Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about How to "Slow down the speed of solidification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing TiAl+Ti2AlNb composite materials by laser melting deposition

ActiveCN110449581ATurn up the plasticityControl the preheating temperatureAdditive manufacturing apparatusTransportation and packagingStress concentrationLaser additive manufacturing

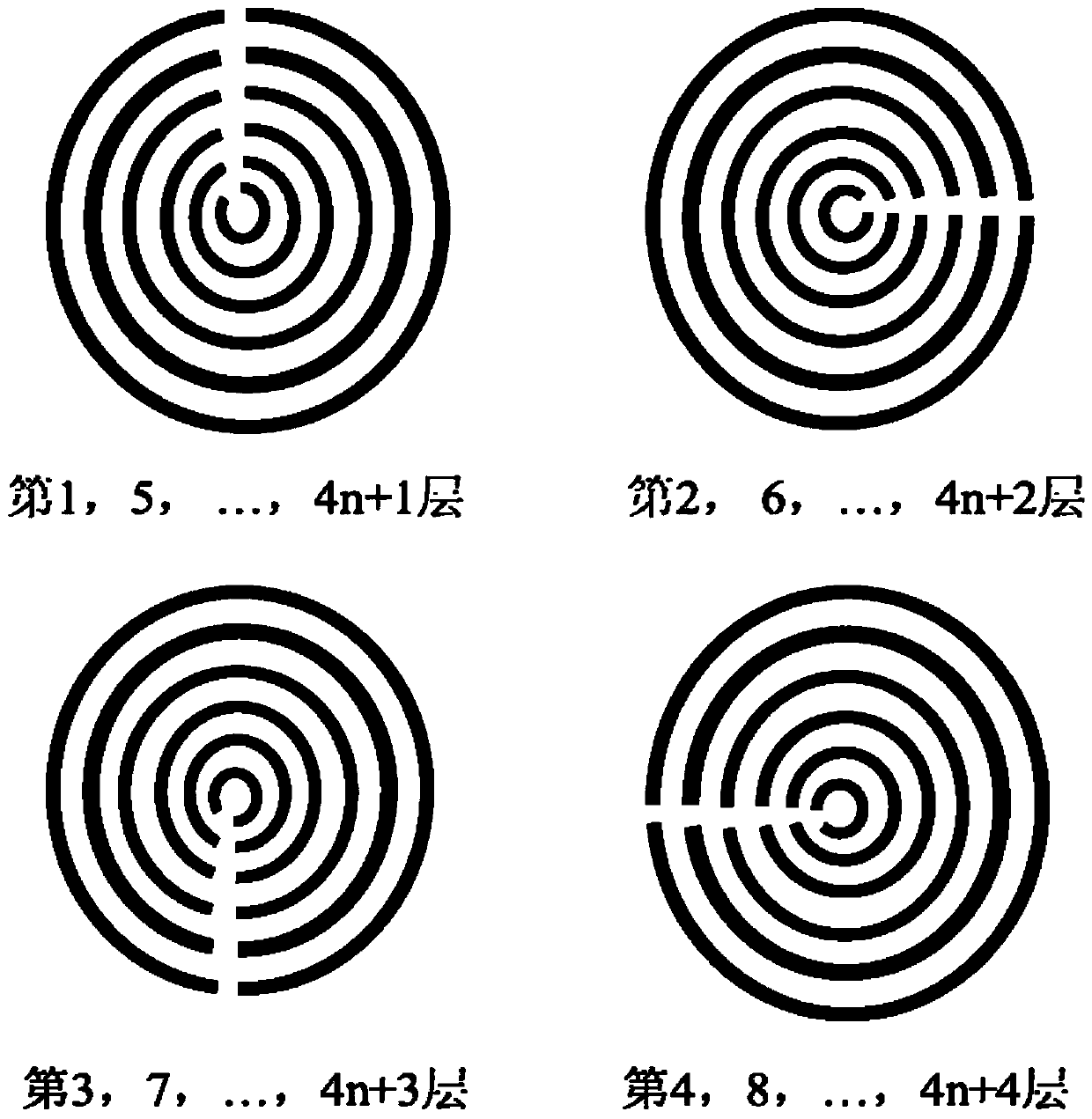

The invention belongs to the technical field of laser added material manufacturing, and relates to a method for preparing TiAl+Ti2AlNb composite materials by laser melting deposition. The laser melting deposition method is adopted to form the TiAl+Ti2AlNb composite materials; and the feeding quantity of Ti2AlNb is adjusted to achieve a pinning effect in composite material structures to improve overall plasticity of the materials. Meanwhile, circular samples are formed, and scanning paths are changed to concentric arcs to prevent the tensile stress of linear scanning paths of rectangular samples; and concentric circle openings on each layer are converted by 60-90 degrees, that is, the positions of scanning initial points on each layer are changed, so that the thermal stress concentration isreduced to prevent cracks. The heat input quantity in the forming process is controlled, and the substrate preheating temperature in the forming process is adjusted to slow down the formed metal solidification speed and cooling speed, so that the stress is released for a longer time.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

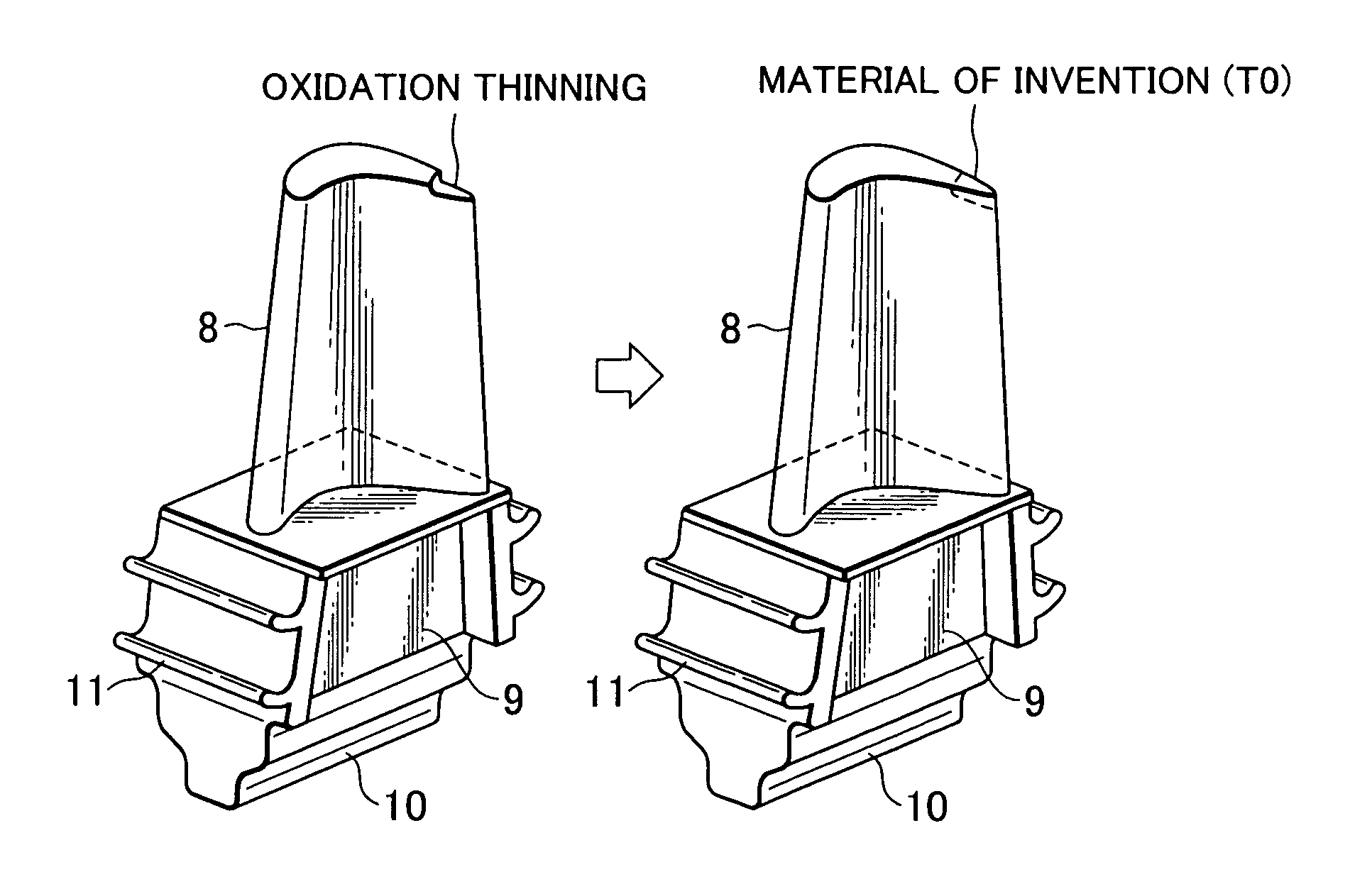

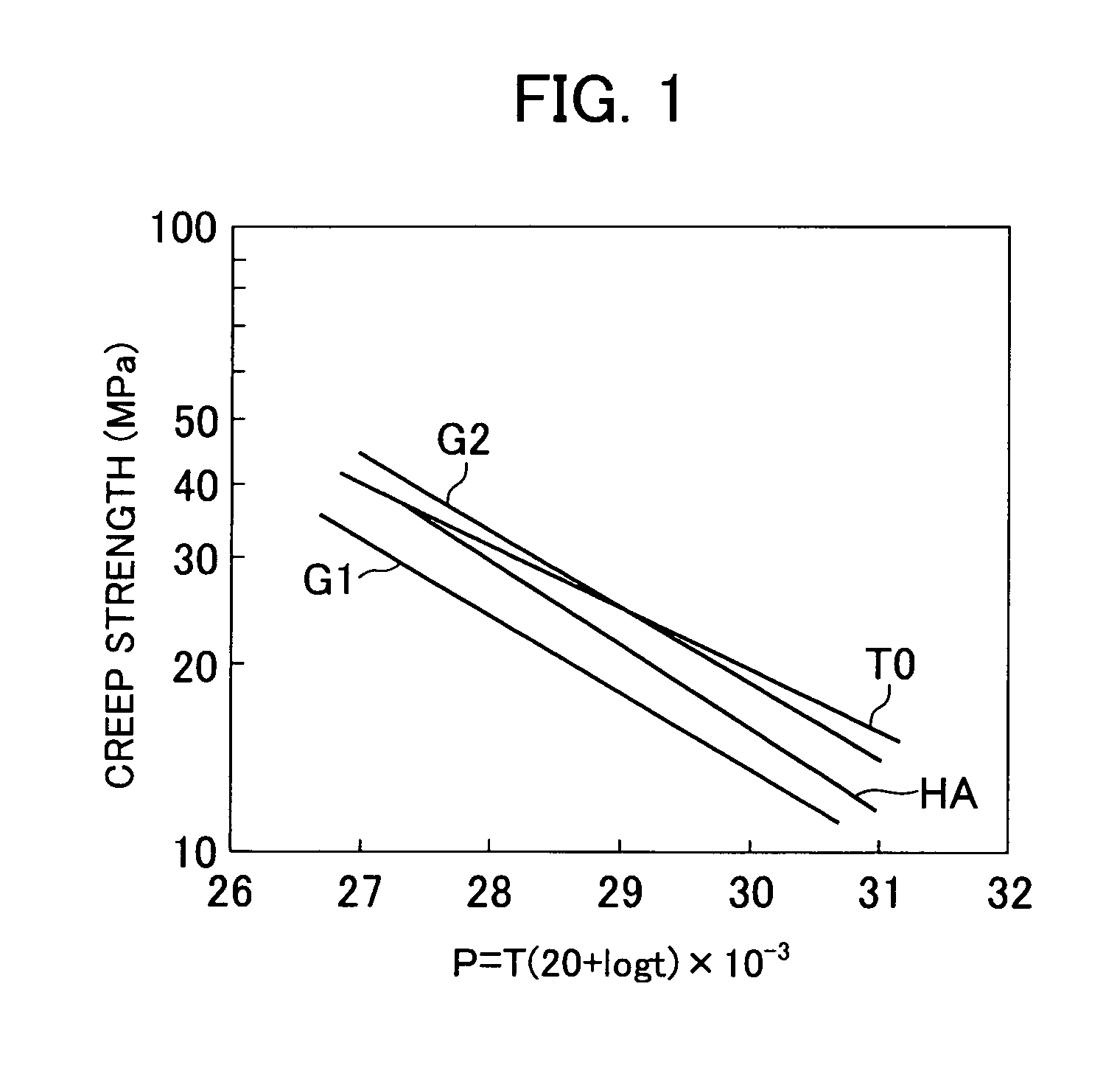

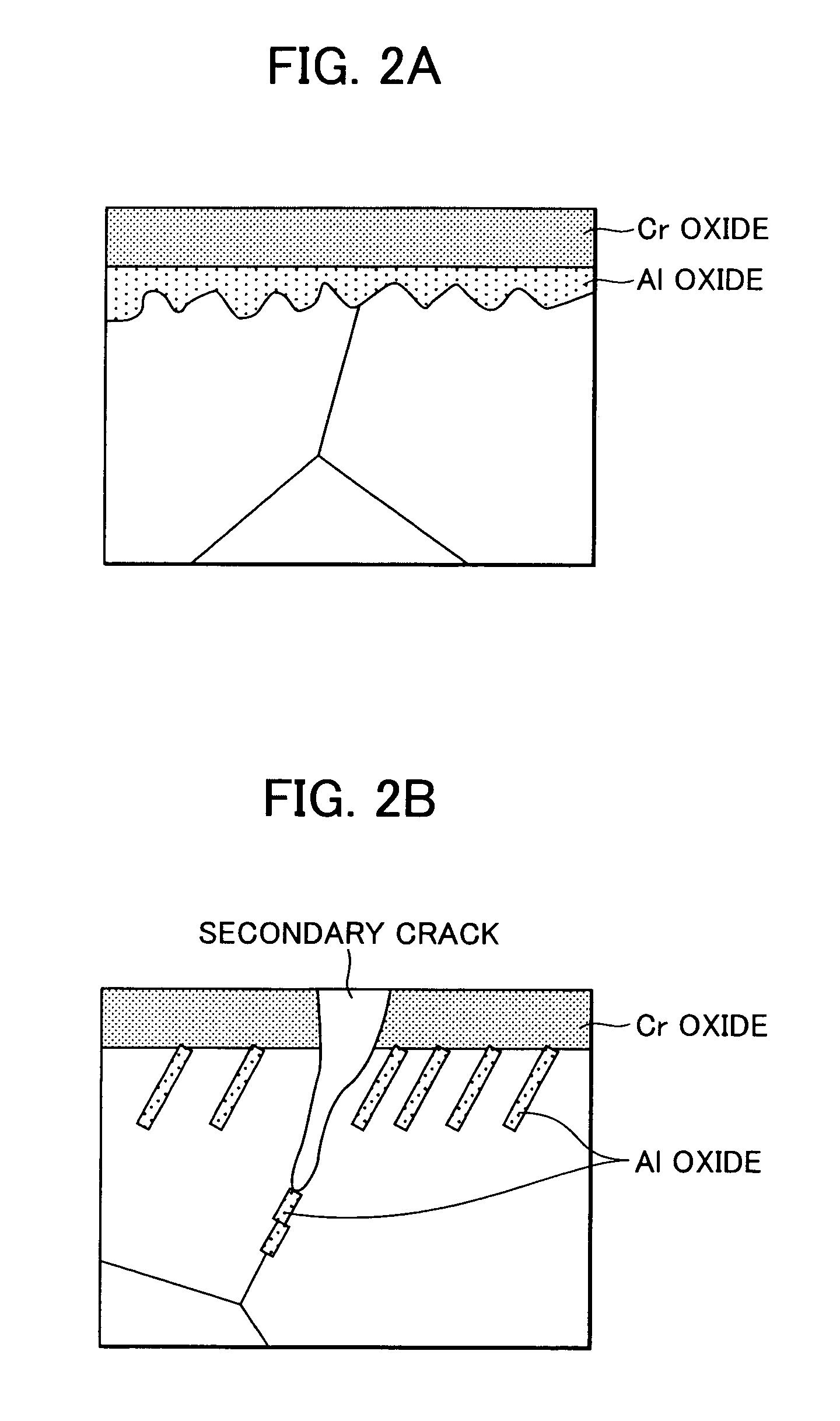

Ni-based alloy member, method of producing the alloy member, turbine engine part, welding material, and method of producing the welding material

ActiveUS20090123290A1Low melting pointReduce the temperaturePropellersArc welding apparatusAlloyTurbine

A Ni-based alloy member has resistance against grain boundary fracture, fatigue strength, and oxidation resistance at temperatures near 1000° C. or higher. The Ni-based alloy member includes a non-repaired region made of a Ni-based alloy base and a region repaired by welding, which is formed on the non-repaired region and which is made of a buildup-welded layer, the buildup-welded layer being made of a Ni-based alloy containing, by weight, 15% or less of Co, 18-22% of Cr, 0.8-2.0% of Al, 5.0% or less of Ta, 0.5% or less of Mo, 0.5% or less of Ti, 13-18% of W, 0.05-0.13% of C, 0.06% or less of Zr, 0.015% or less of B, 0.4-1.2% of Mn, and 0.1-0.3% of Si, the balance of the alloy being preferably essentially made of Ni.

Owner:MITSUBISHI POWER LTD

Manufacturing technology of isometric aluminium nickel cobalt titanium permanent magnet alloy

A process for preparing the permanent-magnet AlNiCo alloy with equiaxed crystals includes such steps as proportionally mixing Al, Ni, Co, Cu, Ti, NbFe (1: 1), Fe, Si, FeS and SmCo, charging the mixture in furnace, preparing casting mould, vacuumizing, electric heating, filling Ar gas, casting, annealing, two-stage preheating, solution treating, magnetic field controlled cooling and three-stage tempering.

