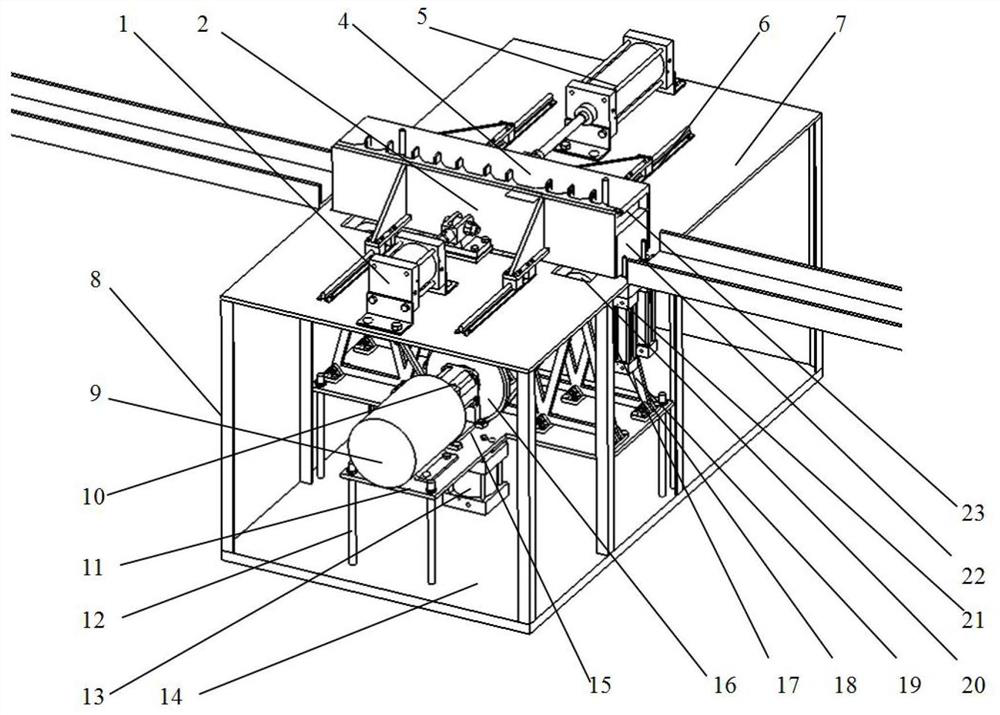

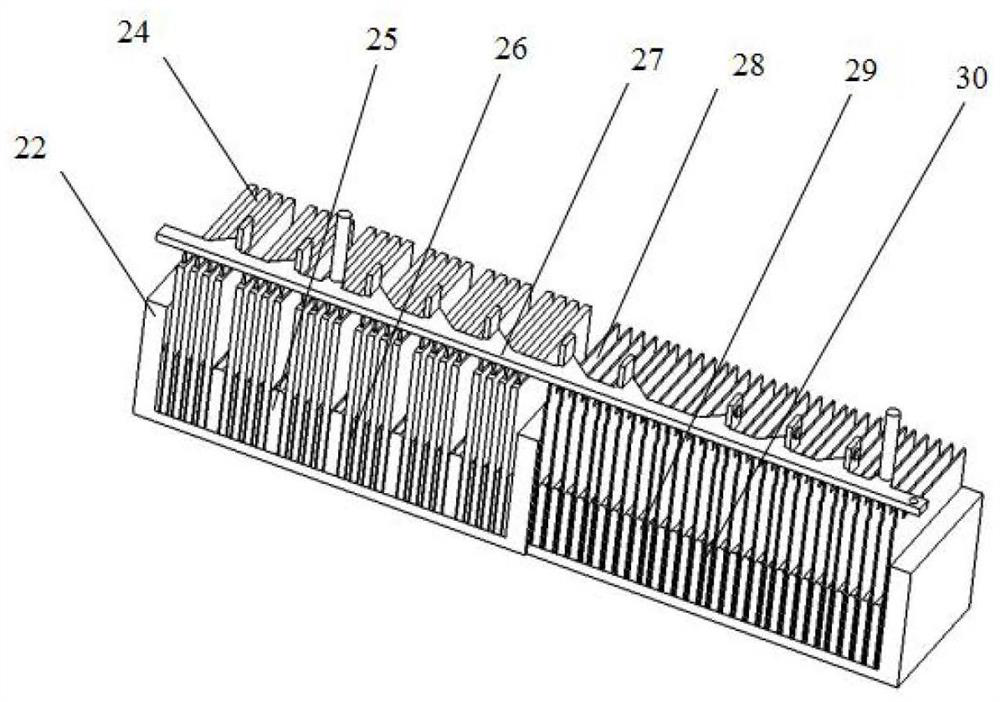

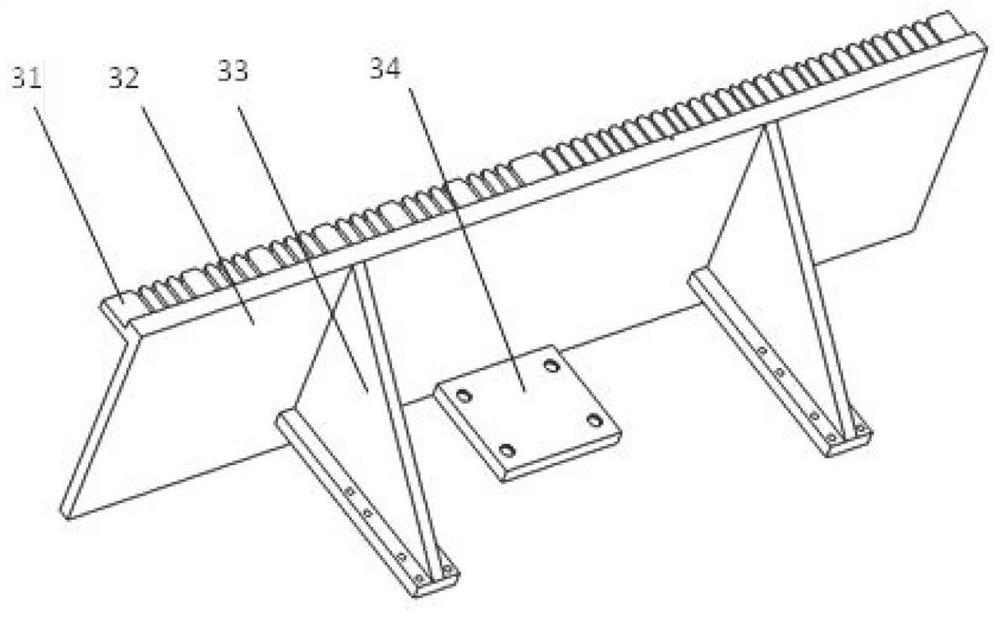

Welding equipment of lead-acid storage battery connecting end

ActiveCN108544078AWon't happenAvoid the problems caused by fusion weldingWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingElectricity

