Control method and system for pulse MIG (Metal-Inert Gas) welding electric arc

A pulse and arc technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

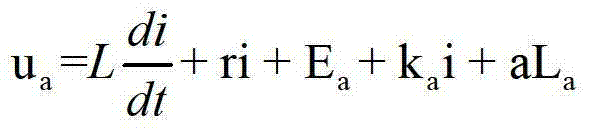

[0038] The invention provides a pulse MIG welding arc control method, the control method adopts the open-loop feedforward control mode of the welding wire feeding speed signal and the closed-loop negative feedback control mode of the arc length signal to jointly control the arc width or pulse frequency of the pulse MIG arc , in order to maintain the dynamic balance of the welding wire feeding speed and melting speed, and maintain the arc length of the system constant and the jet transition of the droplet when the welding current adjustment (through the wire feeding speed adjustment), the wire feeding speed disturbance or the arc length disturbance occurs The method remains the same.

[0039] The pulsed MIG welding arc control method provided by the present invention controls the arc width or pulse frequency of the pulsed MIG arc due to the open-loop feedforward control mode of the welding wire feeding speed signal, that is, the welding average current and the welding average cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com