Owner:宁波盛事达磁业有限公司

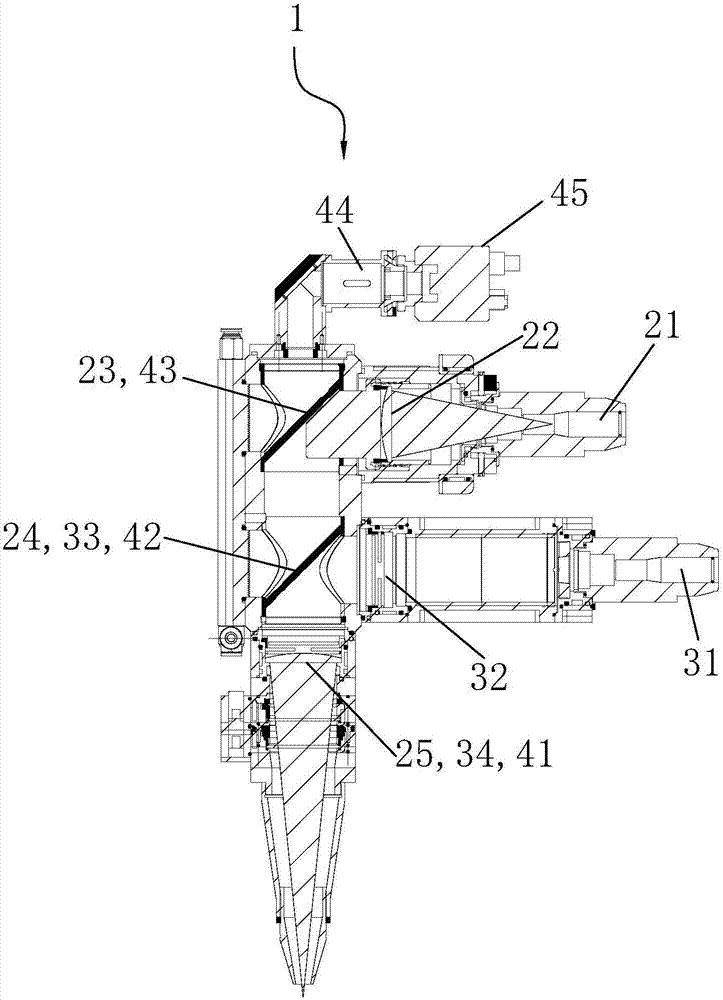

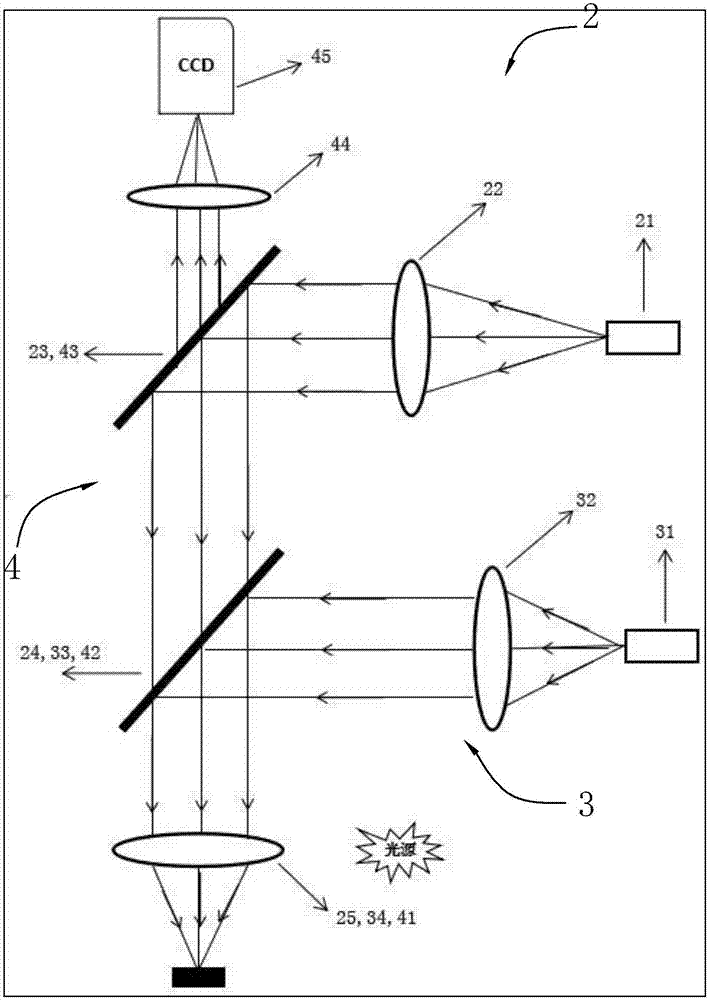

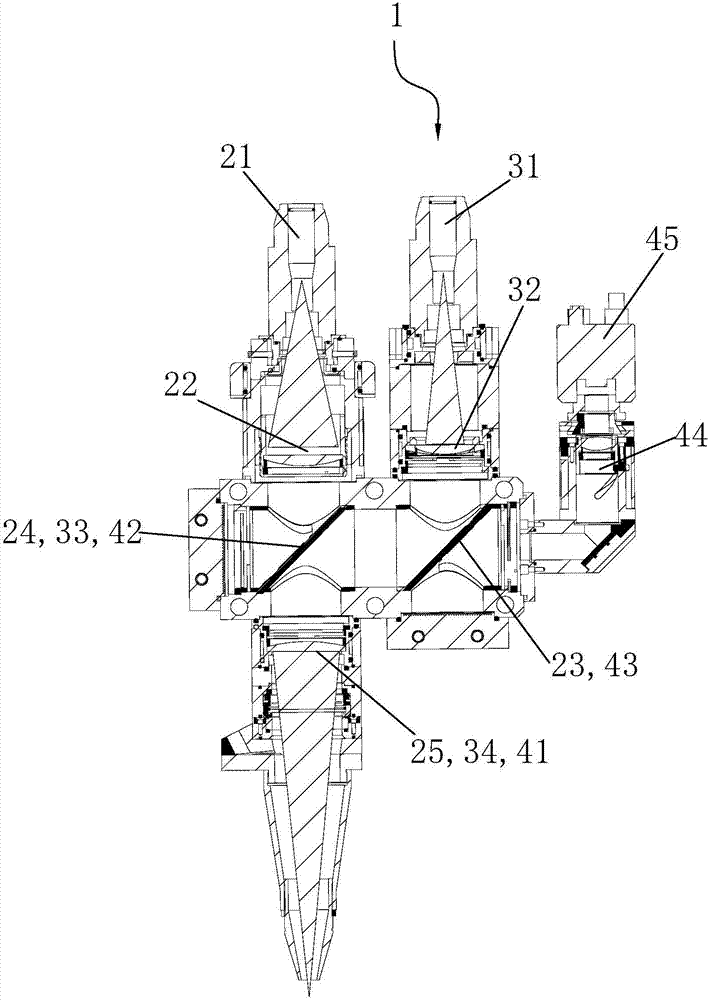

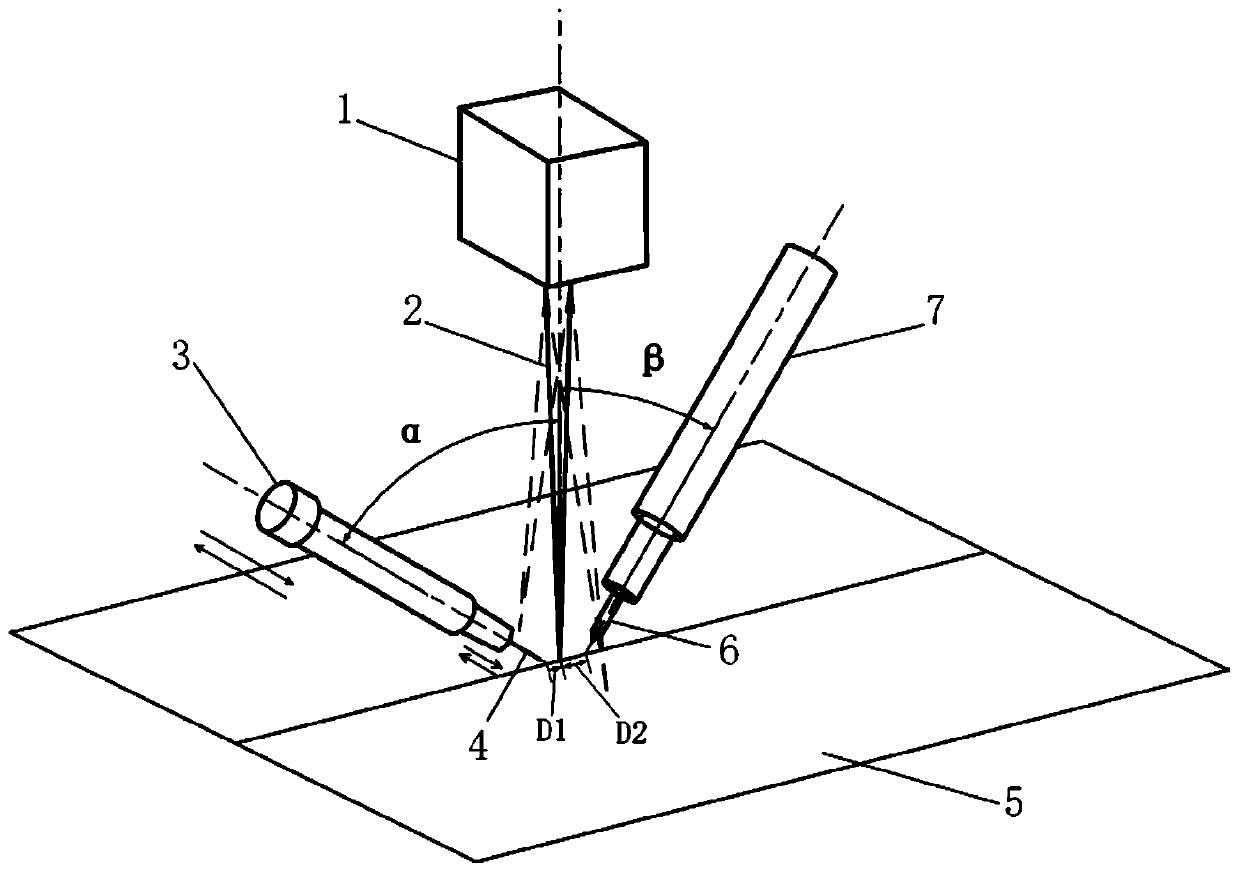

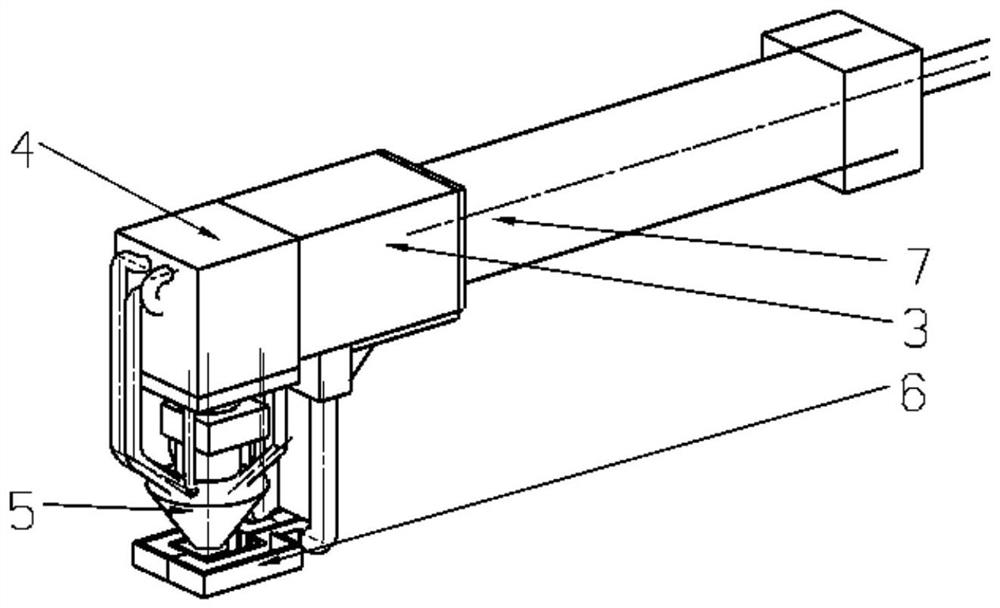

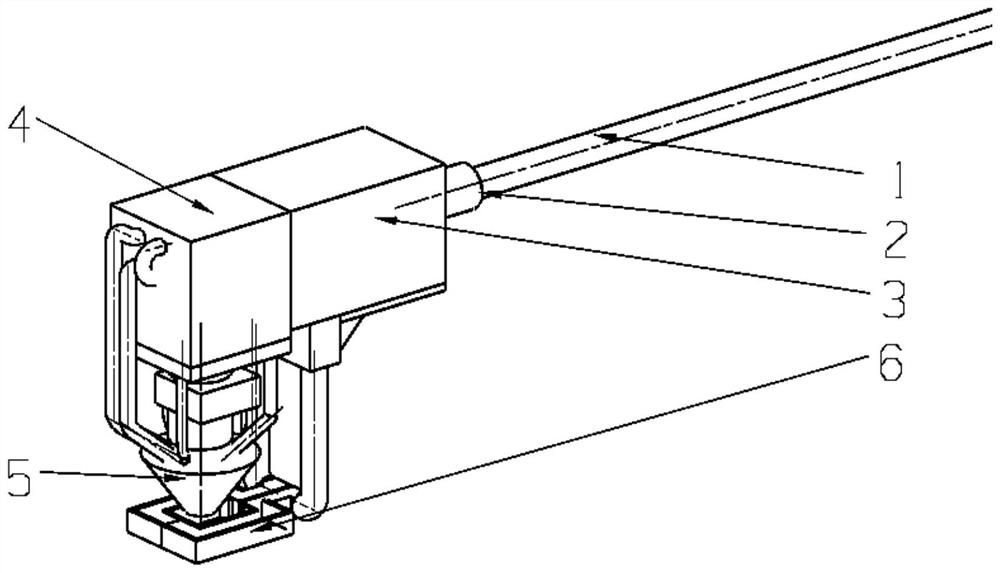

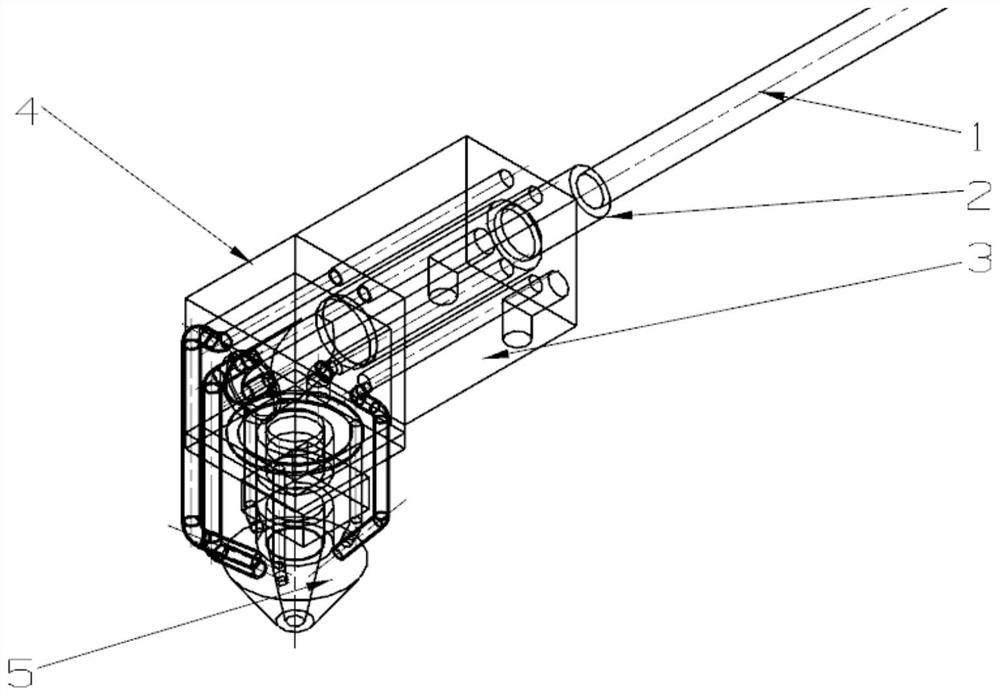

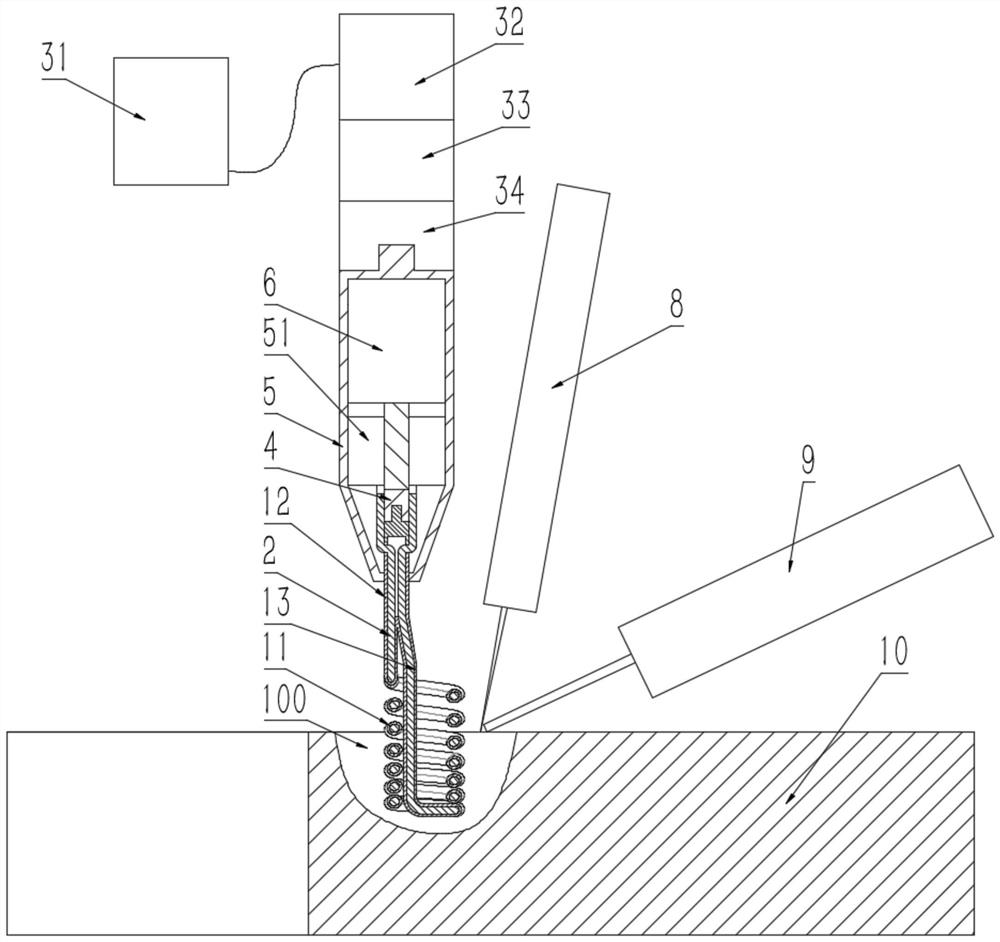

Exiting device for laser hybrid welding

ActiveCN107052580AImprove energy utilizationKeyhole stableLaser beam welding apparatusLaser-hybrid weldingLaser light

The invention discloses an exiting device for laser hybrid welding. The exiting device for laser hybrid welding comprises a laser welding head, a semiconductor laser device and an optical fiber laser device, wherein the semiconductor laser device and the optical fiber laser device are respectively connected with the laser welding head; the semiconductor laser device transmits semiconductor laser; the optical fiber laser device transmits optical fiber laser; a light path of the laser welding head comprises a semiconductor light path, an optical fiber light path and a coaxial monitoring light path; a laser light beam of the semiconductor light path and a laser light beam of the optical fiber light path are superposed into a light beam for welding at a focus point of the laser welding head; a welding position is illuminated through an external light source; and light reflected by the welding position is displayed by a monitor after the welding position is imaged a coaxial monitoring light path. The technical problems that traditional welding pores are abundant, hot crack tendency is high, welding spatter is severe, welding joints are large and the like are solved. The exiting device for laser hybrid welding has the characteristics that energy utilization rate is increased, key holes are stable, the device is suitable for high-speed welding, solidification speed is reduced, the pores are also reduced, hot crack tendency is decreased, welding spatter is reduced, forming of welding joints is improved, so that a welding surface is smooth and the like.