The invention discloses welding equipment of a lead-acid storage battery connecting end. The welding equipment comprises a friction welding machine, a plate electrode assembly box, a welding fixture and a lifting conveying device; the welding fixture is arranged at the upper part of a bracket; the plate electrode assembly box is arranged at the middle part of the welding fixture; the lifting conveying device is arranged in the bracket and is located at the lower part of the plate electrode assembly box; guide rails for conveying the plate electrode assembly box are arranged on the two sides ofthe welding fixture; and the friction welding machine is arranged at the exterior of the bracket. By adopting a friction stir welding method, heat input in the welding process is controlled well, welding can be conducted simply by heating a welding position to a plastic state, no lead steam is generated, the production environment is improved, the internal resistance of the storage battery is reduced, the service life of the storage battery is prolonged, and automatic production is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

Robot double-wire four-pulse novel welding method

ActiveCN109848519AControl heat inputImprove joint performanceWelding accessoriesEngineeringWelding power supply

The invention discloses a robot double-wire four-pulse novel welding method. The robot double-wire four-pulse novel welding method comprises a control part, a wire feeding part, two pulse welding power sources which communicate with each other and a welding gun. The method comprises the following steps that the wire feeding part is used for arranging two welding wires at the welding position in afront-and-back mode at a certain angle; the control part controls the two pulse welding power sources, so that the current provided by a frontward wire is larger than the current provided by a backward wire; and the control part further controls the wire feeding part to provide the same or different wire feeding speeds of the frontward wire and the backward wire, and the pulse welding power sources are controlled to use four independent pulses to provide welding current to the welding wires. The method is wide in control range, attractive in welding effect and high in quality.

