Rapid 3D printing apparatus and method

A 3D printing and fast technology, applied in the field of 3D printing, can solve the problems of difficulty in controlling the positioning accuracy of nozzles, difficulty in printing suspended parts, and insufficient strength of parts, and achieve the effects of overcoming the difficulty of printing in suspended parts, reducing air and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

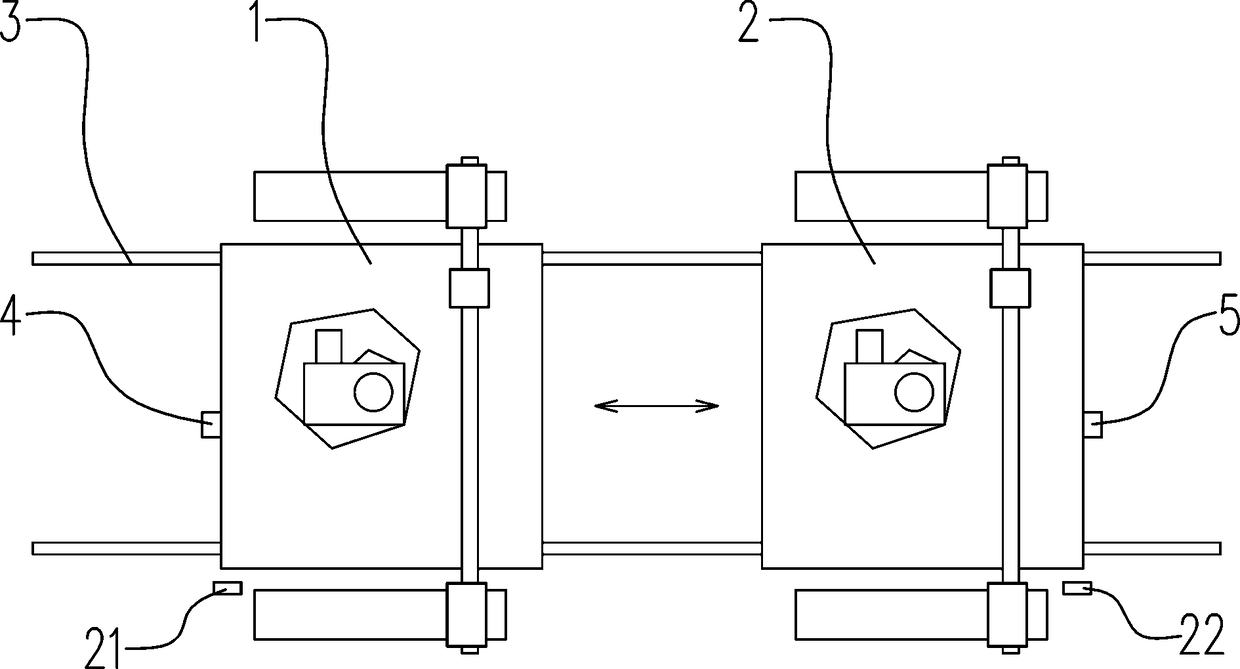