Owner:UNITED WINNERS LASER CO LTD

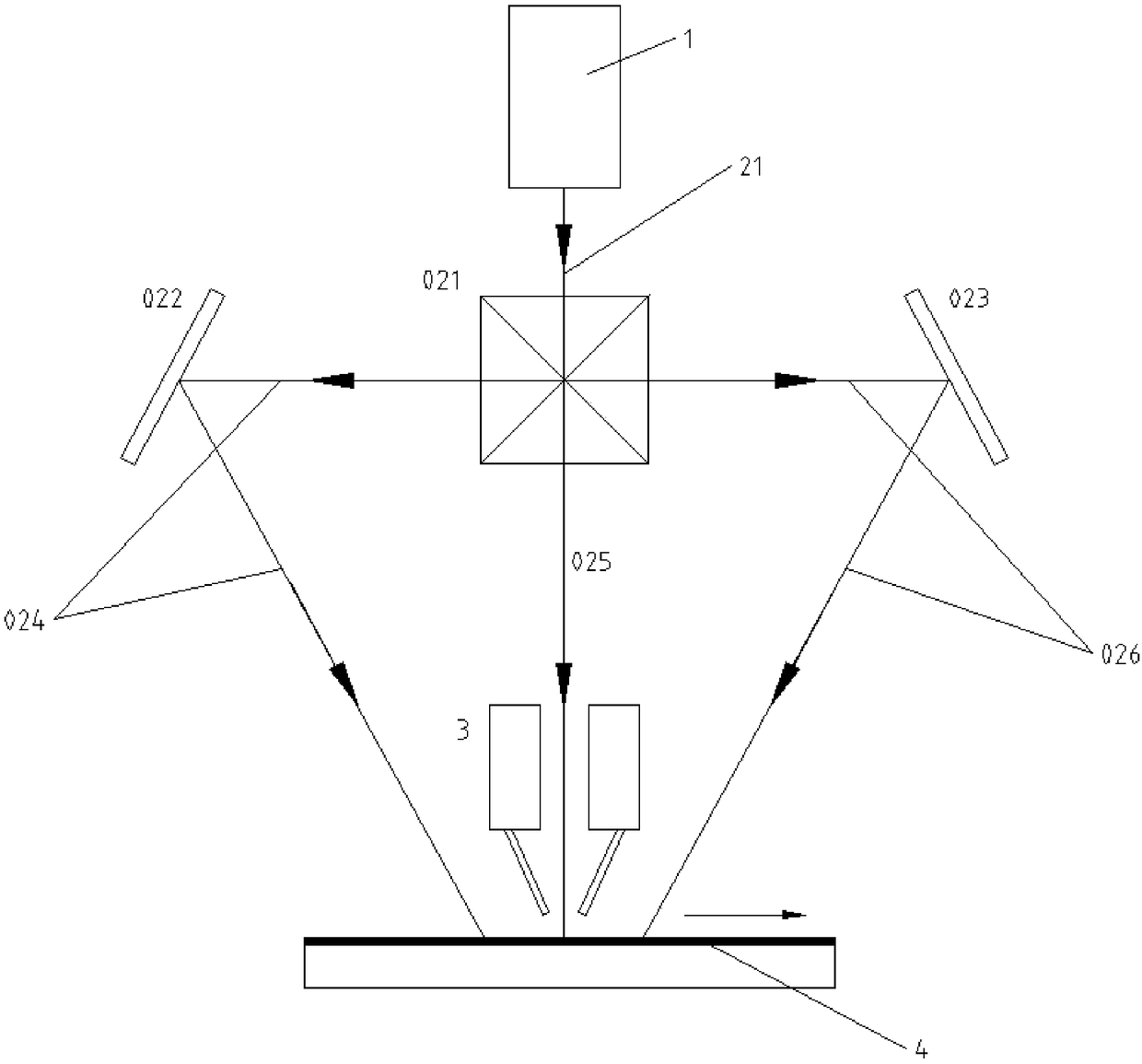

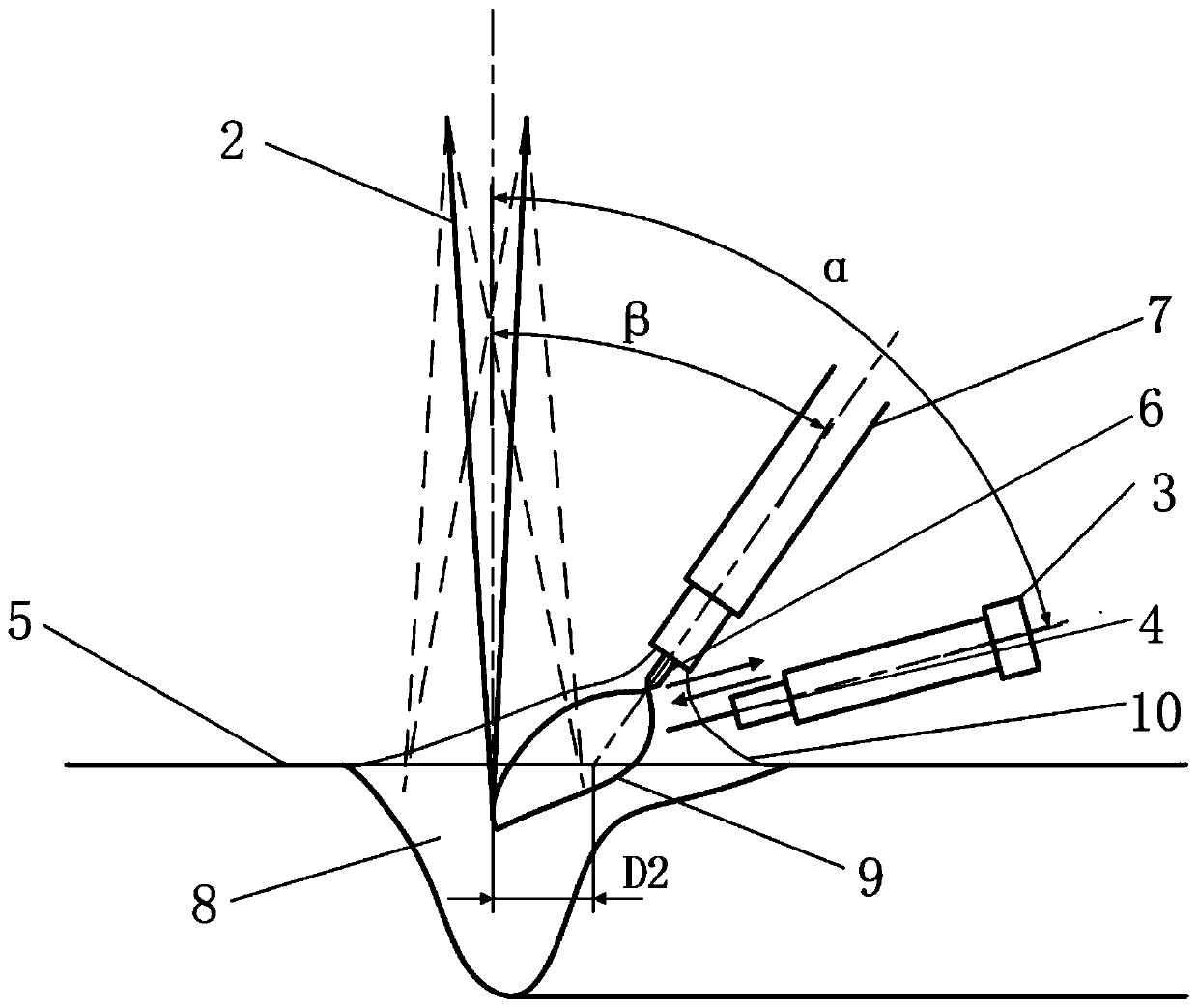

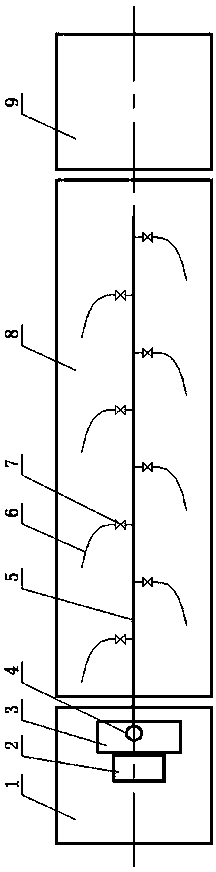

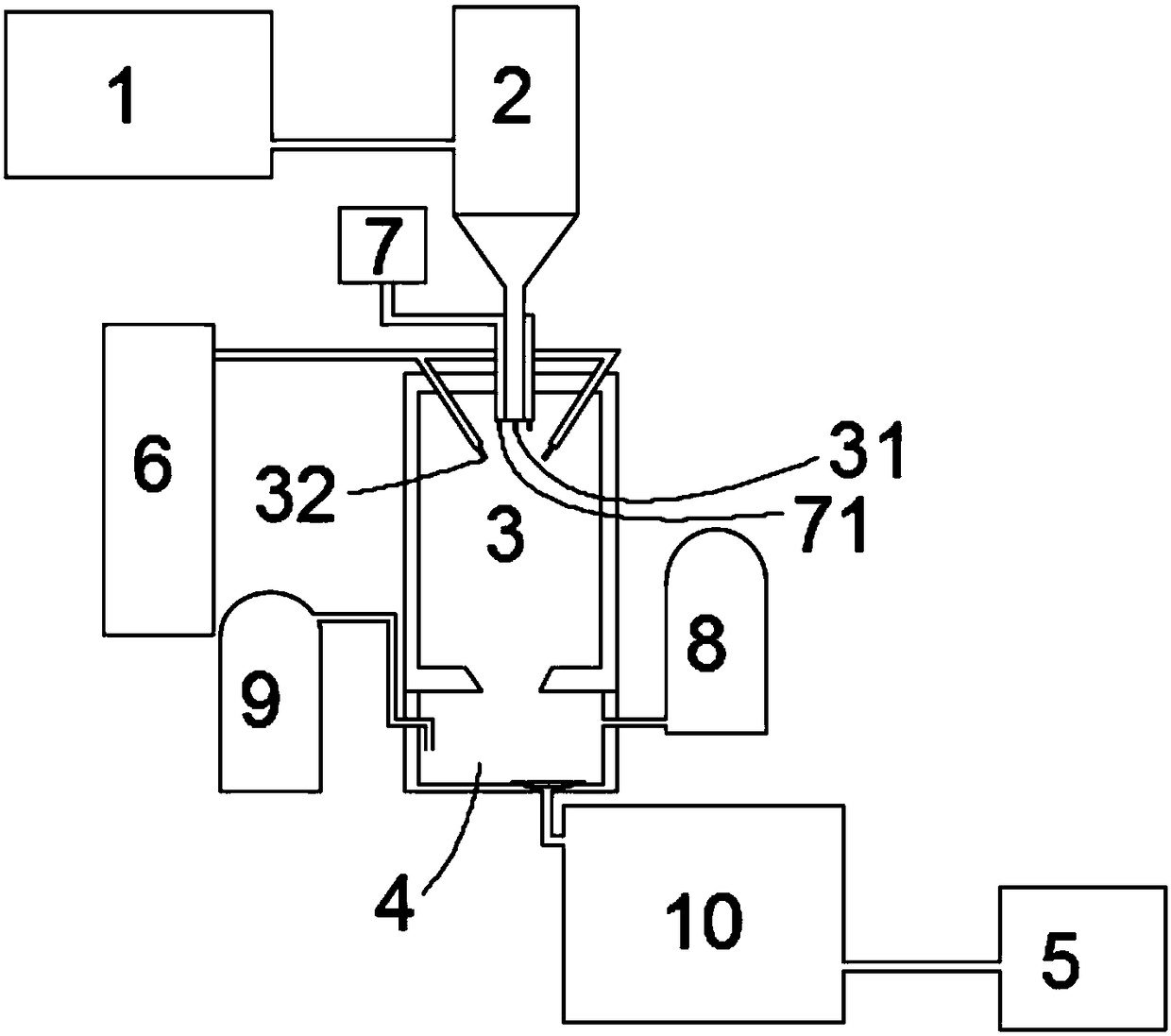

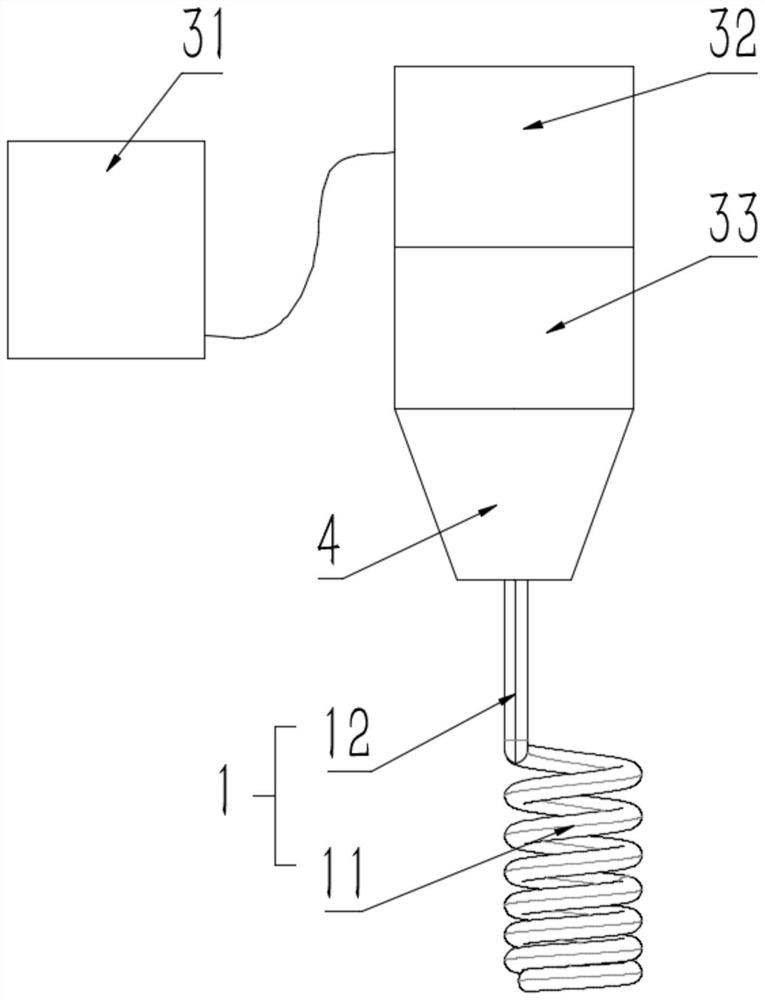

Laser cladding method, laser head, laser and cladding system for realizing laser cladding method

PendingCN108411301AReduces the possibility of crackingAvoid crackingMetallic material coating processesAlloyOptoelectronics

The invention relates to the technical field of laser cladding, and provides a laser cladding method, and a laser head, a laser and a cladding system for realizing the laser cladding method aiming atthe problems of deformation and performance degradation due to the fact that an existing method of laser cladding preheating on a machined workpiece base body cannot realize real-time online heat treatment and high heating input for preheating. The laser cladding method comprises the following steps that 1, outgoing lasers of the laser are divided into preheating lasers, cladding lasers and post-processing lasers; 2, the preheating lasers are irradiated on a workpiece to be processed, and the workpiece is preheated; 3, the cladding lasers are irradiated on the preheated workpiece to be processed to form a molten pool, and at the same time, alloy powder is blown into the molten pool formed on the surface of the workpiece to be processed; and 4, the post-processing lasers are irradiated on acladding layer after cladding, and post-annealing treatment is carried out on the cladding layer.

Owner:XIAN BESAME LASER TECH CO LTD

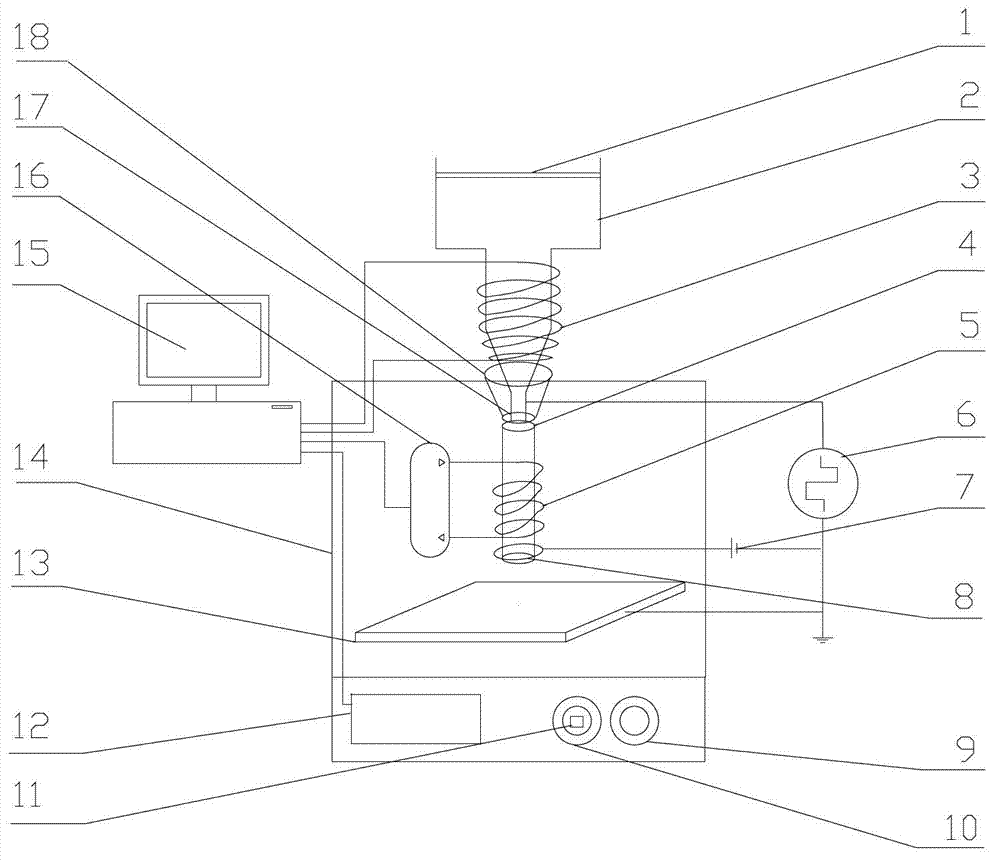

Electro-hydraulic jet printing device of metal micro-nanometer structure

ActiveCN102922891AAchieving Vacuum Environment EjectionIncrease temperatureDuplicating/marking methodsPattern printingTemperature controlElectro hydraulic

The invention discloses an electro-hydraulic jet printing device of a metal micro-nanometer structure and relates to an electrostatic spraying device. The electro-hydraulic jet printing device of the metal micro-nanometer structure, provided by the invention, is good in continuity and stability and is capable of realizing precise jet printing manufacturing of the metal micro-nanometer structure. The electro-hydraulic jet printing device is provided with a pressure controller, a feeding groove, a heater, an insulating sleeve, a temperature-controlled condenser pipe, a high-voltage pulse power supply, an auxiliary power supply, a restraining electrode ring, an air exhausting port, an air inflow port, a pressure valve, a pressure gage, a collection plate, a protection cover, a computer, a temperature controller, a spraying nozzle and an annular air vent. According to the electro-hydraulic jet printing device of the metal micro-nanometer structure, the advantages of alternating current electro-hydraulic jet printing and surrounding atmosphere gas focusing are combined, and the purposes of good continuity, good continuity and precise jet printing manufacturing of metal micro-nanometer structure can be achieved.