Owner:BEIJING XINLI MACHINERY

Method of making an electrically-heated hose assembly

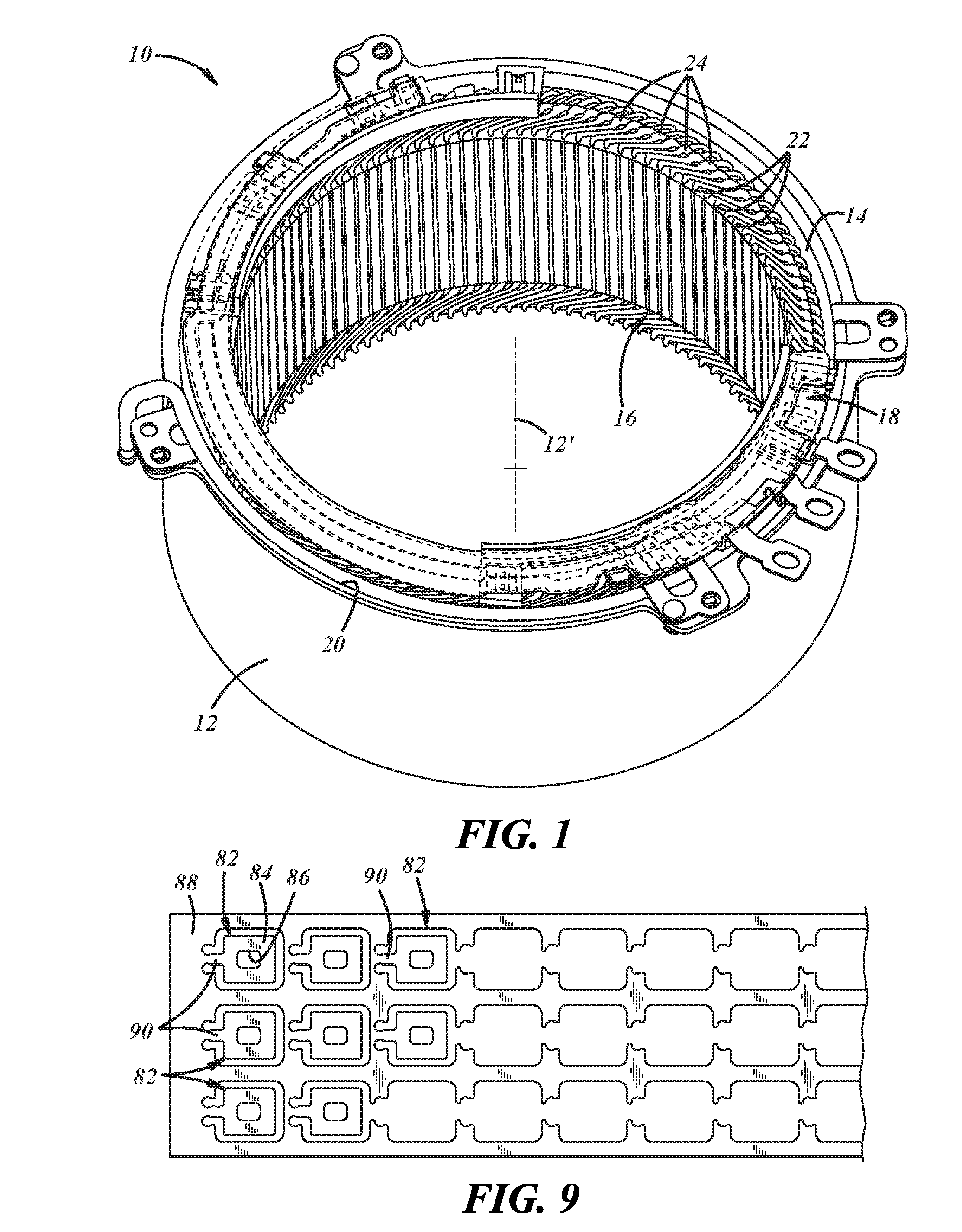

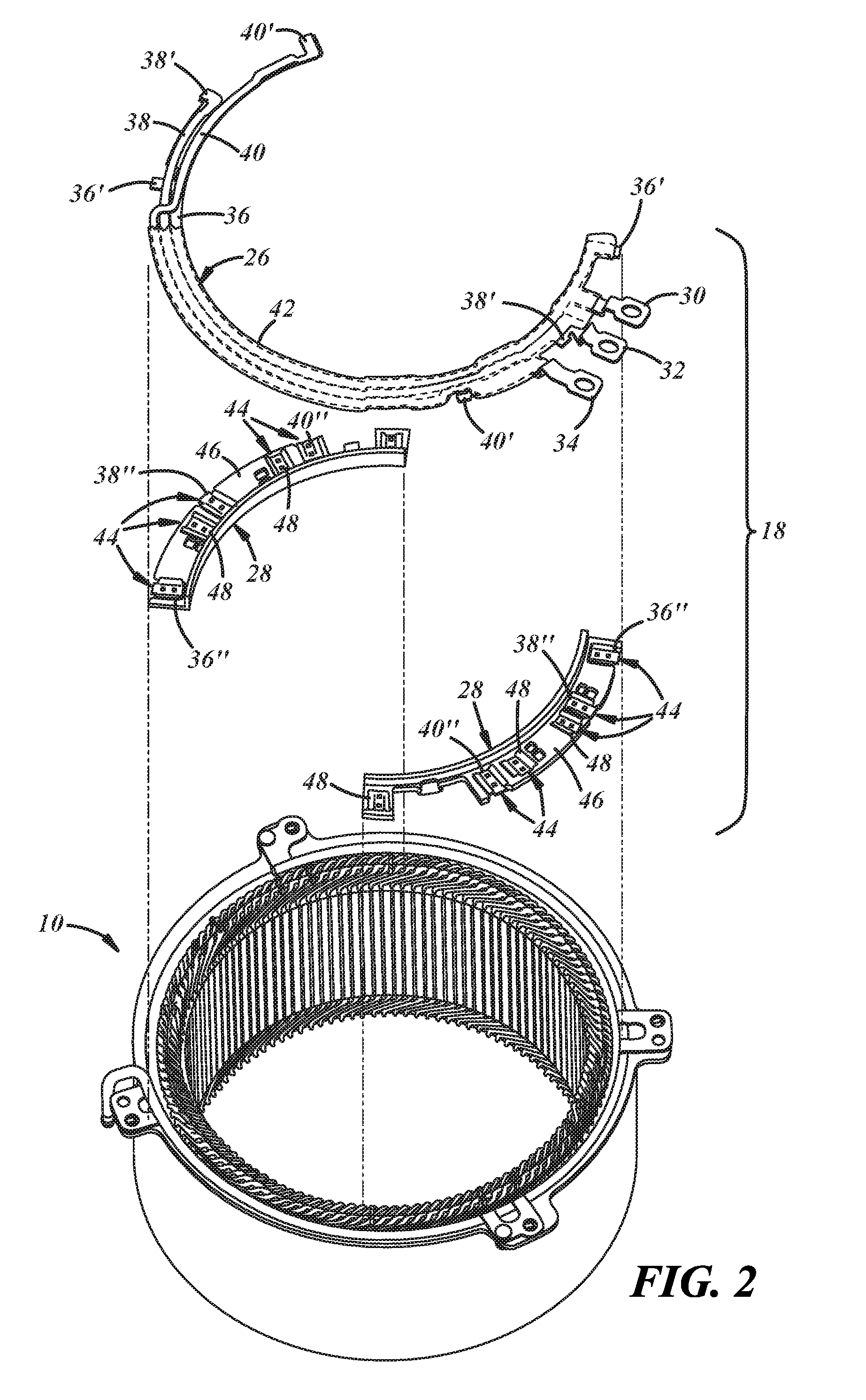

ActiveUS8819922B2Control heat inputReadily apparentEnvelope/housing resistor manufactureInternal combustion piston enginesSpiral woundEngineering

Electrically-heated hose assembly including a hose and a first and a second fitting. The hose is constructed as having a core tube, a pair of spiral wound wires surrounding the core, and a jacket surrounding the core tube. A first end of each of the fittings is within a corresponding end of the hose, with a second end of the fittings extending beyond the hose end. The wires are wound around at least a portion of the second fitting end of a corresponding one of the fittings.

Owner:PARKER INTANGIBLES LLC

Valve seat and valve body welding process

InactiveCN105364268AControl heat inputReduce toughnessWelding/cutting auxillary devicesArc welding apparatusHeat-affected zonePower flow

The invention relates to a valve seat and valve body welding process and specifically relates to a valve seat and valve body assembly welding process for a supercritical thermal power unit. The positive effect of multilayer welding is fully utilized; by utilizing multi-layer welding, the following layer has the effects of hydrogen removal and heat affected zone microstructure improvement on the previous layer. The method of relatively rapid welding of small welding current is used for controlling thermal input; thermal input of welding is strictly controlled; high-strength steel is relatively sensitive to thermal input of welding and excessive thermal input causes reduction of the toughness of a welding joint and reduces the anti-cracking performance. After-heat treatment is performed immediately after welding, so that the problem that cold cracks appear some time after welding is solved and the welding requirement is met. The welding process completely solves the problem of difficulty in welding of WB36 and F6a dissimilar steel, prevents post-welding cracking and can totally guarantee the welding quality.

