A high-speed resin-coated 3D printing system

A 3D printing and resin technology, applied in the field of 3D printing, can solve the problems of large solid-liquid force, long time, damage to samples, etc., and achieve the effect of improving the speed of 3D printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific technical solutions of the present invention are described in conjunction with the examples.

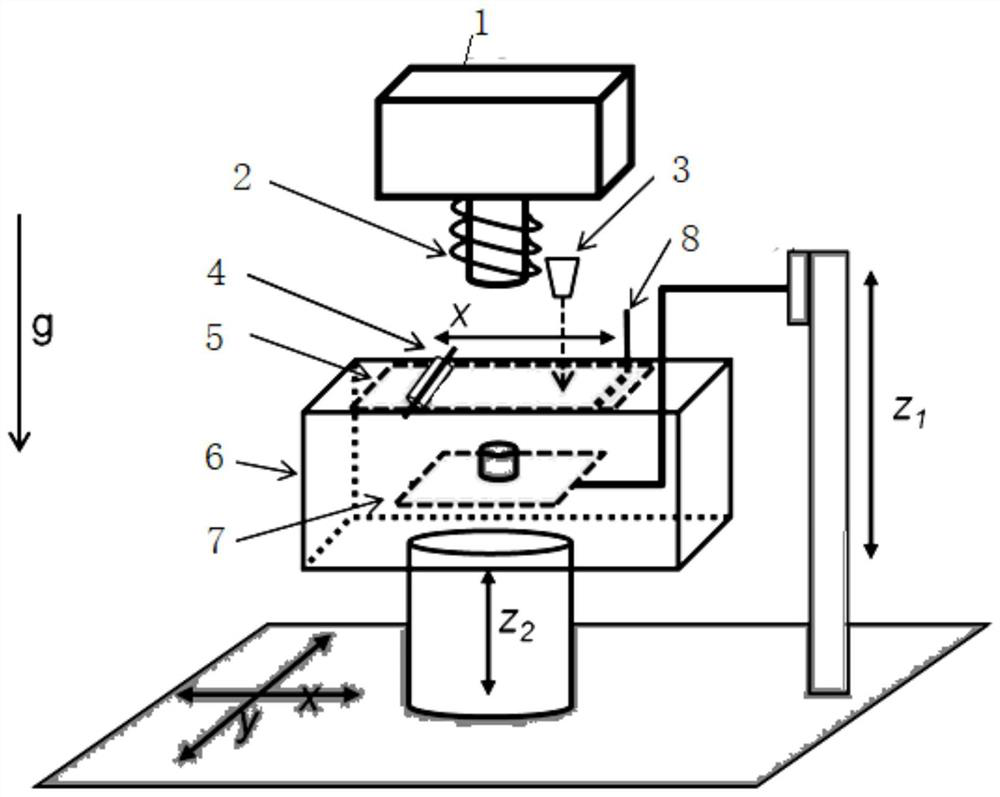

[0019] Such as figure 1 A high-speed resin-coated 3D printing system shown includes an exposure optical system 1, a film 5, a laser displacement meter 3, a hob 4, a bubble scraper 8, a resin tank 6, and a sample table 7;

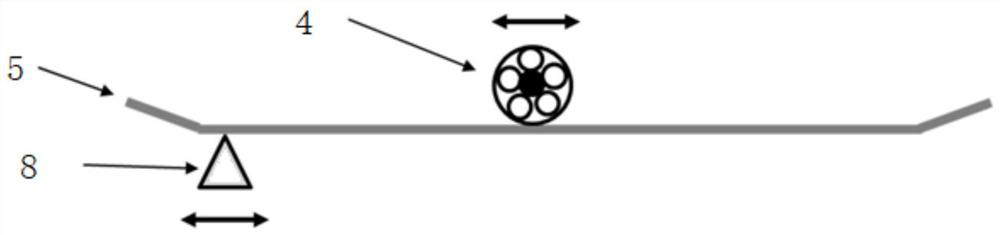

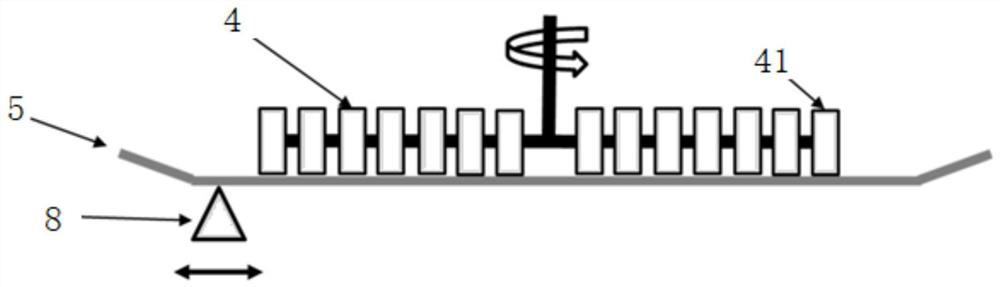

[0020] The sample table 7 is connected with the lifting device, the sample table 7 is located in the resin tank 6, and the film 5 is covered on the resin in the resin tank 6; the resin tank 6 is installed on the three-dimensional motion control axis; the exposure optical system 1 is located in the resin tank 6. Above the groove 6, the projection lens of the exposure optical system 1 faces the film 5, and the projection lens is covered with an electromagnetic coil 2; a laser displacement meter 3 is provided on one side of the projection lens; a hob 4 is provided above the film 5, and a bubble scraper 8 is provided below .

[0021] Such as fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com