Owner:XIAMEN UNIV

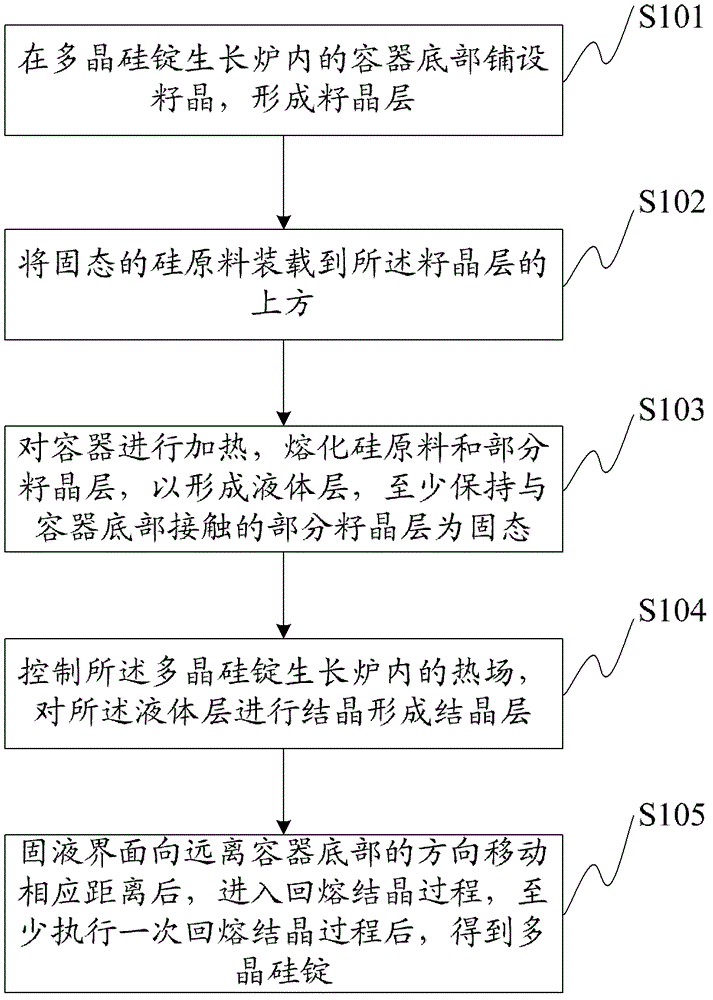

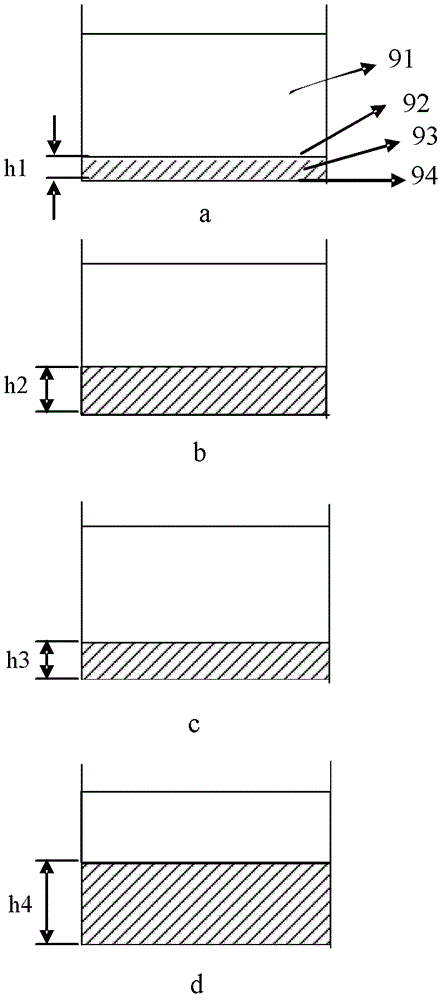

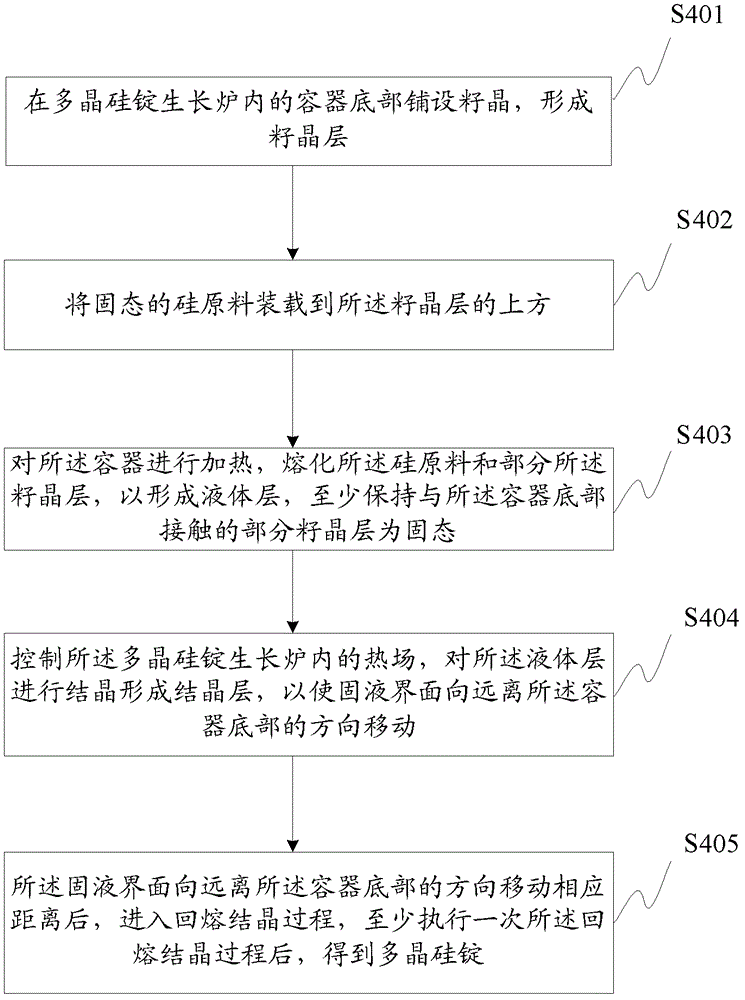

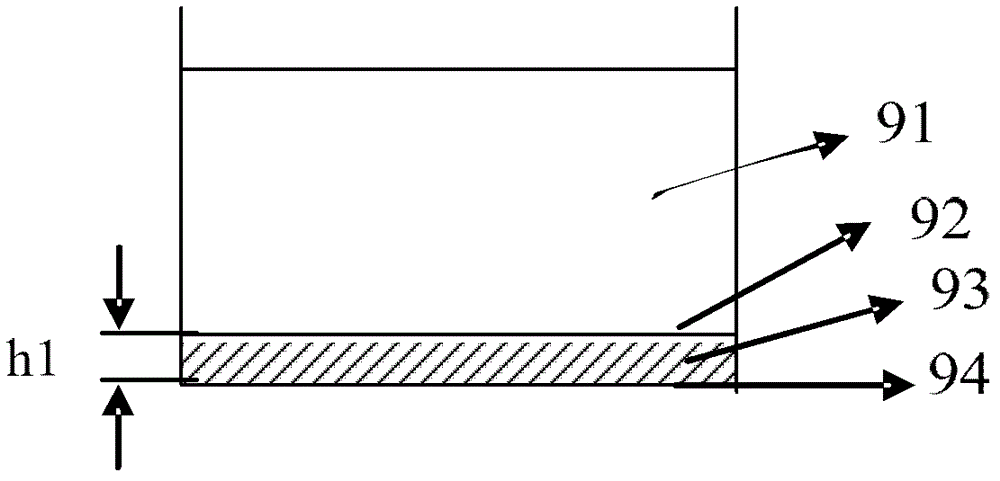

Polycrystalline silicon ingot, manufacturing method thereof and solar cell

InactiveCN102797036ALow oxygen impurity contentReduction factorPolycrystalline material growthPhotovoltaic energy generationLiquid layerAttenuation coefficient

The invention discloses a manufacturing method of a polycrystalline silicon ingot. The manufacturing method comprises the steps of paving seed crystals on the bottom of a container in a polycrystalline silicon ingot growth furnace to form a seed crystal layer; loading solid silicon raw materials on the seed crystal layer; heating the container to melt the silicon raw materials and part of seed crystal layer to form a liquid layer, and at least keeping part of the seed crystal layer contacted with the bottom of the container to be in the solid state; controlling a thermal field in the polycrystalline silicon ingot growth furnace, and crystallizing the liquid layer to form a crystallization layer so as to move a solid-liquid interface to the direction far away from the bottom of the container; moving the solid-liquid interface to the direction far away from the bottom of the container by a corresponding distance, then conducting the meltback crystallization process, at least implementing the meltback crystallization process once to obtain the polycrystalline silicon ingot. The polycrystalline silicon ingot produced by adopting the method disclosed by the invention is low in impurity content, the produced solar cell is low in cost and attenuation coefficient, and the photoelectric conversion efficiency is high.

Owner:ZHEJIANG YUHUI SOLAR ENERGY SOURCE

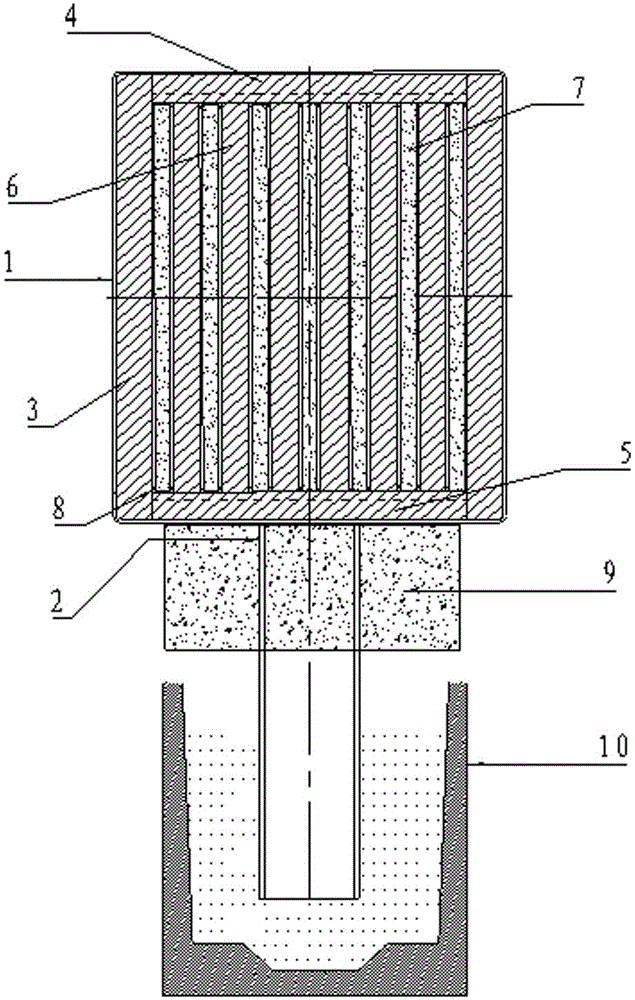

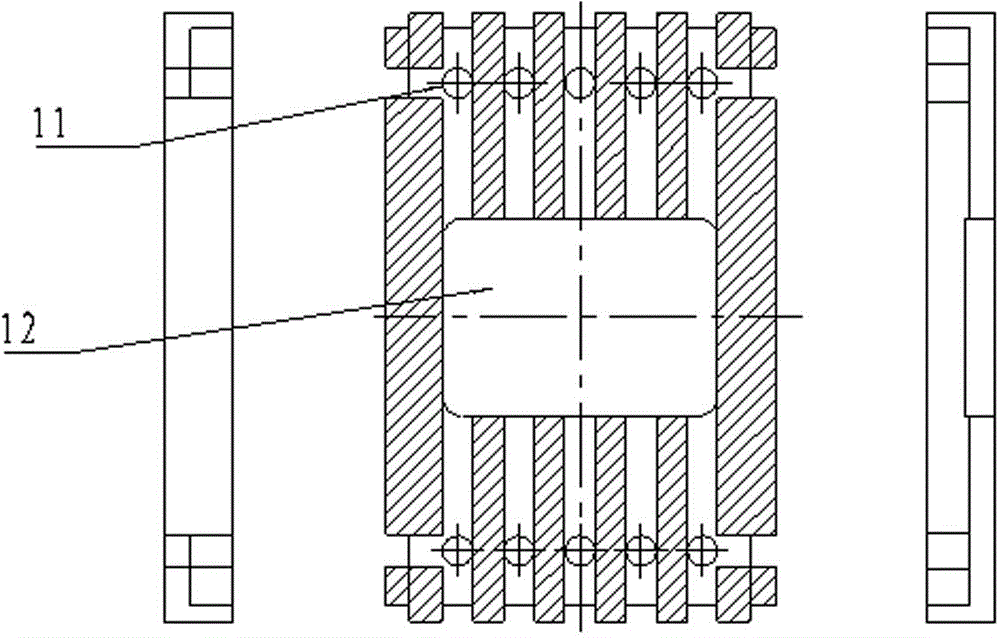

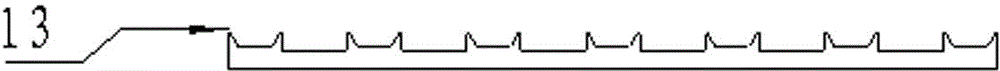

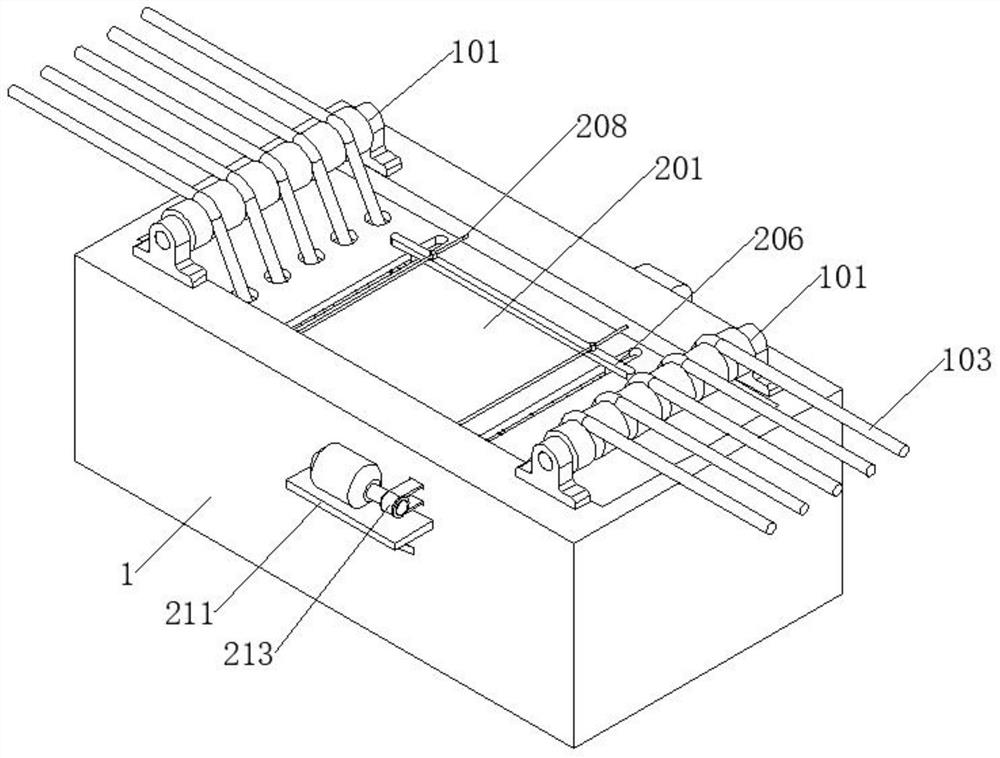

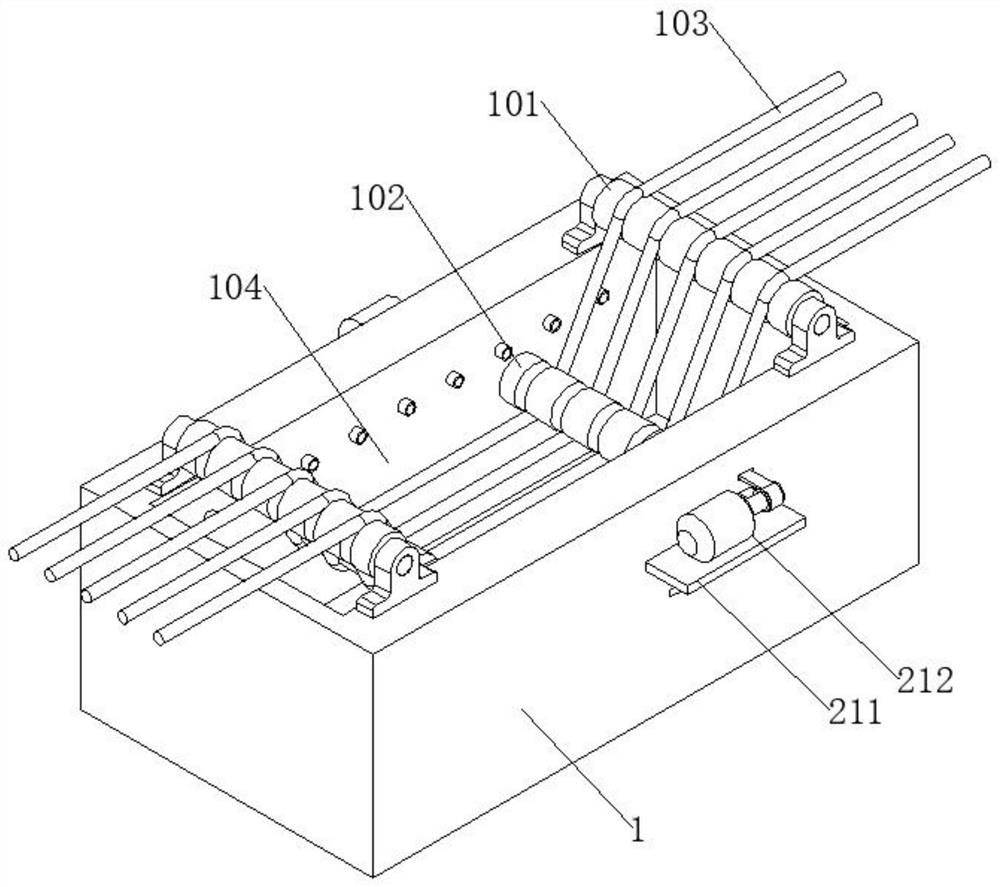

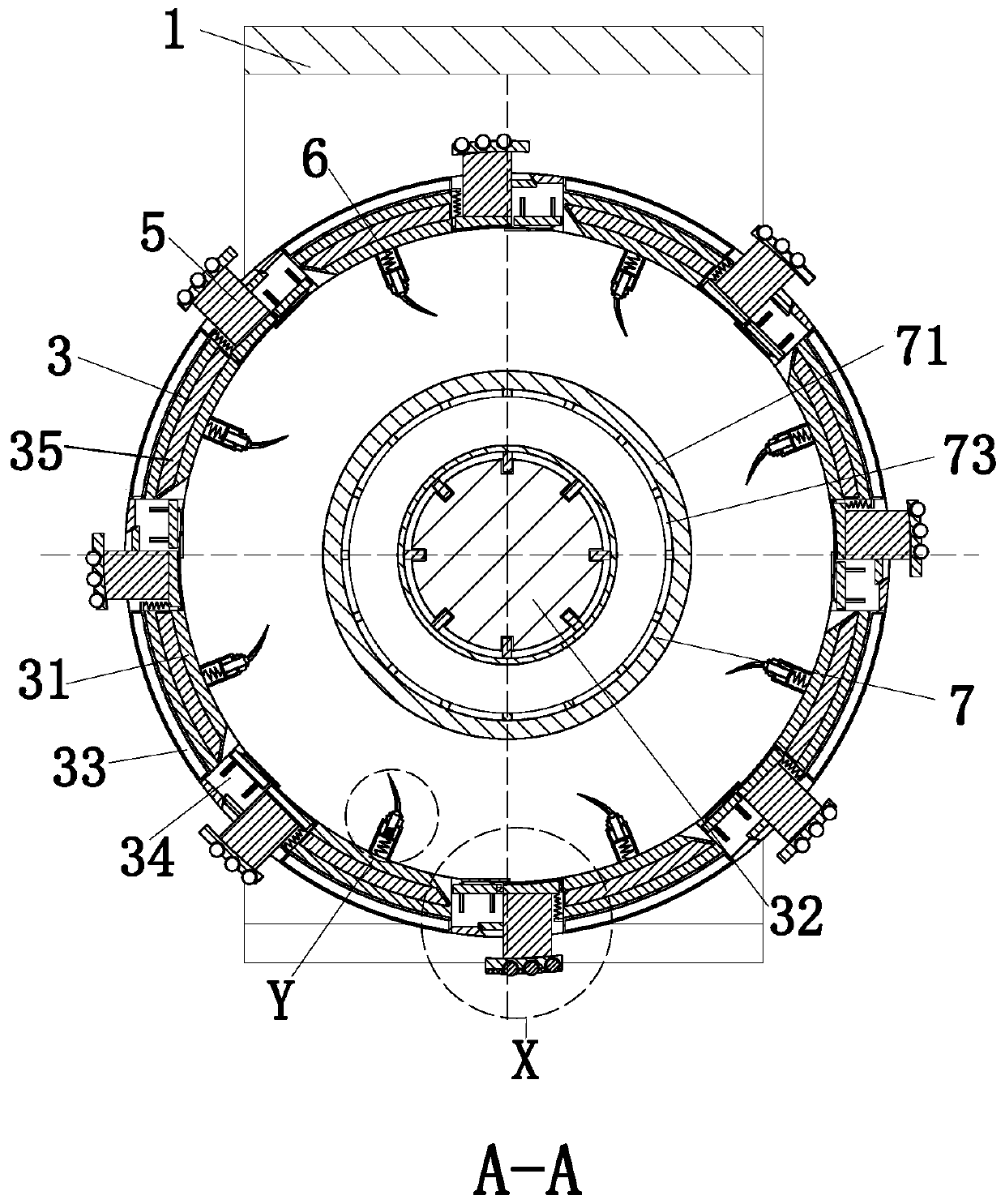

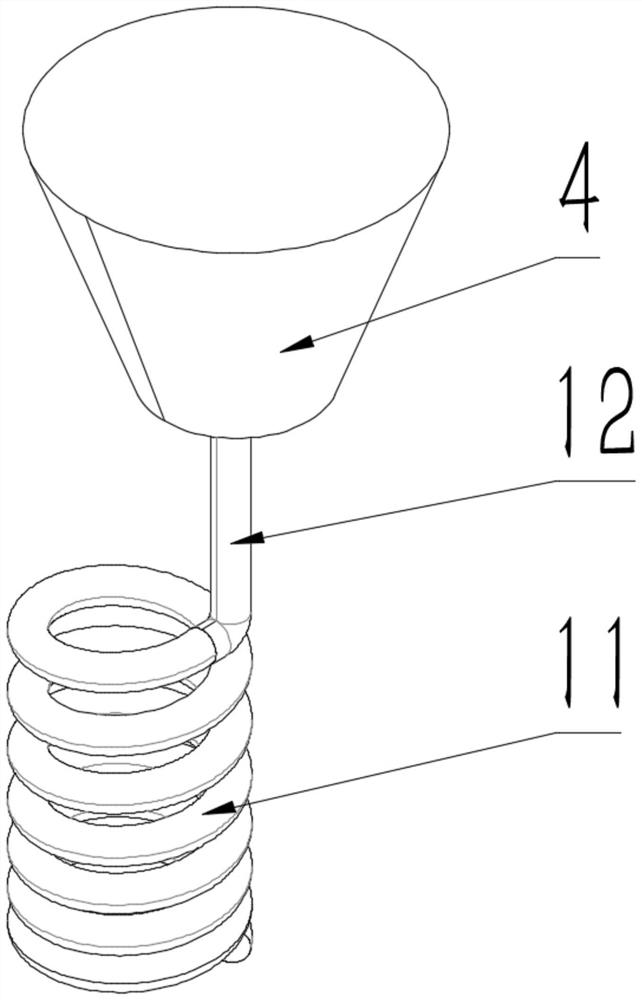

Accurate forming tool of aluminum silicon carbide composite IGBT (insulated gate bipolar translator) baseplate

ActiveCN103600053ASlow down the speed of solidificationPrevent shrinkageGearingCylindersMachining timeAluminium alloy

The invention discloses an accurate forming tool of an aluminum silicon carbide composite IGBT (insulated gate bipolar translator) baseplate. The accurate forming tool comprises an aluminizing box, a guiding pipe and positioning devices, wherein the upper part of the guiding pipe is fixedly connected with a bottom surface of the aluminizing box; the upper part of the aluminizing box is provided with a cover plate which is placed in the aluminizing box, the lower part of the aluminizing box is provided with a bottom plate which is placed in the aluminizing box, the four sides of the aluminizing box are all provided with side plates which are placed in the aluminizing box; the bottom plate is provided with an impregnation flow channel of a molten aluminum alloy liquid; at least two deformation-proof partition plates are arranged among the side plates; the guiding pipe is externally sleeved with a heat preservation device. The accurate forming tool provided by the invention has the advantages that the heat preservation device can reduce the freezing rate of an alloy liquid in the guiding pipe, a final freezing region can be controlled in the position of the heat preservation device, the aluminum alloy liquid can be used for feeding a baseplate material in the aluminizing box in time, and thus a shrinkage cavity of the material is avoided; the positioning devices can strictly control the aluminum covering quantity of the two surfaces of a baseplate, the processing time is short, the cost is low, and the production efficiency is high; the aluminizing flow channel can be used for eliminating a crackle of the material and non-uniformity of an aluminum tape and the material.