Owner:QINGDAO BAIJIANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

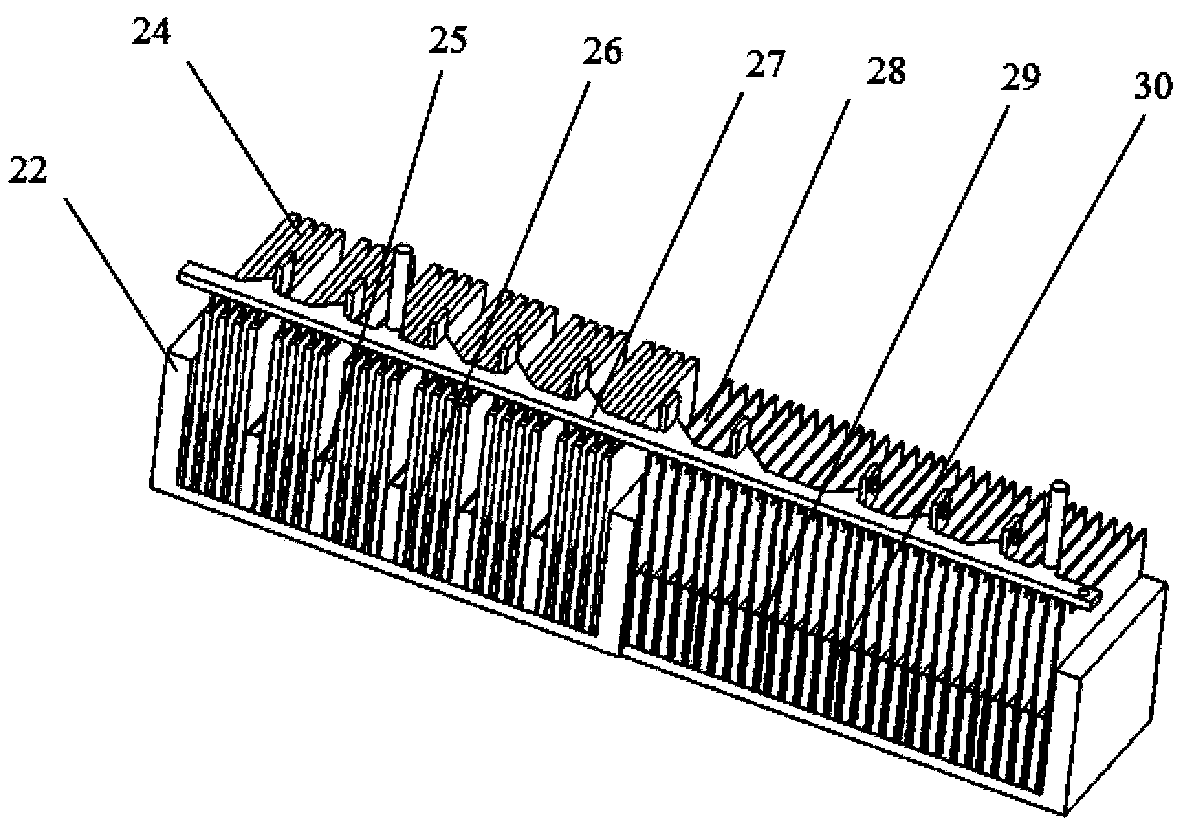

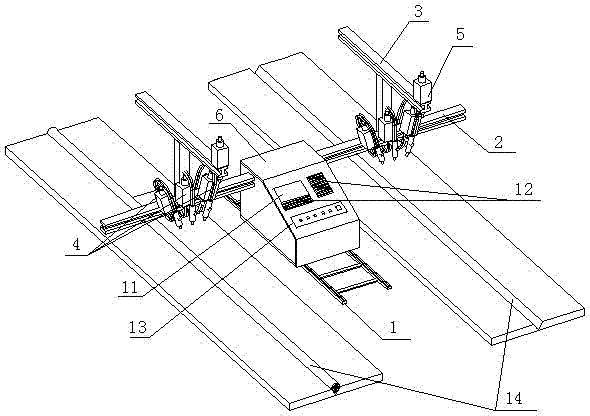

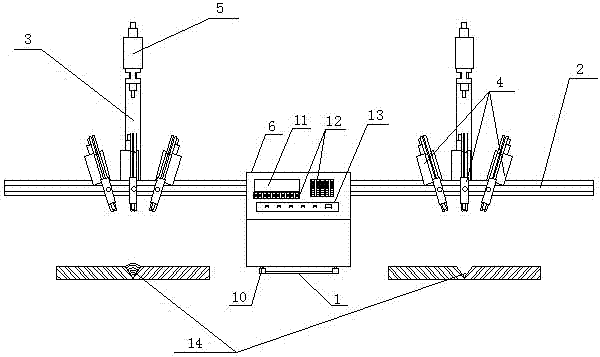

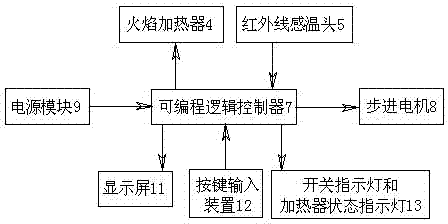

Heat treatment equipment for welding seam of numerical control steel weldment

ActiveCN103045842BGuaranteed mechanical propertiesEnsure safetyFurnace typesHeat treatment process controlNumerical controlProgrammable logic controller

The invention discloses heat treatment equipment for a welding seam of a numerical control steel weldment. The heat treatment equipment comprises a walking track, a controller glidingly arranged on the walking track and an adjusting beam connected onto the controller, wherein a heater and a temperature sensor which are aligned to the welding seam are arranged on the adjusting beam; and the heater and the temperature sensor are both connected with the controller. According to the heat treatment equipment, the temperature sensor is used for acquiring the instant temperature of a heating region and sending a temperature signal to a programmable logic controller, and the programmable logic controller is used for controlling a step motor to accurately control the walking speed of the controller so as to control heat input of the heater, enable the microcosmic crystalline phase structure of weld metal to realize an ideal phase change structure in an ideal temperature environment, guarantee the comprehensive mechanical performance of the weld metal, and effectively guarantee the safety performance of structure members.