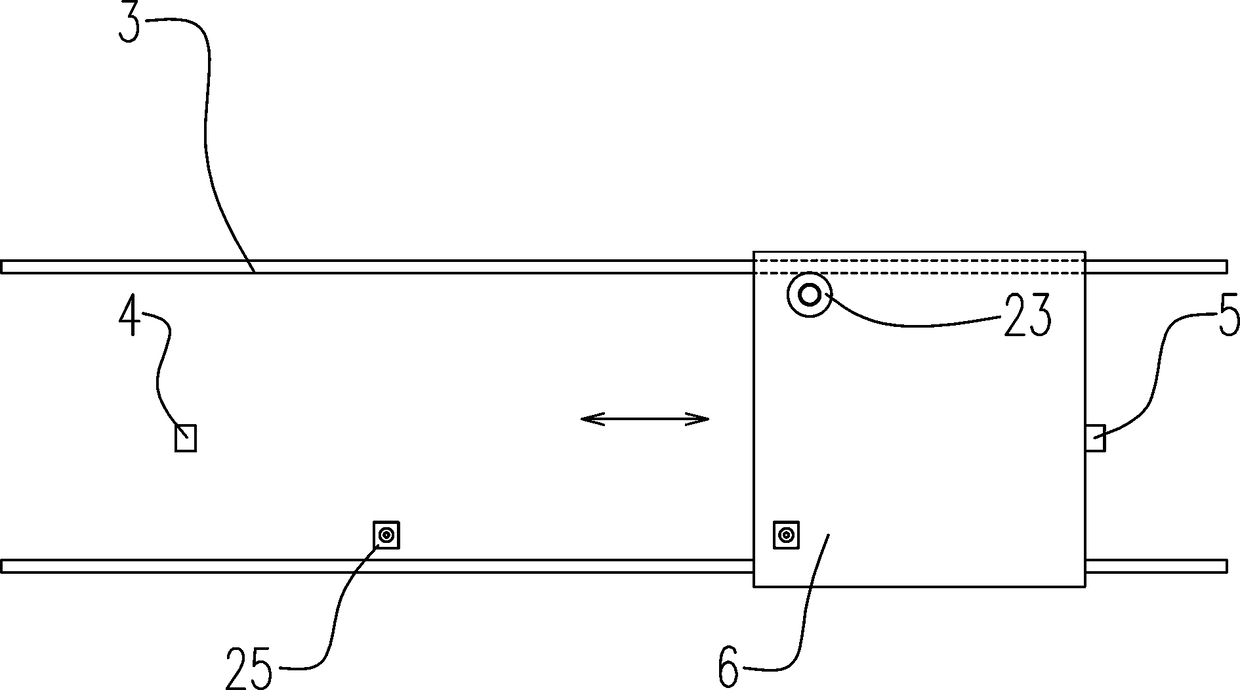

[0038] Such as Figure 1~4 Among them, a fast 3D printing device includes at least two 3D printing devices, at least one synchronous positioning plate 6, a guide device for guiding the synchronous positioning plate 6 is provided between the 3D printing devices, and at the position of each 3D printing device A positioning device for positioning the synchronous positioning plate 6 is provided;