Owner:HUNAN HANGTIAN CHENGYUAN PRECISION MACHINERY

Laser scanning-vibration hot wire TIG hybrid welding method

InactiveCN110961789AWide heating rangeReduce assembly accuracyLaser beam welding apparatusLaser scanningDeposition rate

The invention relates to a laser scanning-vibration hot wire TIG hybrid welding method. The method is mainly formed by compounding laser scanning welding and vibration hot wire TIG welding. During welding, a welding heat source is formed by combining a scanning laser and a TIG electric arc, a welding wire is heated and vibrated in a reciprocating mode at the same time so as to generate a vibrationhot wire, and laser scanning-vibration hot wire TIG hybrid welding is jointly formed by the vibration hot wire and a hybrid heat source. According to the method, on one hand, the laser scanning welding can reduce an assembling precision requirement of a workpiece before welding; and on the other hand, a stirring effect on a molten pool can reduce a porosity and refine a structure; and heat inputduring welding can be reduced by preheating the welding wire, and a deposition rate and welding efficiency are improved. Under a condition that the hot wire is vibrated, on one hand, a molten pool canbe stirred to refine the structure; and on the other hand, a molten drop transition frequency can be increased, and the welding efficiency is improved.

Owner:HARBIN INST OF TECH AT WEIHAI

Ni-based alloy member, method of producing the alloy member, turbine engine part, welding material, and method of producing the welding material

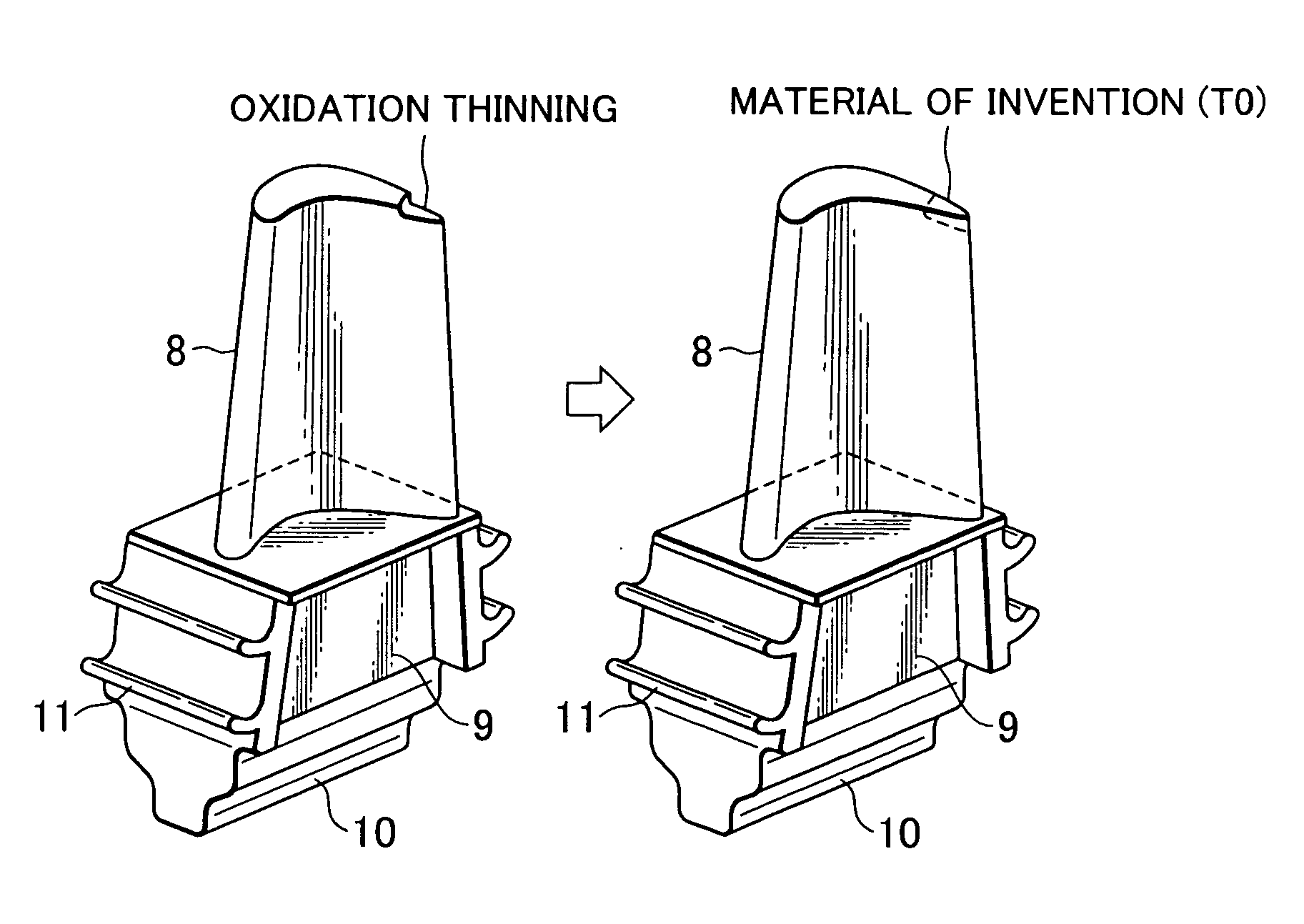

ActiveUS7547188B2Different structureSlow down the speed of solidificationPropellersArc welding apparatusAlloyUltimate tensile strength

A Ni-based alloy member has resistance against grain boundary fracture, fatigue strength, and oxidation resistance at temperatures near 1000° C. or higher. The Ni-based alloy member includes a non-repaired region made of a Ni-based alloy base and a region repaired by welding, which is formed on the non-repaired region and which is made of a buildup-welded layer, the buildup-welded layer being made of a Ni-based alloy containing, by weight, 15% or less of Co, 18-22% of Cr, 0.8-2.0% of Al, 5.0% or less of Ta, 0.5% or less of Mo, 0.5% or less of Ti, 13-18% of W, 0.05-0.13% of C, 0.06% or less of Zr, 0.015% or less of B, 0.4-1.2% of Mn, and 0.1-0.3% of Si, the balance of the alloy being preferably essentially made of Ni.

Owner:MITSUBISHI POWER LTD

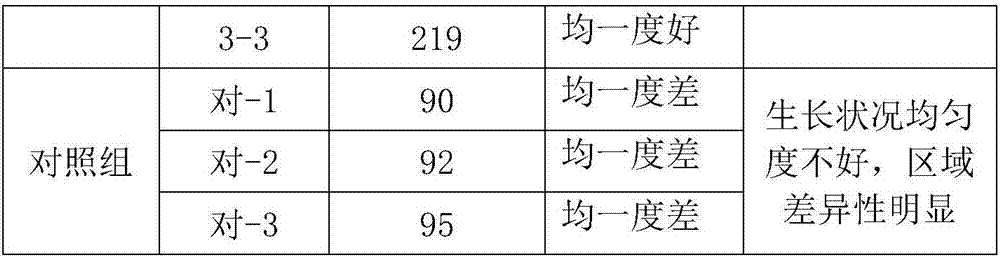

Nanogel inclined plane culture medium and preparation method thereof

ActiveCN107034140AShorten the setting timeSlow down the speed of solidificationMicroorganismsBiotechnologyEngineering

The invention discloses a nanogel inclined plane culture medium and a preparation method thereof and belongs to the field of microculture. Part of agar powder is replaced with part of nanogel particles and agarose gel on the basis of an ordinary inclined plane culture medium. Concretely, by mass percentage, first nanogel particles are used to replace 20-30% of agar powder, and then the agarose gel is used to replace 25%-35% of agar powder. The setting time and setting rate of the culture medium are effectively delayed, the thickness uniformity degree during inclined plane culture medium preparation is improved, the uniform distribution degree of culture medium nutrient substances is also improved, and thus accuracy of culture and subsequent test results is effectively ensured. Repeated testing is avoided, testing time is shortened, errors are reduced, and the precision degree of tests is improved. In addition, the preparation method is reasonable in design and simple and convenient to operate.

Owner:句容亿格纳米材料厂

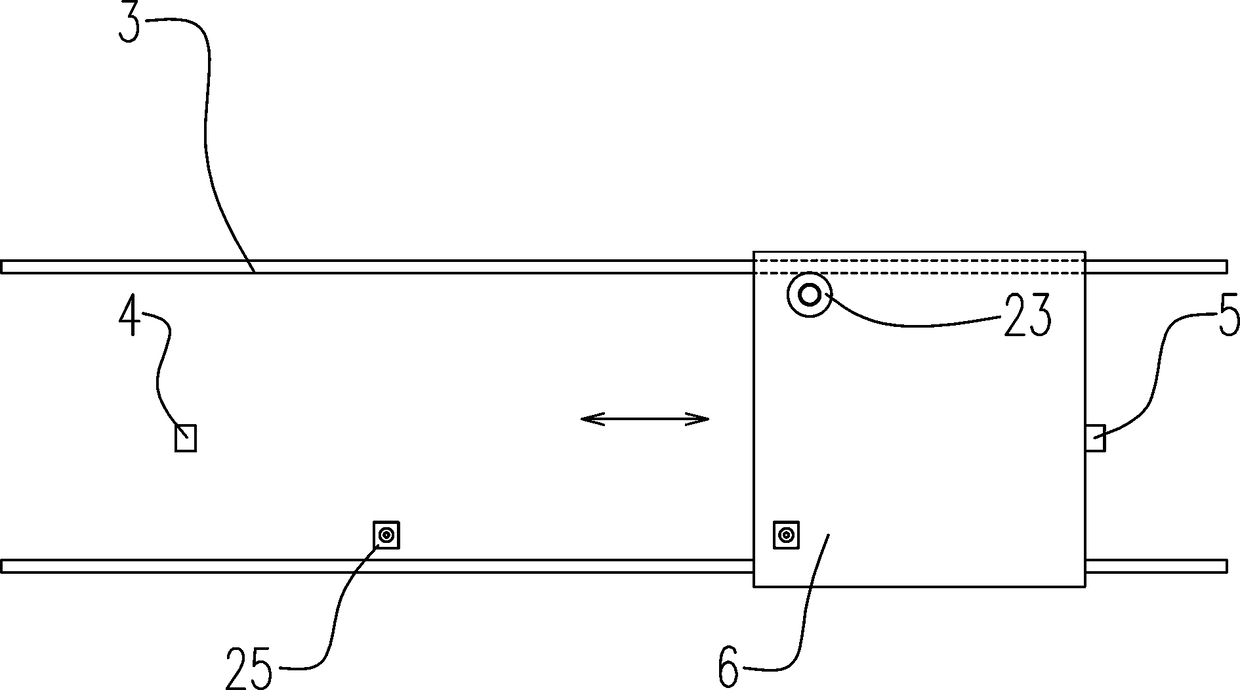

Galvanized steel wire galvanizing device

InactiveCN112251700AAvoid manual operationReduced chance of poisoningHot-dipping/immersion processesEngineeringGalvanization

The invention relates to the field of galvanizing, and particularly relates to a galvanized steel wire galvanizing device. The galvanized steel wire galvanizing device comprises a galvanizing tank, wherein a pair of guide rollers is mounted on the galvanizing tank, a galvanizing solution tank is dug in the galvanizing tank, a pair of limiting rollers are rotatably connected in the galvanizing solution tank, and steel wires are connected between the guide rollers and the limiting rollers; and an automatic heat preservation scraping mechanism is arranged in the galvanizing solution tank, arranged on the upper sides of the limiting rollers and comprises a cover plate. According to the galvanized steel wire galvanizing device, by arranging the corresponding mechanisms on the galvanizing tank,the solidification speed of a surface layer galvanizing solution is greatly decreased, an operator does not need to frequently conduct scraping work, meanwhile, the hands of the operator are liberated, the operator does not need to manually scrape the galvanizing solution solidified on the inner surface layer of the galvanizing tank, the whole device can be automatically removed, the safety of theoperator is greatly improved, meanwhile, the scraping efficiency is improved, the steel wire galvanizing effect is greatly improved, and the situation that the steel wires are affected by the solidified galvanizing solution is avoided.

Owner:ANHUI HUITENG INTELLIGENT TRANSPORTATION TECH CO LTD

Mass concrete and preparation process thereof

The invention discloses mass concrete and a preparation process thereof. The mass concrete comprises 230-235 parts by weight of cement, 110-120 parts by weight of fly ash, 160-165 parts by weight of water, 75-80 parts by weight of mineral powder, 850-860 parts by weight of medium sand, 735-740 parts by weight of broken stones with a respective particle size of 5-25 mm, 220-225 parts by weight of broken stones with a respective particle size of 5-10 mm, 1-1.5 parts by weight of a modifying agent, 0.001-0.005 part by weight of a retarder and 7-7.8 parts by weight of a water reducing agent. The mass concrete and the preparation process thereof disclosed by the invention have the beneficial effects that through the addition of the fly ash and the mineral powder, the adding amount of the cementis reduced, and the heat release of the cement in the hydration process is reduced; meanwhile, the added modifying agent selects copolymer methacrylic acid and copolymerized isoprene polyoxyethyleneether capable of being complexed with the cement or the water reducing agent, so that the degree of hydration of the cement can be changed, the cement hydration peak is delayed, and the staggered peakhydration can be performed during use in the mass concrete. Through integrally selecting the above components, not only is the heat release in the hydration process of the cement reduced, but also the cement hydration peak is delayed, so that the temperature contraction affected by a sharp temperature change is avoided, and further the cracking phenomenon of the mass concrete is avoided.

Owner:成都精准混凝土有限公司

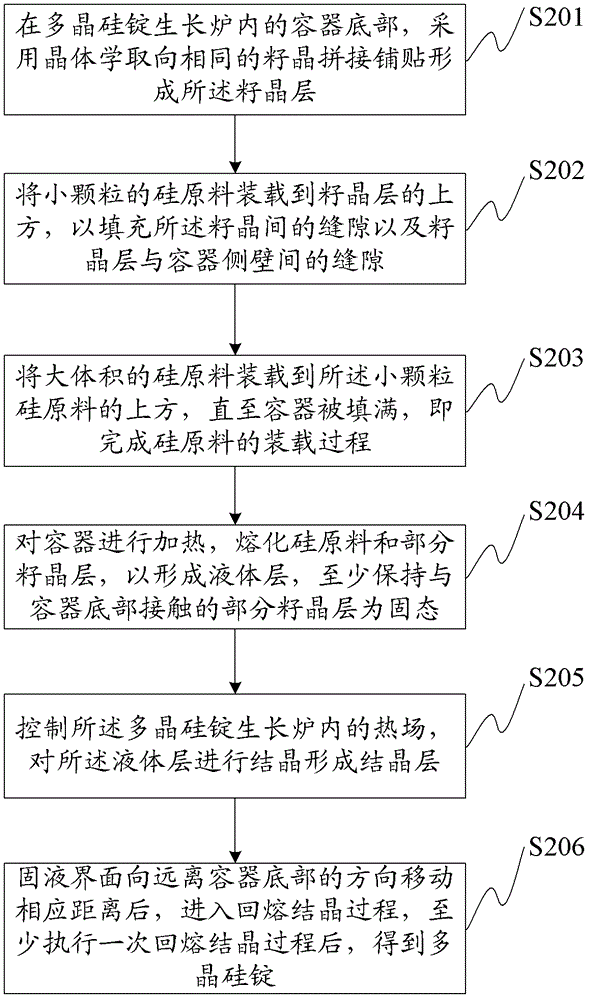

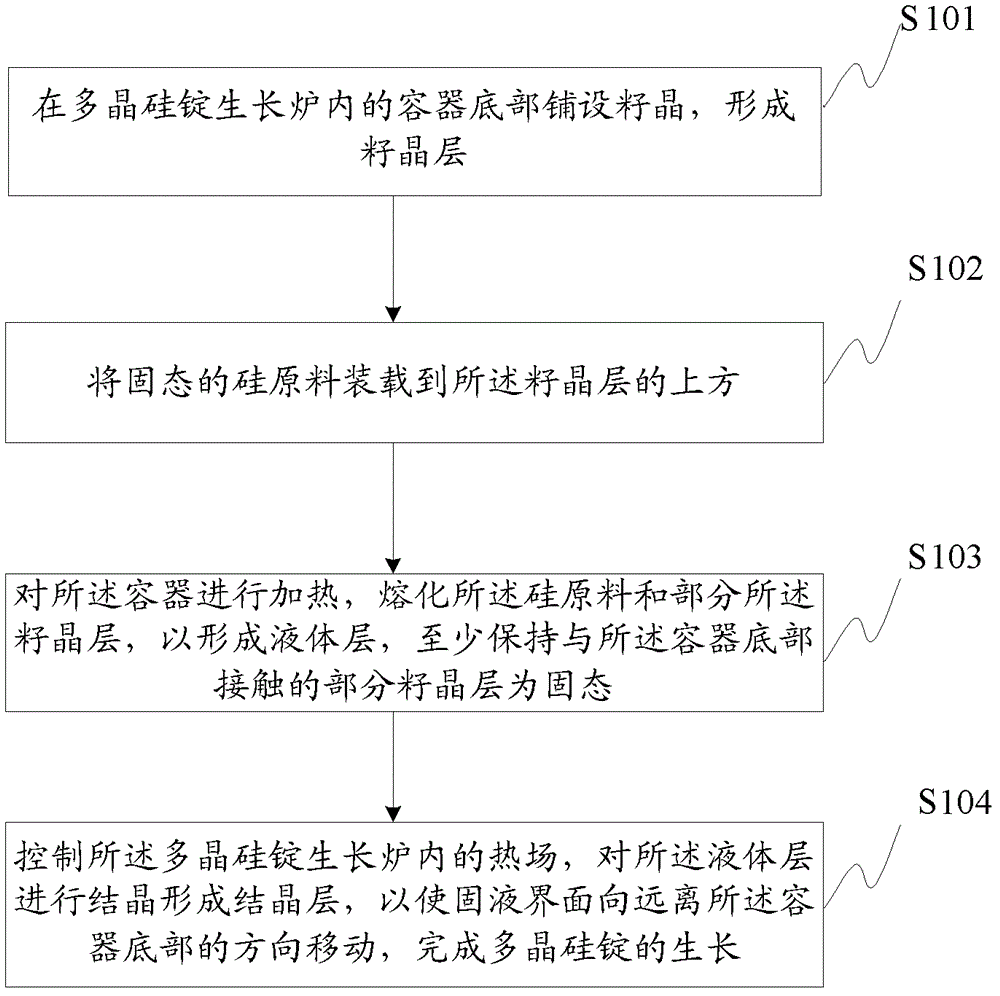

Polycrystalline silicon ingot, manufacturing method thereof and solar cell

InactiveCN102797037ALow oxygen impurity contentReduction factorPolycrystalline material growthLevel indicators by dip membersLiquid layerAttenuation coefficient

The invention discloses a manufacturing method of a polycrystalline silicon ingot. The manufacturing method comprises the steps of paving seed crystals on the bottom of a container in a polycrystalline silicon ingot growth furnace to form a seed crystal layer; loading solid silicon raw materials on the seed crystal layer; heating the container to melt the silicon raw materials and part of seed crystal layer to form a liquid layer, and at least keeping part of the seed crystal layer contacted with the bottom of the container to be in the solid state; controlling a thermal field in the polycrystalline silicon ingot growth furnace, and crystallizing the liquid layer to form a crystallization layer so as to move a solid-liquid interface to the direction far away from the bottom of the container to complete the growth of the polycrystalline silicon ingot. The polycrystalline silicon ingot produced by adopting the method disclosed by the invention is low in impurity content, the produced solar cell is low in cost and attenuation coefficient, and the photoelectric conversion efficiency is high.