Owner:ANHUI WEIHONG STEEL STRUCTURE GRP

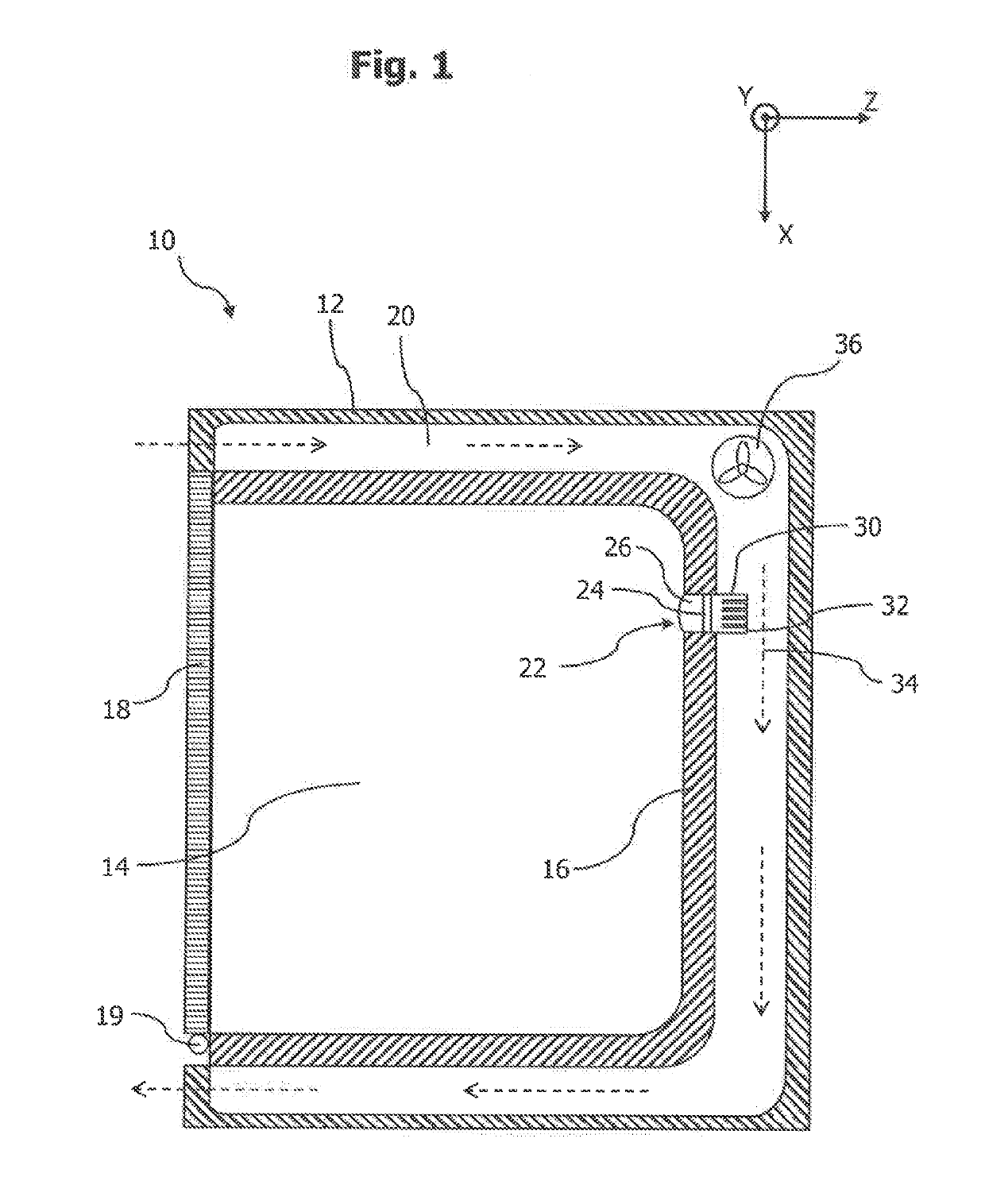

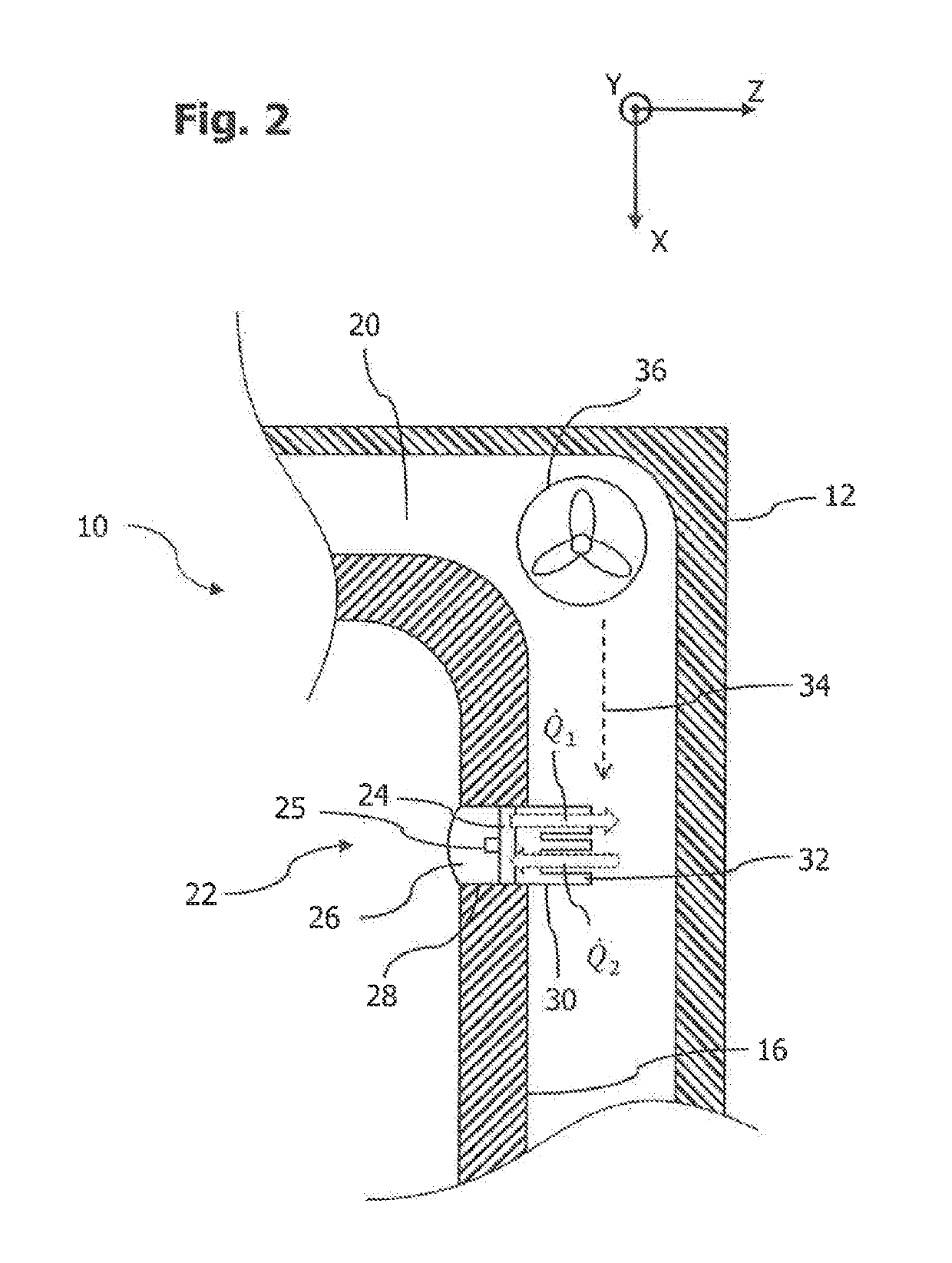

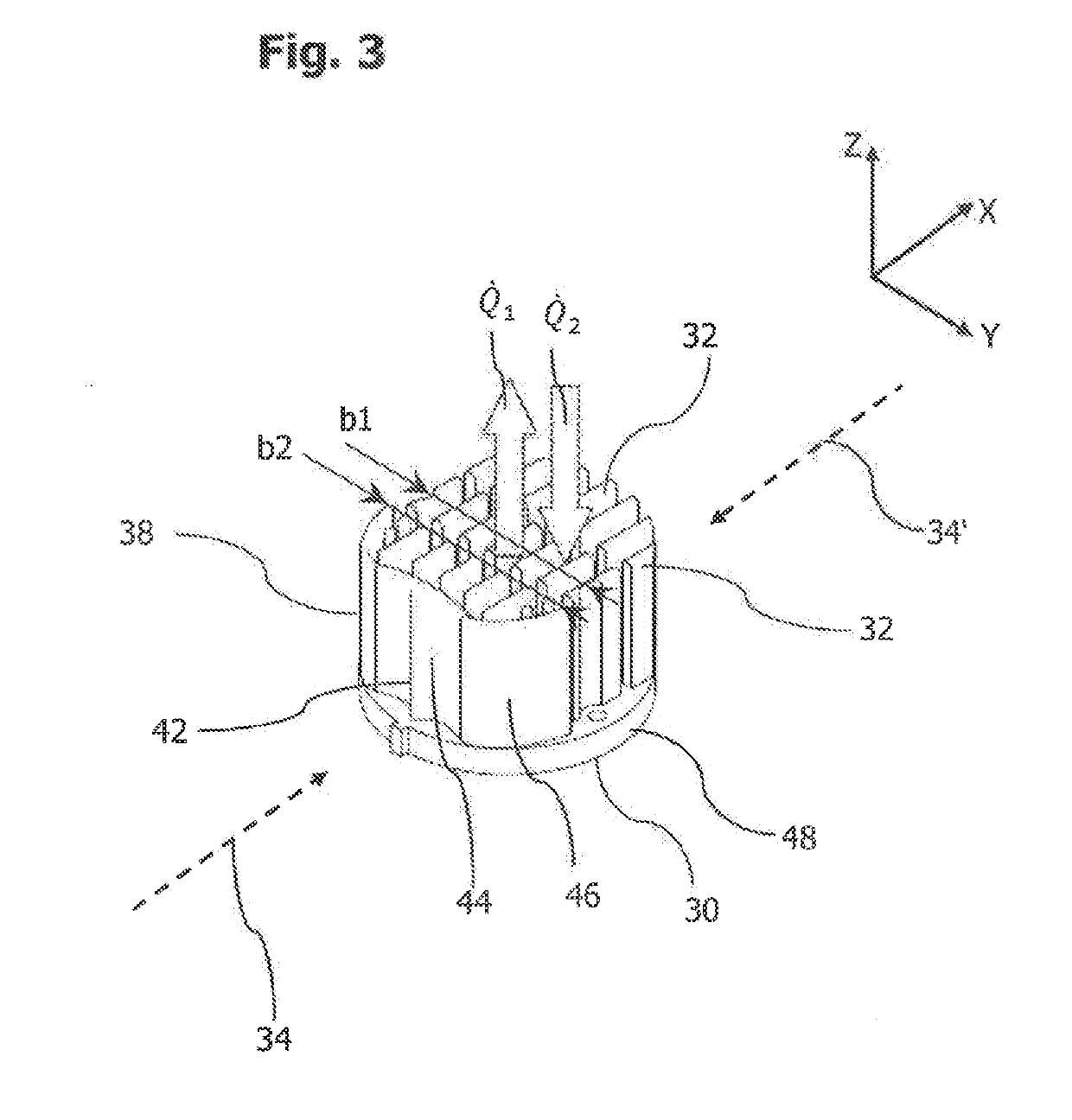