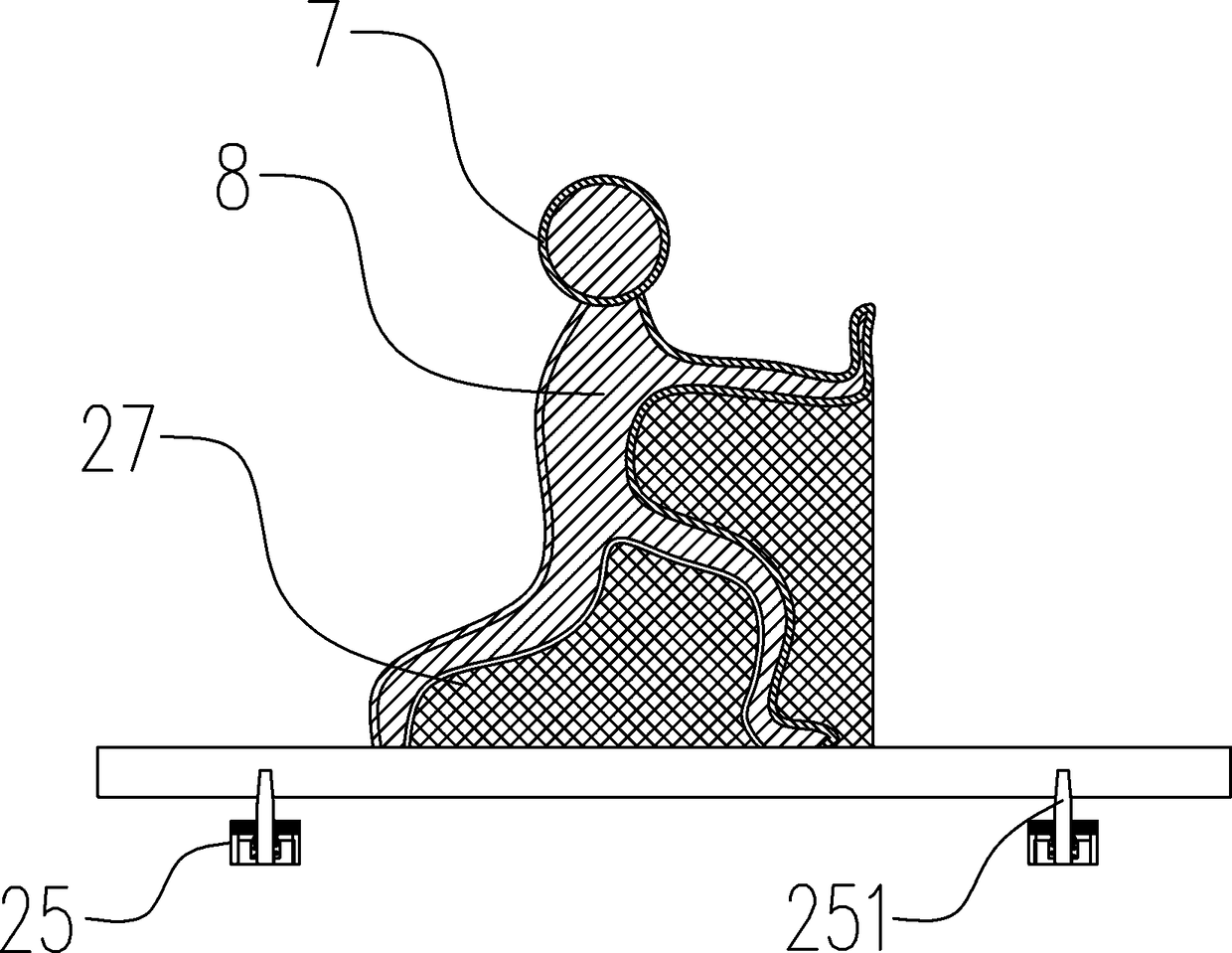

[0039] The 3D printing device is provided with nozzles of different diameters, corresponding to the part outline part 7 and the part filling part 8 respectively. Through the above structure, the part contour part 7 is printed at the position of the first 3D printing device 1, and then the synchronization positioning plate 6 is moved along the guide device to the second 3D printing device 2 to print the part filling part 8, thereby greatly speeding up the printing speed.

[0040] The preferred solution is as figure 1 , 2 Among them, the guide device is a track 3, the synchronous positi...

Embodiment 2

[0047] Different from Example 1, another optional scheme such as Figure 6~9 In the above, the 3D printing device is arranged along the circumference, the synchronization positioning plate 6 is positioned and installed on the rotatable turntable 11 , and the positioning device is a circumferential positioning device 16 .

[0048] The preferred solution is as Figure 8 Among them, the said circumferential positioning device 16 is provided with a limit rod 164 driven by an electromagnet 161, a spring 163 is arranged on the limit rod 164, the limit rod 164 is fixedly connected with the armature 162, and on the turntable 11 A turntable limiting groove 111 engaged with the limiting rod 164 is provided, and the position of the turntable limiting groove 111 on the turntable 11 corresponds to the position of the 3D printing device. The position of the turntable 11 on the circumference is precisely positioned by the circumferential positioning device 16 .

[0049] The preferred solut...

Embodiment 3

[0054] Existing 3D printed plastic parts have the problem of insufficient strength. The inventor sliced the part and observed under a microscope and found that there are many interlayer bubbles on the part, and the bonding interface between the droplets is relatively clear.

[0055] On the basis of Examples 1 and 2, the preferred scheme is as Figure 9 Among them, a sealing cover body 19 is provided outside all 3D printing devices, and the inner cavity of the sealing cover body 19 is connected with a vacuum device; thus, the interlayer air bubbles on the parts are reduced. The relative vacuum can be between -10~-75KPa.

[0056] In a preferred solution, the 3D printing device is also provided with a heating device 20 for heating parts. The heating device in this example is a resistance wire heating device, and the heating temperature is 40 to 80 degrees Celsius.

[0057] By adopting the above scheme, observed under the microscope, the interlayer bubbles are greatly reduced,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com