Owner:ZHEJIANG YUHUI SOLAR ENERGY SOURCE

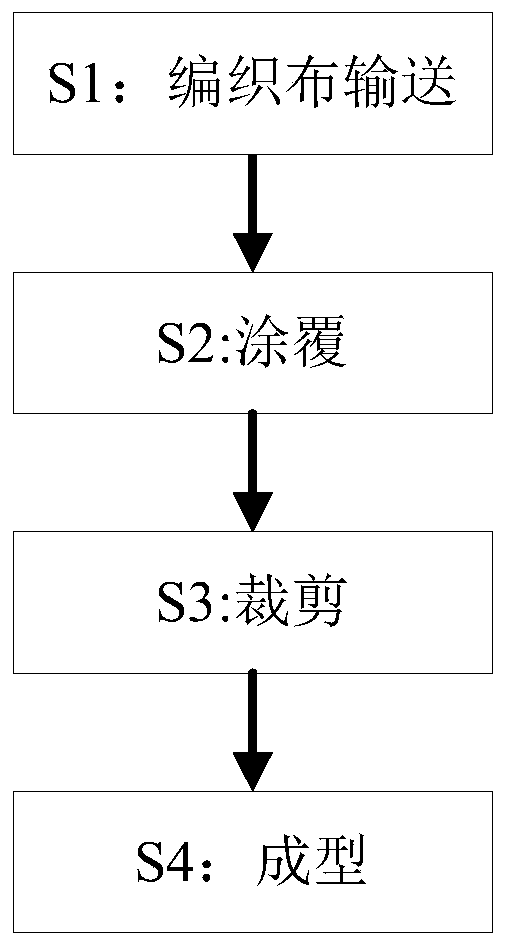

Manufacturing process of two-in-one composite plastic woven cloth

ActiveCN110479535AEffective controlAvoid cooling and solidificationLiquid surface applicatorsCoatingsEngineeringPortal frame

The invention provides a manufacturing process of two-in-one composite plastic woven cloth, wherein a portal frame, a motor, a coating roller, an annular sliding chute, discharging devices, swing devices and a heat conduction cylinder are matched to complete operation. In the existing coating process, in general, a resin solution is directly poured onto the woven cloth, coating is carried out through the coating roller, and due to the fact that the concentration of the resin solution is high, it is difficult for the resin solution to drip, the single pouring amount of the resin solution is always unequal, and the pouring amount cannot be effectively controlled; and the temperature of the resin solution in hot melting state is higher, the phenomenon of cooling and solidification often occurs when the resin solution to be poured out is cooled, and when the resin solution is poured onto the woven cloth, the amount of the resin solution at each position of the woven cloth is unequal, and consequently the thickness of each position of a rolling layer of the woven cloth is uneven during rolling of the coating roller, With the manufacturing process of the two-in-one composite plastic woven cloth, the above problems can be solved.

Owner:浙江兴澳科技有限公司

Coke oven heat-state pumping grouting construction method

ActiveCN103387835ASlow down the speed of solidificationReduce labor intensityCoke oven detailsEngineeringCoke oven

The invention provides a coke oven heat-state pumping grouting construction method. The coke oven heat-state pumping grouting construction method comprises the following construction steps: arranging a slurry mixer on a middle platform or an end platform, arranging a slurry storage box in the front of the slurry mixer, and arranging a vertical slurry pump in the storage box; putting up a support frame with the height of 500 to 600 mm on the top of a furnace, and fixing a main slurry pipeline on the support frame, wherein one end of the main slurry pipeline is connected with the vertical slurry pump; arranging grouting branch pipes at the two sides of the main slurry pipeline at intervals, and arranging stop valves between the grouting branch pipes and the main slurry pipeline; and in the whole grouting process, injecting slurry into each grouting branch pipe all the time, and controlling the stop valve on each grouting branch pipe so as to realize the control on grouting points; and after the periodical grouting is finished, pumping clean water by the vertical slurry pump so as to clean the pipeline. The coke oven heat-state pumping grouting construction method has the advantages that a conventional manual conveying manner is replaced by a manner of conveying the slurry by the pipelines, so that the labor intensity of workers is greatly alleviated, the setting rate of slurry is reduced, the working efficiency is improved, the construction cost is reduced, and the construction period is shortened.

Owner:CHINA 22MCC GROUP CORP

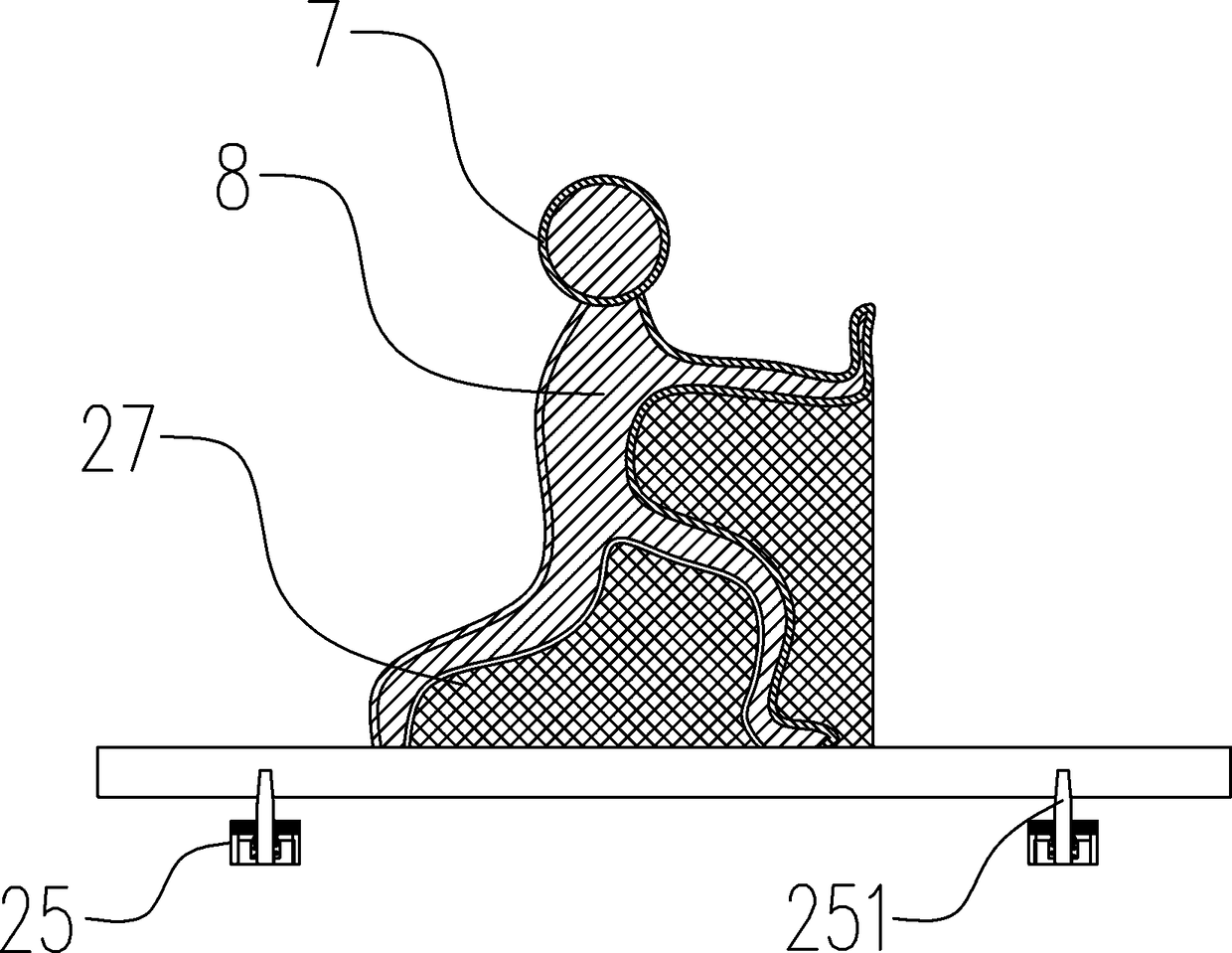

Rapid 3D printing apparatus and method

ActiveCN108312519AImprove 3D printing speedHigh strengthManufacturing heating elementsIncreasing energy efficiencyEngineering3D printing

Owner:WUHAN E YOUCAN MEDICAL TECH CO LTD

Preparation method of recycled concrete based on house construction

InactiveCN112917671AEasy to GrindSlow down the speed of solidificationMixing operation control apparatusHollow article cleaningThermal dilatationElectric machine

The invention discloses a preparation method of recycled concrete based on house construction, and belongs to the field of concrete. According to the preparation method of the recycled concrete based on the house construction, in the scheme, lubricating oil expands in a storage cavity and flows into gaps of a screening cylinder through high temperature generated during friction between concrete waste residues and the screening cylinder, and the probability of screening cylinder blockage caused by concrete blocks is reduced. A main motor is started, a fixed shaft is driven to rotate, the concrete blocks are stirred through a stirring rod and a cleaning plate, when the main motor drives the stirring rod to rotate, the concrete is better ground through grinding beads at the outer end of a grinding ring, and when the concrete is slowly solidified, heat is generated, heat expansion air bags are heated and expand, and T-shaped sliding rods are ejected towards the outer side. Meanwhile, the grinding beads are softened by heat, and the grinding beads are punctured through ejector pins on the outer sides of ejector plates, so that a cement retarder flows out and is mixed into the concrete, and the solidification speed of the concrete is effectively slowed down.

Owner:广西安业建设集团有限公司

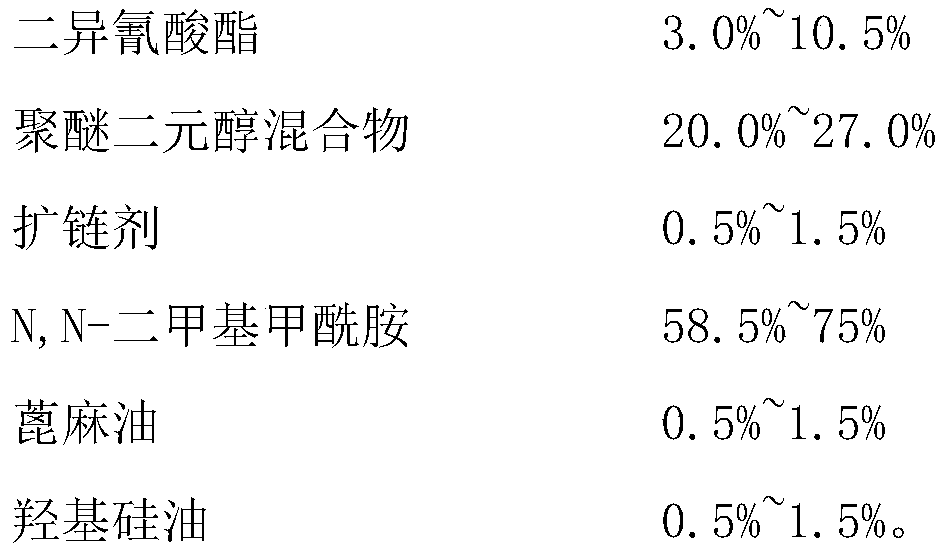

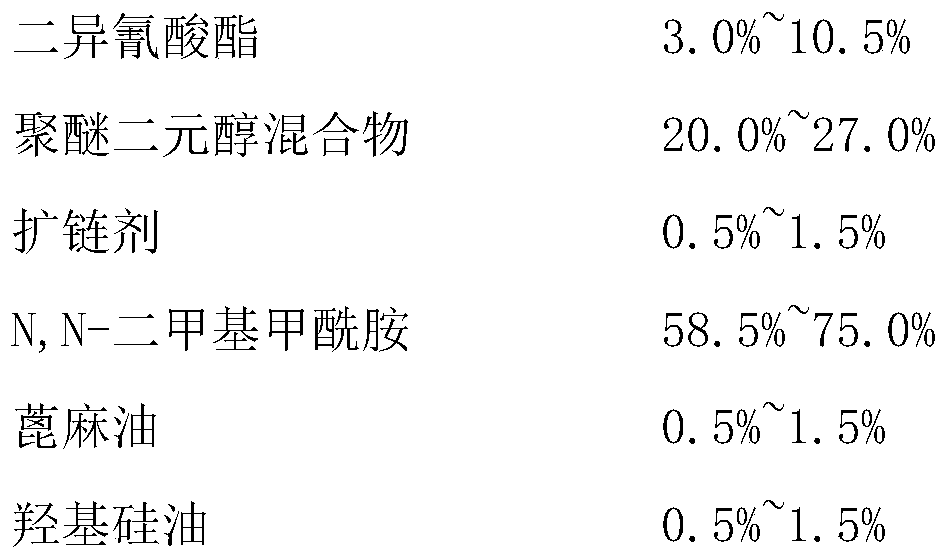

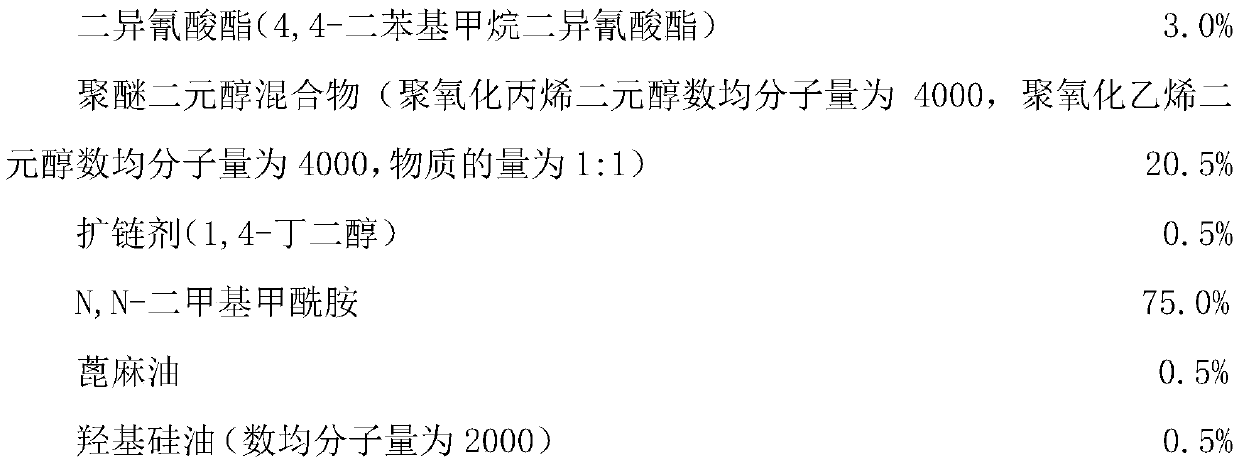

Super-soft and super-cotton type hydrolysis-resistant wet polyurethane resin and preparation method thereof

The invention discloses an ultra-soft and ultra-cotton type hydrolysis-resistant wet polyurethane resin and a preparation method thereof. The invention relates to an ultra-soft and ultra-cotton hydrolysis-resistant wet polyurethane resin, which is prepared by comprising the following components by weight percent: 3.0% to 10.5% of diisocyanate, 20.0% to 27.0% of polyether glycol mixture, 0.5% to 1.5% of chain extender, and 58.5% to 75.0% of N, N-dimethylformamide, 0.5% to 1.5% of castor oil and 0.5% to 1.5% of hydroxyl silicone oil. The synthetic leather prepared by the invention has soft handfeeling and strong cotton feeling. In addition, the addition of hydroxyl silicone oil in the chain termination stage can effectively prevent silicone oil from precipitating fog and resin viscosity reduction during storage. At the same time, because hydroxyl silicone oil is linked on the polyurethane main chain to form a hydrophobic layer, sweat erosion can be prevented and hydrolysis resistance can be further enhanced.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

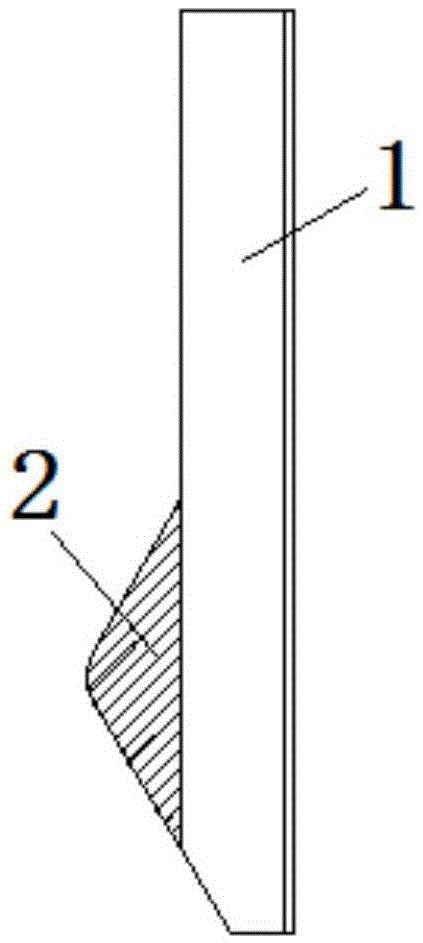

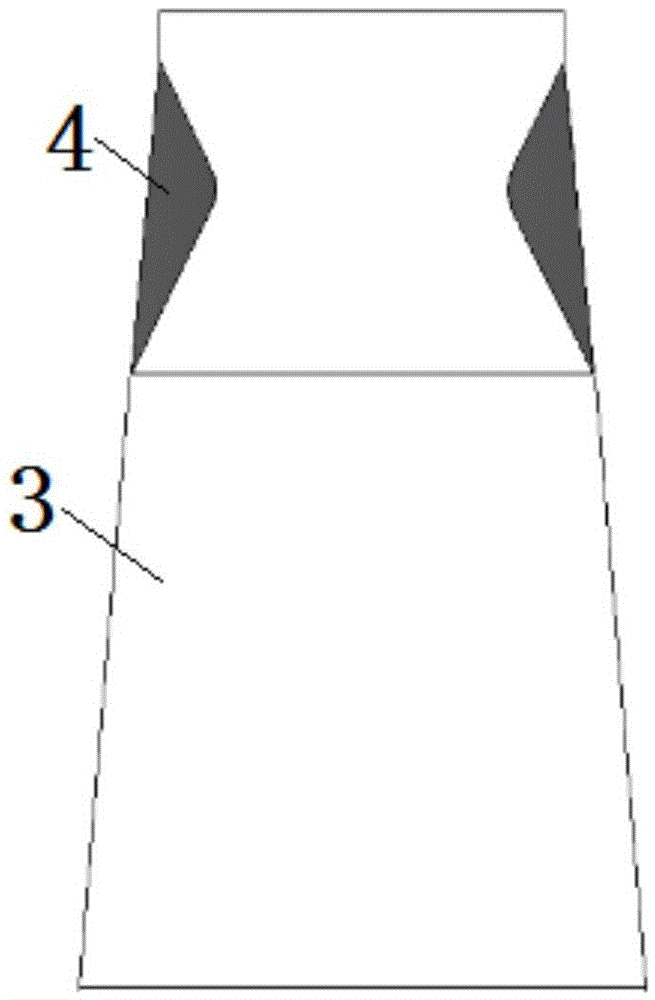

Insertion plate structure of insulating riser of steel ingot mold

The invention discloses an insertion plate structure of an insulating riser of a steel ingot mold. The insertion plate structure of the insulating riser of the steel ingot mold comprises a long strip-shaped insertion plate body. An arc-shaped protrusion is arranged on the surface of one side of the insertion plate body. The arc-shaped protrusion is located at one end, in the length direction, of the insertion plate body. The bottom of the arc-shaped protrusion is in smooth transition with the insertion plate body. The insertion plate structure of the insulating riser of the steel ingot mold is provided with the arc-shaped protrusion so that a corresponding concave part can be generated on a steel ingot, the steel ingot can be positioned and firmly clamped easily by a clamp through the concave part when hoisted, and the requirements for rapid clamping and hoisting the red hot steel ingot are met.