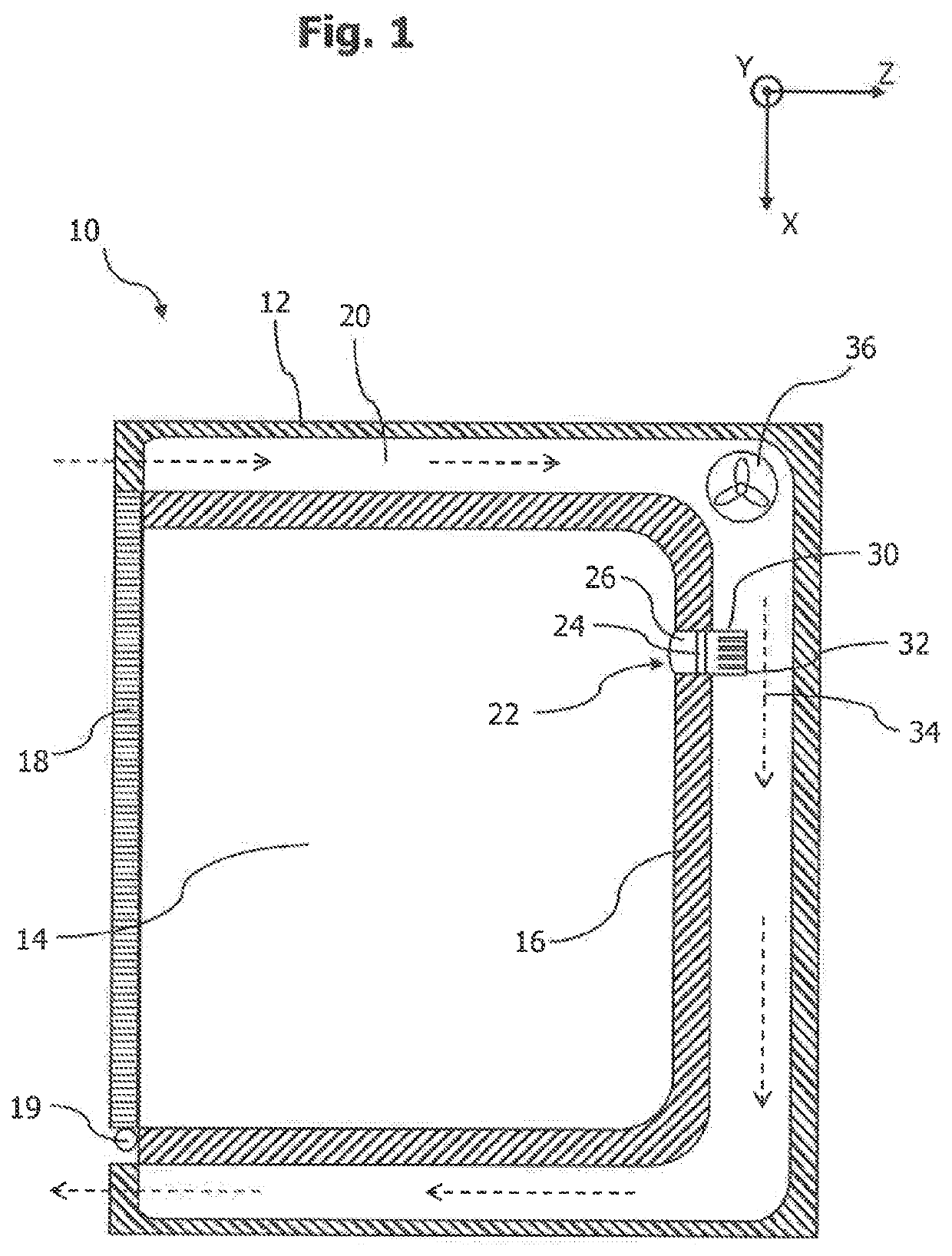

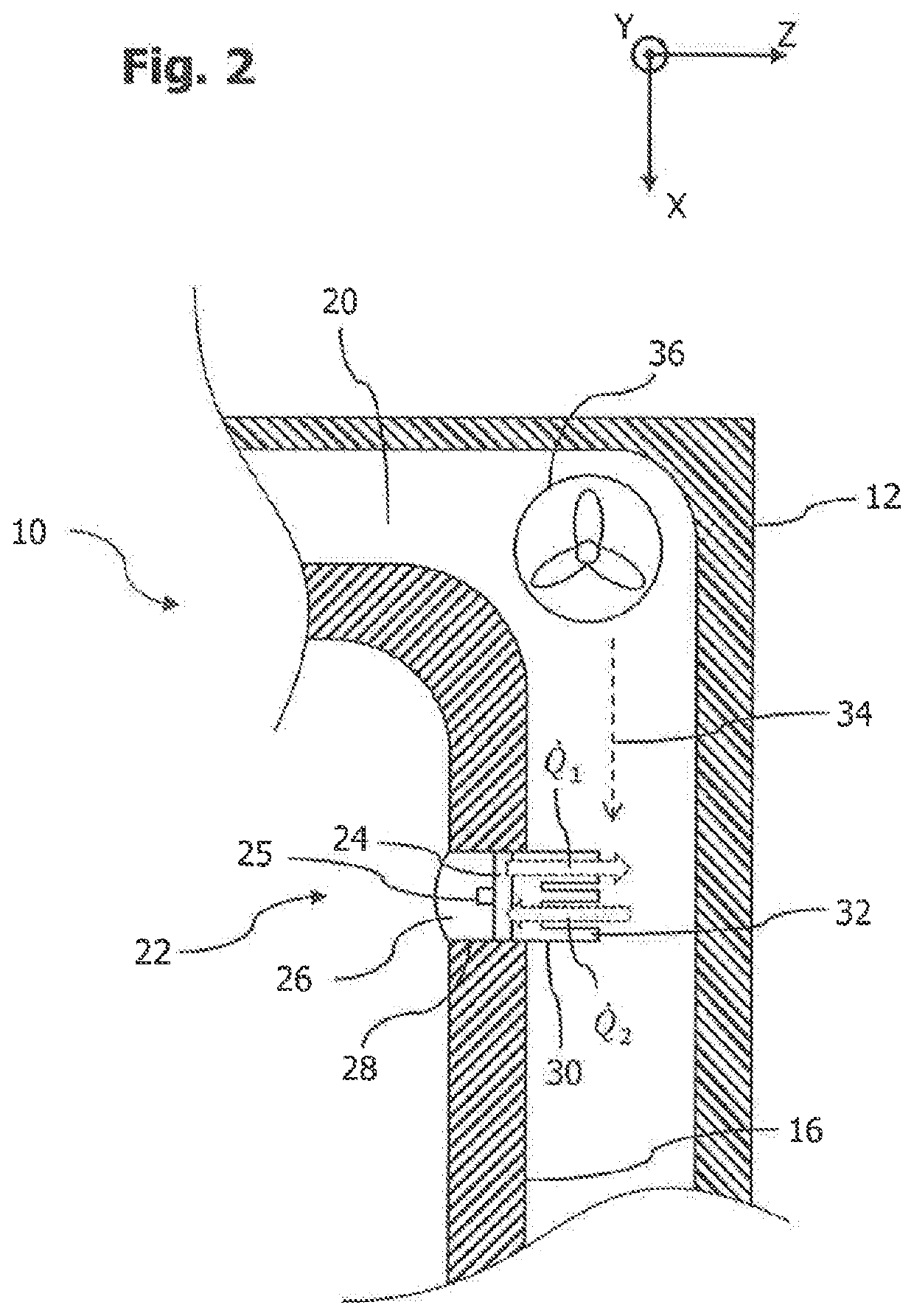

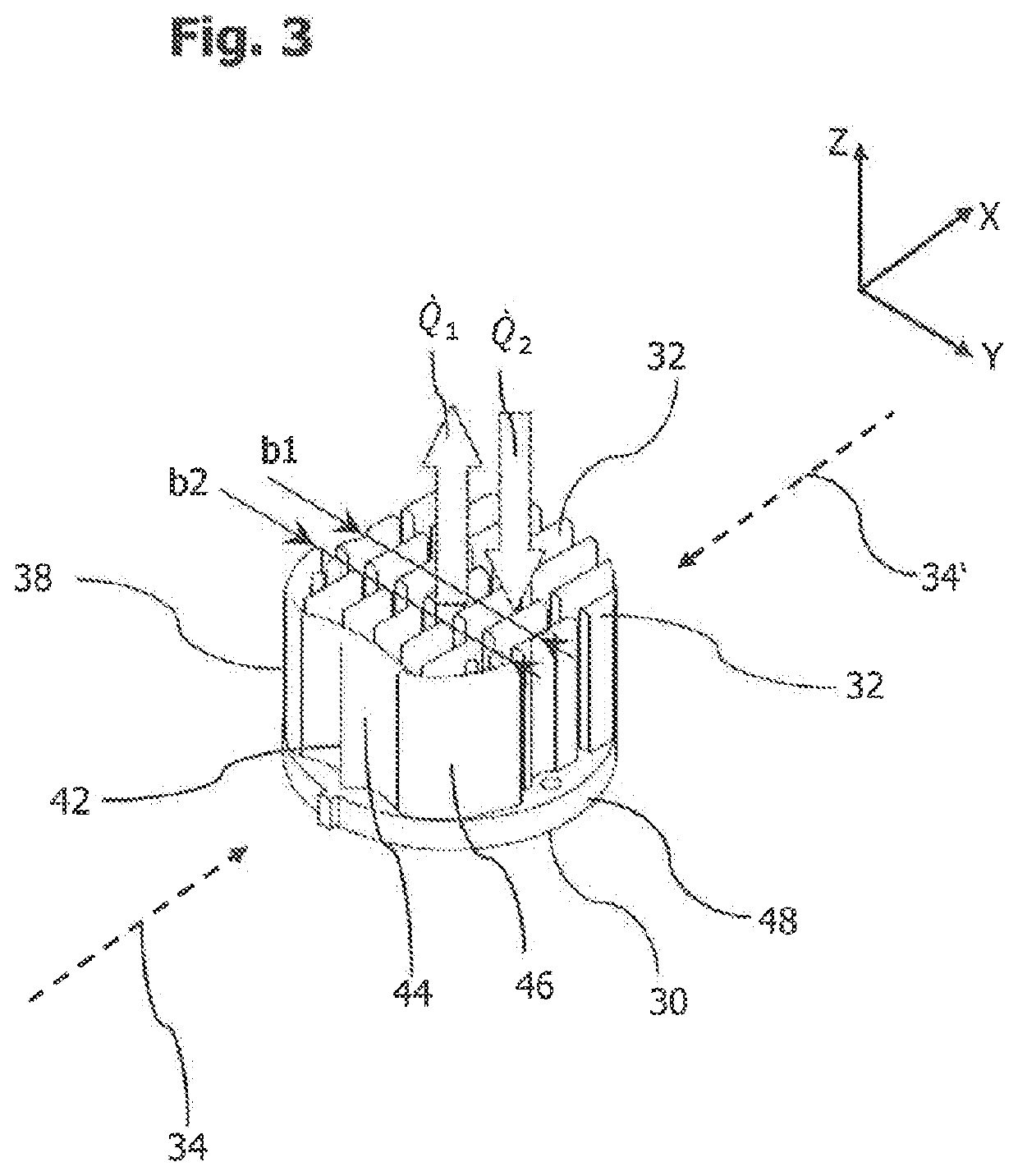

Pyrolytic oven with a lighting module

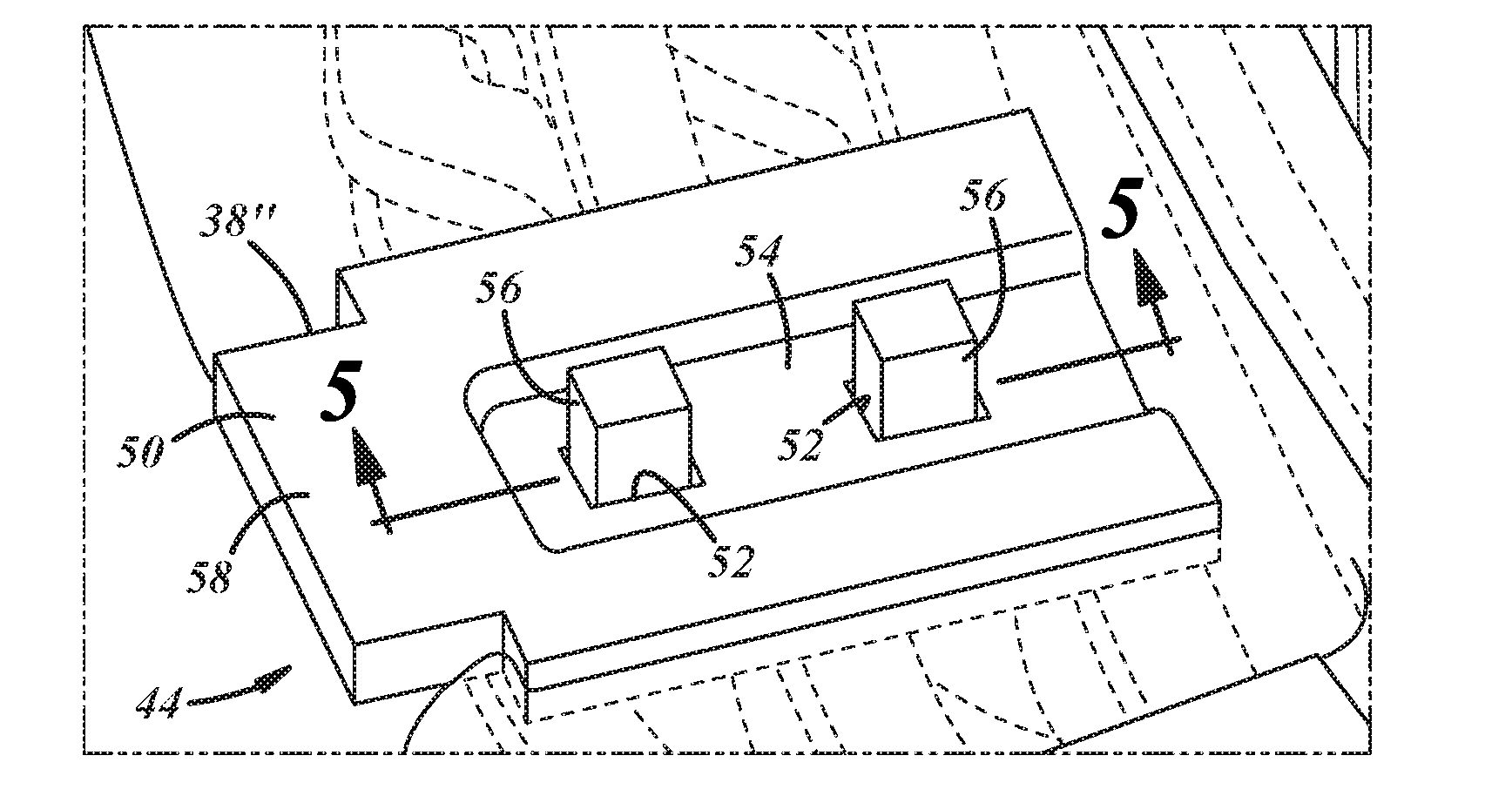

ActiveUS20190107290A1Avoid overall overheatingControl heat inputSelf-cleaning stoves/rangesElectrical heating fuelTransverse planeEngineering