Owner:江苏苏南重工机械科技有限公司

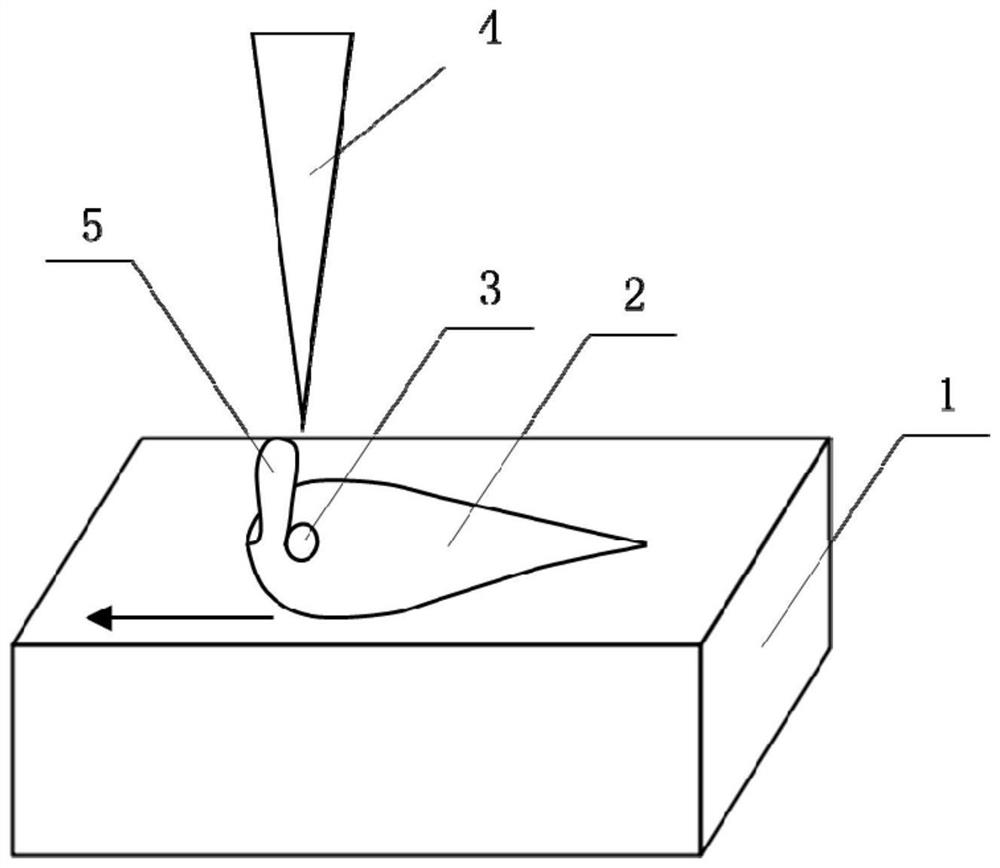

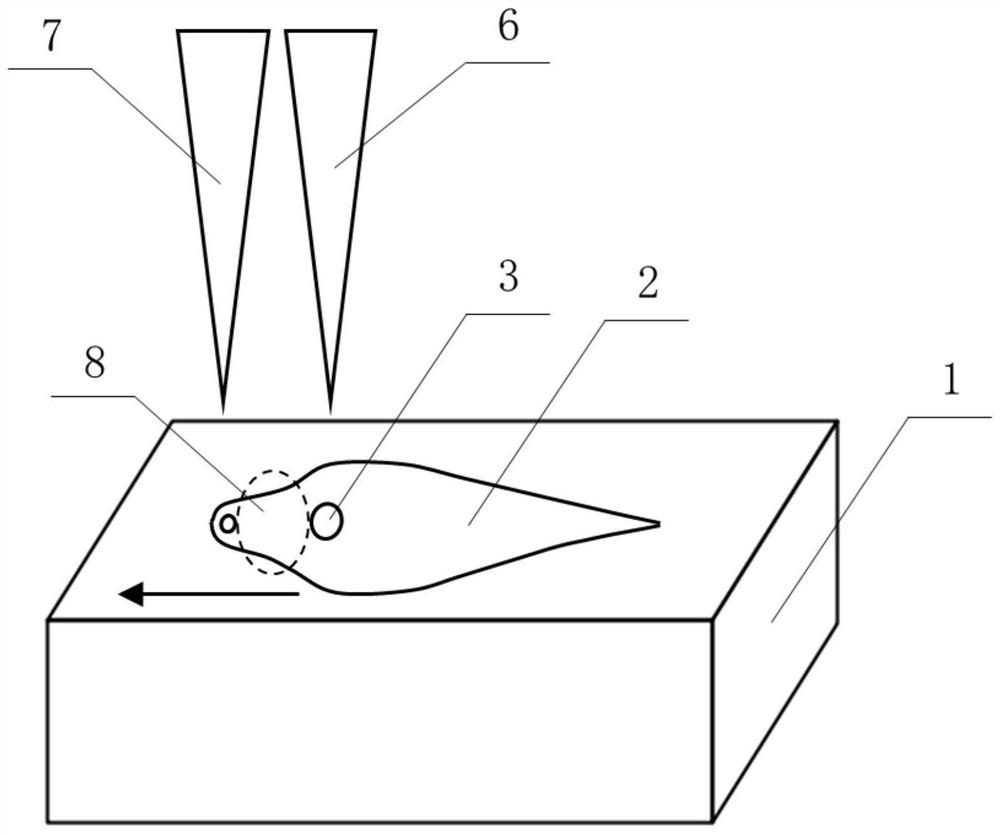

Myriawatt-level laser double-beam welding method for inhibiting welding liquid column and splashing

InactiveCN113182675AReduce generationQuality improvementLaser beam welding apparatusLight spotMetallic materials

The invention discloses a myriawatt-level laser double-beam welding method for inhibiting a welding liquid column and splashing, and belongs to the technical field of laser processing. The technical problem that a large welding liquid column is prone to be formed and is evolved to welding splashing according to an existing myriawatt-level high-power laser in a non-penetration welding mode is solved. According to the method, two double-beam lasers which are arranged front and back in the welding direction and are different in light spot size and laser power are adopted for metal material welding, the rear laser beam is large in power and small in light spot diameter and is used for penetration fusion welding, and the front laser beam is small in power and large in light spot diameter and is used for melting base metal shallow metal to form a front molten pool, which is in Communication with a rear molten pool formed through the rear laser beam, during welding, through the mode that part of metal surges of the rear molten pool are guided to enter the front molten pool, the pressure of liquid metal on the front edge of a keyhole of the rear light beam is reduced, a longitudinal liquid column is prevented from growing and being evolved to splashing, and good surface forming of myriawatt-level high-power laser welding is achieved.

Owner:HARBIN WELDING INST LTD

Preparation method of skin-imitated woven summer sleeping mat synthetic leather

InactiveCN107460744ARich sourcesExtended service lifeSolvent-treatmentOrganic non-surface-active detergent compositionsFiberCarbon fibers

The invention discloses a preparation method of skin-imitated woven summer sleeping mat synthetic leather. The preparation method comprises the following steps: S1, soaking a synthetic leather base fabric into an immersion trough, beating while immersing, taking out the synthetic leather base fabric, squeezing out the water and ironing for later use; S2, dissolving polyurethane resin and polyether resin into a DMF (Dimethyl Formamide) solution, and then adding zinc stearate, calcium stearate, an antistatic agent, carbodiimide and 4,4'-diamido-3,3'-dichlorodiphenylmethane for mixing, then redispersing carbon fibers, aggregate, wood powder and a thickening agent, adding the DMF solution, and adjusting the viscosity of slurry, thus obtaining the slurry; and S3, coating the surface of the base fabric with the slurry until the slurry is completely solidified, taking out, washing with methyl tertiary butyl ether, ethanol and water, then drying, shaping, cooling and carrying out flower roll embossing, thus obtaining the skin-imitated woven summer sleeping mat synthetic leather. The preparation method provided by the invention has the advantages of simple operation, abundant resources of raw materials and low production cost; and in addition, the prepared product has the advantages of smooth surface, high hydrolysis resistance, high wear resistance and long service life.

Owner:TIANSHOU FUJIAN SUPERFIBER TECH

Laser cladding repairing method for inner hole of rolling mill roller end shaft sleeve and composite device for laser cladding

InactiveCN113802117AImprove bindingMinor repairabilityMetallic material coating processesAssembly disassemblySurface cleaning

The invention discloses a laser cladding repairing method for an inner hole of a rolling mill roller end shaft sleeve. The laser cladding repairing method comprises the steps of shaft sleeve assembly disassembly, shaft sleeve surface cleaning, component detection, pre-sequence heat treatment, layered cladding, post-sequence heat treatment, machining, inspection and flaw detection and qualified product delivery. In the step (4) of pre-sequence heat treatment, specifically, preheating is carried out before cladding can be in-furnace heating and heating belt heating; or in-furnace heating and induction device heating are adopted; or the induction device is independently used for heating; and in the step of (6) post-sequence heat treatment, specifically, an induction heating mode can be induction heating or other heating modes. According to the laser cladding repairing method, a cladding layer with high wear resistance, high strength and high binding force is cladded on the surface of the inner hole of a roller end shaft, and the service life of the roller end shaft sleeve is prolonged.

Owner:泰尔(安徽)工业科技服务有限公司

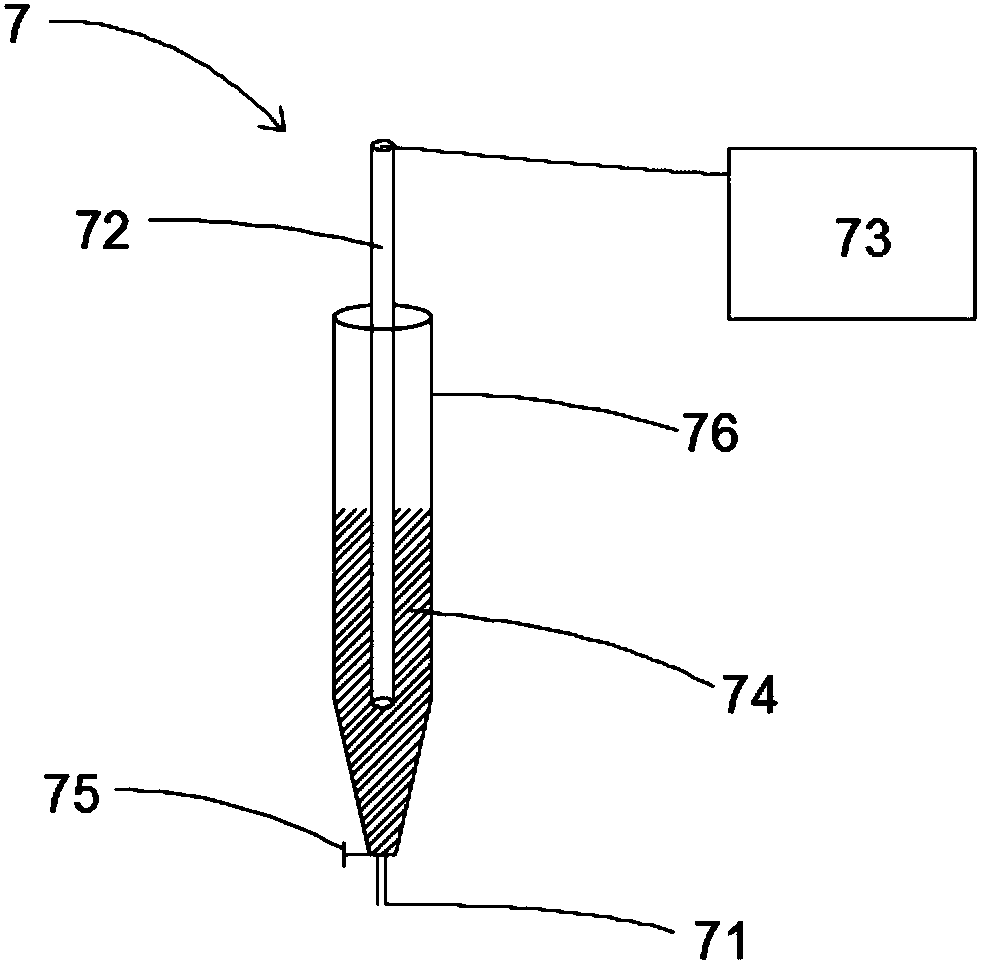

Vacuum atomizing device and method for preparing 3D printing powder

The invention discloses a vacuum atomizing device. The vacuum atomizing device comprises a vacuum induction furnace, a tundish, a gas atomizing device, an atomizing cooling tower and a powder collecting system which are sequentially connected. The vacuum atomizing device further comprises a high-pressure gas supplying system; the gas atomizing device comprises a hot metal spraying head which communicates with the tundish, and a gas spraying head which communicates with the high-pressure gas supplying system. The vacuum atomizing device further comprises a salt bath device which is arranged above the gas atomizing device; the salt bath device comprises a salt bath spraying head which communicates with the salt bath device; and the salt bath spraying head is arranged between the hot metal spraying head and the gas spraying head. According to the device, the salt bath spraying head is additionally arranged between the hot metal spraying head and the gas spraying head, so that the powder surface can be subjected to thermal treatment through salt bath when the hot metal solidifies, and as a result, the powder surface solidification speed is decreased, the sphere similarity of the powderparticle surfaces can be improved, and the powder surface quality is improved.

Owner:福州臻美网络科技有限公司

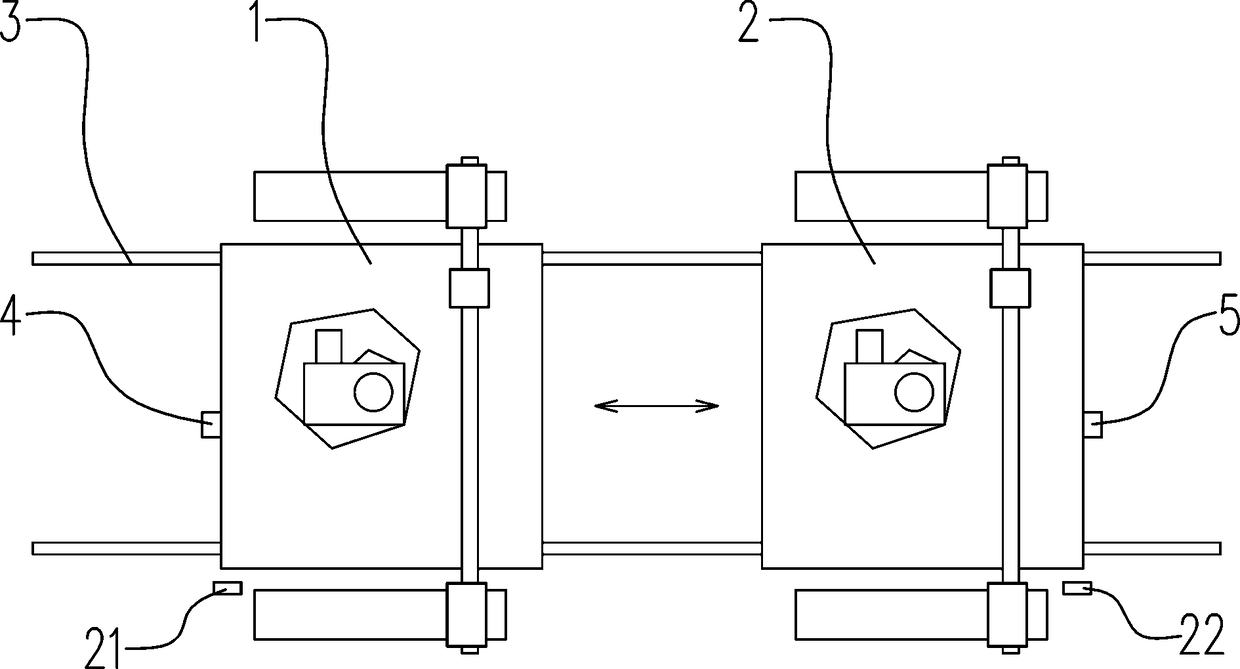

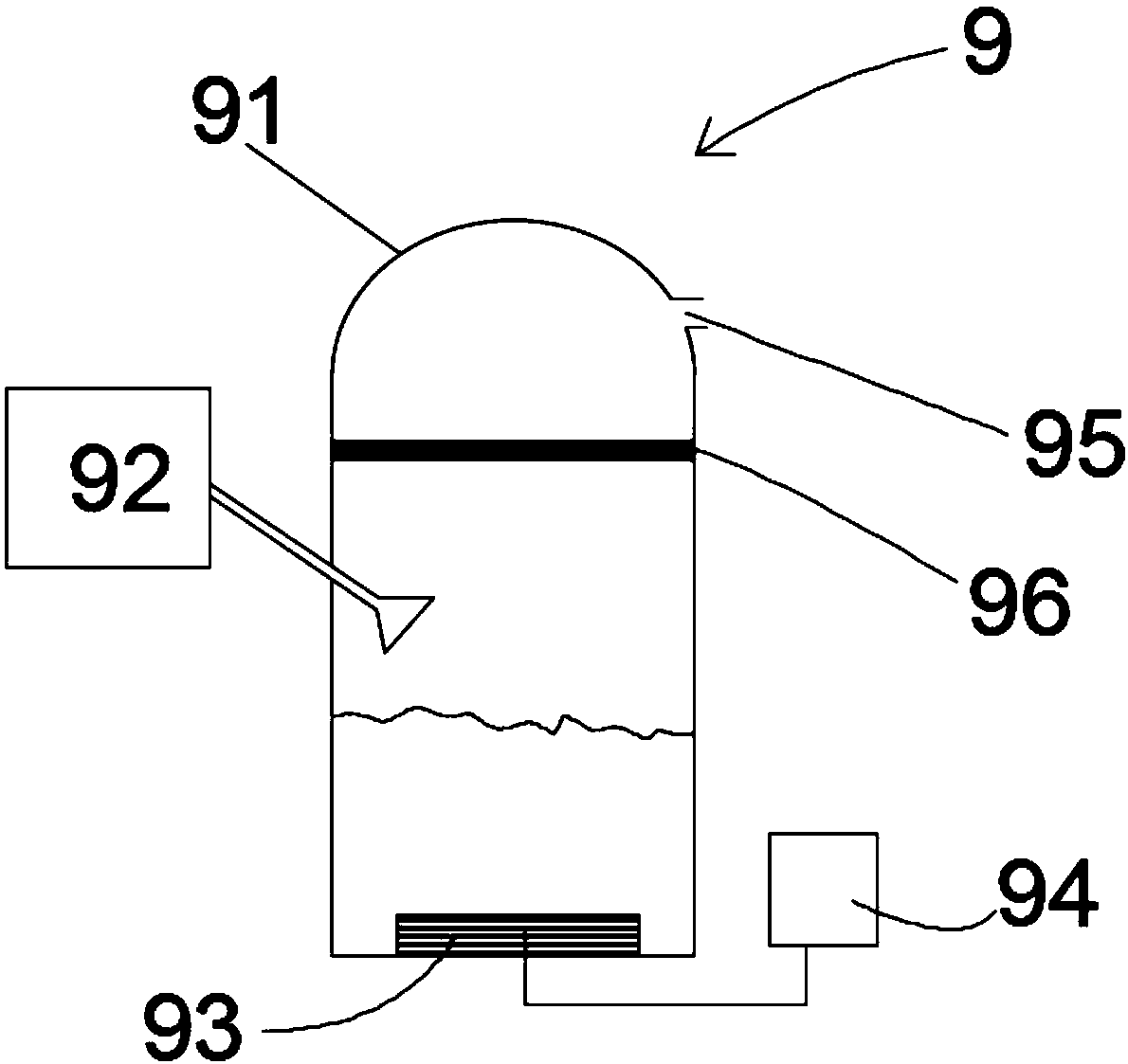

Welding system for reducing aluminum alloy laser-arc hybrid welding air holes and method

ActiveCN113909718AFull flowImprove liquidityWelding/cutting auxillary devicesAuxillary welding devicesLiquid metalMetal

The invention relates to a welding system for reducing aluminum alloy laser-arc hybrid welding air holes and a method. The welding system comprises a vibration device and a probe, the vibration device drives the probe to vibrate, and the probe comprises a spiral stirring part. According to the welding system, through the stirring and vibration effects of the probe, sufficient flowing of molten pool metal is guaranteed, small bubbles existing in a molten pool gather, grow and emerge from the molten pool, and therefore the risk that air holes are generated in a weld joint is reduced, the welding quality of aluminum alloy is improved, and the problem that the porosity of aluminum alloy laser-electric arc hybrid welding is high is solved; and the solidification speed of liquid metal in the molten pool is reduced through the heating probe, and the problem that weld joint components are not uniform due to too high cooling speed and insufficient molten bath flowing is solved.