A pyrolytic oven comprises a housing and a muffle delimiting a cooking chamber inside the housing. A lighting module serves to illuminate the cooking chamber, wherein the lighting module has a cooling structure with an arrangement of cooling extensions formed in particular as pins or ribs, which project into a gap between housing and muffle and have a convection effect in a cooking mode of the oven. A fan device of the oven is configured and controlled to generate an air flow encountering the cooling structure in the gap in a pyrolytic mode of the oven. The cooling structure of the lighting module further has a wall formation, which in pyrolytic mode generates a wind shadow relative to the air flow for a number of cooling extensions of the cooling structure arranged distributed in a transverse plane to the flow direction of the air flow.

Owner:EMZ HANAUER

A kind of welding equipment for the connection end of lead-acid battery

ActiveCN108544078BWon't happenAvoid the problems caused by fusion weldingWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingInternal resistance

The invention discloses a welding device for the connection end of a lead-acid storage battery, which comprises a friction welding machine, an electrode plate assembly box, a welding jig and a lifting transmission device. The lifting conveying device is arranged inside the bracket and at the lower part of the electrode plate assembly box, the two sides of the welding fixture are provided with guide rails for conveying the electrode plate assembly box, and the friction welding machine is arranged outside the bracket. The invention adopts the welding method of friction stir welding to well control the heat input in the welding process, only heat the welding part to the plastic state to carry out welding, and lead vapor will not be generated, the production environment is improved, and the battery capacity is reduced. Increase internal resistance and increase battery life, while realizing automated production.

Owner:NANCHANG HANGKONG UNIVERSITY

Nickel-based alloy welding powder as well as manufacturing method and using method thereof

ActiveCN113909736AReduce welding distortionImprove crack resistanceWelding/cutting media/materialsSoldering mediaNickelWeld bead

The invention relates to nickel-based alloy welding powder as well as a manufacturing method and a using method. The nickel-based alloy welding powder comprises the following components by mass: 0.40%-0.60% of C, 2.30%-2.60% of Si, smaller than or equal to 0.010% of P, smaller than or equal to 0.005% of S, 27.0%-32.0% of Fe, 0.10%-0.40% of Cu, 0.01%-0.06% of Ce, 0.01%-0.05% of Y and the balance Ni. The invention further discloses the manufacturing method and the using method of the nickel-based alloy welding powder. The nickel-based alloy welding powder is reasonable in design, low in weld joint hardness and small in cracking risk, preheating is not needed before welding, and heat treatment is not needed after welding.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

A kind of pulse mig welding arc control method

ActiveCN103203530BControl heat inputImprove performanceArc welding apparatusLoop closingControl manner

Owner:广州焊王电气科技有限公司

Pyrolytic oven with a lighting module

ActiveUS10962231B2Avoid overall overheatingControl heat inputSelf-cleaning stoves/rangesElectrical heating fuelEngineeringMechanical engineering

A pyrolytic oven comprises a housing and a muffle delimiting a cooking chamber inside the housing. A lighting module serves to illuminate the cooking chamber, wherein the lighting module has a cooling structure with an arrangement of cooling extensions formed in particular as pins or ribs, which project into a gap between housing and muffle and have a convection effect in a cooking mode of the oven. A fan device of the oven is configured and controlled to generate an air flow encountering the cooling structure in the gap in a pyrolytic mode of the oven. The cooling structure of the lighting module further has a wall formation, which in pyrolytic mode generates a wind shadow relative to the air flow for a number of cooling extensions of the cooling structure arranged distributed in a transverse plane to the flow direction of the air flow.

Owner:EMZ HANAUER

A new welding method with two-wire four-pulse robot

ActiveCN109848519BImprove performanceControl heat inputWelding accessoriesWelding power supplyEngineering

The invention discloses a new welding method for a robot with two wires and four pulses. The robot includes a control part, a wire feeding part, two pulse welding power sources communicating with each other and a welding torch. Arranged forward and backward at a certain angle to extend to the welding site; the control part controls the two pulse welding power sources so that the current provided to the forward wire is greater than the current provided to the rear wire; and the control part also controls the wire feeding components to provide the same or different wire feed speeds for the front and rear wires, and control the pulsed welding power supply to use four independent pulses to supply the welding current to the welding wire. The method of the invention has a wide control range, and the welding effect is beautiful and high in quality.

Owner:BEIJING XINLI MACHINERY

A clamping tool and a method for capillary pipeline welding using the clamping tool

The invention provides an installing and clamping tool and a method for conducting capillary tube welding through the installing and clamping tool. The installing and clamping tool is used for accurately installing and clamping a capillary tube. The method for conducting capillary tube welding through the installing and clamping tool includes the steps of selecting of argon tungsten-arc welding equipment, workpiece pre-welding washing, installing and clamping of a welding protective device, installing and clamping of a tool mold, installing and clamping of a workpiece, adjusting of a gas flow control device, programming of a welding procedure, workpiece welding, weld joint quality detecting and the like. In addition, in order to achieve welding, high-quality welding of the capillary tube is achieved through the gas flow control device and the welding protective device in the welding process, and wide application prospects are achieved in the field of capillary tube welding.

Owner:BEIJING INST OF CONTROL ENG

Double-sided multi-electrode penetrable electric arc welding method

ActiveCN101559510BRealize free combinationControl heat inputElectrode supporting devicesThick plateWelding power supply

The invention relates to a double-sided multi-electrode penetrated electric arc welding method, which uses three welding guns to weld a workpiece. The welding guns can be assembled randomly and are distributed on two sides of the workpiece to form penetrable electric arcs on the workpiece for welding. A plurality of the welding guns are burnt at the same time to generate the electric arcs and forma controllable triangular electric arc. The heat input is changed by adjusting the current on the workpiece in real time. By changing the space lengths and the included angles of the welding guns, the form of a heat source and the force input to a weld crater can be changed so as to satisfy various welding requirements. The welding method can achieve any combination of heat transfer, force transfer and mass transfer in the process of welding, and the shape of the electric arc can also be controlled randomly. In the process of welding, the penetrable electric arcs can achieve high-speed welding of a thin plate and one-step perforation complete penetration welding of a thick plate. The welding method can perform high-efficiency and high-quality welding by using the prior welding device under the condition with a special welding power supply. Simultaneously, the method can be simplified as double-sided dual-arc welding.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com