Owner:国家高速列车青岛技术创新中心 +1

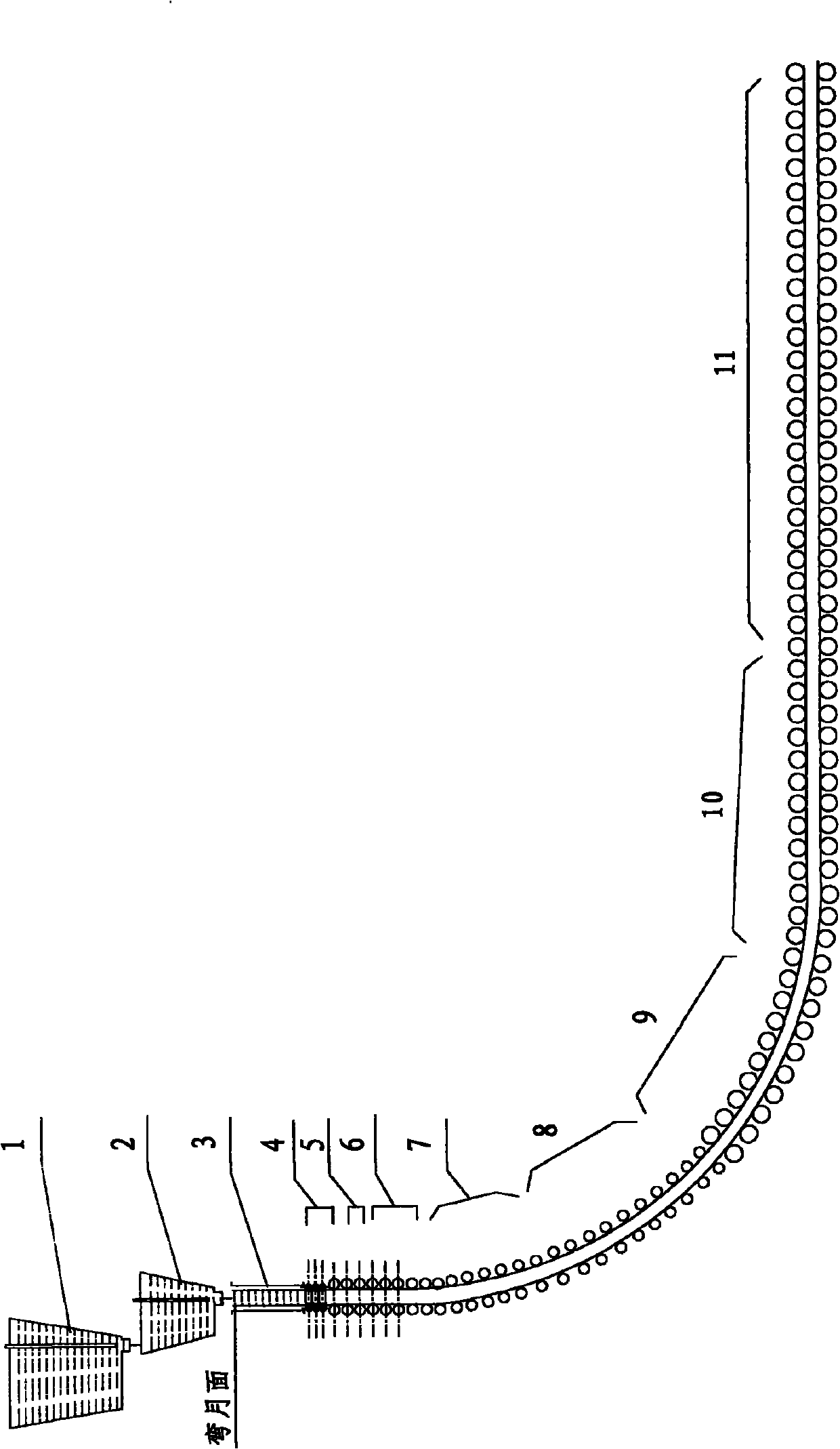

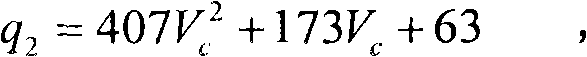

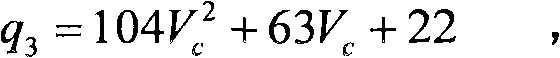

Round billet continuous casting method and round billet continuous casting system

InactiveCN102343429BReduces the chance of thermal cracksReduce the temperature difference between inside and outsideMolten steelUltimate tensile strength

The invention provides a round billet continuous casting method. The method comprises the following steps of: casting molten steel to a tubular round billet crystallizer from a tundish to form a casting billet which is not completely solidified; and then pulling the casting billet which is not completely solidified out of the tubular crystallizer at a pulling speed Vc and passing the casting billet which is not completely solidified through a secondary cooling region and an air cooling region in sequence to finally obtain a completely solidified casting billet, wherein five spray cooling sections which are arranged in sequence are used for performing secondary cooling at the secondary cooling region; and casting billet cooling strength (L / (min.m<2>)) at a unit area of each of the five spray cooling sections is shown in the specification respectively. The invention also provides a round billet continuous casting system. By determining the casting billet cooling strength at the unit area of different spray sections arranged in continuous casting direction according to the pulling speed, a continuous casting billet shell can be uniformly cooled during solidification, cooling and gradual thickening of the billet shell, so that internal defects of central cracks produced by a large round pipe billet and the like are prevented.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

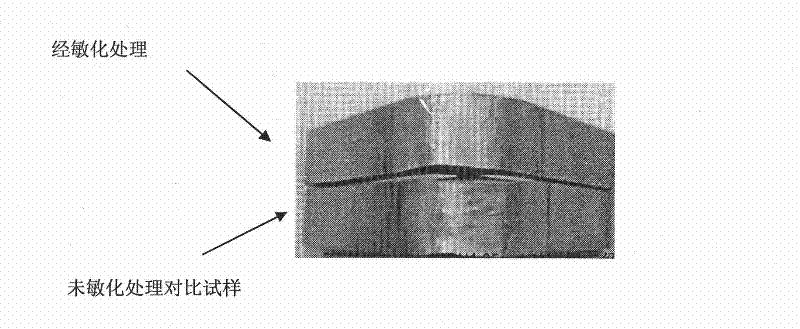

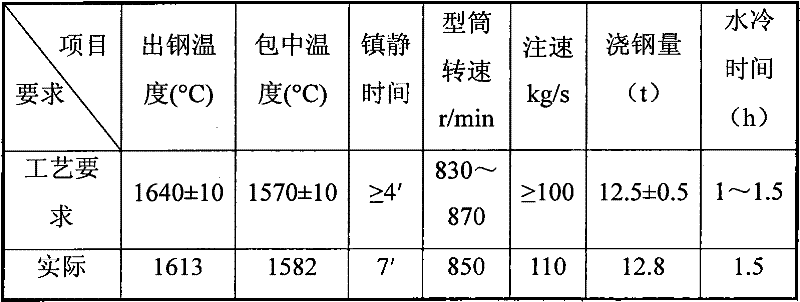

Centrifugal casting method of main pipeline of million-kilowatt nuclear plant

ActiveCN102240789AImprove cooling effectSlow down the speed of solidificationFoundry mouldsFoundry coresNuclear plantCrystal structure

The invention discloses a centrifugal casting method of a main pipeline of a million-kilowatt nuclear plant, which is carried out by centrifugally casting on a horizontal centrifugal casting machine. A mould for forming a centrifugal cast pipe is a forged alloy steel cylinder, inner wall of which is coated through a cylinder. The temperature of used molten steel in a steel ladle is controlled within 1570 plus or minus 10 degrees centigrade. The calm time is not less than 4 min. The rotation speed of the cylinder is controlled within 800-870 r / min. The casting speed is more than or equal to 100 kg / s. After casting, water is cooled below 300 degrees centigrade. Then, the demoulding process is carried out. The thickness of a blank pipe wall of the centrifugal cast pipe is 100 mm. In the event of casting, rapid casting and compulsive water cooling are carried out. Crystal structures can be refined. The operation safety of equipment is improved.

Owner:烟台台海玛努尔核电设备有限公司

Medical adhesive for clinical minor operation incision and preparation method

ActiveCN105412980AHas medical efficacyGood medical effectBandagesDioscorea polystachyaMedical treatment

The invention discloses a medical adhesive for a clinical minor operation incision and a preparation method. The medical adhesive is prepared from, by weight, 3-5 parts of aloe protein, 3-5 parts of Chinese yam protein, 7-9 parts of soluble ginkgo polysaccharides, 12-15 parts of an aqueous polyoxyethylene solution, 3-5 parts of a-cyanoacrylate, 2-3 parts of chitosan, 12-14 parts of polyvinyl alcohol, 4-6 parts of multi-aldehyde sodium alginate, 1-3 parts of pectin, 1-3 parts of gelatin, 12-13 parts of hydrogenated camellia oil and the like. According to the medical adhesive for the clinical minor operation incision and the preparation method, by adopting the functional adding solution, the effects that the adhesive property is good, and disinfecting can be performed to inhibit wound infection are achieved; by adopting the processed chitosan, multi-aldehyde sodium alginate, pectin and gelatin as the main materials, the effects that the solidifying speed is low, and inflammation diminishing, healing and un-scaring of the clinical minor operation incision are facilitated are achieved; meanwhile, the hydrogenated camellia oil is adopted, and therefore a patient can achieve the good experience effect. The medical adhesive can meet the requirements of the clinical minor operation incision and is wide in raw material source and good in medical effect.

Owner:贵州通济智医科技有限公司

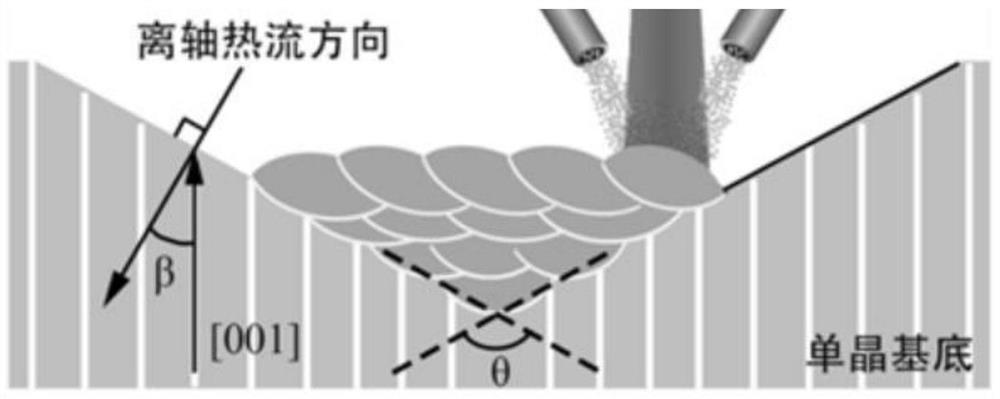

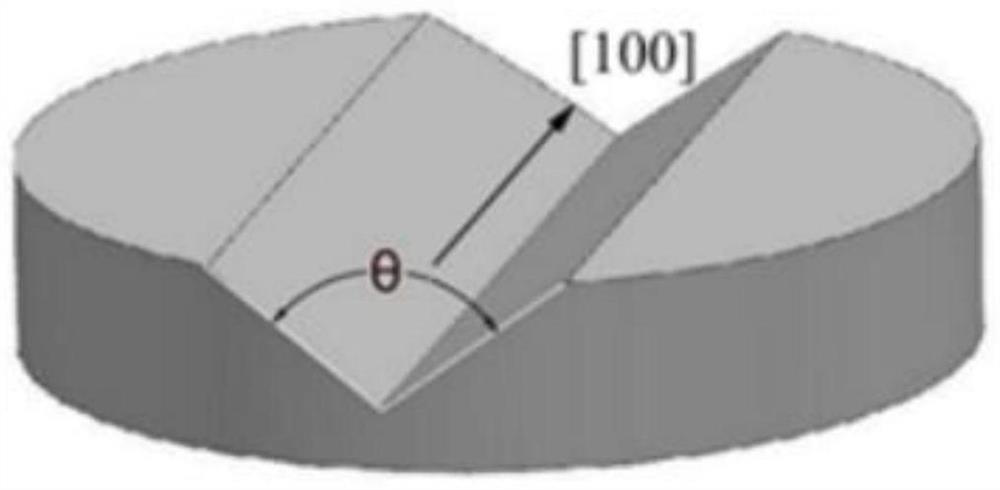

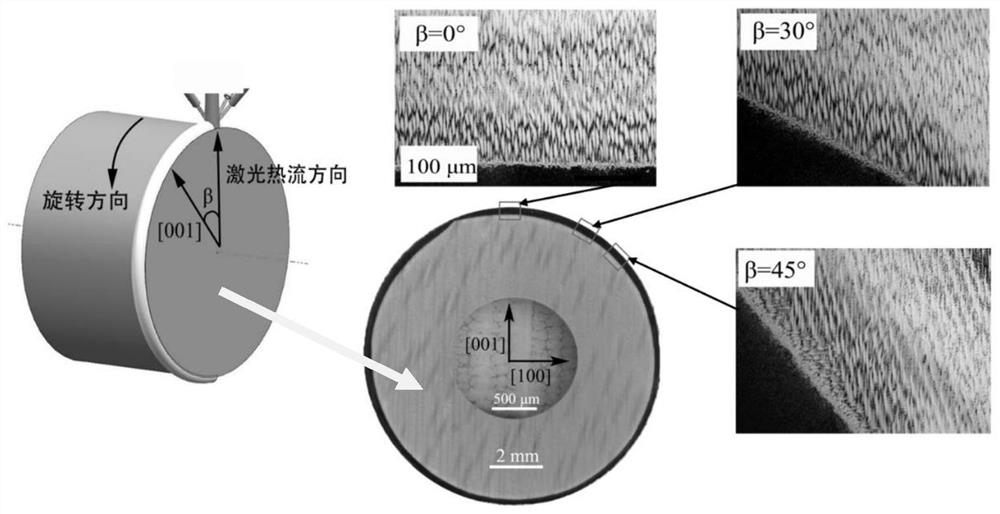

Laser cladding repairing method and repairing system for high-temperature alloy single crystal defects

PendingCN114150367ASlow down the solidification rateElimination of stray crystalsPolycrystalline material growthAfter-treatment detailsHeat flowCrystal orientation

The invention belongs to the related technical field of high-temperature alloy, and discloses a laser cladding repairing method and system for high-temperature alloy single crystal defects. The method comprises the following steps: S1, for a to-be-repaired object made of a high-temperature alloy single crystal, determining the lt of the to-be-repaired object; 001gt, 001gt; crystal orientation; s2, a groove is formed in the to-be-repaired position of the to-be-repaired object, laser cladding is conducted through metal powder to fill the groove layer by layer, so that repairing of the to-be-repaired object is achieved, in the laser cladding process, the off-axis heat flow direction is perpendicular to the inner surface of the slope in the groove, and the off-axis heat flow direction is as long as 1t; 001gt, 001gt; and the included angle of the nearest crystal orientation of the middle angle is not more than 30 degrees, so that the growth of mixed crystals in the repairing process is inhibited. The invention further discloses a repairing system adopted by the repairing method. According to the method, the problem that mixed crystals and cracks are easily generated in the high-temperature alloy single crystal repairing process is solved.

Owner:HUAZHONG UNIV OF SCI & TECH

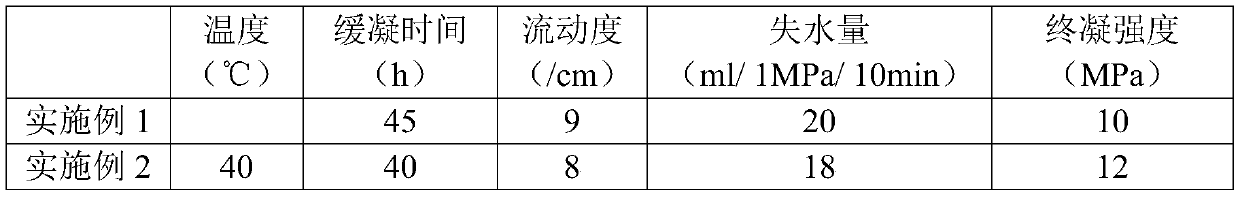

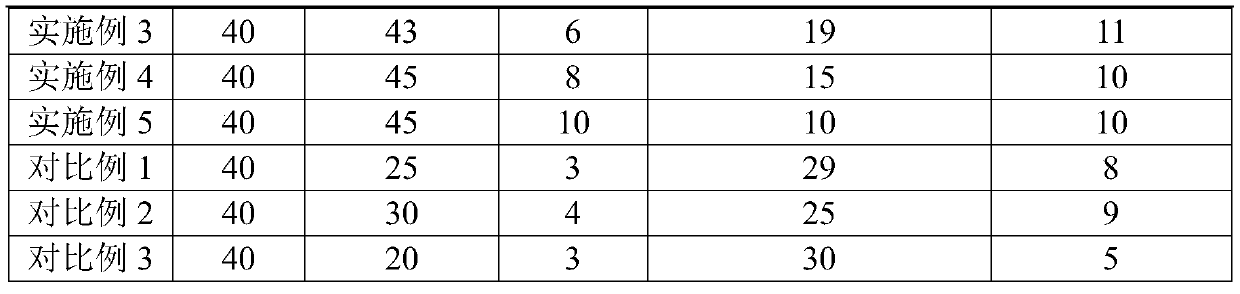

Delayed coagulation cement paste for freezing shaft sinking construction

ActiveCN110482968ASatisfy the seal water requirementImprove freeze-thaw resistanceSealing/packingGlycerolCement slurry

The invention discloses delayed coagulation cement paste for freezing shaft sinking construction and belongs to the technical field of slurry. The cement slurry comprises the following components in parts by weight: 190-210 parts of cement, 780-820 parts of fly ash, 970-1030 parts of water, 180-200 parts of glycerol and 1.3-4 parts of sulfonated lignite resin. On the premise that the final settingstrength of the cement paste reaches 10 MPa, the cement paste can be set slowly for 45 hours at the high temperature of 40 DEG C, and meanwhile, the cement paste has high flowability and low water loss.

Owner:CHINA COAL FIRST CONSTR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com